2 | PaintChecker Mobile

Table of Contents

1. Overview, Measuring Method and Models....................................................................................................................................4

1.1 How to use this manual ..............................................................................................................................................................4

1.2 Challenges for today's coating companies..........................................................................................................................4

1.3 The PaintChecker Mobile - Quick Reference ......................................................................................................................4

1.4 Copyright ©2023 OptiSense.....................................................................................................................................................4

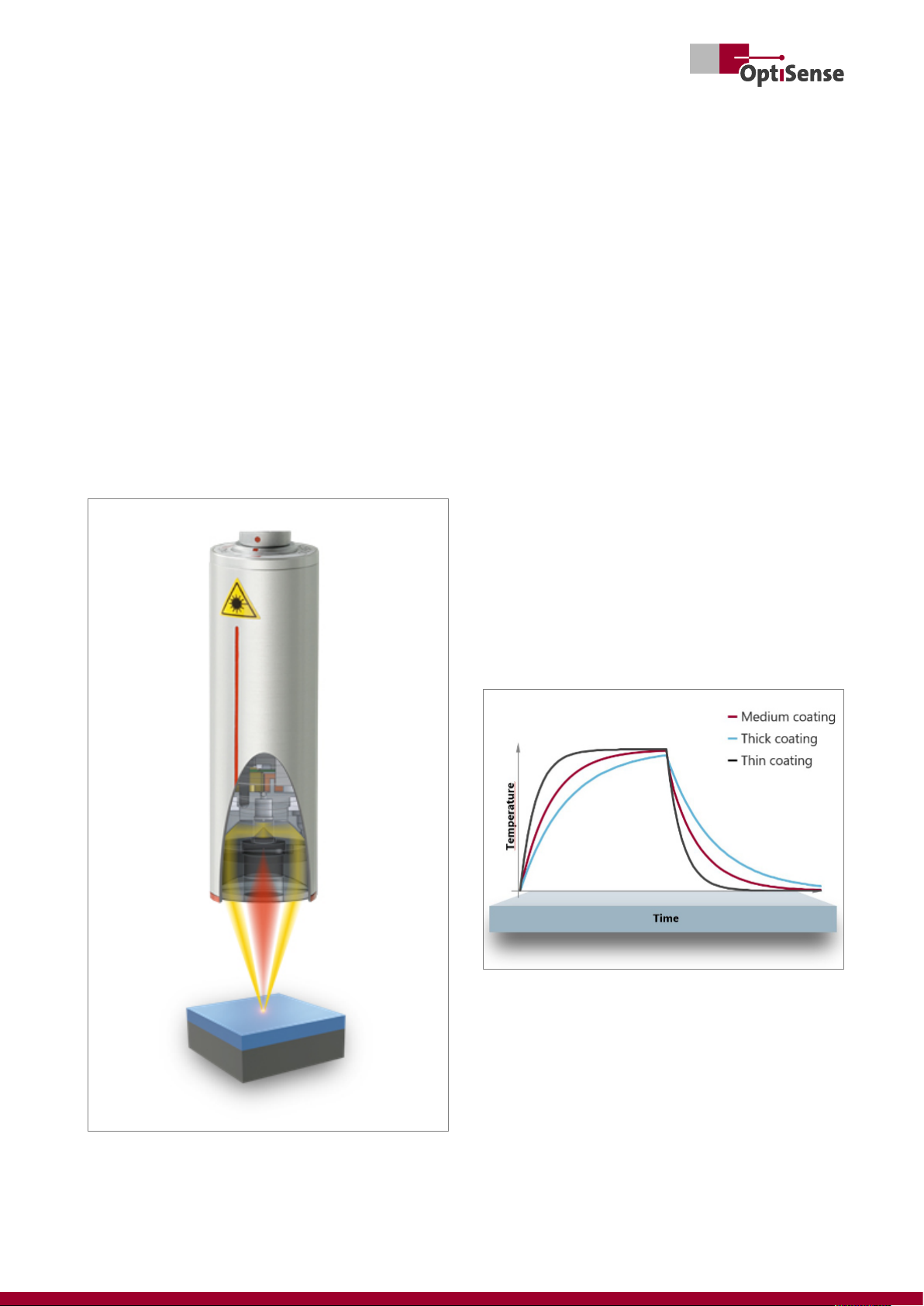

1.5 The photothermal coating thickness measurement ........................................................................................................5

1.6 The model range............................................................................................................................................................................6

1.7 PaintChecker Mobile Delivery Contents ...............................................................................................................................7

1.8 Accessories.......................................................................................................................................................................................7

2. Safety and Responsibility ......................................................................................................................................................................8

2.1 Warning symbols and other guidelines ................................................................................................................................8

2.2 Correct use .......................................................................................................................................................................................8

2.3 Safety markings..............................................................................................................................................................................8

2.4 Intended use....................................................................................................................................................................................9

2.5 Unintended use ..............................................................................................................................................................................9

2.6 Danger from optical radiation..................................................................................................................................................9

2.7 Dangers due to invisible light radiation from the sensor ........................................................................................... 10

2.8 Risks caused by electricity.......................................................................................................................................................11

2.9 Fire hazards................................................................................................................................................................................... 11

2.10 Hazards when handling Li-ion batteries ......................................................................................................................... 11

2.11 Residual hazards....................................................................................................................................................................... 11

2.12 Responsibility of the operator............................................................................................................................................. 11

2.13 Requirements for personnel ................................................................................................................................................ 12

3. Setup and first steps ............................................................................................................................................................................ 13

3.1 Charging the batteries.............................................................................................................................................................. 13

3.2 Insert batteries............................................................................................................................................................................. 13

3.3 Connecting sensor and controller........................................................................................................................................ 14

3.4 Switching the device on and off ........................................................................................................................................... 14

4. Operation ................................................................................................................................................................................................. 15

4.1 Display............................................................................................................................................................................................. 15

4.2 Keys.................................................................................................................................................................................................. 15

4.3 Menu navigation......................................................................................................................................................................... 16

4.4 Instrument Settings ................................................................................................................................................................... 16

4.5 PC connection and OS Manager .......................................................................................................................................... 18

5. Measuring with the PaintChecker Mobile ................................................................................................................................... 19

5.1 Performing a measurement .................................................................................................................................................... 19

5.2 Measurement with spacer cap and tripod........................................................................................................................19

5.3 Measuring with OS Manager .................................................................................................................................................20

5.4 Measurement batches .............................................................................................................................................................. 20

5.5 Create a new batch .................................................................................................................................................................... 20

5.6 Recording a batch ...................................................................................................................................................................... 21

5.7 Evaluating a batch ...................................................................................................................................................................... 21

5.8 Appending to a batch............................................................................................................................................................... 21

5.9 Deleting a batch.......................................................................................................................................................................... 22

5.10 Setting limits .............................................................................................................................................................................. 22

5.11 Changing the application...................................................................................................................................................... 22

5.12 LARES® – Safety redefined.................................................................................................................................................. 23

6. Applications............................................................................................................................................................................................. 24

6.1 Creating a new application ..................................................................................................................................................... 24

6.2 Applications for measuring uncured coatings ................................................................................................................26