3

Q4SXINIB and 06SXINIB EXCITER

WIRING

DIAGRAM

06SX

Spec

B

Static

Exciter

Wiring

Diagram

in

Pictorial

(With

residual

reset

switch)

h(

~~

-<

~.

w~

,,~

·-·~r

~o

Io

.

'"

"'

..

<"

,,'"

..

~

......

--

---1

"

I

---

------~----

-----

-..l

I'

I

04SX

Spec

B

Static

Exciter

Wiring

Diagram

in

Pictorial

(With

residual

reset

switch)

"

~

...

~;

;~

~~

...

to

a~

.,,,

......

.,!

~

...

~

'"

...

..

j;

1

;i

~~

j

~I

~I

I

-l

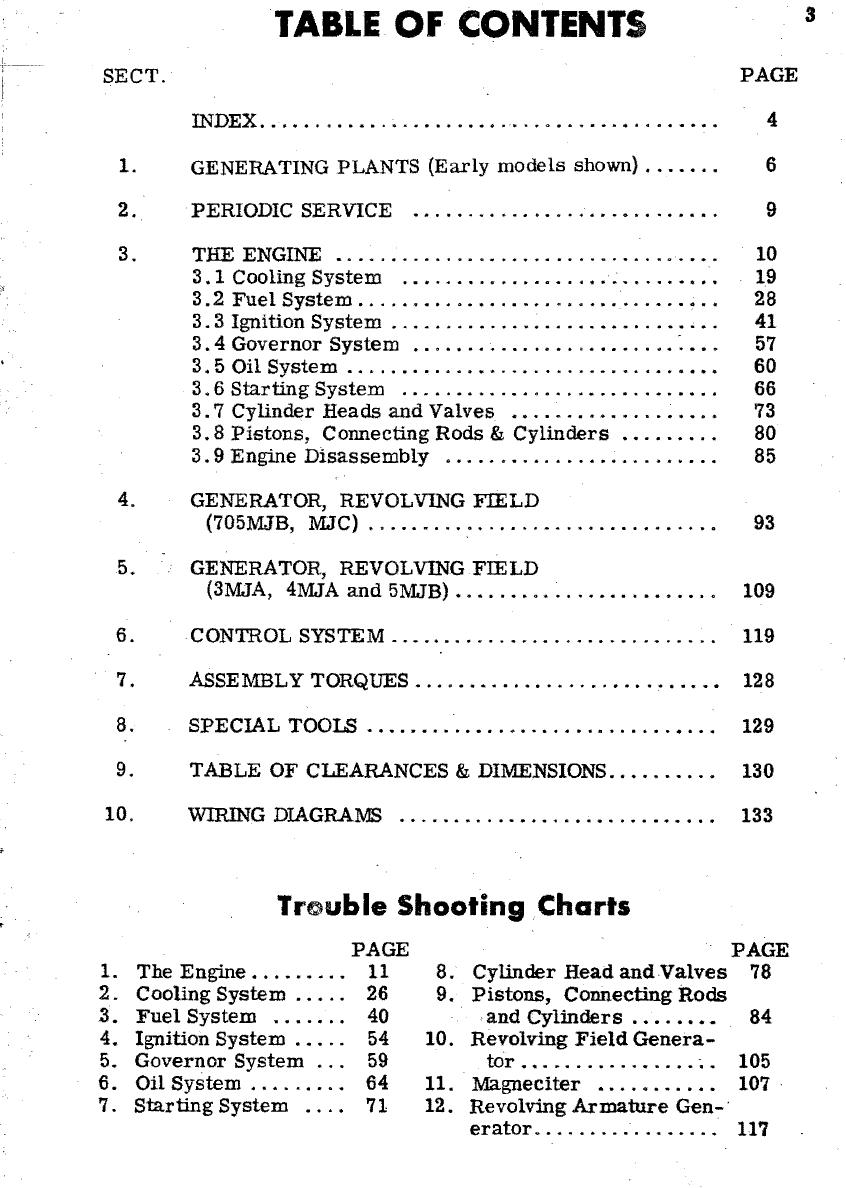

TABLE

OF

CONTENTS

SECT.

INDEX

.................................•........

1.

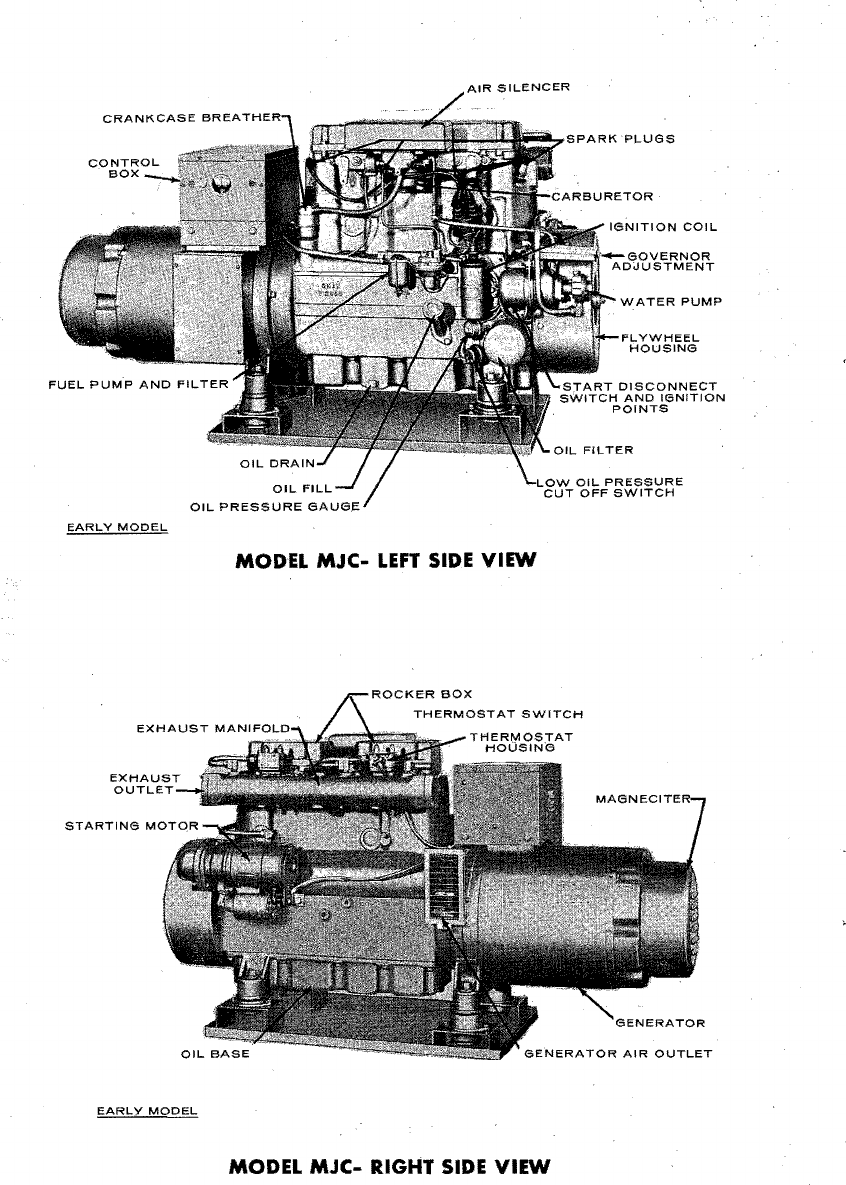

GENERATING PLANTS

(Early

models

shown)

.....

"

2.

PERIODIC SERVICE

...................•........

3. THE ENGINE

•................................•.

3.

1 Cooling

System

............................

.

3.2

Fuel

System

..............................•..

3.3

Ignition

System

...................•.......••.

3.4

Governor

System

........................

~

•..

3.

5

Oil

System

..............................•.••

3.

6

Starting

System

............................

.

3.7

Cylinder

Heads

and

Valves

••................•

3.8

Pistons,

Connecting

Rods

&

Cylinders

.•.......

3.9

Engine

Disassembly

........................

.

4. GENERATOR, REVOLVING

FIELD

(705MJB, MJC)

...............................

.

5. GENERATOR, REVOLVING

FIELD

(3MJA, 4MJA

and

5MJB)

•.......................

6. CONTROL SYSTEM

.............................

.

7. ASSEMBLY TORQUES

...........................

.

8.

SPECIAL

TOOLS

.............................•...

9. TABLE

OF

CLEARANCES & DIMENSIONS

.••......•

10.

~G

DIAGRA~

..................•..........

Trouble

Shooting

Charts

PAGE

1.

The

Engine.

. . . . . .

..

11

2.

Cooling

System

..

.

..

26

3.

Fuel

System

.......

40

4.

Ignition

System

...

. . 54

5.

Governor

System

...

59

6.

Oil

System

...

. . . .

..

64

7.

Starting

System

....

71

8.

9.

10.

11.

12.

Cylinder

Head

and

Valves

Pistons,

Connecting

Rods

and

Cylinders.

. . . ••

••

Revolving

Field

Genera-

tOr

••.........•....

~.

Magneciter

•...•......

Revolving

Armature

Gen-'

erator....

..

......

.....

PAGE

4

6

9

10

19

28

41

57

60

66

73

80

85

93

109

119

128

129

130

133

PAGE

78

84

105

107,

117