3. Structure and Working Theory

3.1 Mechanical System

Swing barrier mechanical system is divided into two parts, namely: machine box and machine core.

Machine box is carrier with direction LED, reader and writer, infrared sensor etc; machine core

including motor, motor shed, transmission shaft, arm etc.

3.2 Electrical Control System

Electrical control system including: reader, main control panel, infrared sensor, direction LED,

alarm, limit switch, transformer etc. Reader (self-provided): Read information from cards, judging

and processing, sends signal to the main control panel for passing (open-close signal)

Main Control panel: Control center of the system, receiving signals from readers and infrared sensor ,

and logically judging and processing signals, sends orders to direction LED, motor, counter, alarm.

Direction LED: Show the current passing status and guide the passengers to pass in order.

Alarm: The system will alarm when unauthoried person passes.

Limit switch: Control arm turning position.

3.3Swing Barrier System Working Theory

1. Power on and the system will begin to work in 3s.

2 Valid card read, good sounds from buzzer to inform that card is read successfully;

meanwhile, reader judges and processes the information and send signal for passing to the

control panel.

3. Main Control panel gets the signal from reader and infrared sensor, processing it,

sending signal to direction LED and motor. Now direction LED will show green arrow for

passing. If system is normal close, motor turning, limit witch controls motor turning

angle, arm opens. (Normal open, motor remain stop). Passenger is allowed to pass.

4. Passenger gets through the swing barrier according to the direction guide, infrared sensor

detects the whole process of the passing and continously sends signals to the main control

panel until passenger finishs passing.

5. If card is not read or invalid card read, system sends signal of no passing (if normal open, arm

will close; if normal close, arm remains stop), and alarm calls until passenger is back from

swing barrier. Valid card to be read and passenger can get through.

4. Installation and Adjustment

4.1. Installation

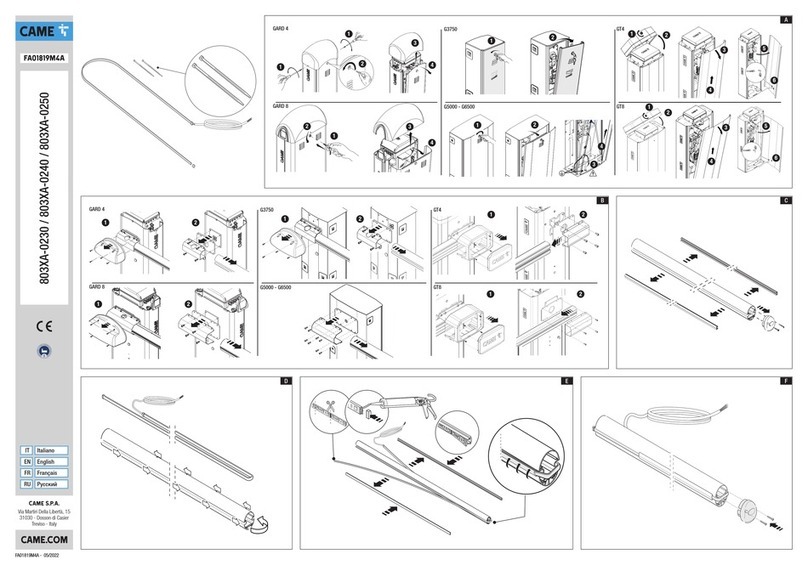

3.1.1. Check the spare parts according to the parking list.

3.1.2. Make sure the place where to install swing barrier according to system components,

place features and swing barrier type.

3.1.3. Confirm installation holes according to the following drawing. Pre-bury M12 anchor

bolts or M12 expansive bolts