EVBUM2290/D

www.onsemi.com

2

Locations such as the secondary side medium voltage

(MV) transformers and overhead lines can deliver

tremendous amounts of energy and pose high risks.

For 230 VAC systems, only single-phase operation is

supported, i.e. with the power cable connected from neutral

to phase. Operation across two phases is not possible.

If damage is suspected, stop using the evaluation kit.

Contact ON Semiconductor to have it re-tested and

repaired.

Your sales representative or field application engineer can

also help you with other safety questions −do not hesitate to

contact them.

Primary-side Modifications and Measurements

From a safety point of view it is of course preferred to use

the evaluation kit with the mains-connected part unchanged.

However, testing customer-specific parts is often desired.

Preferably, the protective cover should only be removed for

the modification work (with the power cable unplugged!).

Before starting, ensure the board is safe. During operation

some primary-side capacitors are charged up to 350 VDC.

Although bleeding resistors bridge all high-voltage

capacitors, measuring the residual voltage on critical

capacitors remains a good habit.

Following modifications, most measurements can

proceed with the enclosure back in place and screwed-down.

If measurements on the primary side are truly needed and

the enclosure blocks access, a risk analysis must be

performed. Formal safety systems greatly help with this,

though this is outside the scope of this document; only a few

hints are noted below.

As an obvious safety precaution, shield as many

components as possible.

Limiting the energy available during an accident should

also be a priority.

Do not rely on the circuit breakers of the electrical

installation. Connecting the evaluation kit directly to the

mains, while fine for normal use, should never be done with

modified boards. Instead, use an AC power supply with low

trip current setting or an isolation transformer. Isolating the

board also protects measurement instruments. It may also be

required to avoid tripping residual current breakers.

Consider the required measurement method and

instruments carefully to avoid unsafe working and damage.

A good guide is available from Tektronix [23].

Never remove the protective earth of a measurement

instrument; while this allows floating measurements to

some extent, it exposes the operator to lethal voltages on the

instrument connectors.

Ensure the voltage rating of oscilloscope probes is

appropriate in order to protect the operator and the

oscilloscope. High-voltage probes are preferable to

general-purpose probes.

Consider slowly ramping up the AC voltage; gross defects

such as short-circuits or inverted diodes will be equally

obvious at lower voltages but will cause less damage.

Electrical shocks can cause cramps and unconsciousness.

Therefore, never work alone on energized low-voltage

systems; always ensure a knowledgeable colleague can raise

the alarm.

When the fuse fitted on the motherboard has blown,

replace it with a suitable type. A fast fuse of 1.6 A or less is

recommended3.

Evaluation Boards

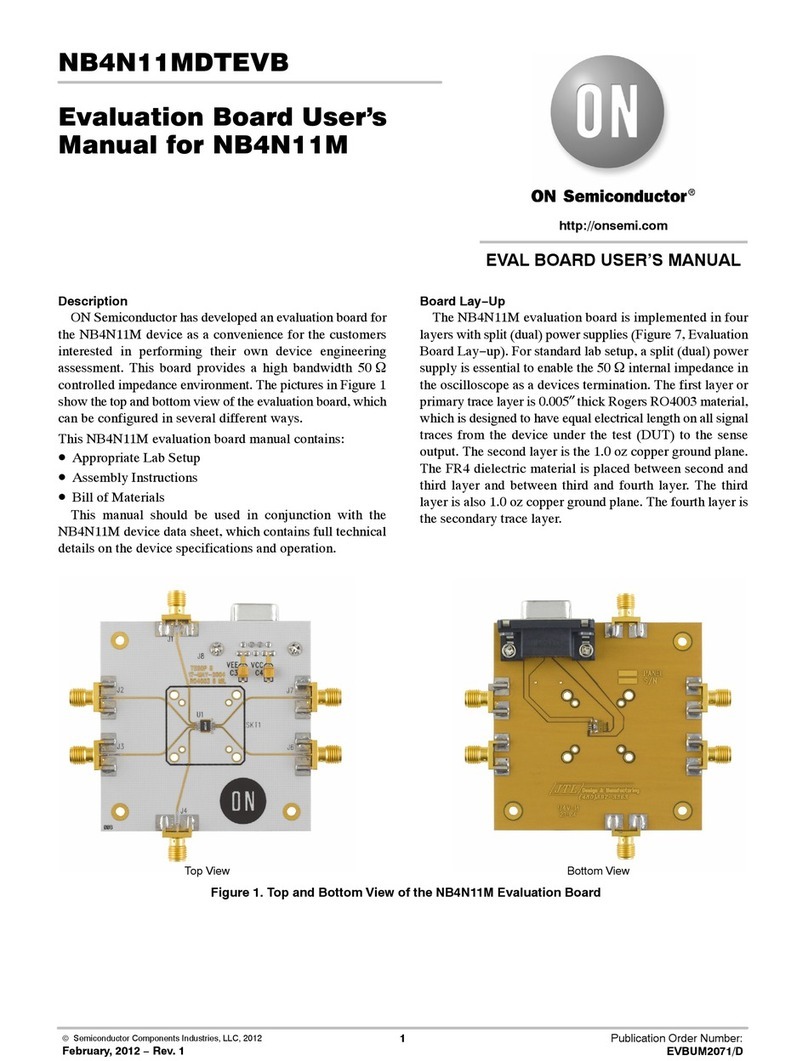

The evaluation circuit is split up in a motherboard and

a daughterboard (Figure 1). Refer to [11, 14, 15] for the full

schematics.

Figure 1. Evaluation Boards: Motherboard and

Plugged-on Daughterboard

The motherboard contains the power supply, mains

coupling circuit (including the zero-crossing detection) and

a USB-to-teletype converter.

The daughterboard contains the modem itself, the power

amplifier, the receive and the transmit filter and the

protection circuit. Refer to the “Evaluation Kit Design”

section for a list of available daughterboards4.

Power Supply

An enclosed switching mode power supply (SMPS)

converts the AC voltage to a 12 V, 1 A DC voltage. An input

filter is required to comply with EME regulations.

Additionally, the impedance on the line must be sufficiently

high for the PLC frequencies. This precludes the use of

a capacitor directly between the phases. Instead, a fourth

order LC filter is used. For more information refer to the

application note “PLC modem power supplies”.

The input range of the power supply is 85–264 VAC and

120–370 VDC5. The coupling stage should work with any

power line with a voltage of less than 260 VAC (frequency

60 Hz or less) and 370 VDC.

Operation with a power line voltage above the given range

is not safe.

3The high current rating does not stem from the power supply,

which consumes 150mA at most, but from the PLC signal.

4If no daughterboard is available for the product or frequency

band you are interested in, contact your sales representative to

obtain tuned daughterboards.

5Consult the manufacturers datasheet for details: for the Mean

Well supplies refer to [8]; for the CUI supplies to [1].

Note that the IEC standard and IEC firmware requires a mains

zero crossing to synchronise transmission. Only the ON−PL110

firmware can operate without zero crossing, if it is configured to

do so (page 10).