Onan MCCK Instruction Manual

Other Onan Portable Generator manuals

Onan

Onan 25.0 DEH-53R Series Instruction Manual

Onan

Onan MJA Series User manual

Onan

Onan MEP-003A User manual

Onan

Onan Protec Series User manual

Onan

Onan aj series User manual

Onan

Onan KVC Series User manual

Onan

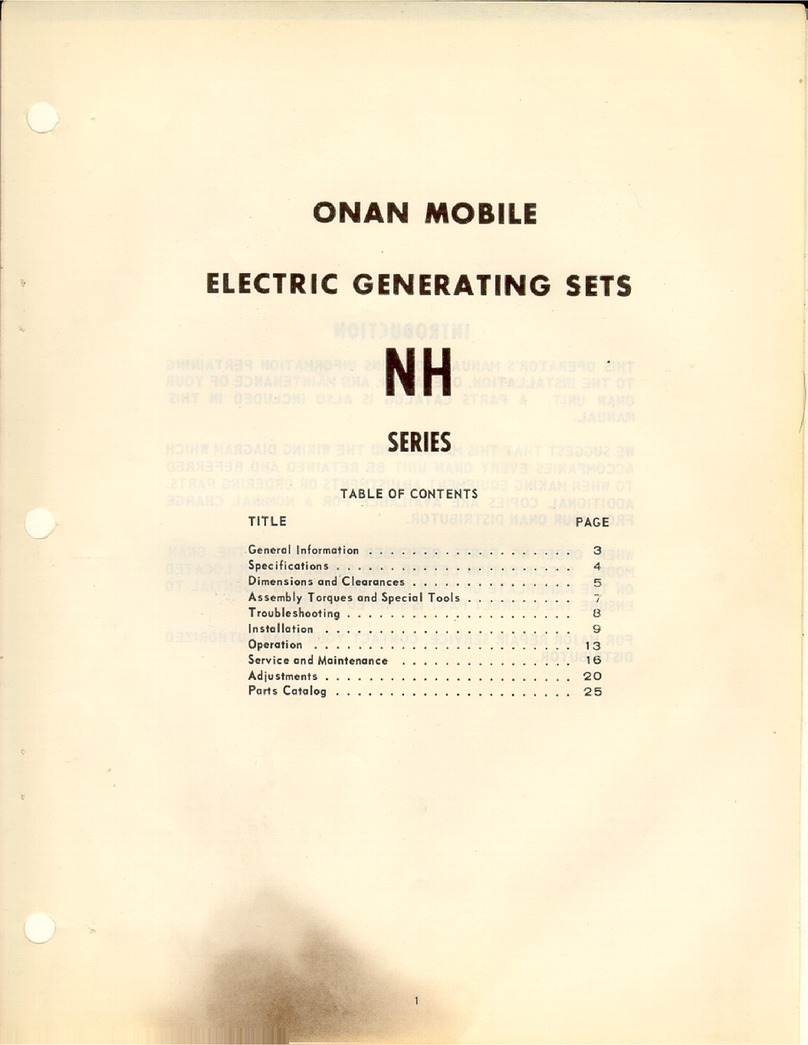

Onan NH User manual

Onan

Onan MGKBC Series User manual

Onan

Onan K5000 User manual

Onan

Onan Emerald Plus BGE Series User manual

Onan

Onan JB Series User manual

Onan

Onan BF Series User manual

Onan

Onan HDCAC User manual

Onan

Onan BGE User manual

Onan

Onan 12.0 RDJC Series User manual

Onan

Onan CCK Series User manual

Onan

Onan MDJF Series Instruction Manual

Onan

Onan MDKBK User manual

Onan

Onan 50.0DDB-15R Series Instruction Manual

Onan

Onan 3.0 AJ User manual