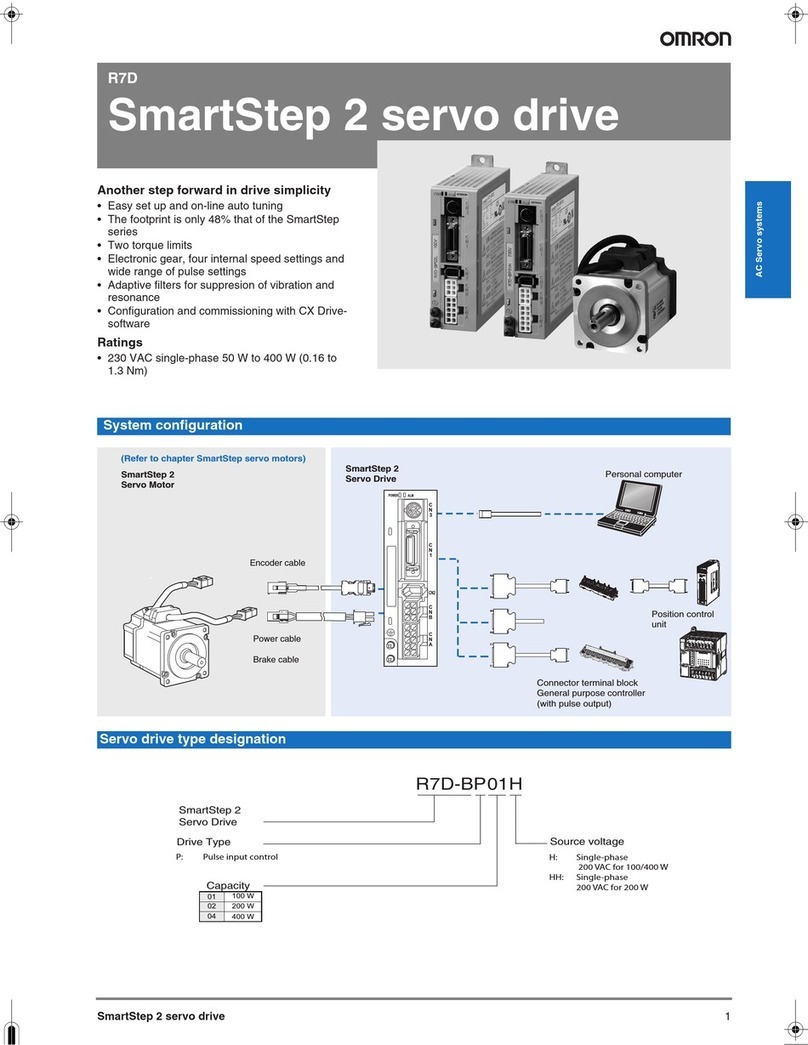

162 AC servo systems

Control cables (for CN1)

Cable for CN3 Cable for CN4

Filters

Connectors

External regeneration resistor

Parameter unit & computer software

Symbol Name Compatible units Model Available lengths

DServo relay unit Use with position control units

(doesn’t support communications functions.)

Units: CS1W-NC113/133, CJ1W-NC113/133, C200HW-NC113, and

C200H-NC112

XW2B-20J6-1B

(1 axis) ---

Use with position control units

(doesn’t support communications functions.)

Units: CS1W-NC213/233/413/433, CJ1W-NC213/233/413/433,

C200HW-NC213/413, C500-NC113/211, and C200H-NC211

XW2B-40J6-2B

(2 axes)

Use with position control units

(doesn’t support communications functions.)

Units: CQM1H-PLB21, and CQM1-CPU43-V1

XW2B-20J6-3B

(1 axis)

Use with position control units (supports communications functions.)

Units: CS1W-NC213/233/413/433, CJ1W-NC213/233/413/433 XW2B-40J6-4A

(2 axes)

Use with CJ1M-CPU22/23

(doesn’t support communications functions.) XW2B-20J6-8A (1 axis)

XW2B-40J6-9A (2 axes)

ECable to servo drive Doesn’t support communications functions. (For the XW2B-@@J6-@B) XW2Z-@@@J-B5 1 m or 2 m

(the cable length goes in

the empty boxes.)

Supports communications functions. (For the XW2B-@@J6-4B) XW2Z-@@@J-B7

FCable to position

control unit CQM1H-PLB21 and CQM1-CPU43-V1 XW2Z-@@@J-A3 0.5 m or 1 m

(the cable length goes in

the empty boxes.)

C200H-NC112 XW2Z-@@@J-A4

C200H-NC211 and C500-NC113/211 XW2Z-@@@J-A5

CS1W-NC113 and C200HW-NC113 XW2Z-@@@J-A8

CS1W-NC213/413 and C200HW-NC213/413 XW2Z-@@@J-A9

CS1W-NC133 XW2Z-@@@J-A12

CS1W-NC233/433 XW2Z-@@@J-A13

CJ1W-NC113 XW2Z-@@@J-A16

CJ1W-NC213/413 XW2Z-@@@J-A17

CJ1W-NC133 XW2Z-@@@J-A20

CS1W-NC233/433 XW2Z-@@@J-A21

CJ1M-CPU22/23 XW2Z-@@@J-A26

GControl cable For general-purpose controllers R88A-CPU@@@S 1 m or 2 m

(the cable length goes in

the empty boxes.)

HConnector terminal block

cable For general-purpose controllers R88A-CTU@@@N

Connector terminal block XW2B-40F5-P ---

Symbol Name Model

IComputer monitor cable R7A-CCA002P2

Symbol Name Model

JAnalog monitor cable R88A-CMW001S

Symbol Applicable servo drive Filter model Rated current Rated voltage

KR7D-APA3H, R7D-APA5H, R7D-AP01H, R7D-AP02H R88A-FIW104-E 4A 250 VAC single phase

R7D-AP04H R88A-FIW107-E 7A

R7D-AP08H R88A-FIW115-E 15A

Specifications Model

Control I/O connector (for CN1) R88A-CNU01C

SmartStep connectors kit. Models included in kit R7A-CNA00K-DE

SmartStep encoder connector (for CN2) R7A-CNA01R

Hypertac power connector female SPOC-06K-FSDN169

Hypertac encoder connector female SPOC-17H-FRON169

Hypertac power connector male (used in the motor) SRUC-06J-MSCN236

Hypertac encoder connector male (used in the motor) SRUC-17G-MRWN087

Specification Model

220 W, 47 ΩR88A-RR22047S

Specifications Model

Parameter copy unit (with cable) R7A-PR02A

Configuration and monitoring software tool for servo drives and inverters. (CX-drive version 1.11 or higher) CX-drive

Complete OMRON software package including CX-drive. (CX-One version 1.1 or higher) CX-One

In the interest of product improvement, specifications are subject to change without notice.

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. I46E-EN-01

Y203-EN2-02-Katalog.book Seite 162 Mittwoch, 24. Mai 2006 2:22 14