Version 1.3.2 vom 2023-3-21Page 2 Originalbetriebsanleitung

335 2042EN

1 Table of contents

1.1 Intended use .............................................................................................................................................3

1.2 Safety instructions ....................................................................................................................................3

1.3 Scope of delivery ......................................................................................................................................3

1.4 Technical specification..............................................................................................................................4

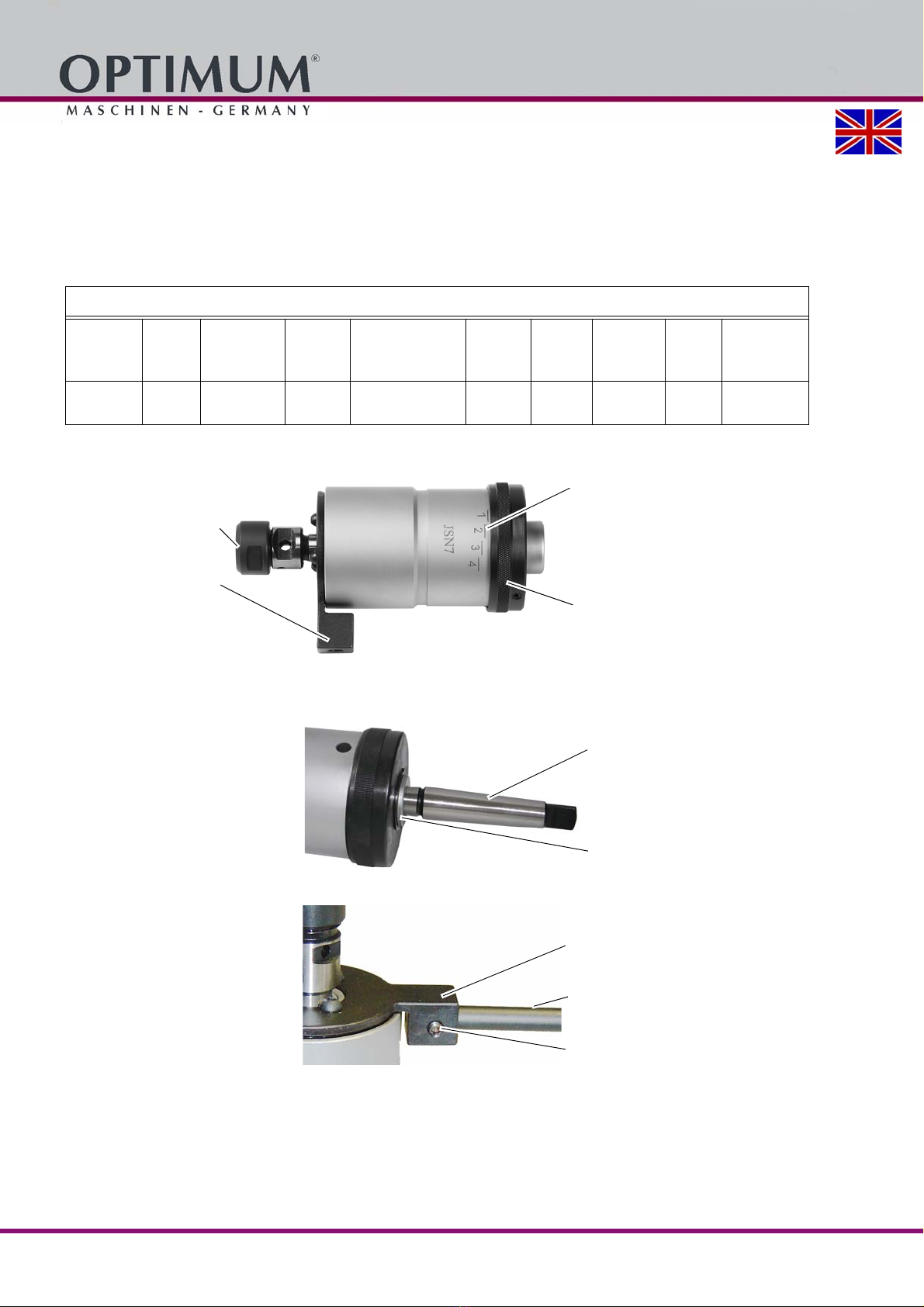

1.5 Structure ...................................................................................................................................................4

1.6 Assembly ..................................................................................................................................................4

1.7 Operation ..................................................................................................................................................5

1.8 Insert tap...................................................................................................................................................5

1.9 Torque adjustment....................................................................................................................................6

1.10 Maintenance and servicing .......................................................................................................................7

1.11 Change information operating manual......................................................................................................7

Preface

Dear customer,

Thank you very much for purchasing a product made by OPTIMUM.

OPTIMUM metal working machines offer a maximum of quality, technically optimum solutions and convince

by an outstanding price performance ratio. Continuous enhancements and product innovations guarantee

state-of-the-art products and safety at any time. Before commissioning the machine please thoroughly read

these operating instructions and get familiar with the machine. Please also make sure that all persons

operating the machine have read and understood the operating instructions beforehand. Keep these

operating instructions in a safe place nearby the machine.

Information

The operating instructions include indications for safety-relevant and proper installation, operation and

maintenance of the machine. The continuous observance of all notes included in this manual guarantee the

safety of persons and of the machine.

The manual determines the intended use of the machine and includes all necessary information for its

economic operation as well as its long service life. In the paragraph "Maintenance" all maintenance works

and functional tests are described which the operator must perform in regular intervals. The illustration and

information included in the present manual can possibly deviate from the current state of construction of your

machine. Being the manufacturer we are continuously seeking for improvements and renewal of the

products. Therefore, changes might be performed without prior notice. The illustrations of the machine may

be different from the illustrations in these instructions with regard to a few details. However, this does not

have any influence on the operability of the machine.

Therefore, no claims may be derived from the indications and descriptions. Changes and errors are reserved!

Your suggestion with regard to these operating instructions are an important contribution to optimising our

work which we offer to our customers. For any questions or suggestions for improvement, please do not

hesitate to contact our service department.

If you have any further questions after reading these operating instructions and you are not able to

solve your problem with a help of these operating instructions, please contact your specialised

dealer or directly the company OPTIMUM.

Optimum Maschinen Germany GmbH

Dr.- Robert - Pfleger - Str. 26

D-96103 Hallstadt, Germany

Fax (+49)0951 / 96555 - 888

Internet: www.optimum-machines.com