Orenco Systems®• 800-348-9843 • +1 541-459-4449 • www.orenco.comNIM-EPS-1

Rev. 6 © 10/21

Page 8

Biotube ProPak and LOS Pump Package Installation Manual

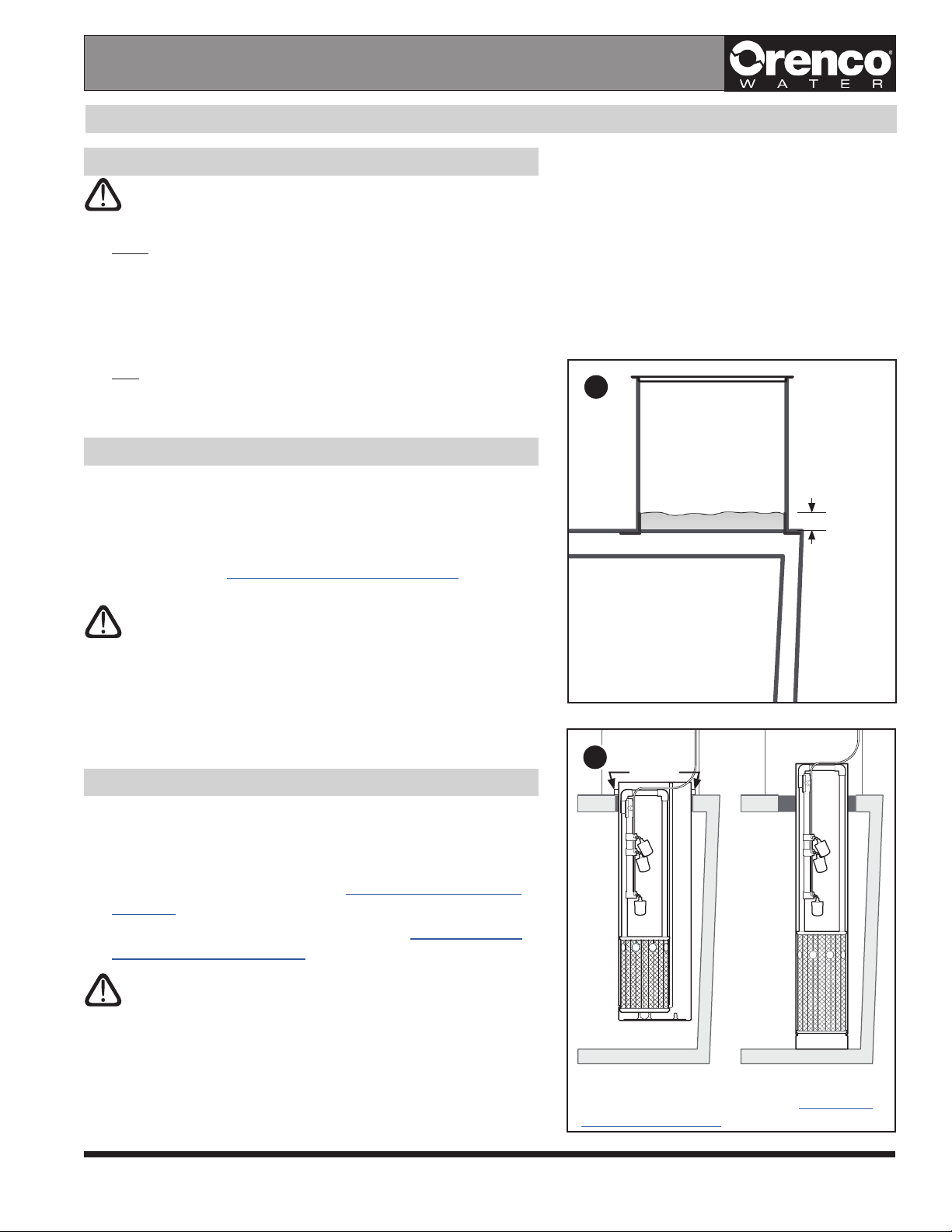

Step 8. Test Float Switches and Control Panel

• If you’re using a generator for pump operation, contact your dealer to

make sure it can supply sufficient starting amperage to the pump(s).

• Make sure there’s enough liquid in the tank to safely run the pump –

at least 4in (100mm) above the bottom float switch – and make sure

the pump doesn’t run dry during testing.

Step 8a: Make sure that the control panel has power and that the float

switch assembly has been removed from the tank.

Step 8b: Perform an operational test of the float switches in the float switch

assembly, based on the applicable configuration found in this section.

• If the panel doesn’t perform as it’s supposed to, check the wiring

diagram for proper wiring. Contact your distributor for assistance.

Demand-Dose: “Y,G” or “Y,G,W” Float Switch Assemblies

(MVP-S, S1, or S1RO Control Panels)

• Place the “Pump On/Off” and the “Redundant Off/Low-Level Alarm” (if

included) switches in the “up” position.

– The pump begins to run.

• Place the “High-Level Alarm” switch in the “up” position.

– The audible alarm sounds; the panel door alarm light turns on.

• Place the “High-Level Alarm” switch in the “down” position.

– The audible alarm goes silent; the panel door alarm light turns off.

• Place the “Pump On/Off” switch in the “down” position.

– The pump stops running.

• Place the “Redundant Off/Low-Level Alarm” switch (if included) in the

“down” position.

– The audible alarm sounds; the panel door alarm light turns on.

(On MVP panels, the panel door alarm light begins to blink.)

Demand-Dose: “Y,B,R” or “Y,B,R,W” Float Switch Assemblies

(MVP-S, S1, or S1RO Control Panels)

• Place the “Pump Off” and the “Redundant Off/Low-Level Alarm” (if

included) switches in the “up” position.

• Place the “Pump On” switch in the “up” position.

– The pump begins to run.

• Place the “High-Level Alarm” switch in the “up” position.

– The audible alarm sounds; the panel door alarm light turns on.

• Place the “High-Level Alarm” switch in the “down” position.

– The audible alarm goes silent; the panel door alarm light turns off.

• Place the “Pump On” switch in the “down” position.

– The pump continues to run.

• Place the “Pump Off” switch in the “down” position.

– The pump stops running.

• Place the “Redundant Off/Low-Level Alarm” switch (if included) in the

“down” position.

– The audible alarm sounds; the panel door alarm light turns on.

(On MVP panels, the panel door alarm light begins to blink.)

8

Lift and lower float switches to test switches and controlLift and lower float switches to test switches and control

panel functions (three-float configuration shown).panel functions (three-float configuration shown).

Installation Steps