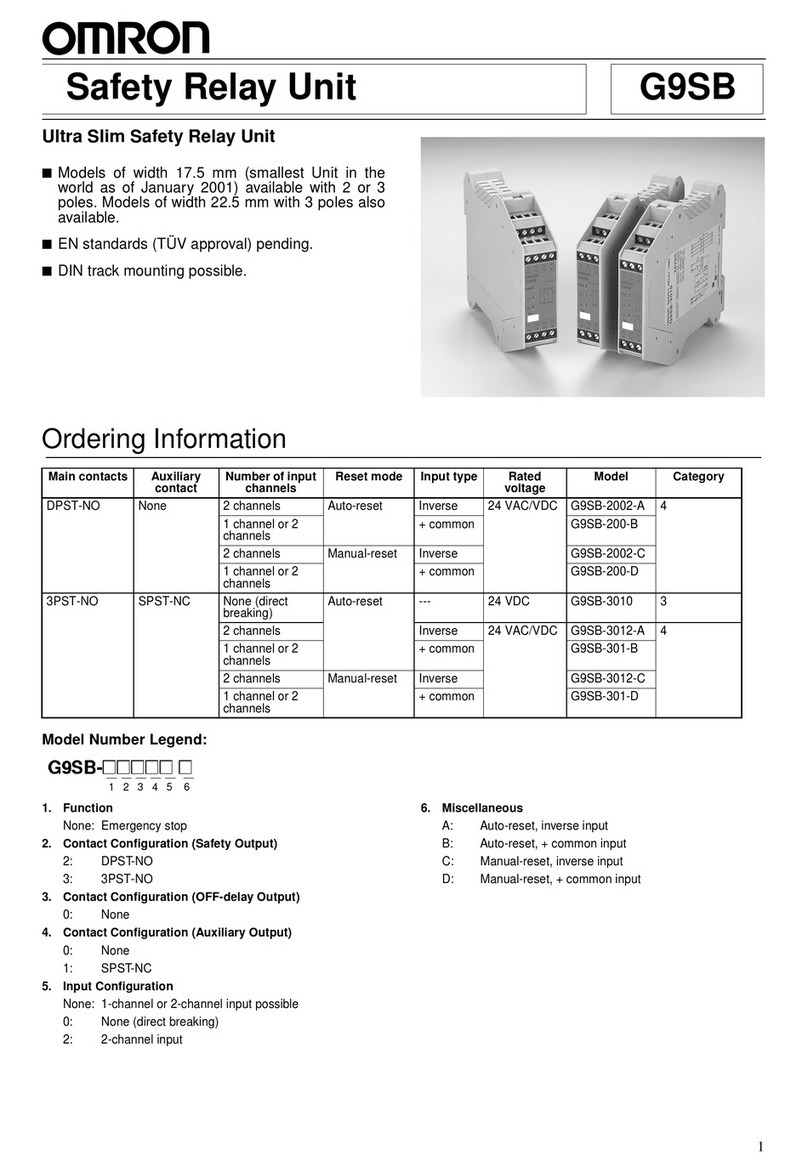

Safety Relay Unit

G9SA

The G9SA Series Offers a Complete Line-up

of Compact Units.

• Four kinds of 45-mm wide Units are available:

A 3-pole model, a 5-pole model, and models with 3 poles and 2

OFF-delay poles, as well as a Two-hand Controller.

Also available are 17.5-mm wide Expansion Units with 3 poles

and 3 OFF-delay poles.

• Simple expansion connection.

• OFF-delay models have 15-step OFF-delay settings.

• Conforms to EN standards. (BG approval)

• Certified by UL and CSA.

• Both DIN track mounting and screw mounting are possible.

Note: Be sure to read the “Safety Precautions” on page 13.

Ordering Information

Emergency-stop Units

Emergency-stop OFF-delay Units

Note: The following 15-step OFF-delay time settings are available:

T075: 0.5, 1, 1.5, 2, 2.5, 3, 3.5, 4, 4.5, 5, 5.5, 6, 6.5, 7, and 7.5 s

T15: 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, and 15 s

T30: 2, 4, 6, 8, 10, 12, 14, 16, 18, 20, 22, 24, 26, 28, and 30 s

Two-hand Controller

Expansion Unit

The Expansion Unit connects to a G9SA-301, G9SA-501, G9SA-321, or G9SA-TH301.

Main contacts Auxiliary contact Number of input channels Rated voltage Model Category

3PST-NO SPST-NC 1 channel or 2 channels possible 24 VAC/VDC G9SA-301 4

100 to 240 VAC

5PST-NO 24 VAC/VDC G9SA-501

100 to 240 VAC

Main contacts OFF-delay

contacts

Auxiliary

contact

Number of

input channels

OFF-delay

time

Rated voltage Model Category

3PST-NO DPST-NO SPST-NC 1 channel or

2 channels

possible

7.5 s 24 VAC/VDC G9SA-321-T075 Main contacts:

4

OFF-delay

contacts:

3

100 to 240 VAC

15 s 24 VAC/VDC G9SA-321-T15

100 to 240 VAC

30 s 24 VAC/VDC G9SA-321-T30

100 to 240 VAC

Main contacts Auxiliary contact Number of input channels Rated voltage Model Category

3PST-NO SPST-NC 2 channels 24 VAC/VDC G9SA-TH301 4

100 to 240 VAC

Main contacts Auxiliary contact Model Category

3PST-NO SPST-NC G9SA-EX301 4

http://www.ia.omron.com/ 1

(c)Copyright OMRON Corporation 2007 All Rights Reserved.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com