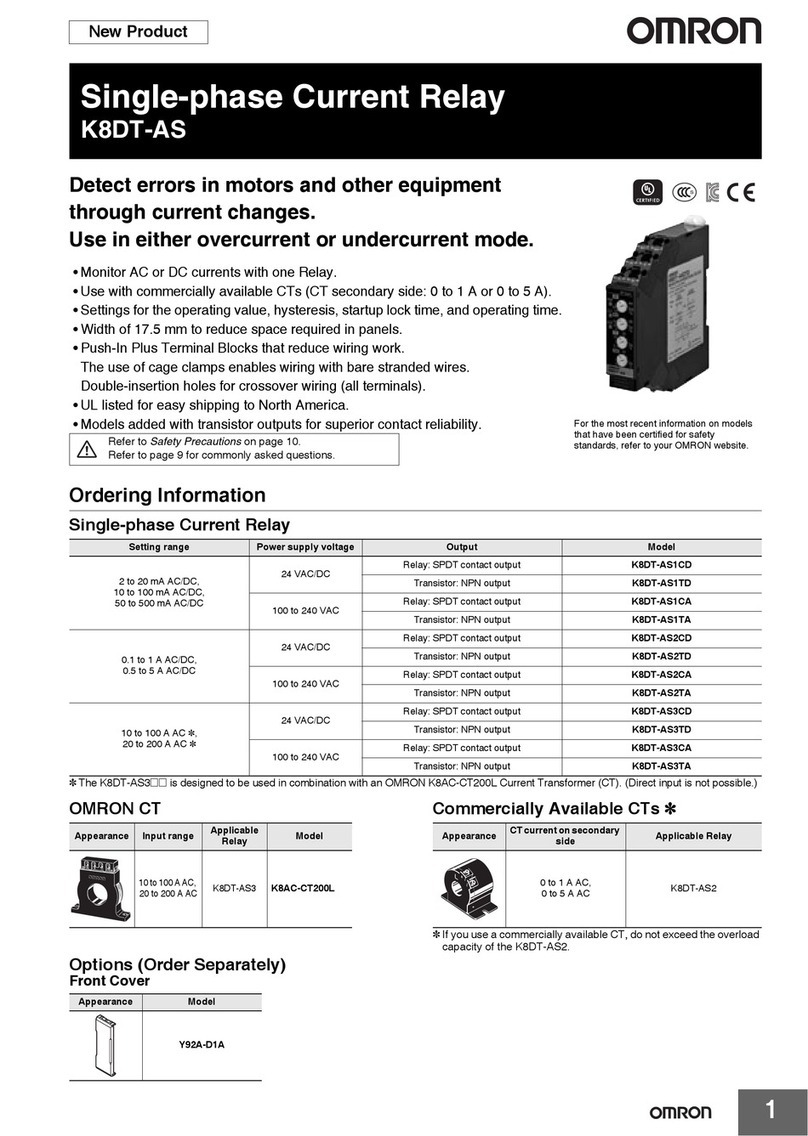

K8DT-AS

3

Ratings Specifications

Power supply voltage K8DT-AS@@D: 24 VAC 50/60 Hz, 24 VDC

K8DT-AS@@A: 100 to 240 VAC 50/60 Hz

Power consumption 24 VAC/DC: 1.8 VA/1 W max.

100 to 240 VAC: 2.5 VA max.

Rated insulation

voltage 600 VAC

Operating value

setting range (SV)

10% to 100% of the maximum value of the setting range

K8DT-AS1: 2 to 20 mA AC/DC

10 to 100 mA AC/DC

50 to 500 mA AC/DC

K8DT-AS2: 0.1 to 1 A AC/DC (Compatible with

commercially available CTs.)

0.5 to 5 A AC/DC (Compatible with

commercially available CTs.)

K8DT-AS3: When used with the OMRON CT

(K8AC-CT200L).

10 to 100 A AC

20 to 200 A AC

Operating value 100% operation at set value

Reset value setting

range (HYS) 5% to 50% of operating value

Reset method

Manual reset/automatic reset (switchable)

Note: Manual reset: Turn OFF power supply for

1 s or longer.

Operating time

setting range (T) 0.1 to 30 s

Startup lock time

setting range (LOCK)

0 to 30 s

(The startup lock timer starts when the input has

reached approximately 30% or more of the set value.)

Note:

Enabled only for overcurrent operation.

LED Indicators Power (PWR): Green, Output (OUT): Yellow,

Alarm outputs (ALM): Red

Input impedance Refer to Input Range on page 2.

Output form

Relay: SPDT contact output

Transistor: Open collector

Switchable between normally open and normally

closed with a DIP switch setting.

Output relay ratings

Rated load: 250 VAC 5 A or 30 VDC 5 A

(resistive load),

250 VAC 1 A (inductive load),

48 VDC 0.2 A (inductive load)

Minimum load: 5 VDC, 10 mA (reference values)

Mechanical life: 10 million operations min.

Electrical life: 5 A at 250 VAC or 30 VDC: 50,000

operations

3 A at 250 VAC or 30 VDC:100,000

operations

Transistor output

ratings

Contact form: SPST-NO (Open collector)

Rated voltage: 24 VDC (maximum voltage: 26.4 VDC)

Maximum current: 50 mA DC

Ambient operating

temperature 20 to 60°C (with no condensation or icing)

Storage temperature 25 to 65°C (with no condensation or icing)

Ambient operating

humidity 25% to 85% RH (with no condensation)

Storage humidity 25% to 85% RH (with no condensation)

Altitude 2,000 m max.

Applicable wires Stranded wires, solid wires, or ferrules

Applicable wire size 0.25 to 1.5 mm2(AWG24 to AWG16)

Wire insertion force 8 N max. for AWG20 wire

Screwdriver

insertion force 15 N max.

Wire stripping length 8 mm

Ferrule length 8 mm

Current capacity 10 A (per pole)

Number of insertions

50 times

Case color N1.5

Case material PC, UL 94 V-0

Weight Approx. 100 g

Mounting Mounts to DIN Track, or screw mounting

Dimensions 17.5 90 90 mm (WHD)

Allowable operating

voltage range 85% to 110% of power supply voltage

Allowable operating

frequency range 50/60 Hz 5 Hz

Input frequency range

K8DT-AS1 and K8DT-AS2:DC input or AC input

(45 to 65 Hz)

K8DT-AS3: AC input (45 to 65 Hz)

Overload capacity

K8DT-AS1 and K8DT-AS2:

Continuous input at 120% of

maximum input, 1 s at 150%

K8DT-AS3:Continuous input at 120%, 30 s at

200%, and 1 s at 600% with an

OMRON CT (K8AC-CT200L)

Note: Overload capacity of primary side of CT.

Repeat error

Operating

value

0.5% full scale (at 25C and 65% humidity, rated

power supply voltage)

Operating

time

50 ms (at 25C and 65% humidity, rated power

supply voltage)

Applicable

standards

Conforming

standards

EN 60947-5-1

Installation environment (pollution level 2,

Overvoltage category III)

EMC EN 60947-5-1

Safety

standards

UL 60947-5-1 (Listing), Korean Radio Waves Act

(Act 10564), CCC (GB14048.5)

Insulation resistance

20 Mmin.

Between external terminals and case

Between power supply terminals and input

terminals

Between power supply terminals and output

terminals

Between input terminals and output terminals

Dielectric strength

2,000 VAC for one minute

Between external terminals and case

Between power supply terminals and input

terminals

Between power supply terminals and output

terminals

Between input terminals and output terminals

Impulse withstand

voltage

6 kV (between live terminals and exposed,

non-charged metal parts)

Noise immunity

Square-wave noise of 1-s/100-ns pulse width

with 1-ns rise time

100 to 240 VAC: 1,500 V power supply terminal

common/normal mode

24 VAC: 1,500 V power supply terminal common/

normal mode

24 VDC: 480 V power supply terminal common

Vibration resistance

Frequency 10 to 55 Hz, 0.35-mm single

amplitude, acceleration 50 m/s2

10 sweeps of 5 min each in X, Y, and Z directions

Shock resistance

100 m/s

2

, 3 times each in 6 directions along 3 axes

Degree of protection Terminals: IP20