PUSHCORP, INC.

AFD1200 Manual 3

2.0 General Overview

The PushCorp, Inc. AFD1200 Adjustable Force Devices (US Patent No. 5,448, 46)

provide a superior force application system. The AFD can be placed in any position to

enable a variety of manufacturing operations requiring a consistent applied force with

.6 inches (40 mm) of compliant stroke. The AFD is designed to withstand continuous

use in harsh industrial grinding, polishing, and drilling operations.

The AFD1200 utilize a pneumatic actuator to provide the force and a load cell force

sensor to provide closed-loop feedback to an FCU1000 Active Compliance Controller.

The AFD1200 can apply up to a maximum 250 lbs. ( 2 N) of force. The AFD contains

an accelerometer that monitors orientation and allows the unit to automatically

compensate for gravitational and inertial effects. A linear potentiometer is also present

within the AFD to sense the position of the Carriage.

Only two external connections are required to operate the AFD1200. First, dry, non-

lubricated, filtered 80 - 90 psi (5.5 – 6.2 bar) supply air must be provided through flexible

tubing. Second, the AFD must be connected to the FCU 000 Controller with a

PushCorp high flex multi-conductor cable. An optional Purge Port is provided for

applications where excessive fine dust particles are created. This Purge Port

connection provides additional airflow and internal positive pressure to minimize

contamination entering the AFD. The Carriage has threaded mounting holes to provide

easy process equipment attachment.

All these features combine to make the PushCorp AFD1200 Adjustable Force Device a

rugged, state-of-the-art technology capable of providing reliable, precise, and consistent

results in a variety of industrial applications.

3.0 Quick Start

This section contains step-by-step instructions on how to quickly get the AFD1200

Adjustable Force Device up and running for a quick test of its capabilities. Complete

details on all the features are described in the sections that follow. It is recommended

that the user read the entire manual before beginning any operations to fully understand

all the aspects and features of the AFD1200.

Step : Carefully unpack the AFD1200 Force Device and the FCU 000 Controller.

Verify that all parts indicated on the packing list are present and in good

condition. If there is a problem, please notify the factory immediately so

that corrective action may be promptly initiated.

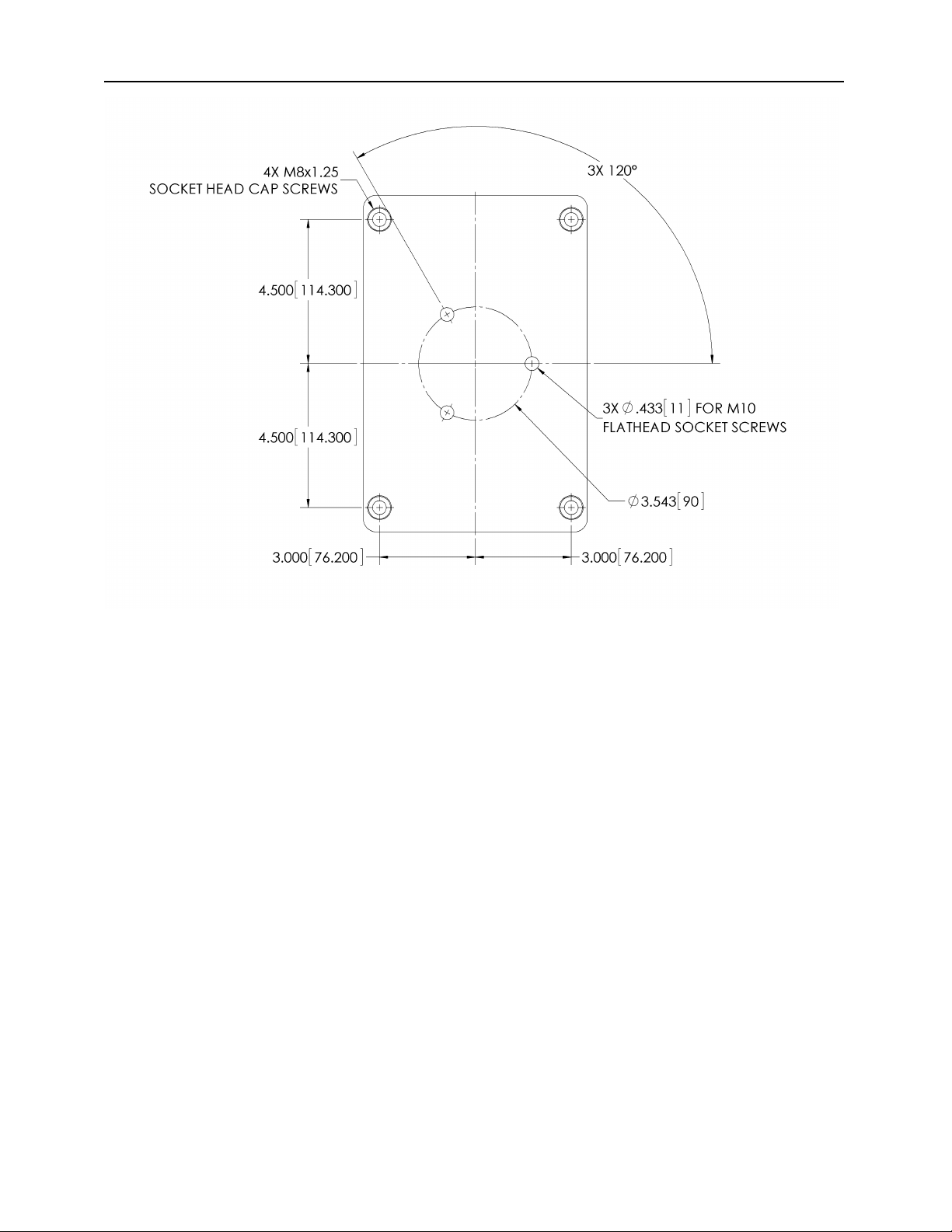

Step 2: Securely attach the AFD1200 Mounting Bracket to the manipulator

mounting flange or support table per Section 4.2.

Step 3: Connect a dry, non-lubricated, 5 µm filtered 80 to 90 psi (5.5 to 6.2 bar) air

supply to the force device per Section 4.3.

Step 4: Consult the FCU 000 Manual for electrical connections and software setup

information.

Please read the following sections to learn the full potential and features of the

PushCorp AFD1200 Adjustable Force Device.