Eurocode (Analogue) 26/04/05 Page 3

IMPORTANT SAFETY INSTRUCTIONS

1. Read these instructions carefully. Follow all warnings and instructions marked on the product.

2. Always disconnect the printhead and controller from the mains electricity and air supply before attempting to clean or

service it.

3. Never operate the printhead unless it is installed within the mounting frame supplied. When installed correctly the gap

between the printer and print base should not be greater than 4mm (see page 30).

4. Do not use the product near water. Never spill liquid of any kind on to the product.

5. Do not place this product on an unstable stand, table or machine. It may fall causing serious damage to the product or

injury to the operator.

6. Never insert objects of any kind into this product through any openings or gaps as they may touch dangerous voltage

points or short circuit parts that could result in fire or electric shock.

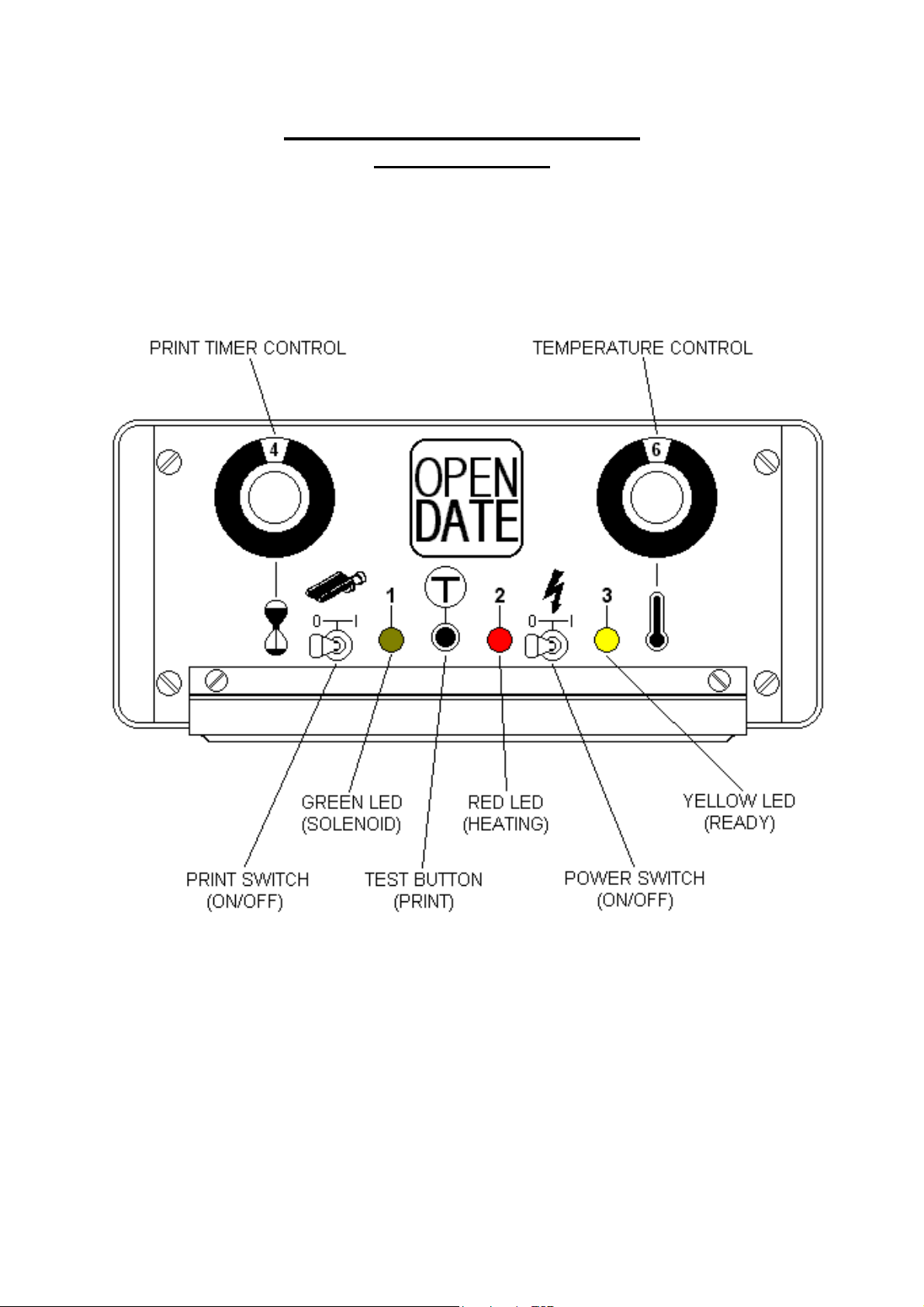

7. This product should only be operated from the type of electrical supply as indicated on the rear of the printhead control unit

(see page 7).

8. Ensure that the printhead connection cable is fully secured to the printhead with the screws attached to the "D" connector

cover. Failure to do this will result in the machine not being properly earthed.

9. Use only the power cable supplied with the product. The cable supplied is three core, utilising one wire as a grounding

conductor. This must be connected to a suitable earthing point at the electrical supply This is a safety feature. If any doubt

arises in trying to connect the power cable, please contact the manufacturer or agent who supplied the product.

10. Do not allow anything to rest on the power cable. Do not locate the product where persons will walk on the cable.

11. If an extension cable is used with this product, make sure that the total ampere ratings of the equipment plugged into the

extension cable does not exceed the extension cable ampere rating. Also make sure that the total rating does not exceed

the fuse rating.

12. Do not service this product yourself as opening or removing guards may expose you to dangerous voltage points, major

burns and other risks. Refer all servicing to qualified personnel.

13. Do not attempt to use to use this product in areas where explosive gases or substances are present.

14. Once the product is under normal working conditions, care must be taken when removing the type holder as you can

easily burn yourself. There is a yellow warning sign on the type holder access door indicating a danger. Open the door by

gripping it at the side. The type holder should be held by its plastic handle only. Never touch metal parts as temperatures

could be as high as 220 degrees C.

15. Disconnect the product from the electrical and air supplies and refer servicing to qualified personnel under the following

conditions.

a. If the power cable is damaged or frayed.

b. If the air pipes are damaged in any way.

c. If liquid has been spilled into or if the product has been exposed to rain or water.

d. If the product does not operate normally when the operating instructions are followed. Adjust only those controls

that are covered by the instructions. Improper adjustment may result an damage needing qualified technicians

to restore the product to normal operating conditions.