.

EDITION 01-2017

EB-2/11

MODEL

EB

INDEX

INDEXINDEX

INDEX Page

0.- Description .........................…………………………………..……................................. 2

1.- Handling ..................................………..............................……………………………… 2

2.- Installation .................................………..................................................................... 4

3.- Actuators .....................................………................................................................... 6

4.- Maintenance .....................................……….............................................................. 7

4.1.- Gland packing and seal replacement .…....................................................... 7

4.2.- Lubrication …………………….………………………………………………..…… 9

5.- Storage …………................................…..………....................................................... 10

6.- Parts list & drawing ..................................……………………………………..…............ 11

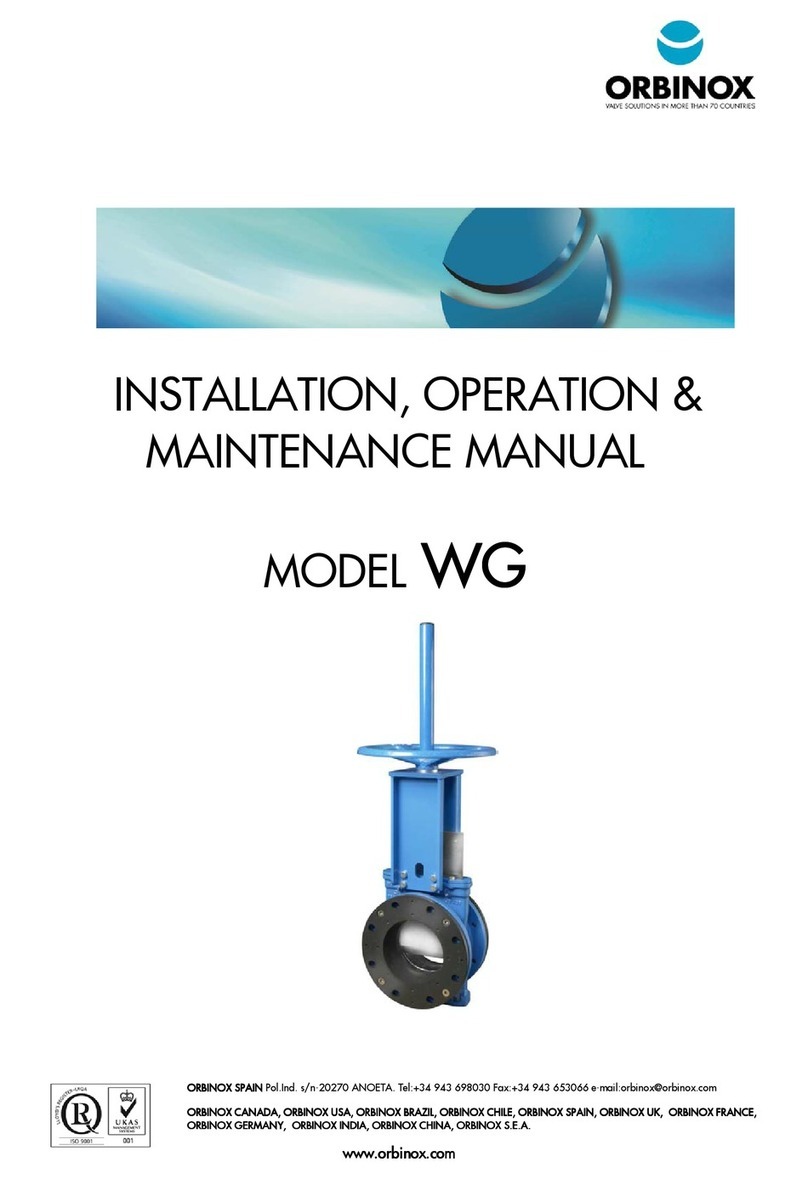

0.- DESCRIPTION

The EB model knife gate is a bi-directional valve and consequently it can be installed without

considering the flow direction.

This valve is designed for general industrial service applications. The design of the body and seat

assures non-clogging shut-off with suspended solids.

The EB valve complies with the following European directives:

- DIR

DIR DIR

DIR 2006

20062006

2006/

//

/42

4242

42/EC (machines)

/EC (machines)/EC (machines)

/EC (machines)

- DIR

DIR DIR

DIR 2014/68/EU

2014/68/EU 2014/68/EU

2014/68/EU (PED)

(PED)(PED)

(PED)

luid: Group 1 (b), 2 (Cat. I, mod.A)

It may also comply with the directive:

DIR

DIR DIR

DIR 2014/

2014/2014/

2014/34

3434

34/EU

/EU /EU

/EU (Explosive Atmospheres)

(Explosive Atmospheres)(Explosive Atmospheres)

(Explosive Atmospheres)

The EB valve may comply with the directive regarding equipment and protective systems for their

use in explosive atmospheres. In these cases, the logotype shall appear on the identification

label of the valve. This label shows the exact classification of the zone where the valve can be

used. The user will be liable for its use in any other zone.

This directive only applies in the following atmospheric conditions:

0,8 bar ≤ P ≤ 1,2 bar

-20ºC < T < 60ºC

Any increase in temperature due to frictional warmth is negligible, since the relative speed of

the moving parts is extremely low.

The risk analysis associated to this directive does not take into account the fluid that goes

through the valve, even when such fluid produces an explosive atmosphere. The user must take

into account the risks that the fluid generates, such as:

-heating of the valve surface.

-generation of electrostatic charges caused by displacement of the fluid.

-shock waves caused by the installation (water hammer), internal crashes generated by the

pellets or the risks due to foreign bodies susceptible of being present in the installation.

1.- HANDLING

(01909) 530444

Fax (01909) 530044

Eurovalve UK Limited

Unit 1D Campbell Way

www.eurovalve.co.uk

The valves are packed according to the appropriate transport standards. If you receive the packing

damaged, please inform the transport company in writing and speak to a company

representative. .