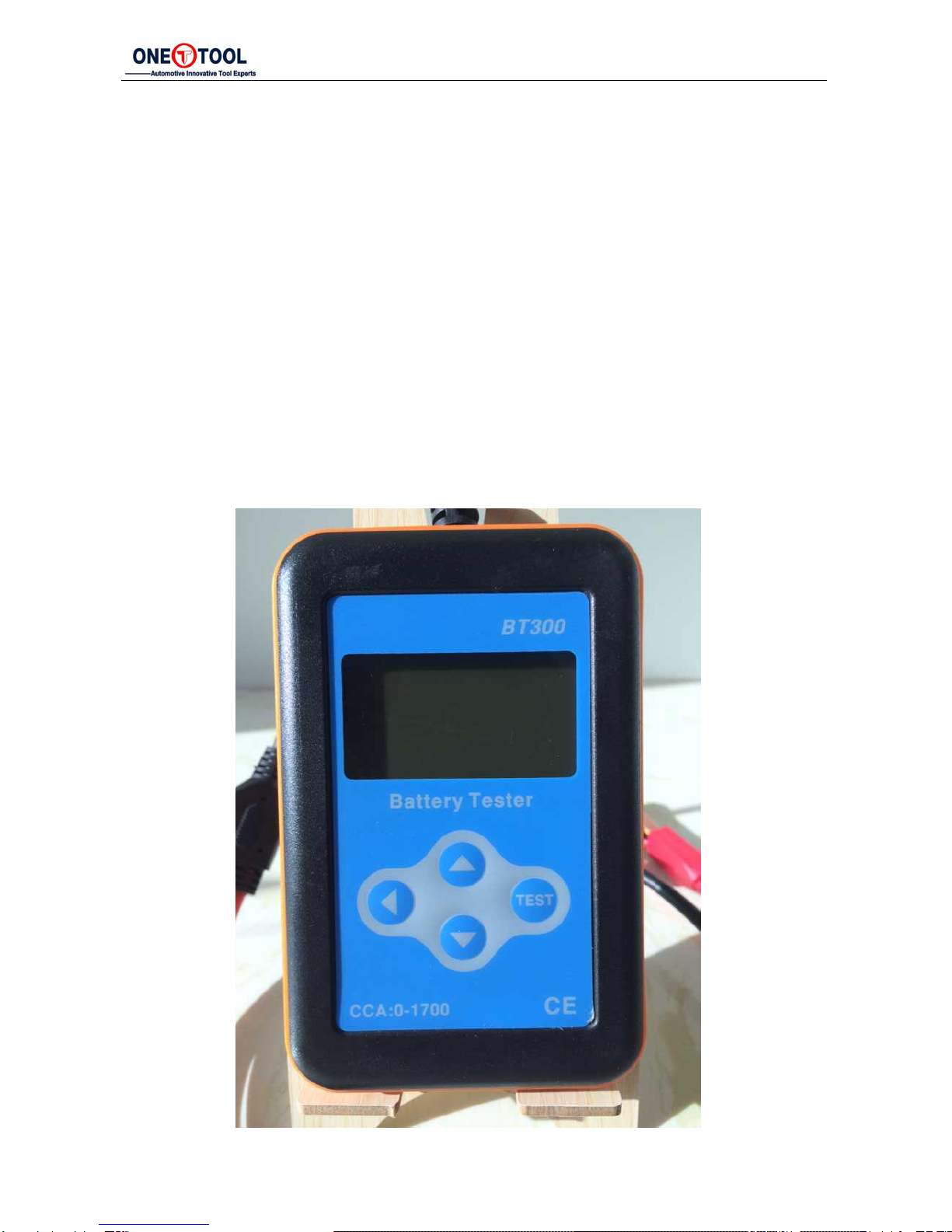

Battery Tester BT300

1

Chapter 1 Product Summary

1.1 Product Profile

BT300 Battery Tester adopts currently the world's most advanced conductance

testing technology to easily, quickly and accurately measure the actual cold

cranking amps capability of the vehicle starting battery, healthy state of the

battery itself, and common fault of the vehicle starting system and charging

system, which can help maintenance personnel to find the problem quickly and

accurately, thus to achieve quick vehicle repair.

1. Test all automotive cranking lead acid battery, including ordinary lead acid

battery, AGM flat plate battery, AGM spiral battery, and Gel battery, etc.

2. Directly detect bad cell battery.

3. Polarity reverse connection protection, reverse connection will not damage

the tester or affect the vehicle and battery.

4. Directly test the battery with loss of electricity, no need to full charge before

testing.

5. Testing standards include currently the world's majority of battery

standards, CCA, BCI, CA, MCA, JIS, DIN, IEC, EN, SAE, GB.

6. Support multi-languages, customer can select different language package,

which includes: Chinese Simple, Chinese Traditional, English, Japanese,

Russian, Spanish, French, Italian, German, etc. Other languages can also

be customized according to user's need.

1.2 Product Function

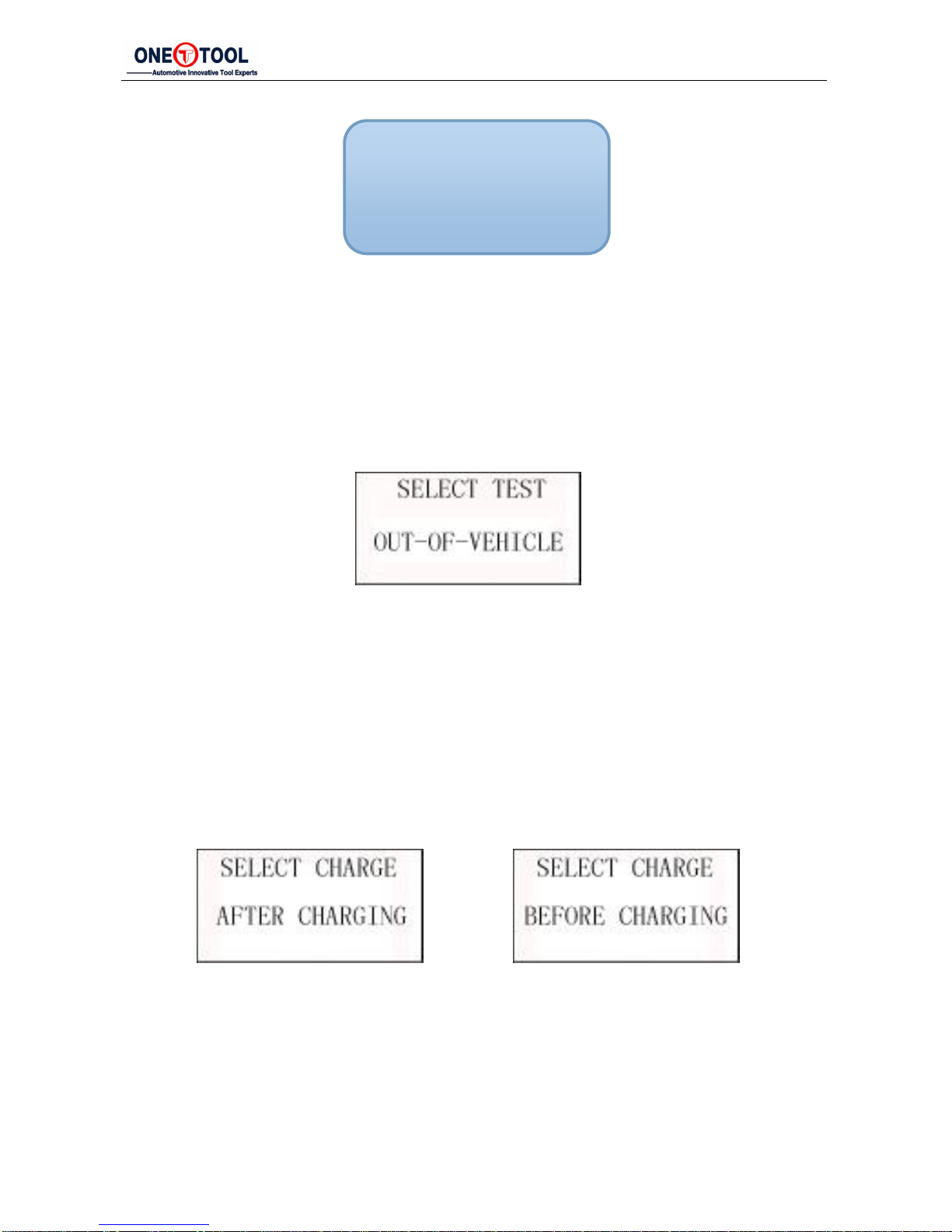

Main functions of BT300battery tester include: battery test, cranking test,

charging test and other additional functions.

Battery test is mainly targeted to analyze the battery healthy status to

calculate the actual cold cranking capability of the battery and the aging extent,

which provide reliable analysis evidence for the test and maintenance of the

battery. It notifies the user to replace battery in advance when the battery

getting aged.

Cranking test is mainly to test and analyze the starting motor. Through testing