vii

About this Manual:

This manual describes the installation and operation of the R88A-MCW151-E and R88A-MCW151-

DRT-E Motion Control Option Boards (MC Units) and includes the sections described below.

Please read this manual and the related manuals listed in the following table carefully and be sure you

understand the information provided before attempting to install or operate the MC Unit. Be sure to

read the precautions provided in the following section.

Precautions provides general precautions for using the MC Unit and related devices.

Section 1

describes the features and system configuration of the R88A-MCW151-E and R88A-

MCW151-DRT-E Motion Control Units and concepts related to their operation.

Section 2

describes the MC Unit components and provides the information for installing the MC Unit.

Section 3

describes the different Motion Control features of the MCW151. Also the functionality of the

Servo Driver related commands are explained.

Section 4

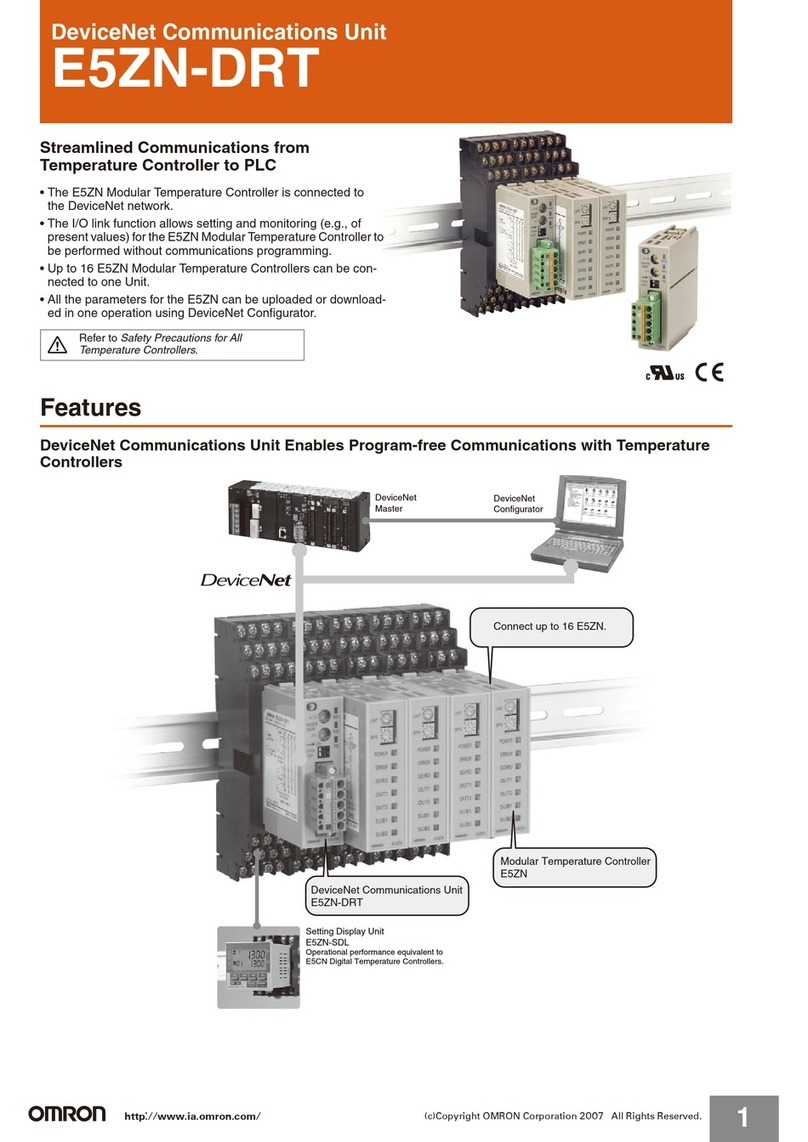

describes the communication components of the MCW151-E and MCW151-DRT-E. The

functionality of the serial communication protocols and the DeviceNet interface are explained.

Section 5

provides an overview of the fundamentals of multitasking BASIC programs and the methods

by which programs are managed in the MC Unit.

Section 6

describes all commands, functions and parameters required for programing the motion con-

trol application using the MC Unit.

Section 7

describes the operation of the Motion Perfect programming software package. Motion Per-

fect provides the user a tool to program, monitor and debug motion based applications for the MC Unit.

Section 8

describes error processing and troubleshooting procedures needed to keep the system

operating properly.

Section 9

explains the maintenance and inspection procedures that must be followed to keep the MC

Unit operating in optimum condition. It also includes proper procedures when replacing an MC Unit.

The Appendices provide the required parameter settings for the Servo Driver, the DeviceNet protocol

specification and some general programming examples.

Name Cat. No. Contents

MCW151 Series

R88A-MCW151-E

R88A-MCW151-DRT-E

Operation Manual

I203 Describes the installation and operation of the R88A-MCW151-E

and MCW151-DRT-E Motion Control Units.

(This manual)

OMNUC W-series

R88M-W❏(AC Servomotors)

R88D-W❏(AC Servo Drivers)

User’s manual

I531 Describes the installation and operation ofthe W-series Servo Driver

and Servomotor.

DeviceNet Operation Manual W267 Describes the configuration and construction of a DeviceNet net-

work, including installation procedures and specifications for cables,

connectors, and other connection devices, as well as information on

the communications power supply.

DeviceNet Configurator Oper-

ation Manual W328 Describes the operation of the DeviceNet Configurator to allocate

remote I/O areas according to application needs, as well as proce-

dures to set up a DeviceNet network with more than one master.

!WARNING

Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.