Ceiling smoke alarm DRM 3.3 – bus-enabled for STG 1.2

Fire Protection | Data sheet No. 40102 | Version 01-2011 | 1| 4

Technical Data

Power supply: 24 V DC nominal voltage

17 – 41 V DC from STG 1.2

via system ringbus

Power consumption:

Standby current: 460 µA (60 µA RMS+ 400 µA RM)

Alarm current: < 10 mA

Short-circuit current : < 10 mA

Rated continuous current: 1 A (RMS), 30 mA (RM)

LED displays:

Alarm: 2 red LEDs light up on RM 3.3

Short-circuit: yellow LED lights up on the side

of the RMS 3.3

Alarm + fault signals: via bus on STG 1.2

Rated

operating temperature: -10 °C – +50 °C

Rated

storage temperature: -30 °C – +60 °C

Rated humidity: 10 – 95% RH (at 40 °C)

Housing: ABS plastic

Dimensions: Ø 100 x 52 mm

Weight: approx. 0.1 kg

Installation: wall/ceiling installation

Protection type: IP 42

Colors: white RAL 9010 (WHT)

Connections: screw terminals max. 2.5 mm²

Certication: EN 54-7

VdS-certication: G208038

Labeling RM 3.3: ALK-E 0832-CPD-0611 & CE

Labeling RMS 3.3: YBO-R/SCI 0832-CPD-0963 & CE

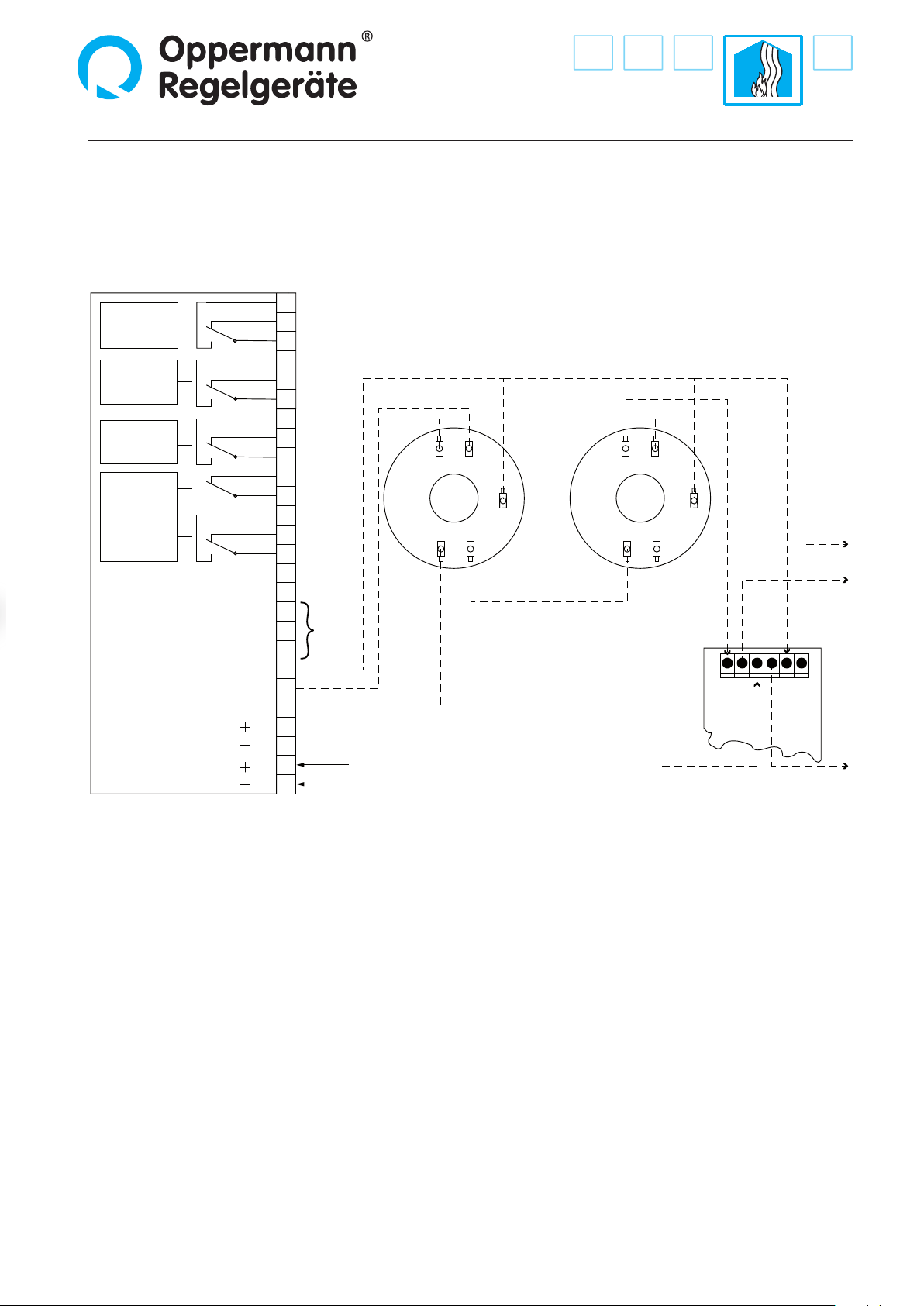

• Operated with Oppermann control unit STG 1.2

• Up to 99 DRM 3.3 can be connected per STG 1.2

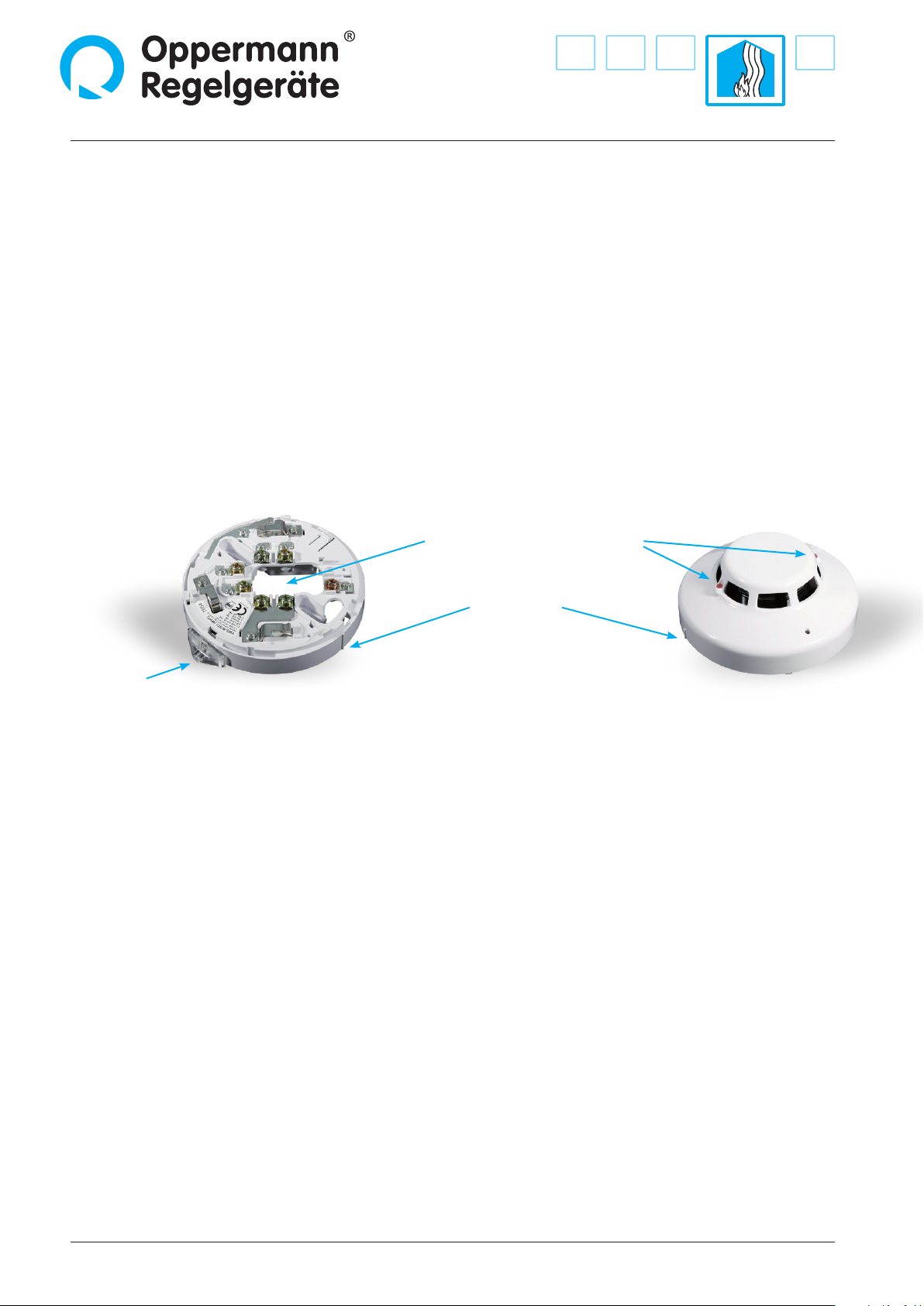

• The DRM 3.3 consists of smoke alarm RM 3.3

and smoke alarm socket RMS 3.3

• Power supply and communication via safety

ringbus – monitored for short-circuit and

broken cable

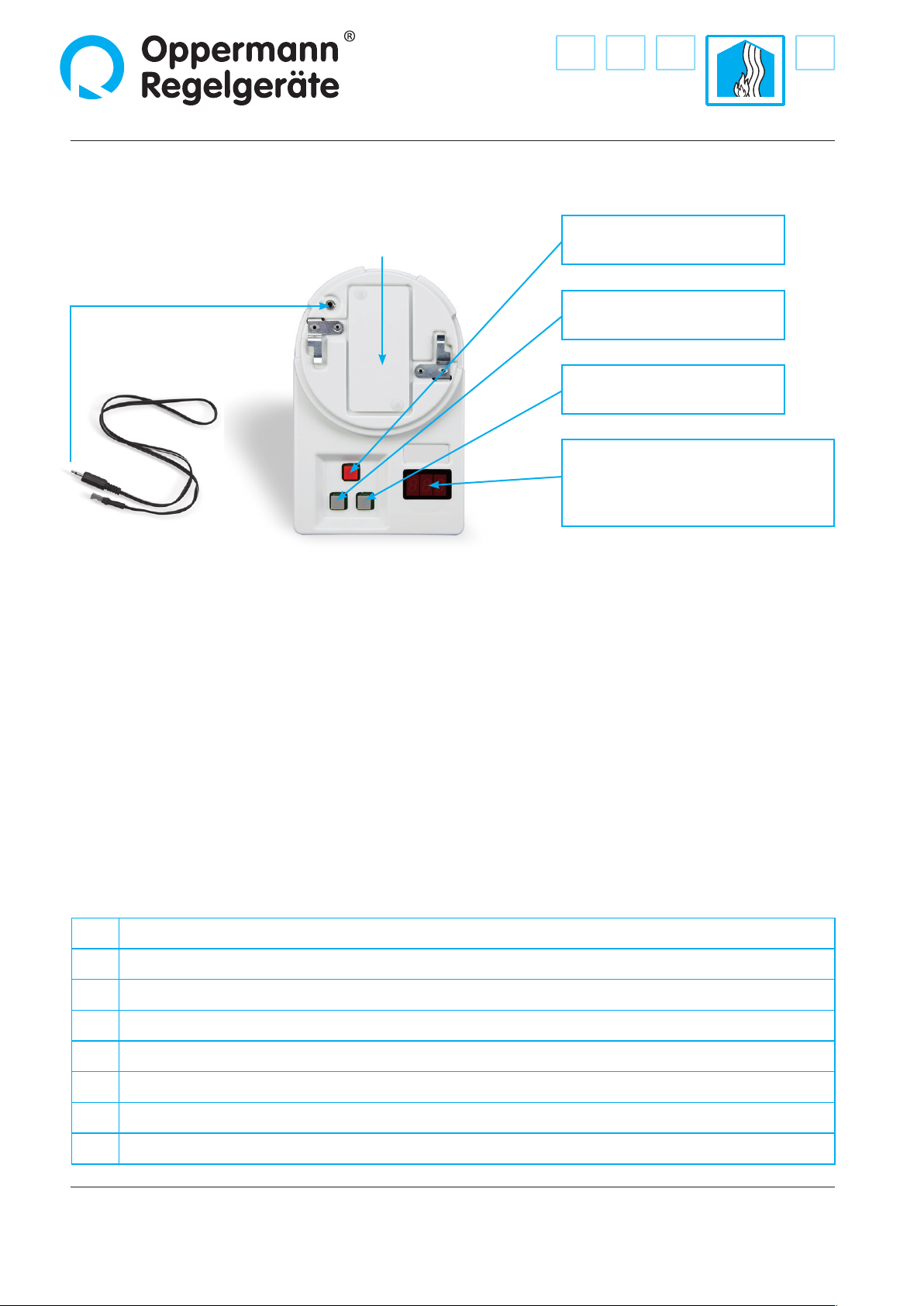

• LED display on alarm (red – RM 3.3) and

short-circuit (yellow – RMS 3.3)

• Easy and convenient installation

Product description/functionality

The DRM communicates with the STG control unit via the safety-

monitored system ringbus. The alarms forward fault and alarm

messages to the STG and indicated on a display. A technician or

building manager can therefore see all connected alarms at a

glance. The system ringbus monitors for short-circuits and broken

cables. An alarm or fault message is indicated on the STG in each

case. Messages must be manually reset on the STG after the fault

has been lifted (not self-canceling).

The optical alarm (scattered light eect) provides early warning

for incipient res with smoke, in particular smoldering res. The

sensor cavity houses a dual infrared light source with 360° detec-

tion. Normally, the pulsating light ray from the transmitter does

not reach the receiver. If smoke particles enter the sensor cavity,

a portion of the light is reected to the receiver resulting in an

alarm trigger. Two red LEDs on the RM 3.3 smoke alarm and one

red LED on the STG 1.2 indicate an alarm.

The alarm status on the RM 3.3 smoke alarm expires automati-

cally after the alarm cavity is free (LEDs on RM go dark). The alarm

remains intact on the STG until it is manually reset at the control

unit. The STG can only be reset when the alarm LEDs in the smoke

alarm have gone dark.

Starting at a contamination level of 70 %, the STG 1.2 indicates

a message to prompt targeted maintenance. An alarm is issued

starting at 99% contamination.

Important note: Please also note separate specication sheets

for STG 1.2.