1

Contents

1. Symbols and Indications ........................................................2

2. Safety Precautions...................................................................2

3. Warnings.....................................................................................3

4. System Package.......................................................................4

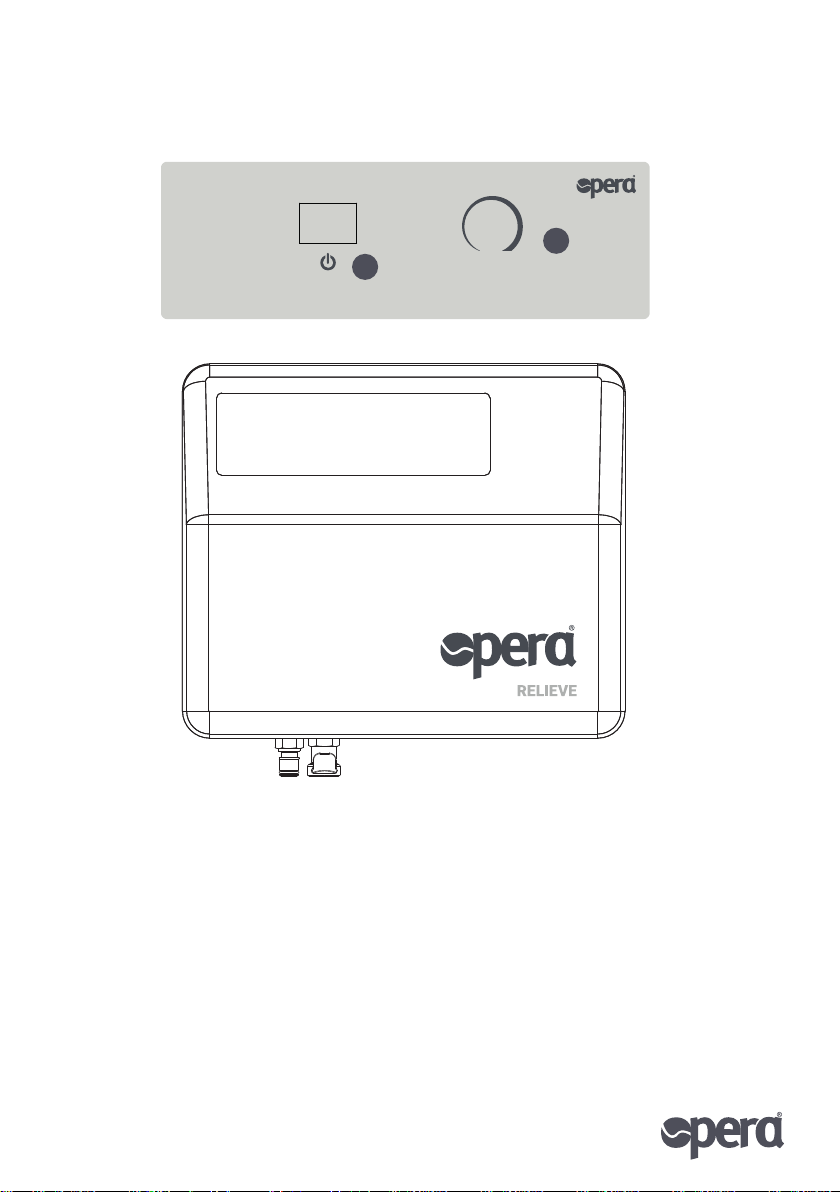

5. Features ......................................................................................5

6. Mattress and Power Unit Installations.................................7

7. Program Settings......................................................................8

8. Patient Transfer and Transport..............................................8

9. ......................................................9

10. Cleaning Instructions...............................................................9

11. Rountine Maintenance and Storage.....................................9

12. Troubleshooting .....................................................................10

13. Returns for Service................................................................11

14. Warranty...................................................................................11

15. .........................................................12

Thank you for purchasing this anti- decubitus mattress replacement system.

PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE SETTING

UP AND USING THE DEVICE. Pay special attention to the warnings and

other safety information. Use of genuine components is essential for

optimal performance. If you do not fully understand all the instructions,

safety precautions, and warnings, do not use this device. In case you have

questions, please contact Opera Care on 0333 222 8584 .

16. EMC Declaration......................................................................13