Calibrating Servo start, mid and end positions.

Each servo can have it’s start and end settings adjusted independently.

The S1 servo knob is used to adjust all four servo settings.

The transmitter and receiver must be already bound together and tested.

It’s on video, if you prefer , see our website for the link.

The Calibration procedure must be carried out within 20 seconds of turning on the re-

ceiver, so start by ensuring everything is off, then power up the receiver.

1 Press and hold buttons 2 and 3, then turn Transmitter ON

2 Wait until both LEDS go solid, then release the buttons, you are now in calibration

mode and the only exit is to power off the transmitter.

3 LED 1 will be flashing the selected SERVO, use Button 1 to move to the next one.

4LED 2 will be indicating which servo position you wish to set, use button 2 to move to

the next one:

One flash = Start position of servo swing (When knob is fully anticlockwise)

Two flash = Mid position of servo swing (Not available on servos 1,2 and 4)

Three flash = End position of servo swing (when knob is fully clockwise)

5 Having selected the servo and the position you wish to set, use the S1 knob to set

the actual position of the servo arm and then save the position by pressing button 3.

6You can now go on to set more positions or leave the process by turning off the trans-

mitter, then back on again to check the results of your efforts.

Re-Programming Servo 3 and 4 to momentary or latching mode

Servo 3, when set to latching, toggles between mid and end positions on buttons 1 and

2, when set to momentary, will move from mid to start on button 1 and mid to end on

button 2, then back to the middle again.

Servo 4, when set to latching, toggles position from one end to the other on each press

of button 3 and when set to momentary moves from start to end position and back

again.

The Calibration procedure must be carried out within 20 seconds of turning on the re-

ceiver, so start by ensuring everything is off, then power up the receiver.

1 Press and hold buttons 1 and 2, then turn Transmitter ON

2Wait until both LEDS go solid, then release the buttons, you are now in calibration

mode and the only exit is to power off the transmitter.

3LED2 now indicates which servo is being set, one flash for SERVO 3 and 2 flashes

for SERVO 4. Use button 2 to move to the next one.

4Set the S1 (Regulator) knob to fully Anticlockwise for Momentary or fully Clockwise

for latching mode.

5Press button 3 to save this setting.

6Proceed with further settings OR power off the transmitter to leave the procedure.

on 01254 814675

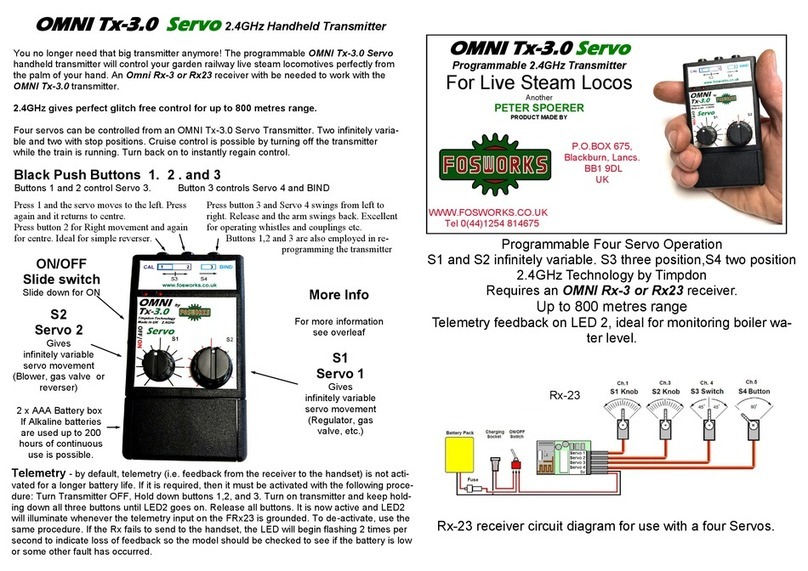

Re-programming the OMNI system to suit your needs.

Your OMNI transmitter and receiver comes to you all pre-set and ready to run

Live Steam Locomotives. Each servo is set for a full 90 degree swing. Normally

there should be no need to change these settings, However should the swing of

a servo need to be modified, it can be done by reprogramming the receiver.

The OMNI R/C system is unique, in that when you wish to re-program it to suit

the special needs for a particular loco, it is not the transmitter you are re-

programming, but the receiver in the loco. The Transmitter tells the receiver what

is expected of it in the future, and it is the receiver that remembers it. In this way,

one OMNI Tx-3.0 STEAM transmitter can control many different types of Live

Steam locos, each with its own very different requirements.

It is possible to change all or just one of the servo movements. The start and stop

position of each servo swing is adjustable. You can even reverse the servo

swings by setting the 1st position as the end and the 2nd position as the start.

Binding Procedure.

Now simpler than ever!

1. Turn on the Receiver (or the model, if it’s al-

ready fitted inside) then….

2. Hold down black buttons 1 and 3, then turn on

the transmitter

3. Successful binding is indicated by LED 2 going

fully ON.

4. Release the two buttons and the job is done. .

13

LED 1

On

LED 2

Low battery warning

When the batteries in the handset get too low for reliable operation, both LED 1 and

2 start flashing together. Replace them with quality alkaline AAA cells for the best

results,