OPW 1-3100 Series Spill Container Page 29

OPW Installation and Maintenance Instructions

OPW DW-VAC-TEST Double Wall Spill Container Vacuum Test Instructions

IMPORTANT: Please read these warnings and use the

assembly instructions completely and carefully before

starting. Failure to do so may cause product failure, or

result in environmental contamination due to liquid

leakage into the soil, creating hazardous spill conditions.

IMPORTANT: The OPW DW-VAC-TEST Double Wall

Vacuum Tester is pre-assembled for your convenience

and ease of use. Check to make sure the unit is intact and

undamaged and all parts have been supplied. Never

substitute parts for those supplied. Doing so may cause

product failure.

WARNING-DANGER: Using electrically operated

equipment near gasoline or gasoline vapors may result in

a fire or explosion, causing personal injury and property

damage. Be sure that the working area is free from such

hazards, and always use proper precautions.

NOTE: At all times when product is in the storage tank

keep the riser pipe capped, so the vapors cannot escape

into the environment.

Notice: OPW products must be used in compliance with

applicable federal, state, and local laws and regulations.

Product selection should be based on physical

specifications and limitations and compatibility with the

environment and material to be handled. All illustrations

and specifications in this literature are based on the latest

production information available at the time of publication.

Prices, materials, and specification are subject to change

at any time, and models may be discontinued at any time,

in either case, without notice or obligation.

Standard Product Warranty

OPW warrants that products sold by it are free from

defects in materials and workmanship for a period of one

year from the date of manufacture by OPW (ECO products

two years from date of manufacture.) Proof of purchase

may be required. As the exclusive remedy under this

limited warranty, OPW, will at its sole discretion, repair,

replace, or issue credit for future orders for any product

that may prove defective within the one year date of

manufacture period (repairs, replacements, or credits may

be subject to prorated warranty for remainder of the

original warranty period, complete proper warranty claim

documentation required.) This warranty shall not apply to

any product that has been altered in any way, which has

been repaired by any party other than a service

representative authorized by OPW, or when failure is due

to misuse, or improper installation or maintenance. OPW

shall have no liability whatsoever for special, incidental or

consequential damages to any party, and shall have no

liability for the cost of labor, freight, excavation, clean up,

downtime, removal, reinstallation, loss of profit, or any

other cost or charges.

For any product certified to California 2001 standards,

OPW warrants that product sold by it are free from defects

in material and workmanship for a period of one year from

date of manufacture or one year from date of registration

of installation not to exceed 15 months from date of

manufacture by OPW.

THIS WARRANTY IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, AND

SPECIFICALLY THE WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. THERE ARE NO

WARRANTIES, WHICH EXTEND BEYOND THE

DESCRIPTION ON THE FACE HEREOF.

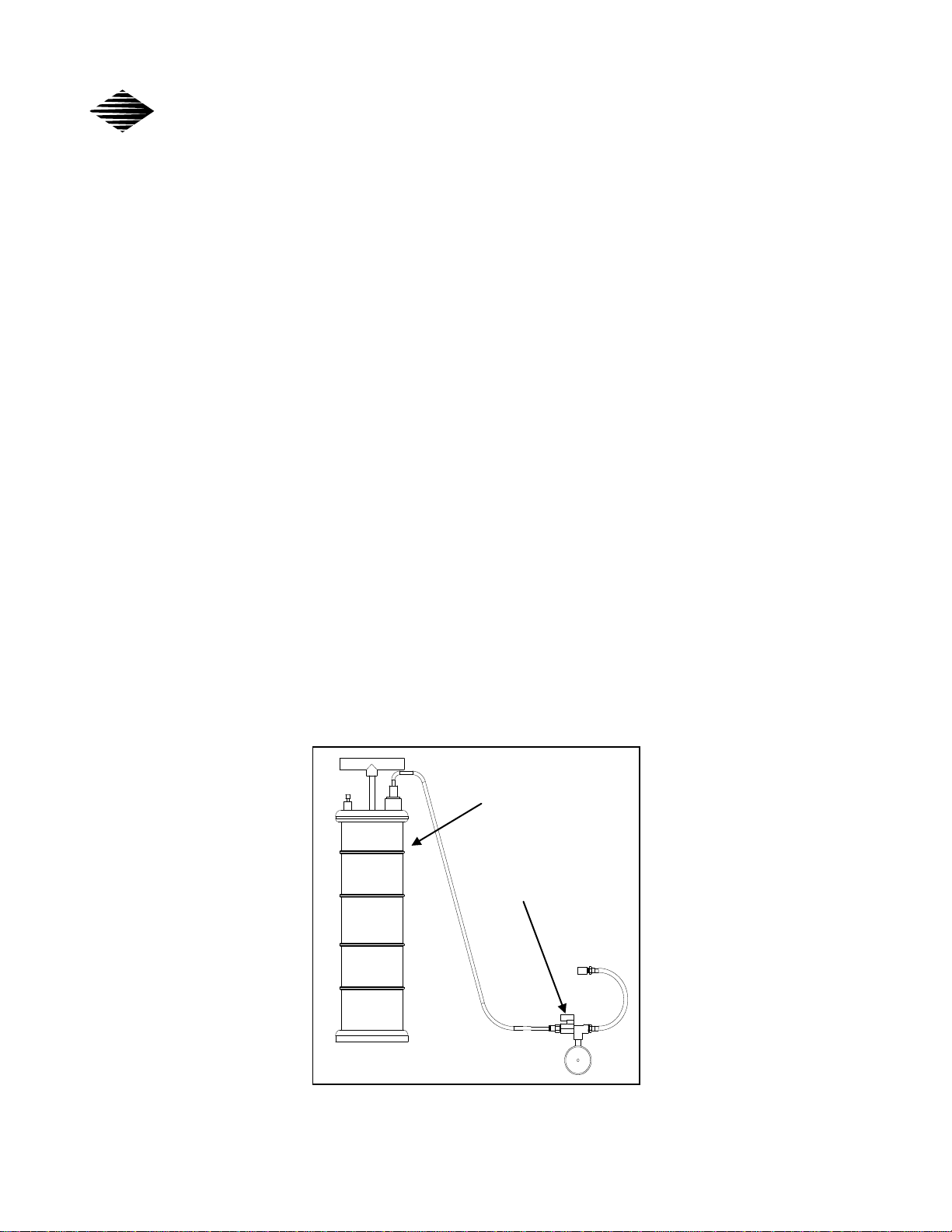

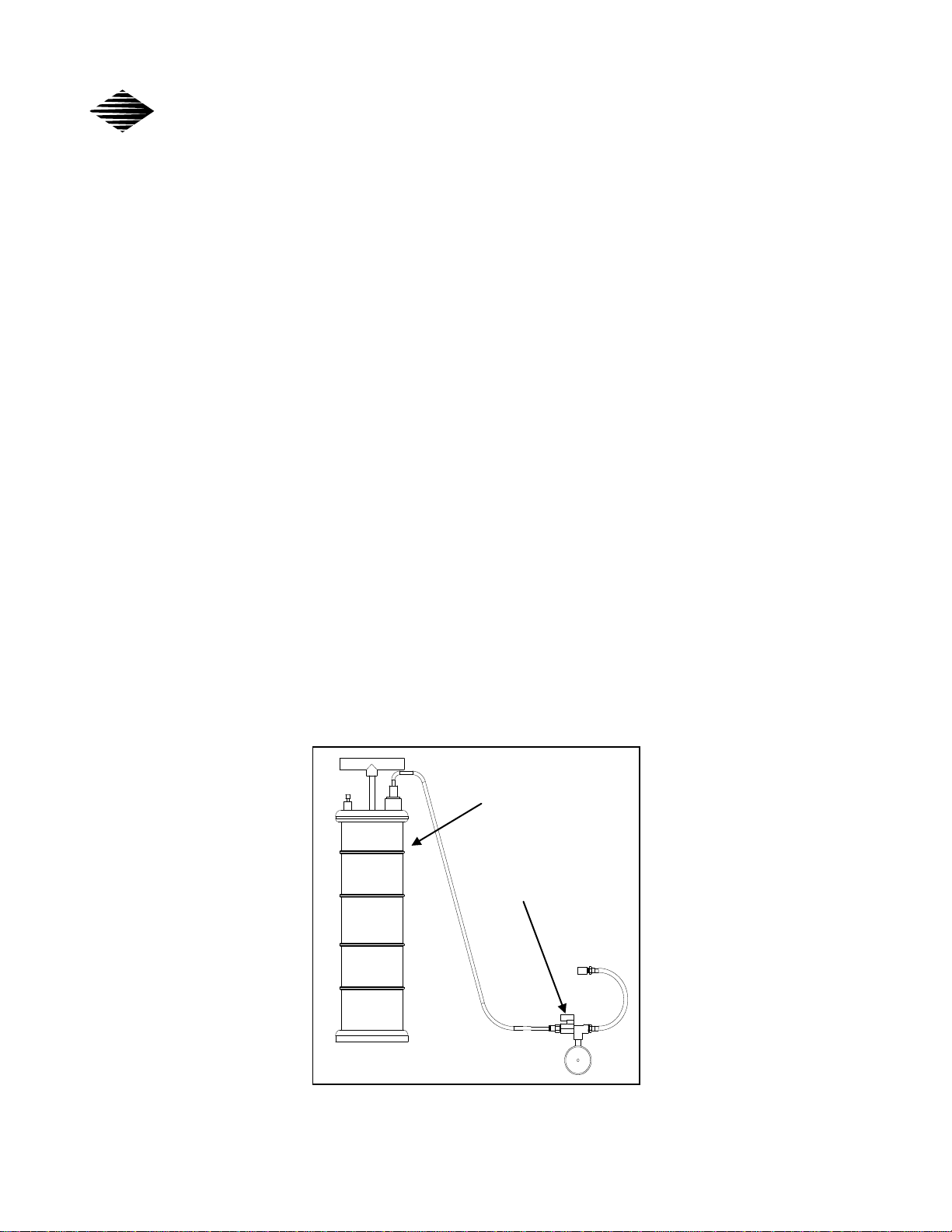

Figure 1