2

IT

FR

EN

ES

DE

PT

1 Avvertenze generali 3

2 Dichiarazione di conformità 3

3 Destinazione d’uso 3

4 Limiti di impiego 4

5 Descrizione del prodotto 4

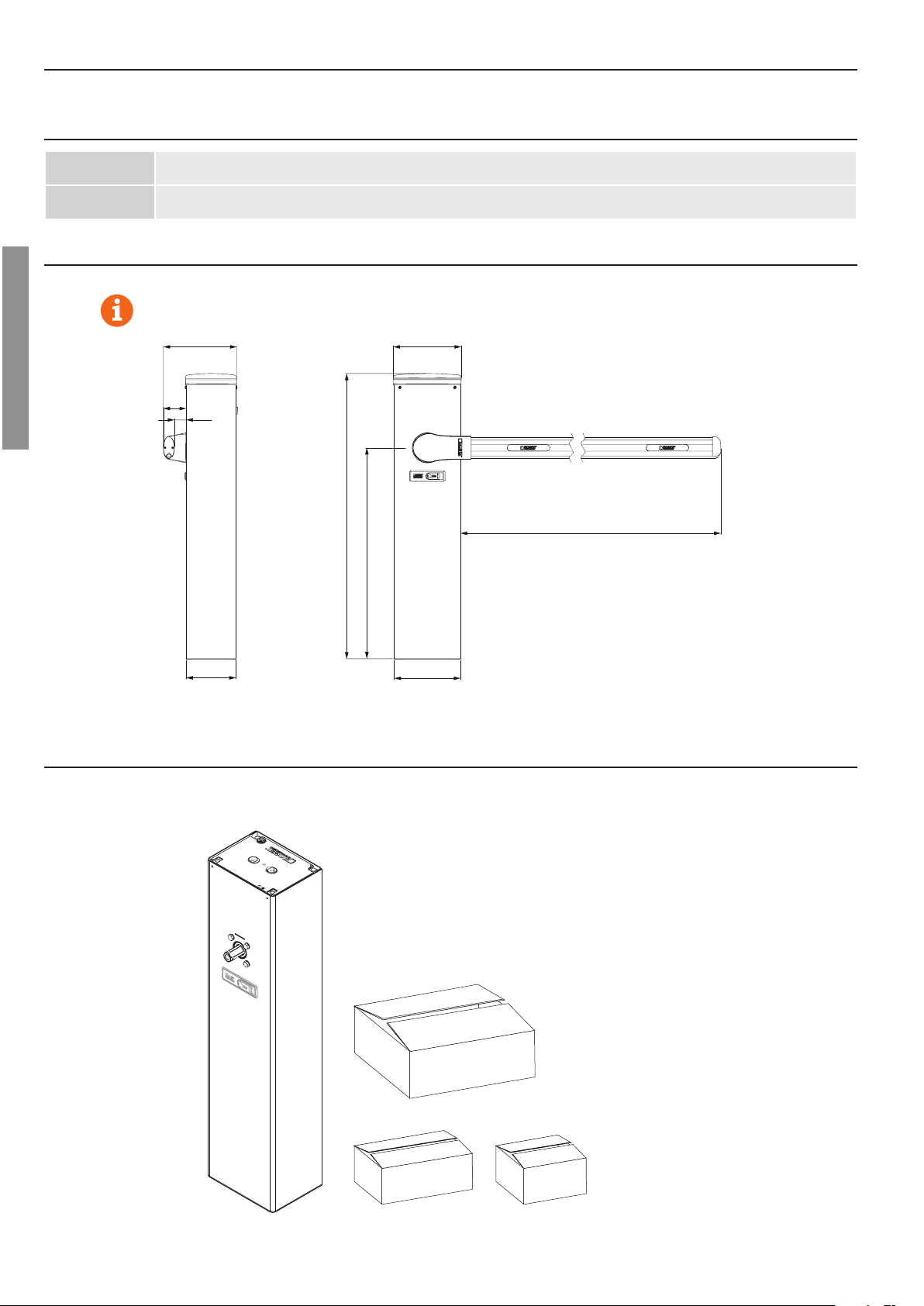

6 Dimensioni 4

7 Contenuto dell’imballo 4

8 Caratteristiche tecniche 5

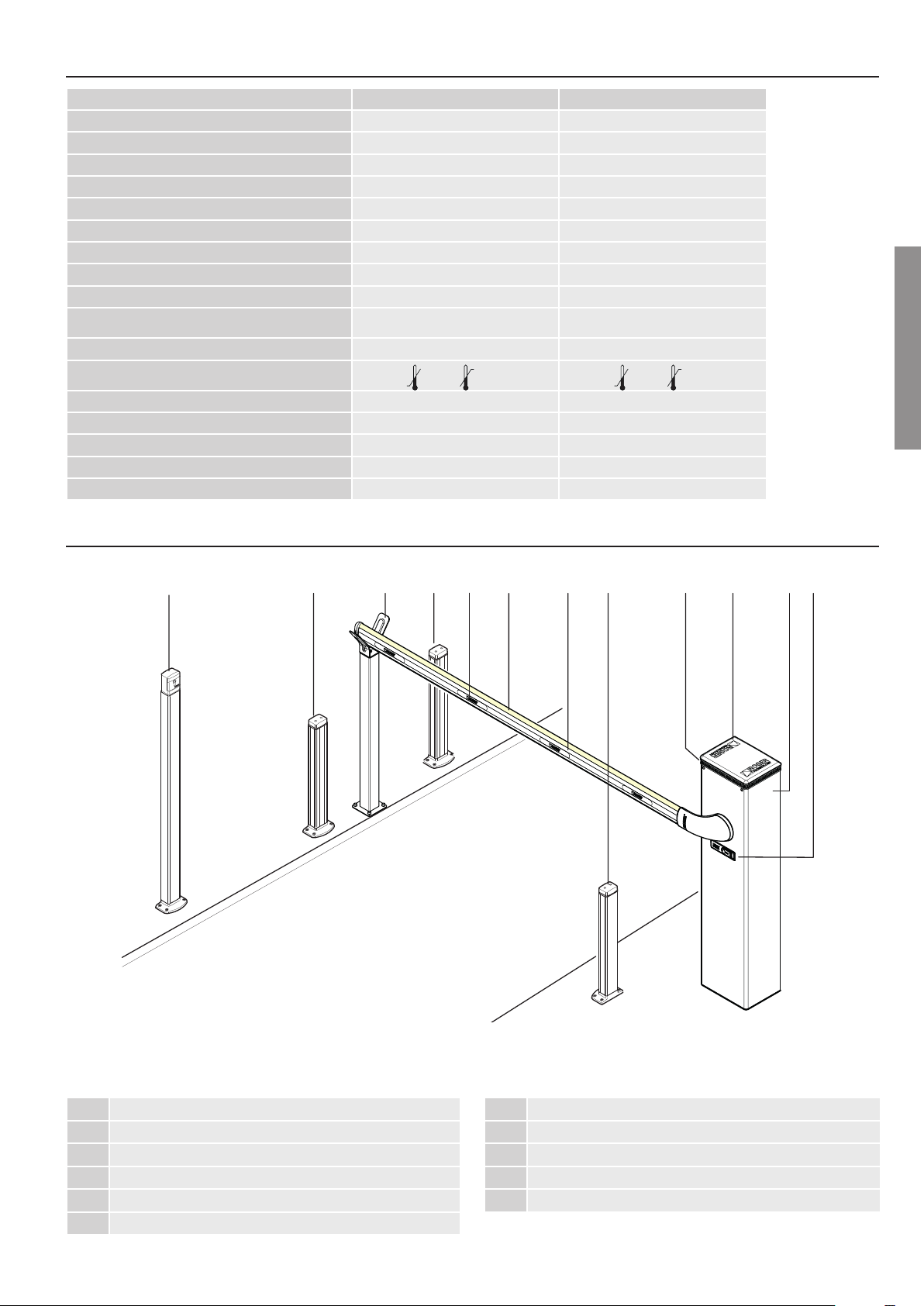

9 Installazione tipo 5

10 Riferimenti e accessori 6

11 Installazione 7

11.1 Verichepreliminari 7

11.2 Installazione piastra di base 7

11.3 Installazione barriera 7

11.4 Selezione senso di apertura 9

11.5 Installazione supporto e asta 10

12 Installazione e regolazione della molla 11

12.1 Scelta della molla 12

13 Regolazione fermo meccanico 13

14 Collegamento fotocellule 13

15 Collegamenti elettrici 14

16 Installazione kit batterie (opzionali) 14

17 Installazione lampeggiante a led bi/bled 15

18 Piano di manutenzione 16

19 Smaltimento 16

20 Informazioni aggiuntive e contatti 16

21 Operazione di sblocco / blocco 16

1 General safety precautions 17

2 Declaration of conformity 17

3 Intended use 17

4 Limitations use 18

5 Description of the product 18

6 Dimensions 18

7 Package content 18

8 Technical characteristics 19

9 Typical installation 19

10 References and accessories 20

11 Installation 21

11.1 Preliminary checks 21

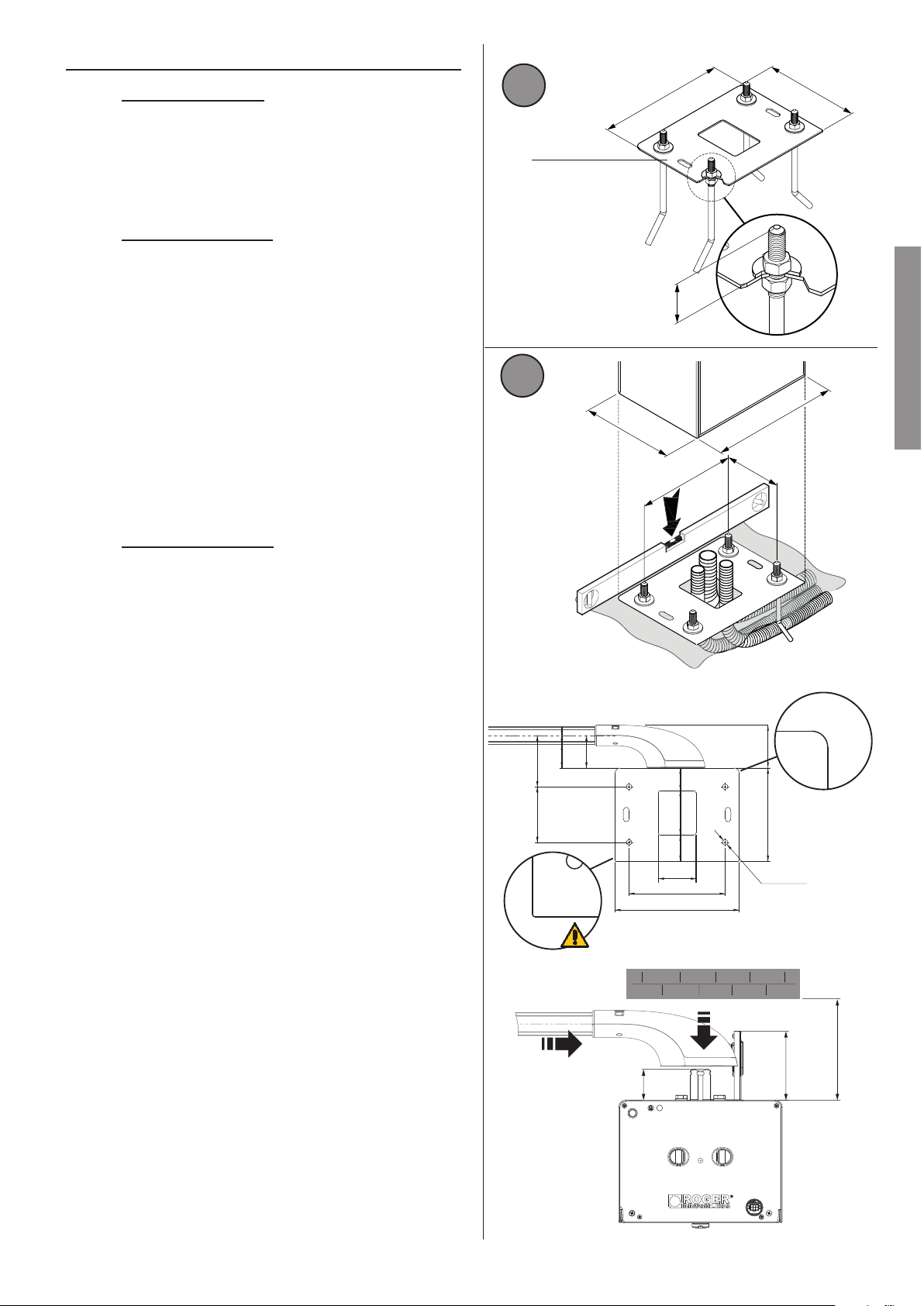

11.2 Installing base plate 21

11.3 Installing the barrier 21

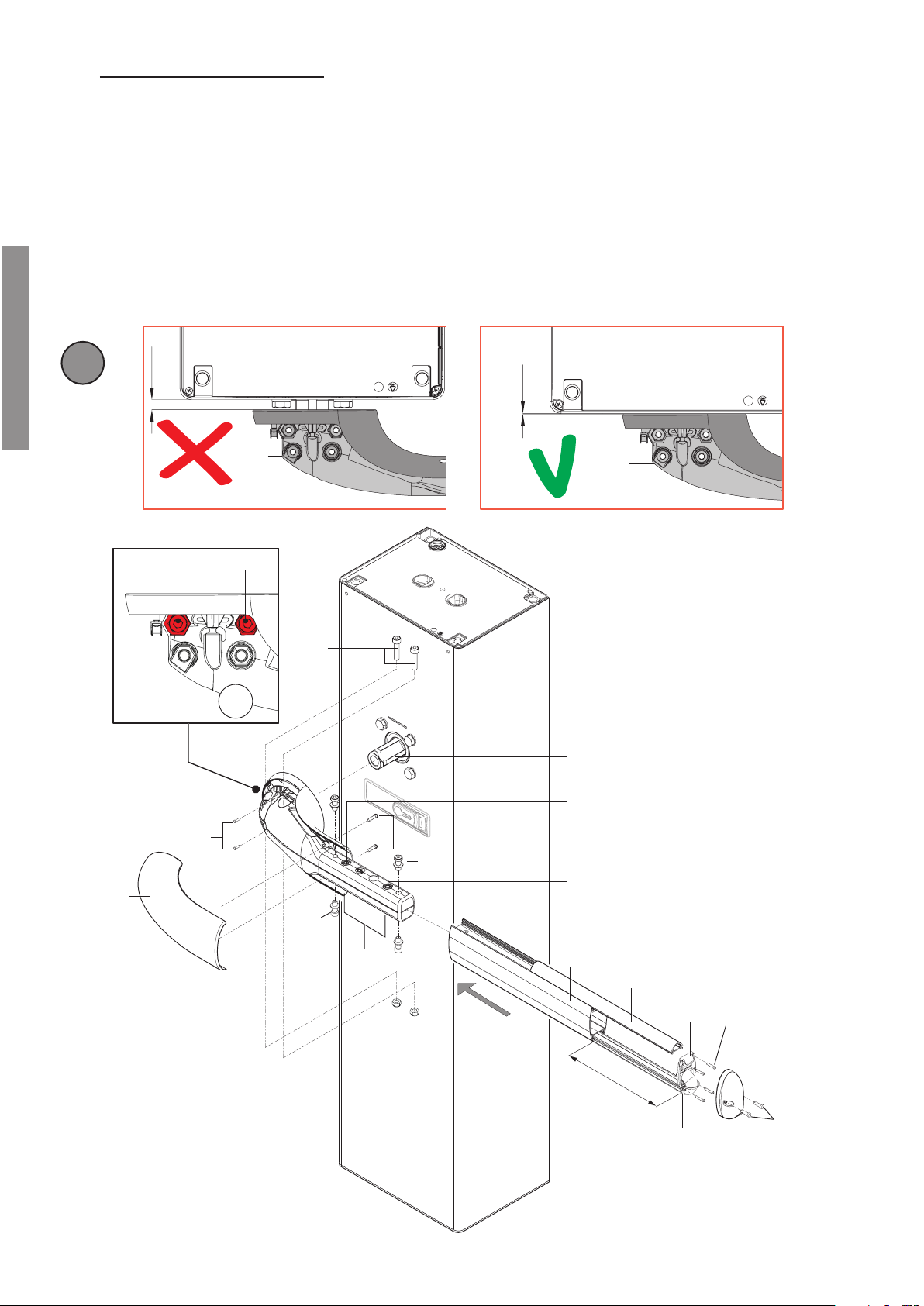

11.4 Selecting direction of aperture 23

11.5 Support and boom installation 24

12 Installing and adjusting the spring 25

12.1 Spring selection 26

13 Adjusting the mechanical stop 27

14 Connecting photocells 27

15 Electrical connections 28

16 Installing the battery kit (optional) 28

17 Installingthebi/bledledashinglight 29

18 Maintenance 30

19 Disposal 30

20 Additional information and contact 30

21 Release and lock procedure 30

1 Allgemeine sicherheitshinweise 31

2 Konformitätserklärung 31

3 Nutzungsbedingungen 31

4 Gebrauchsbegrenzung 32

5 Beschreibung des produkts 32

6 Abmessungen 32

7 Inhalt der verpackung 32

8 Technische daten 33

9 Typische installation 33

10 Hinweise und Zubehör 34

11 Installation 35

11.1 Vorab-prüfungen 35

11.2 Installation der grundplatte 35

11.3 Installation der schranke 35

11.4 Wahl der öffnungsrichtung 37

11.5 Installation von halterung und schlagbaum 38

12 Installation und einstellung der feder 39

12.1 Wahl der federn 40

13 Einstellung mechanischer feststeller 41

14 Anschluss der lichtschranken 41

15 Elektrische anschlüsse 42

16 Installation akkusatz (optional) 42

17 Installation led-blinkleuchte bi/bled 43

18 Wartungsplan 44

19 Entsorgung 44

20 Zusätzliche informationen und kontakte 44

21 Entriegelung und verriegelung 44

1 Consignes générales de sécurité 45

2 Déclaration de conformité 45

3 Destination d’utilisation 45

4 Limites d’emploi 46

5 Description du produit 46

6 Dimensions 46

7 Contenu de l’emballage 46

8 Caractéristiques techniques 47

9 Installation type 47

10 References et accessoires 48

11 Installation 49

11.1 Véricationspréliminaires 49

11.2 Installation de la plaque de base 49

11.3 Installation de la barrière 49

11.4 Sélection du sens d’ouverture 51

11.5 Installation support et barre 52

12 Installation et réglage du ressort 53

12.1 Choix des ressorts 54

13 Réglage de la butée mécanique 55

14 Raccordement des photocellules 55

15 Raccordements électriques 56

16 Installation du kit batteries (en option) 56

17 Installationduashclignotantàledbi/bled 57

18 Plan de maintenance 58

19 Élimination 58

20 Informations complémentaires et contacts 58

21 Opérations de déblocage et blocage 58

1 Advertencias generales 59

2 Declaración de conformidad 59

3 Uso previsto 59

4 Límites de uso 60

5 Descripción del producto 60

6 Dimensiones 60

7 Contenido del embalaje 60

8 Características técnicas 61

9 Instalación básica 61

10 Referencias y accesorios 62

11 Instalación 63

11.1 Controles preliminares 63

11.2 Instalación de la placa de base 63

11.3 Instalación de la barrera 63

11.4 Selección del sentido de apertura 65

11.5 Instalación del soporte y del asta 66

12 Instalación y ajuste del muelle 67

12.1 Cómo elegir los muelles 68

13 Ajuste del tope mecánico 69

14 Conexión de las fotocélulas 69

15 Conexiones eléctricas 70

16 Instalación del kit de baterías (opcional) 70

17 Instalación del intermitente de led bi/bled 71

18 Plan de mantenimiento 72

19 Eliminación 72

20 Información adicional y contactos 72

21 Operaciones de desbloqueo y bloqueo 72

1 Advertências gerais 73

2 Declaração de conformidade 73

3 Destino de uso 73

4 Limites de emprego 74

5 Descrição do produto 74

6 Dimensões 74

7 Conteúdo da embalagem 74

8 Características técnicas 75

9 Instalação do tipo 75

10 Referência e acessórios 76

11 Instalação 77

11.1 Vericaçõespreliminares 77

11.2 Instalação da chapa de base 77

11.3 Instalação da barreira 77

11.4 Seleção do sentido de abertura 79

11.5 Instalação de suporte e haste 80

12 Instalação e ajuste da mola 81

12.1 Escolha das molas 82

13 Ajuste do retentor mecânico 83

14 Ligação das fotocélulas 83

15 Ligações elétricas 84

16 Instalação de kits de baterias (opcionais) 84

17 Instalação do pisca de led bi/bled 85

18 Plano de manutenção 86

19 Descarte 86

20 Informações adicionais e contatos 86

21 Operações de libertação e bloqueio 86