Tiso RB343-21 User manual

Page

Size А4

Installation and Operation Manual

Revision 3.2 2023

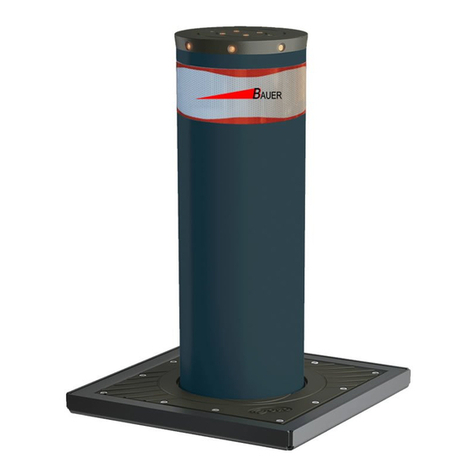

Traffic bollards automatic

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global -1-

Size А4

Installation and Operation Manual

Revision 3.2 2023

Traffic bollards automatic

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global Original guideTRAFFIC AUTOMATIC Bollard(Series of RB343-21, RB343-23, RB349-11, RB349-12, RB343-24, RB343-26, RB349-14, RB349-15)OPERATION MANUAL. PART I

Page

Size А4

Installation and Operation Manual

Revision 3.2 2023

Traffic bollards automatic

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global -2-Warning -This symbol tells you that the sections concern safety issuesАttribution - This symbol tells you to read the section with particular careСaution - This symbol indicates that the sections warn of problems with the release of high pressure oilСaution -This symbol tells you that the sections concern pressure hazardСaution - Moving parts and crush hazard - mind your handsDefinition - This symbol tells you to describe abbreviations for conventionsIMPORTANT INSTALLATION, SAFETY INSTRUCTIONSџCAUTION: IMPROPER INSTALLATION MAY CAUSE SERIOUS DAMAGE, FOLLOW ALL INSTALLATION INSTRUCTIONS CAREFULLYџTHIS MANUAL IS ONLY FOR PROFESSIONAL OR QUALIFIED INSTALLERSџTO ENSURE THE SAFETY OF PEOPLE, IT IS IMPORTANT THAT YOU READ ALL THE FOLLOWING INSTRUCTIONS.џINSTALLATION, CONNECTION AND COMMISSIONING WORKS SHALL BE PERFORMED BY SPECIALISTS OF THE APPROPRIATE QUALIFICATION.џPERSONNEL INVOLVED IN MAINTENANCE OF EXISTING ELECTRICAL INSTALLATIONS OR COMMISSIONING, ELECTRICAL INSTALLATION, REPAIR WORK, MAINTENANCE AND INSTALLATION SHALL BE TRAINED TO WORK WITH THIS MODEL OF THE DEVICE! TRAINING SHALL BE CARRIED OUT AT THE MANUFACTURER'S REPRESENTATIVES' OR AT THE MANUFACTURERS' OF THE PRODUCT.

Page

Size А4

Installation and Operation Manual

Revision 3.2 2023

Traffic bollards automatic

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global -3-Table of contents1. General provisions .............................................................................................................. 52. Description ......................................................................................................................... 83. Intended use ....................................................................................................................... 84. Technical data .................................................................................................................... 95.Specifications ......................................................................................................................106. Installation.......................................................................................................................... 127. Bollard communication connection.................................................................................... 208. Commissioning works ...................................................................................................... 229. Operational procedures .................................................................................................... 2510. Hydraulic system.............................................................................................................. 2911. Notes ............................................................................................................................... 32The manual is provided for use along with Operational Procedures. Part II. Electric connection of traffic bollards (series RB). џThis Manual is an integral part of the product and shall be transferred to the consumer. Keep the Manual and refer to it if necessary for clarification.џIf the bollard is subject to reselling, transfer to another owner or shipment to another location, make sure that this Manual is provided with the product for use by the new owner and/or maintenance staff during installation and/or operation. The following abbreviations have been used in this Manual: џТM – technical maintenance; џHS – hydro station; џHC – hydro cylinder; џLP - Level of paving (relative mark 0.000)

Page

Size А4

Installation and Operation Manual

Revision 3.2 2023

Traffic bollards automatic

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global -4-DECLARATION OF CONFORMITY OF EQUIPMENT There is confirmed the compliance with the basic safety requirements of following EU Directives:- 2006/42/ EC;- 2014/30/EC;- 2014/35/EC;

Page

Size А4

Installation and Operation Manual

Revision 3.2 2023

Traffic bollards automatic

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global -5-џTiSO" ensures its best effort for guarantee and correctness of this Manual and reflecting material changes in the design. However, a policy of continuous improvement can lead to insignificant differences between the equipment supplied and the description in this document.џThe Manual shall be kept.џDo not allow children and unauthorized persons to stay near operating equipment. The manufacturer shall bear no responsibility for violation of safety rules.џAny actions that are not explicitly listed in these instructions shall be prohibited.џSafety devices shall protect potentially hazardous areas.1.The traffic area regulated by the bollards shall contain appropriate warning signs effective for the territory of the country (see clause 6.5)! For safe operation of the bollard, the other warning sign shall be installed at a distance of at least 50 m according to the current traffic regulations!In the event of violation of the operating rules and the requirements of the operational documentation, the bollard may present a danger to human life and health by virtue of high voltage and moving parts of the product! Transportation of the product shall be ensured in the lowered state only!Personnel involved in maintenance of existing electrical installations or commissioning, electrical installation, repair work, maintenance and installation shall be trained to work with this model of the device! Training shall be carried out at the manufacturer's representatives' or at the manufacturers' of the product. Read the Manual carefully before installation and operation of the equipment to ensure safety of people. Improper installation or misuse of products does not directly guarantee safety.General safety provisions.Rising bollard

Warning sign (conditionally)

Page

Size А4

Installation and Operation Manual

Revision 3.2 2023

Traffic bollards automatic

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global -6-1.1 Instructions to the installer:1. For your safety, follow the installation instructions;2. The product shall be installed in accordance with applicable regulations and rules, in compliance with safety precautions during installation work;3. Installation of the equipment shall be carried out with the power supply disconnected;4. Packaging materials shall be disposed of in accordance with applicable standards;5. Strictly observe the sequence of operations for assembling the blocker specified in the instruction;џIt is forbidden to make changes to the arrangement of equipment and use of materials and components that are not included in the contents of delivery and are not provided for in this manual.џDo not install this equipment during a lightning storm, heavy rain or snow, in an explosive atmosphere and in poor visibility. Mounting zone is equipped according to the current standards.џInstallation, connection and commissioning works shall be performed by specialists of the appropriate qualification.6. If faults or defects are detected, contact the supplier's service desk.7. The installer shall provide the user with the necessary information on the operation of the system in manual mode in the event of an emergency.8. The manufacturer is not responsible for the operation of the equipment in the following cases:џ non-compliance with the installation technology,џuse of non-standard materials and components,џperformance of work by unqualified personnel9. The manufacturer is not responsible for the safety measures when installing the equipment by personnel not involved in the company's service desk.Check the integrity of the product after transportation.Check availability of a plate with the manufacturer's details:

Page

Size А4

Installation and Operation Manual

Revision 3.2 2023

Traffic bollards automatic

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global -7-1.2 Instructions to the user:1. Strictly follow the operational procedures prescribed in this manual.2. Do not make any changes to the equipment components.3. Use the equipment as directed by the manufacturer.4. Do not attempt to repair or adjust the bollard yourself, contact the appropriate service desk. Breaking of seals will make manufacturer's warranty null and void.5. Points (control panels) for controlling the bollard shall not be accessible to outsiders.6. TiSO is not liable for improper operation of the equipment, violation of safety measures by the user.џOnly certified specialists who have the appropriate qualification and knowledge of the product and its technical documentation are allowed to install, start-up, and service the bollard:- Manual on the installation and operation of the bollard (Part I, Part II);- Technical sheet of the product;џPerform technical inspections, maintenance, adjustment and repair work only with the power off of the bollard.џThe device shall be labelled in accordance with CE standards, developed and manufactured in accordance with EU directives.*See section "Bollard electrical circuit" Operating manual. Part II. Electric connection of traffic bollards (series RB)Terminal box*230 V

Page

Size А4

Installation and Operation Manual

Revision 3.2 2023

Traffic bollards automatic

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global -8-2.1 Retractable road blocking system (bollard) is an automatic retractable pillar. In the lowered state, it is at the level of the roadway and does not interfere with the movement of vehicles. In the raised position, the bollard blocks unauthorized passage.2.2 The control of the bollard can be carried out:• from the guard post;• from the remote control;• from an external control point;• automatically, at a specified time interval;• in manual mode;There is possible to ensure independent control of two bollards from one control unit and parallel (simultaneous) control of groups of more than two bollards.2.3 The Bollard is equipped with a light signal system.2.4 Additional options:• bollard heating (for climatic zones with low winter temperatures);• induction loops ;• siren of sound alarm ;• additional remote control devices.2. Description3. Intended useOFFICESPLANTSSPORT COMPLEXES TRANSPORT ENTERPRISES PPPPARKING LOTS3.1 Retractable traffic blockers (bollards) are used at state, commercial and private facilities to limit unauthorized entry and exit of vehicles, to regulate and organize traffic on sites and adjacent territories, to organize parking lots and parking spaces. 3.2 Road blockers are recommended for sites with passenger transport, entrances to sports facilities and state institutions, for installation in front of shops, hotels, large shopping and office centers, health care facilities, at entrances to cottages and cottage settlements, for installation at central urban and historical sites, on industrial and special objects.

Page

Size А4

Installation and Operation Manual

Revision 3.2 2023

Traffic bollards automatic

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global -9- Technical data4.Table 1. Technical data* of automatic traffic bollard

Technical data:

Model

RB343- 21

RB343- 23

RB349- 11

RB349- 12

RB343- 24

RB343- 26

RB349- 14

RB349- 15

Installation type submerged Drive type / location hydraulic / internal Overall dimensions (LxWxH), mm · Raised foundation anchors · Lowared foundation anchors

610x755x980

660x830x980

610x755x1170

660x830x1170

460x610x980 515x685x980 460x610x1170 515x685x1170 Tube height (h), mm 600 800 Rising time*, (±1 s) 7 9 Lowering time*, (±1 s) 5,5 8 Tube diameter (D), mm 114 170 220 273 114 170 220 273 Wall thickness of cylinder, mm 3 5 4 8 3 5 4 8 Weight, kg 100 105 110 130 120 115 120 142 Working pressure, bar 40 Power supply 1Ph 230W, 50/60 Hz Power consumption, W 330 Axle load, t 15 Temperature mode - 10 °C / +40 °C Temperature conditions with heating system (optional) - 40 °C / +60 °C** Protection class ІР 67 (for bollard) ІР 55 (for control box) Intensity of use Average** Material of retractable cylinder Stainless steel; Painted steel (any RAL color); upon customer's request

Options:

Light indication + (RYG) Manual mode of lowering the cylinder +

Additional options:

Sound signal + Radio controller for wireless remote control + Remote control + Coating the cylinder in the selected RAL + Bollard heating + Forced water disposal + Induction loop controllers + *Technical data subject to change without notice. ** At temperatures above +40 °C intensity of use is lower than average

Page

Size А4

Installation and Operation Manual

Revision 3.2 2023

Traffic bollards automatic

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global -10-5.Specifications 5.1. General view 5.2. General view:Assembled bollard. Assembly box (Casing).

Symbol: 1. Retracting cylinder; 2. Assembly box; 3. Frame; 4. Front plate; 5. М8 screw - 8 pcs.; 6. Foundation anchor; 7. Terminal block; 8. Hydro station; 9. Hydro cylinder 879236415

Page

Size А4

Installation and Operation Manual

Revision 3.2 2023

Traffic bollards automatic

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global -11-

5.3. Bollard dimensions:Overall dimensions of the bollard with raised foundation anchorsOverall dimensions of the bollard with lowered foundation anchors

Models

Dimensions (LxWxH), mm

Cylinder diameter (D), mm

Cylinder height (h), mm

with raised foundation anchors

with lowered foundation anchors

RB343-21

610x755x980 460x610x980 114 600

RB343-23

170

RB349-11

220

RB349-12

660x830x980 515x685x980 273

RB343-24

610x755x1170 460x610x1170 114 800

RB343-26

170

RB349-14

220

RB349-15

660x830x1170 515x685x1170 273 Table 2. Overall dimensions of traffic automatic bollard

H

h

WH

h

D

100

Ø 34LLW

W55

Page

Size А4

Installation and Operation Manual

Revision 3.2 2023

Traffic bollards automatic

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global -12-6.1 Arrangement of the installation site:џThe installation site shall comply with the requirements of applicable regulations and standards.џThe work site is fenced along the perimeter by a temporary protective barrier or signal tape at a distance of 3 meters from the installation site.џPrior to entering the site, the relevant warning signs ISO 7010: 2011 are displayed.џMake sure there are no underground utilities on site!џDo not allow unauthorized persons to stay in the work area!џFollow the safety instructions for installation work!6.2 Sequence of installation works:џPreparation of a well (pit);џInstallation of the installation box in the pre-project design position;џInstallation of the installation box in the pit;џLaying communication pipes*;џConcreting pit;џInstallation of the bollard in the assembly box;џConnection of communications*;*To provide additional options - light and sound indication, heated bollard, forced drainage;6.3 Arrangement of the well (pit): The pit scheme may vary depending on the type of soil on the site. The characteristics of soils largely depend on their type, composition, and bearing capacity.6. Installation of the bollard.R.s.l. (±0.000) Symbol: 1. The pit (1280 mm / 1470 mm)*;2. Sand bedding;3. Geotextiles (EN 13256-2009);4. Gravel fraction 10-20 mm (BS EN 13043);5. Drainage pipe PVC 57 (EN 1401-1);6. Protective layer of concrete 50 mm (C25/30 ENV206);7. Pipe (corrugated hose) supply of communications (Do.d. 34 mm);8. Bollard in the mounting box;9. Concrete 980 mm or 1170 * mm (C25/30 ENV206);10. Road surface;*The depth of the pit is determined according to the model of the bollard (see Table 3)

250

456

980 / 117050

889231

1280 / 1470155

7

10

Page

Size А4

Installation and Operation Manual

Revision 3.2 2023

Traffic bollards automatic

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global -13-

Bollard model

Pit dimensions А, mm B, mm C, mm

RB343-21

650 800 1280

RB343-23

RB349-11

RB349-12

700 900

RB343-24

650 800 1470

RB343-26

RB349-14

RB349-15

700 900

6.4 Technology of installation works: 6.4.1 Preparation of the installation well (pit): 1. Make the necessary markup in accordance with the design solutions;2. Remove the roadbed if necessary;3. Excavate the pit * with dimensions A x B mm, depth C = 1 280 mm or 1 470 mm (according to the scheme of the assembly well (pit) of the selected model of the bollard, item 6.3);*In the case of loose soils, the size of the pit shall be determined by the installation organization.џMake sure that the soil absorbs water. Pour approximately 40 liters of water into the pit and check that it is completely absorbed into the ground in less than 30 minutes.џIn case of insufficient water permeability of the ground or abundant groundwater, it is recommended to use pumps forcibly diverting water to the existing sewage system or to the soil.Table 3. Overall dimensions of the pit for automatic parking bollard

mm ,A

С,mm

Direction of movement

Direction of movement

Direction of movement

Direction of movement

Page

Size А4

Installation and Operation Manual

Revision 3.2 2023

Traffic bollards automatic

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global -14-6.4.2 Installing the assembly box in the design position: 1. Remove the product from the packaging;2. Check the external condition and completeness of the bollard;3. Remove the front plate;4. Take the bollard from the assembly box;5. Install assembly box* in the pre-design position;6. Expand the foundation anchors;4. Fill the bottom of the pit with geotextile;5. Fill the pit with gravel (BS EN 13043) to a height of 250 m (fraction 10-20 mm) and tamper it to avoid shrinkage in the future.6. Install the drainage pipe 75 mm (EN 1401-1) to a depth of 50-100 mm;7. Fill the bottom of the pit with a protective layer of concrete 50 mm (C25/30 ENV206);8. Dig a trench of communication laying (100 mm);~

SECTION 1 - 1

11R.s.l. (±0.000)

980/117025050

B

A

C

А

Page

Size А4

Installation and Operation Manual

Revision 3.2 2023

Traffic bollards automatic

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global -15-7. Install the 2 M8 eyebolts;8. Tighten the eyebolts and install the assembly box in the pre-design position.9. Lower the assembly box into the pit with a lifting gear;Assembly box in the pre-design positionFoundation anchors М8 eyebolt 2 pc.View АџInstall the bollard with lifting devices;џObserve Safety Rules according to current standards for handling!џPerform stringing of cargo involving sling operator with appropriate qualifications and admission;џAccess to unauthorized persons on the installation site during loading and unloading is PROHIBITED! Sling hook0,1-0,2 t А

Page

Size А4

Installation and Operation Manual

Revision 3.2 2023

Traffic bollards automatic

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global -16-џSet assembly box on the central vertical axis of the pit;џEnsure vertical position by eliminating deviations;џThe top face of the bollard shall be at the level of the road surface (conditional mark 0.000). 10. Use the level to check the horizontal position;11. Lay communication corrugated pipes to the assembly box;12. Protect the box with additional coating before concreting;13. Fill the pit with the assembly box with the first layer of concrete 50% -60% (Concrete C25/30 according to ENV-206);14. Fill the pit with the assembly box with a second layer of concrete to the level of the roadway (concrete of strength class C25/30 according to ENV-206);Concreting shall be carried out in accordance with applicable standards.It is recommended to use hydro-insulating additives to produce waterproof concrete.Drying of first layer of concrete takes at least 5 hours!Complete drying of the concrete foundation is at least 28 days!Concrete C25/30 Road pavingR.s.l. (±0.000)Service ductAssembly box in the design position:

SECTION 2 - 2

22Concrete C25/30 1 layer50% 2 layer50 % Protective coatingConstruction level ruler

Page

Size А4

Installation and Operation Manual

Revision 3.2 2023

Traffic bollards automatic

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global -17-6.4.3 Installing bollard in assembly box: Bollard in pre-design position џThe installation of the bollard in the assembly box is carried out only in the lowered state!џBe especially careful when positioning the cable between the walls of the mounting casing and the bollard during lowering, and also when it is connected to the junction box located on the side of the bollard.џAfter all installation work, restore the road surface around the bollard, arrange proper state of the mounting area (site).1. Remove the protective cover from the assembly box;2. Install the 2 M8 eyebolts at the top of the bollard;3. Lower the bollard in the assembly box to the level of connecting the communications;4. Lay the electrical cables in the communication pipe;5. At half-empty state of the bollard in the assembly box connect the electrical cables to the bollard's inspection box (see Section 7 for more details);The loose ends of the electrical cables must be sealed tightly to prevent from dirt, moisture and other objects.6. Completely lower the bollard;7. Remove the eyebolts;8. Install the front plate;9. Fix the bollard with fixing screws (6 pcs.);

B (1 : 2)

М8 screw - 6 pcs.;0,1- 0,2 t B0,1- 0,2 t

Page

Size А4

Installation and Operation Manual

Revision 3.2 2023

Traffic bollards automatic

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global -18-Electronic control unitControl point (CP) conditionallyVIEW АParking bollardPipe (corrugated hose) of communications6.5 Installation of automatic parking bollard:Road surfaceWarning signџTraffic sites, regulated by the bollards, shall contain appropriate warning signs applicable in the country!џBollards can be installed with other traffic management systems (traffic lights, etc.) and to prevent unauthorized passage! (conditionally) (conditionally)STOP

Page

Size А4

Installation and Operation Manual

Revision 3.2 2023

Traffic bollards automatic

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global -19-Pipe for forced drainageOption CStorm drainage systemPipe for natural drainageDrain pumpOption АWater drain options (conditionally):6.6. Recommended options for water drainage for a bollard:Pipe for forced drainageStorm drainage systemOption ВџNormal operation of the device requires a guaranteed water disposal ensured by the user.џIf there is no possibility of using natural drainage of water in the ground, it is necessary to ensure the drainage in a separate pit.

Page

Size А4

Installation and Operation Manual

Revision 3.2 2023

Traffic bollards automatic

ROAD BLOCKING SYSTEMS Office and Production site: Tel.: +380 (44) 291-21-11 14 Promyslova str., 02088, Kyiv, Ukraine, Fax: +380 (44) 291-21-02 E-mail: [email protected] www.tiso.global -20-7.1 Bollard connection to the control unit*.1. bollardEach is connected connected to control unit with one control electric cable OLFLEX CLASSIC 12 х0,75 and one cable .PE PV 1x2.5 2. To ensure repair work - leave a cable with length of 50 cm on each side.7.2. Bollard connection to additional devices:Additional automatic options can be provided for automatic parking bollard: a heating unit with a thermostat, sound alarm, radio controller for wireless remote control, controllers of induction loops.7.Bollard communication connection џBefore connecting the bollard, carefully study the hydraulics and power supply circuits of the product;џWhen connecting - follow the instructions carefully! The installation manual is provided for use with "Operational Procedures. Part II. Electrical connection and operation of bollards with integrated mini hydroelectric station";џOnly specialists with the appropriate qualifications are allowed to deal with connecting the bollard communications; * The control unit can be located up to 100 m The design position is determined by individual design solutions.The general scheme of connection of bollards to the control unit AUIA349-CU-230VAC and additional devices is given in Appendix 1 and Appendix 2 of the Operator's Manual. Part II. Electrical connection and operation of bollards with integrated mini hydro station џProtect ends of high-pressure hoses, by wrapping them in foil or film, before pulling through underground conduits, to prevent getting dirt and dust into hoses and hydraulic systemџIt is advised to lay electrical cables in corrugated tube to protect them against mechanical damages and environmental harmful impacts.џPlugs of the high-pressure hoses should be removed only before connection to blocker/HPU, and only after they were cleaned from any external dirt. Same to be done on the sides of blocker and HPU.

This manual suits for next models

7

Table of contents

Other Tiso Automatic Barrier manuals