3

4.3 WIRING DIAGRAMS ................................................................18

4.3.1WIRING DIAGRAM OF THE THREE PHASE SYSTEM ......................18

4.3.2WIRING DIAGRAM OF THE SINGLE PHASE SYSTEM .....................19

4.4 GENERAL OPERATION CONTROL ...............................................20

CHAPTER 5 USING THE MACHINE....................................................... 20

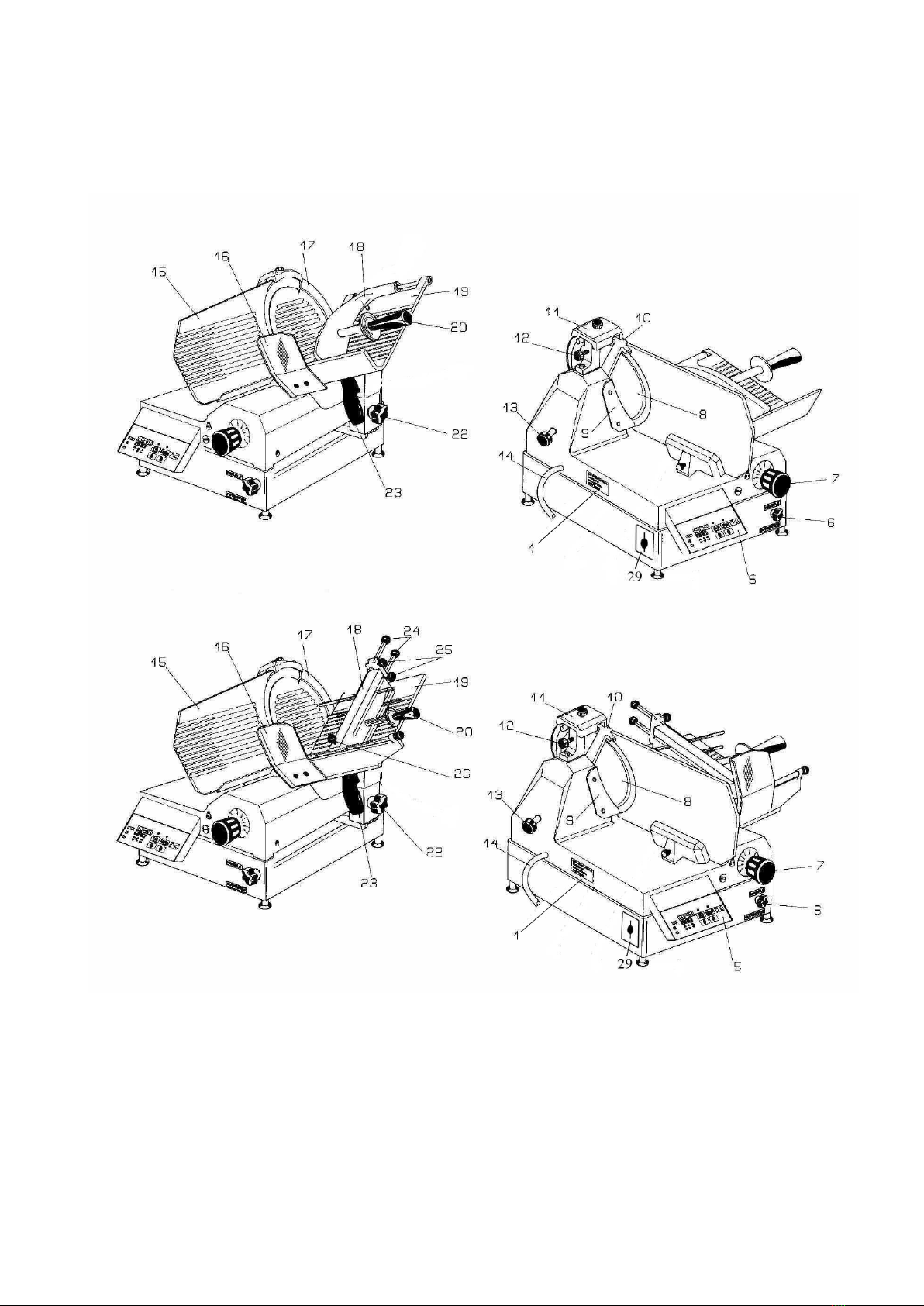

5.1 CONTROLS.............................................................................20

5.2 OPERATION............................................................................21

5.2.1MANUAL OPERATION...............................................................21

5.2.2COMPLETE AUTOMATIC OPERATION..........................................21

5.2.3SEMIAUTOMATIC OPERATION ..................................................21

5.3 LOADING AND CUTTING THE PRODUCT .....................................22

5.3.1NORMAL TRAY ........................................................................22

5.3.2TRAY WITH CONTROL RODS ....................................................23

5.3.3TRAY WITH SPECIAL ARM ........................................................24

5.4 SHARPENING THE BLADE.........................................................25

CHAPTER 6 ROUTINE CLEANING ........................................................ 26

6.1 GENERAL INFORMATION..........................................................26

6.2 HOW TO CLEAN THE SLICING MACHINE ....................................26

6.2.1CLEANING THE PRODUCT HOLDER TRAY....................................26

6.2.2CLEANING THE BLADE, THE BLADE GUARD AND THE RING ..........27

6.2.3CLEANING THE SHARPENER .....................................................28

6.2.4CLEANING THE SLICE DEFLECTOR ............................................28

CHAPTER 7 MAINTENANCE................................................................. 29

7.1 GENERAL INFORMATION..........................................................29

7.2 MAINTENANCE .......................................................................29

7.2.1BELT .....................................................................................29

7.2.2FEET .....................................................................................29

7.2.3POWER CABLE........................................................................29

7.2.4 BLADE ...................................................................................29

7.2.5WHEELS ................................................................................29

7.2.6LUBRICATING THE SLIDING GUIDES.........................................30

CHAPTER 8 DEMOLITION AND DISPOSAL........................................... 30