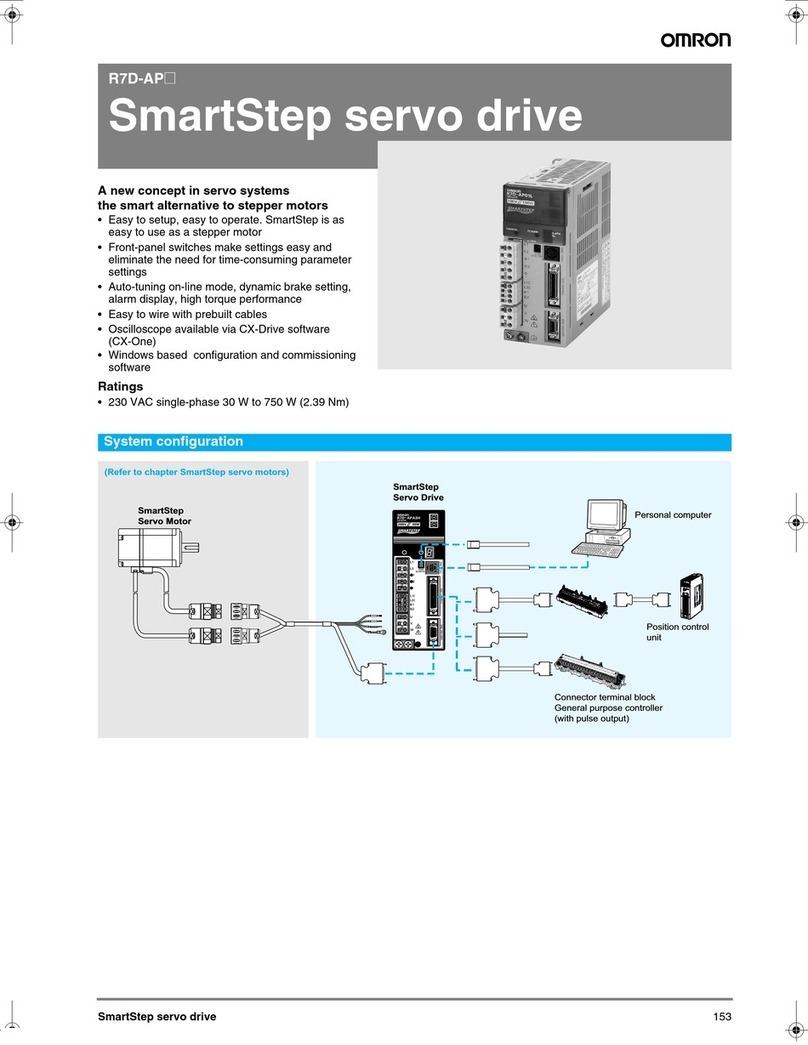

Easy to set up, easy to program

With SmartStep, easy-to-use dip-switches on the front panel

enable you to program basic parameter settings, including

auto-tuning, resolution setting, command pulse input setting,

and dynamic brake setting. he smoothness and

responsiveness of the motor is adjustable via the gain

adjustment switch.

Enhanced programming options

You can program the SmartStep with enhanced parameter

settings using Omron’s digital operator. his parameter unit

can be connected easily to the servo drive via a cable.

It can also be used to copy parameters from

one drive to another, enabling you to have

multiple drives in the same machine with

parameters at precisely the same settings.

In addition, Omron’s Wmon software package

can be used to program the servo drive, and

store the parameters in a PC.

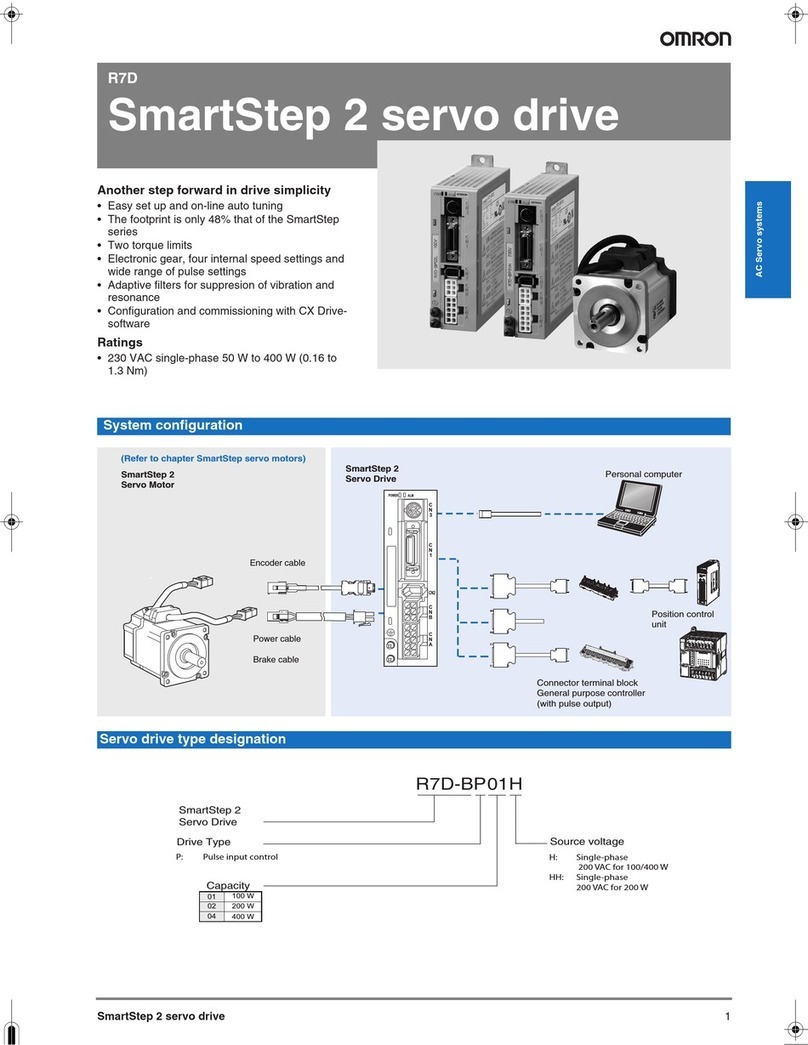

Easy to connect

SmartStep is easy to commission via the pre-assembled

control cable, enabling SmartStep to be connected to an

external intelligence source like a PLC. Omron provides a wide

range of accessories for this called ‘relay units’. Furthermore,

SmartStep is easy to commission via the pre-assembled two-

in-one cable that handles both motor power and encoder

signal feedback.

Auto-tuning online

SmartStep’s auto-tuning function counteracts any vibration

caused by load variations, by adjusting settings automatically

and precisely to the machine movements.

The smart solution

SmartStep is the logical progression from

stepper motors to the servomotor world.

With SmartStep, the machine motor does not

lose position because the servo system has

positional closed-loop feedback, it is designed

to support big load ratio changes, and it is

faster and more precise, thanks to the

servomotor’s use of high encoder resolutions.

Digital operator

parameter nit