(15) Use M4 screws and washers to install the switch and actuator.

Tighten the screws with a specified torque. After installing and

commissioning, coat the switch-actuator fixing screws with

tamper-proof varnish or similar compound for locking. Using

anaerobic locking compounds can have a detrimental effect on

the plastic switch case if the compounds contact with the switch case.

Compact Non-Contact Door Switch

INSTRUCTION MANUAL

Type D40Z

English

Precautions for Safe Use

Meaning of Warning Sign

The following warning sign is used in this manual.

Indicates mandatory actions.

Meaning of Alert Symbol

The following alert symbol is used in this manual.

Alert Statements

WARNING

WARNING

Precautions for Safe Use

Precautions for Correct Use

D1 D2 D3 D4

G9SX-NS202

G9SX-NSA222

Total wiring length

100m max.

Connection Example

5

Black

Brown

White

Blue

Black

Brown

Black

Brown

Black

Brown

White

Blue

White

Blue

White

Blue

Yellow

Gray

Yellow

Gray

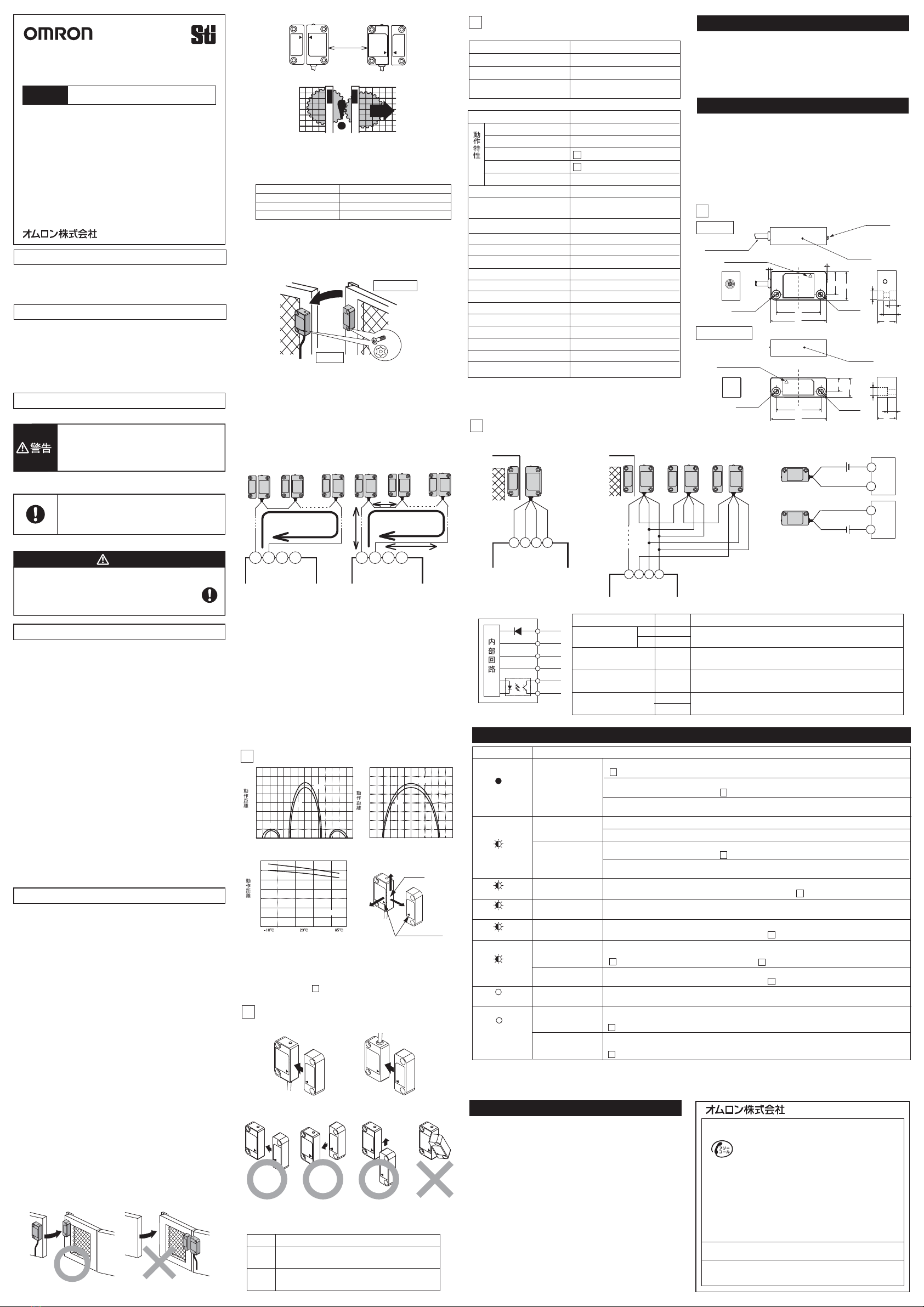

Ratings and Specifications

3

Item

Power consumption (Note 1)

D40Z-1Cڧ

0.5 W max.

Supply voltage 24 VDC +10% / -15%

Operating

distance

(Note 2)

Response time (ON to OFF)

(Note 3)

Ambient humidity

Degree of protection

Material

Mounting method

Tightening torque

5 mm min.

25 ms max.

25 to 85%RH

IP67

Molded PBT

M4 screws

1N .m

Auxiliary output

Photocoupler output

24VDC Load current: 10 mA

Ambient temperature

-10 to +65

°

C

(No freezing or condensation)

Operating time (OFF to ON)

(Note 3)

100 ms max.

(for a 5-mm distance between sensing

surfaces of switch and actuator)

OFF to ON

ON to OFF

Differential travel

Temperature influence

15 mm max.

Note1. Power consumption of loads is not included.

Note2. This is the distance where the switch operates from OFF to ON

when approaching and the distance where the switch operates

from ON to OFF when separating when the switch and actuator

target marks are on the same axis, and the sensing surfaces

coincide.

Note3. The value of Non-contact door switch output is indicated.

Dimensions

4

Performance Levels / Safety Categories

Inspection / Maintenance

• Daily inspection:

1. Check every guard door to see that machine stops

when guard door is opened.

• 6-month inspection:

1. Isolate all power.

2. Check the switch and actuator for proper alignment.

3. Check terminals for proper connections.

4. Check wiring for signs of damage.

5. Before resuming normal machine operation,

check every guard door to see that machine stops

when the guard door is opened.

Fault in power supply

Input (brown/blue)

Fault in Non-contact

door switch output

(black)

Sensing fault

Fault in Non-contact

door switch signal

input (white)

Actuator fault

Note1. Another possible cause is a failure in internal circuit. In this case, replace with a new D40Z.

Yet another possible cause is excessive noise. In this case, check and correct ambient noise environment.

Note2. The case where the guard door is closed (Switch detects actuator) is indicated.

Causes and Corrective Action (Note 1)

LED indicator

Noise or

D40Z failure There may be excessive noise. Check and correct ambient noise environment.

There may be a failure in internal circuit. Replace with a new D40Z.

Invalid actuator may be in a close range to switch.

Use the dedicated actuator.

Another D40Z may be in OFF state.

Check status of another D40Z connected to the white line and the wiring.

Refer to Section 2. Switch and actuator operation and Section 5. Connection Examples.

There may be a failure in actuator. Replace with a new D40Z.

OFF

Red continuously

blinking

Red Solid-ON (Note 2)

Red blinks twice for 2s

Red blinks once for 2s

Red blinks thrice for 2s

Yellow

Blinking

Power supply input may be improperly wired. Check and correct wiring of brown and blue lines.

Refer to Section 5. Connection Examples.

Black line may be shorted to other line. Check and correct wiring of black line if the black line is

shorted to other lines. Refer to Section 5. Connection Examples.

Faulty signal may be input to white line. Check and correct wiring of white line.

Refer to Section 5. Connection Examples.

White line may be disconnected.

Check and correct wiring of white line.

Refer to Section 5. Connection Examples.

Troubleshooting

Switch and actuator operation

2Switch and Actuator Mounting Directions

Switch and Actuator Operating Directions

Switch Actuator Switch

Actuator

Detection Ranges (Typical data)

1

XSensing surface

(12) When installing two or more adjacent switches, keep a distance

of at least 50 mm from one another.

50mm Min.

Switch

Actuator

LED Display

LED color

Status

ON: Switch does NOT detect actuator.

Blinking: Switch detects a fault.

ON: Switch detects actuator.

Blinking: Switch detects actuator,

and non-contact door switch signal input is in OFF state.

RED

YELLOW

Metallic material Operating distance

Iron Approximately 75% of the original value

Aluminum Approximately 85% of the original value

Stainless steel Approximately 85% of the original value

ZY

Target mark

D1 D2 D3 D4

G9SX-NS202

G9SX-NSA222

D1 D2 D3 D4

G9SX-NS202

G9SX-NSA222

Single switch connection

with G9SX-NS Multiple switch connection with G9SX-NS Wiring example of

auxiliary output

Maximum 30 switches connectable in series

Note 1. Maximum auxiliary output current is 10mA.

Incorrect wiring may damage the auxiliary output circuit.

Note 2. Refer to the D40Z catalog for other types of wiring.

24VDC

PLC, etc

24VDC

Internal Circuit

brown

white

black

gray

yellow

blue

Signal Name

Color of

Conductor

Brown

Blue

White

Black

Yellow

Gray

+

-

Non-contact door switch

power input

Non-contact door switch

signal input

Non-contact door switch

Output

Description of Operation

Power supply for D40Z

To set non-contact door switch output in ON state,

non-contact door switch signal input must be in ON state.

Auxiliary monitoring

Output Output status depends on status of actuator.

When a fault is detected, turns into OFF state regardless of actuator status.

Output status depends on statuses of actuator and

non-contact door switch signal input.

EU Declaration of Conformity

Standards

Original instructions

See 1 Detection ranges

See 1 Detection ranges

Thank you for purchasing D40Z Compact Non-contact

Door Switch.

Please read and understand this manual before using

the products.

Keep this manual ready to use whenever needed.

Only qualified person trained in professional electrical

technique should handle D40Z.

Please consult your OMRON representative if you have

any questions or comments.

Make sure that information written in this document are

delivered to the final user of the product.

OMRON declares that D40Z is in conformity with the

requirements of the following EU Directives:

Machinery Directive 2006/42/EC

EMC Directive 2004/108/EC

D40Z is designed and manufactured in accordance with the

following standards:

EN954-1 Cat. 4 (with G9SX-NSڧ)

EN ISO13849-1:2008 Cat. 4 PL e (with G9SX-NSڧ),

IEC/EN61508 SIL3 (with G9SX-NSڧ)

IEC/EN60947-5-3 PDF-M (with G9SX-NSڧ),

IEC/EN61000-6-4, EN1088,

UL508, CAN/CSA C22.2 No.14

Indicates a potentially hazardous

situation which, if not avoided, will result

in minor or moderate injury, or may result

in serious injury or death.

Additionally there may be significant

property damage.

Machine may start operating and may result serious

injury or death.

Do not put the actuator close to the switch when the

door is opened.

(1) Disconnect D40Z from power supply when wiring D40Z. Failure to

do so may cause unexpected operation of devices connected to

D40Z.

(2) Do not operate D40Z with flammable or explosive gas.

(3) Incorrect wiring may lead to loss of safety function. Wire

conductors correctly and verify the operation of D40Z before using

the system in which D40Z is incorporated.

(4) Auxiliary monitoring output is NOT safety output. Do not use

auxiliary monitoring output individually for any safety function. Such

incorrect use causes loss of safety functions of D40Z and its

relevant systems.

(5) After installation of D40Z, qualified personnel should verify to see

that the installation, inspection, and maintenance are properly

performed. The qualified personnel should be qualified and

authorized to secure the safety on each phases of design,

installation, running, maintenance and disposal of system.

(6) Qualified personnel, who are familiar to the machine in which

D40Z is to be installed, should conduct and verify the installation.

(7) Be sure to inspect D40Z daily and every 6 months. Otherwise,

serious injury may possibly occur due to a system malfunction.

(8) Do not dismantle, repair, or modify D40Z. Doing so may lead to

loss of its safety functions.

(9) Do not apply DC voltages exceeding the rated voltages, nor any

AC voltages to D40Z.

(10) Use a DC supply satisfying the requirements given below to

prevent electric shock.

- A DC power supply with double or reinforced insulation, for

example, according to IEC/EN 60950 or EN 50178, or a

transformer according to IEC/EN 61558.

- A DC supply satisfying the requirements for class 2 circuits or

limited voltage/current circuits stated in UL 508.

(11) Use only appropriate components or devices complying with

relevant safety standards corresponding to the required

performance level and safety category. Conformity to

requirements of the performance level and safety category must

be determined as an entire system. It is recommended to consult

a certification body regarding assessment of conformity to the

required safety level.

(1) Always use D40Z with dedicated actuator and dedicated controller

to comply with the requirements of EN ISO 13849-1.

(2) Handle with care

Do not drop D40Z to the ground or expose to excessive vibration or

mechanical shocks. Doing so may damage D40Z and cause failure.

(3) Conditions of storage and usage

Do not store or use D40Z under the following conditions. Doing so

may damage D40Z and cause failure.

1) In direct sunlight

2) At ambient temperatures out of the range of -10 to +65

°C

3) At relative humidities out of the range of 25% to 85% or under

such temperature change that causes condensation.

4) In corrosive or combustible gases

5) With vibration or mechanical shocks out of the rated values.

6) Under splashing of oil or chemicals

7) In the atmosphere containing dust, saline or metal powder.

8) Where steel scrap or metal powder may fall directly to D40Z.

(4) Do not use D40Z at altitudes over 1,000 meters.

(11) Be sure to install D40Z switch and actuator in such as appropriate

distance that does not create a gap accessible to the hazard.

(13) Be sure that the machine is stopped whenever the guard door

is open.

(18) D40Z is a class A product. In residential areas D40Z may cause

radio interference, in which case the user may be required to take

adequate measures to reduce interference.

(19)

D40Z may not function properly in surrounding environment with strong

electromagnetic equipment such as RFID system, proximity sensor, motor,

inverter, and switching power supply. If you use D40Z near such equipment,

be sure to verify effects of such equipment on D40Z before using.

(20) Handle cables with care:

1) For bending cables, it is recommended to bend them with a

radius of bend no less than six times the cable outer diameter.

2) Do not apply a tensile strength of 50N or greater to the cables.

(21) To determine safety distance to hazards, take into account the

delay of non-contact door switch output caused the response time.

(22)

If there is any machine that has a large surge current (e.g., a motor) near

D40Z, connect a surge absorber to D40Z between the blue and the other

cables (white, black, and brown), respectively, and between the yellow and

the gray cables. Suggested surge absorber's specification is as follows:

- Peak pulse power: 600W (10/1000ȣs) or more

(Per IEC61000-4-5(surge immunity))

- Breakdown voltage: 27-33V

Note1. Operating distance means the distance of the sensing surfaces

between the switch and actuator.

Note2. Above graph is only for reference temperature at 23°C.

Actual operating distance may vary depending on the

surrounding metals or temperature.

Note3. Surfaces other than the sensing surfaces of the switch and

actuator may activate the detection. Be sure to install the switch

and actuator so that the sensing surfaces oppose one another,

according to the following "2. Switch and Actuator Operation"

D40Z can achieve the corresponding performance levels and

categories up to PL e and Category 4 per EN ISO 13849-1 by

the combined use with the controller G9SX-NSڧ.

Note that the performance levels and categories are based on

the example circuits that we recommend. This does NOT

mean that the combination of D40Z and G9SX-NSڧcan

always achieve the performance levels and categories under

all the similar conditions and situations.

UL does not provide ULcertification for any functional safety

rating or aspects of the D40Z device.

Conformity to the performance levels and categories must be

assessed as a whole system. When using D40Z and

G9SX-NSڧfor performance levels and safety categories,

perform the installation, inspection, and maintenance properly,

and be sure to confirm the conformity as a whole system.

Internal connection

ە30 or less D40Z connected

Item D40Z-1Cڧ

ەRatings

ەSpecification and Performance

Wiring

Power supply to D40Z may be insufficient.

Check the power-supply voltage of D40Z fills ratings. Refer to Section 3. Ratings and Specification.

The wiring length or size of the wire may not be to the specification.

Check the wiring length and size of the wire. Refer to Precautions for Correct Use.

Power supply to D40Z may be insufficient.

Check the power-supply voltage of D40Z fills ratings. Refer to Section 3. Ratings and Specification.

The wiring length or size of the wire may not be to the specification.

Check the wiring length and size of the wire. Refer to Precautions for Correct Use.

Fault in power supply

Input (brown/blue)

Fault in Non-contact

door switch signal

input (white)

OFF state

of another D40Z

Yellow Solid-ON

(Note 3)

Note3. The case where the system stops though the guard door is closed (Switch detects actuator) is indicated.

Fault in Non-contact

door switch signal

input (white)

Fault in Non-contact

door switch output

(black)

White line connected to D1 terminal of G9SX-NSڧmay be shorted to other line.

Check and correct wiring of white line connected to D1 terminal of G9SX-NSڧ

if the white line is shorted to other lines. Refer to Section 5. Connection Examples.

Black line connected to D2 terminal of G9SX-NSڧmay be disconnected.

Check and correct wiring of black line connected to D2 terminal of G9SX-NSڧ.

Refer to Section 5. Connection Examples.

Weight (D40Z-1C5) Switch: approx. 175 g

Actuator: approx. 20 g

D1 D2 D3 D4

G9SX-NS202

G9SX-NSA222

Total wiring length

200m max.

ە15 or less D40Z connected

(Note)

(Note)

(Note)

Note. The wiring length between the products must be 100m max.

(17) Use cables of a total length of 100m max. to connect multiple

D40Z switches. However, the total length of 200m max. is possible

depending on the number of D40Z switches connected. The

supply voltage to D40Z may decrease by the voltage drop

depending on the cable or the wiring configuration. Check the

power-supply voltage is in the rated range.

(5) Do not use to connect other switches or sensors to the wire

conductors of D40Z.

(6) Disconnect D40Z and the controller connected to D40Z from power

supply when replacing D40Z. Failure to do so may cause

unexpected operation of devices connected to D40Z.

(7) Keep D40Z from solvent such as alcohol, thinner, trichloroethane or

gasoline. Such solvents make the marking on D40Z illegible and

cause deterioration of parts.

(8) Do not use D40Z in the magnetic field of 1.5 mT or more, otherwise

D40Z may not function properly.

(9) Do not use D40Z in the water or continuous water exposure

environment, otherwise water may leak into D40Z. (An enclosure of

IP67 rating, which D40Z is rated, protects against temporary

immersion in water.)

(10) Do not use D40Z switch or actuator as a stopper. Use a stopper to

protect the switch and the actuator. Keep a distance of at least

1mm between the switch and the actuator.

(16) Wiring:

1.Use conductors of the following sizes to wire D40Z:

-Stranded wire: 0.2 to 2.5mm

2

AWG24 to AWG12

-Solid wire: 0.2 to 2.5mm

2

AWG24 to AWG12

2.

When not using auxiliary output, cut off the unused conductors and

protect by insulating-taping to prevent contacting with other terminals.

3.When you use an additional cable of 20m or longer, use a

multiconductor cable to group the white, black, brown, and

blue lines together.

(Note)

Note. When using the operating direction along the sensing surface,

be sure to install the switch and actuator so as not to be affected

by the side lobe.

COM

IN

PLC, etc

COM

IN

Repeat accuracy (max.)s10% of operating distance at 23Υ

As per IEC/EN 60947-5-3

Electromagnetic compatibility

Pollution degree 3

Dielectric strength

(Between all conductive parts

and switch case) 1000 VAC for 1min

Insulation resistance

(Between all conductive parts

and switch case) 50 Mohm min.

(at 500 VDC megger)

Shiokoji Horikawa, Shimogyo-ku, Kyoto, 600-8530 JAPAN

OMRON Corporation (Manufacturer)

OMRON EUROPE B.V. (Importer in EU)

Wegalaan 67-69, NL-2132 JD Hoofddorp THE NETHERLANDS

PHONE 31-2356-81-300 FAX 31-2356-81-388

OMRON SCIENTIFIC TECHNOLOGIES INC.

6550 Dumbarton Circle, Fremont CA 94555-3605 U.S.A

PHONE: 1-510-608-3400 FAX: 1-510-744-1442

OMRON ASIA PACIFIC PTE. LTD.

438A Alexandra Road # 05-05/08,

Alexandra Technopark Singapore 119967 SINGAPORE

PHONE: 65-6-835-3011 FAX: 65-6-835-2711

Note: Specifications subject to change without notice.

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower, 200 Yin Cheng Zhong Road,

PuDong New Area, Shanghai, 200120, China

PHONE: 86-21-5037-2222 FAX: 86-21-5037-2200

Suitability for Use

OMRON shall not be responsible for conformity with any

standards, codes, or regulations that apply to the

combination of the products in the customer's application or

use of the product.

Take all necessary steps to determine the suitability of the

product for the systems, machines, and equipment with

which it will be used. Know and observe all prohibitions of

use applicable to this product.

NEVER USE THE PRODUCTS FORAN APPLICATION

INVOLVING SERIOUS RISK TO LIFE OR PROPERTY

WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE

HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND

THAT THE OMRON PRODUCT IS PROPERLY RATED

AND INSTALLED FOR THE INTENDED USE WITHIN THE

OVERALL EQUIPMENT OR SYSTEM.

Vibration resistance

Frequency: 10 to 55 to 10Hz

Amplitude: 0.75mm half amplitude

Mechanical shock resistance 300m/s

2

Min.

(14)

Installing the switch and actuator on a metallic material may affect the

operating distance. In addition, any instruments nearby that generate strong

radio waves or magnetic fields may affect the operating distance via the

metal. Do not install the switch and actuator directly on a metallic material.

If installation on a metallic material is necessary, be sure to check the effect

on the operating distance before use. Reference values for the effects of

installation on a metallic material.

It is recommended that the switch and actuator unit be separated

at least 10 mm from any metal parts or metallic materials.

M4

1N.m

21.5

38

48

25

20

16 10.5

5.5

(7.2 dia.)

38

48

17

12

16 7

(7.2 dia.)

Sensing surface

Sensing surface

Switch

Actuator

(mm)

(mm)

Cable diameter

: 4.2 dia.

Indicator

Target mark

Target mark

Two. 4.2 dia.

Two. 7.2 dia.

Two. 4.2 dia. Two. 7.2 dia.

Operating Distance Y (mm)

Distance from the target mark on the switch X (mm) Distance from the target mark on the switch Z (mm)

Temperature Influence

Operating Distance Y (mm)

Operating Distance Y (mm)

㻜

㻞

㻠

㻢

㻤

㻝㻜

㻝㻠

㻝㻢

㻝㻞

㻙㻟㻡 㻙㻟㻜 㻙㻞㻡 㻙㻞㻜 㻙㻝㻡 㻙㻝㻜 㻙㻡 㻜 㻡 㻝㻜 㻝㻡 㻞㻜 㻞㻡 㻟㻜 㻟㻡

㻜

㻞

㻠

㻢

㻤

㻝㻜

㻝㻠

㻝㻢

㻝㻞

OFF

ON

OFF

ON

㻙㻟㻜 㻙㻞㻡 㻙㻞㻜 㻙㻝㻡 㻙㻝㻜 㻙㻡 㻜 㻡 㻝㻜 㻝㻡 㻞㻜 㻞㻡 㻟㻜

Side lobe Side lobe

㻜

㻞

㻠

㻢

㻤

㻝㻜

㻝㻠

㻝㻞

OFF

ON

X=0, Z=0

2137840-7C