INDEX

GUIDE TO THE MANUAL ......................................................................................................5

GENERAL INTRODUCTION.................................................................................................. S

1 TRANSPORT 7

1.1 Packing ..........................................................................................................7

1.2 Transport .......................................................................................................7

1.3 Unpacking ......................................................................................................7

1.4 Handling the machine ....................................................................................7

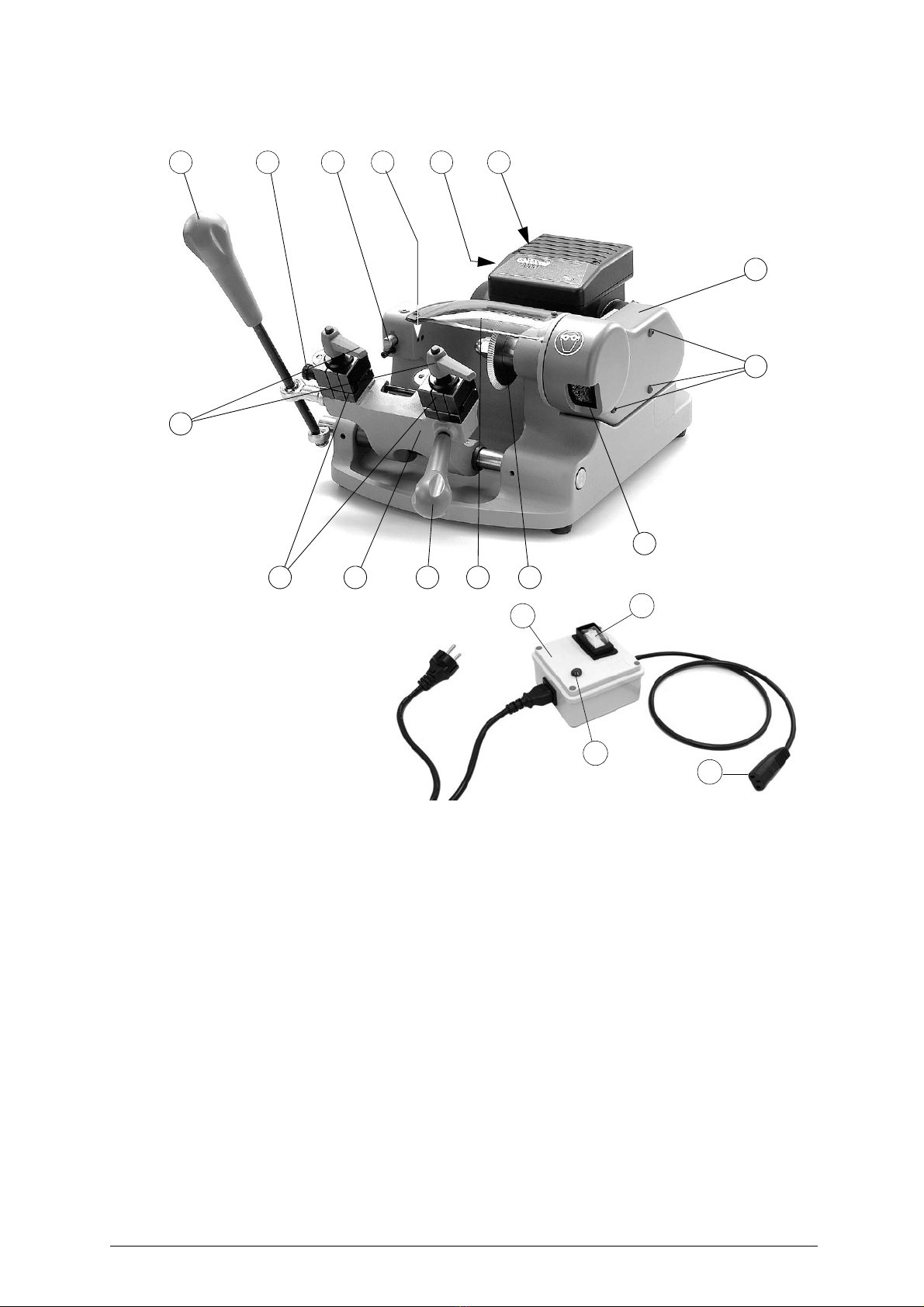

2 MAIN WORKING PARTS ................................................................................8

3 MACHINE DESCRIPTION ...............................................................................9

3.1 Technical Data .............................................................................................10

3.2 Electrical system ..........................................................................................11

4 ACCESSORIES PROVIDED .........................................................................12

5 MACHINE INSTALLATION AND PREPARATION .......................................13

5.1 Checking for damage ...................................................................................13

5.2 Environmental conditions .............................................................................13

5.3 Positioning ...................................................................................................13

5.4 Description of work station ...........................................................................13

5.5 Graphics ......................................................................................................14

5.6 Separate parts .............................................................................................14

5.7 Removing the blocks ...................................................................................14

5.8 Connection to the mains ..............................................................................14

6 REGULATION AND USE OF THE MACHINE ..............................................15

6.1 Checking and setting ...................................................................................15

6.2 Calibration ....................................................................................................15

7 Key cutting ....................................................................................................16

7.1 Key cutting ...................................................................................................16

7.2 Using the accessories ..................................................................................17

8 MAINTENANCE .............................................................................................19

8.1 Replacing the cutting tool ............................................................................19

8.2 Replacing the brush .....................................................................................19

8.3 Replacing the belt ........................................................................................20

8.4 Replacing the tracer point ............................................................................20

8.5 Replacing the fuses .....................................................................................20

9 DISPOSING OF MACHINE ...........................................................................21

10 AFTER-SALES SERVICE .............................................................................22

10.1 How to request service ................................................................................22