FOR TRAINED AND CERTIFIED OPEMED PARTNERS ONLY

Page 2 of 35 OT200 Compact Technical Manual.docx 12/05/15

1!ABOUT THIS MANUAL!.........................................................................................................!4!

"#"!$%&'()$!######################################################################################################################################!*!

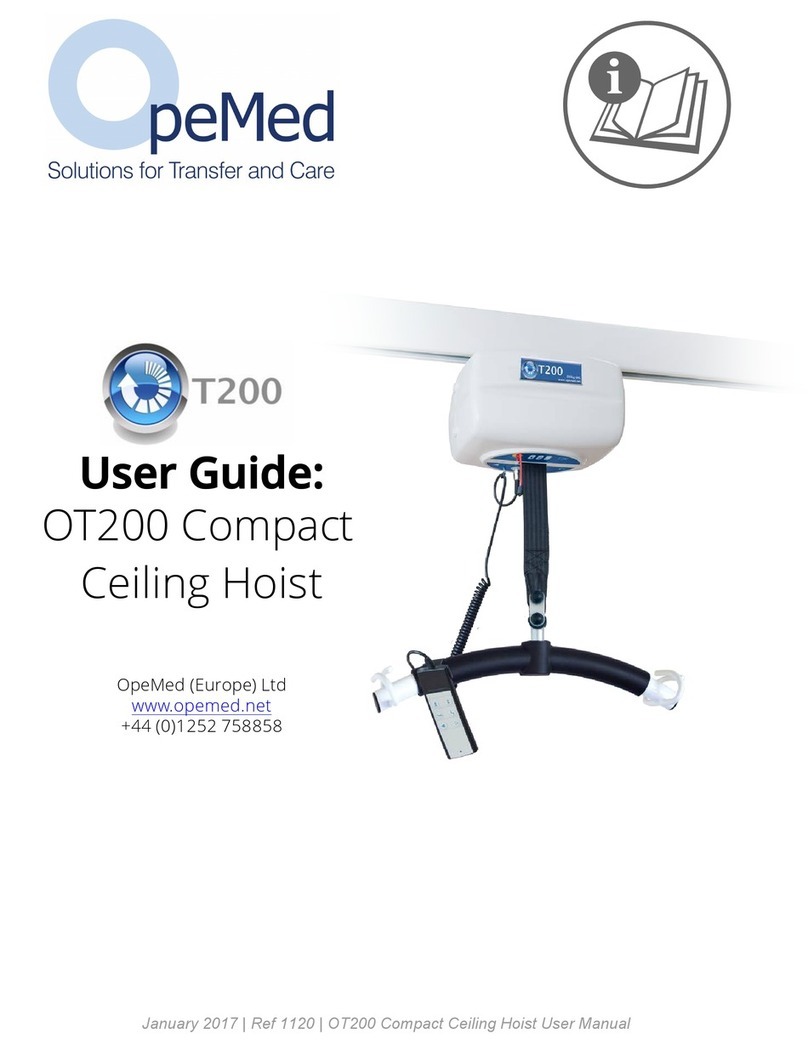

2!THE OT200 CEILING HOIST!.................................................................................................!5!

+#"!,(-./$!(0!1//2./-(.!####################################################################################################################!3!

1.1.!Technical Data!""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""!#!

+#+!$4&&15%!(0!,15/$!#######################################################################################################################!6!

+#7!)28!-.8-91/(5!)-:;/$!###################################################################################################################!<!

$"%"&!'())*!+*,+-./0(!12*304456!3!""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""!7!

$"%"$!2(.*8)!9.//)(:!+*,+-./0(!;!""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""!7!

$"%"%!<),!4.+=>()!+*,+-./0(!""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""!7!

+#*!2&25:2.9%!$/(,!1.8!)(=25!#########################################################################################################!<!

+#>!9;15:-.:!(/+??!#########################################################################################################################!<!

+#3!;1.8$2/!######################################################################################################################################!<!

3!USING THE RAIL SYSTEM!.................................................................................................!10!

7#"!@%!(5!;!$%$/2&!0(5!5((&!9(A251:2!##########################################################################################!"?!

7#+!/45./1')2!#################################################################################################################################!"?!

7#7!:1/2!B=-/;!@C%!$%$/2&$!0(5!5((&C5((&!9(./-.4(4$!/519DE!######################################################!"?!

7#*!2@9;1.:25!(5!F4.9/-(.!#############################################################################################################!"?!

4!HANGER BAR OPTIONS!....................................................................................................!11!

*#"!;1.:25!'15!###############################################################################################################################!""!

4.1.1!Standard – 2 Point Spreader Bar!"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""!&&!

4.1.2!Optional – Manual Cradle (Clip Slings only)!""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""!&&!

4.1.3!Optional - Powered Cradle (Clip Slings only)!"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""!&&!

4.1.4!OT400 Hanger Bar!"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""!&&!

5!SLINGS!.................................................................................................................................!12!

>#"!$)-.:!1//19;&2./!#####################################################################################################################!"+!

5.1.1!Loop Slings!"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""!&$!

5.1.2!Clip Slings (depends on clip sling used – please refer to sling instructions)!"""""""""!&$!

6!USING THE OT200 CEILING HOIST!..................................................................................!12!

6.1.1!Before Use Checks!""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""!&$!

6.1.2!Lifting From a Chair!"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""!&%!

6.1.3!Lifting From a Bed!""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""!&%!

6.1.4!Moving the Patient!"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""!&%!

6.1.5!Step 1a Lifting Towards a Bed!"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""!&?!

6.1.6!Lifting Towards a (Wheel) Chair!""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""!&?!

6.1.7!Lifting Towards a Toilet!"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""!&?!

7!MAINTAINING THE OT200 CEILING HOIST!.....................................................................!15!

G#"!-.$/1))1/-(.!$-:.!(00!H!925/--91/2!(00!-.$/1))1/-(.!####################################################################!">!

G#+!9)21.-.:!-.$/549/-(.$!###############################################################################################################!"3!

G#7!81-)%H=22D)%!&1-./2.1.92!#######################################################################################################!"3!

G#*!3!&(./;)%!9;29D$!#####################################################################################################################!"3!

G#>!1..41)!-.$,29/-(.!1.8!&1-./2.1.92!########################################################################################!"G!

#"@"&!A).B>(+*8!C)4=)-/+0*!"""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""""!&#!

G#3!,52A2./1/-A2!&1-./2.1.92!########################################################################################################!"6!

G#G!-0!/;2!(/+??!8(2$!.(/!04.9/-(.!###############################################################################################!"6!

G#6!8-$,($1)!####################################################################################################################################!"6!

8!TROUBLESHOOTING!.........................................................................................................!19!

9!SERVICE!PROCEDURES!.............................................................................................................!20!

<#"!52&(A-.:!/;2!9(A25!##################################################################################################################!+?!