4

•Unauthorized reproduction or copying of all or part of this manual is prohibited.

•Oriental Motor shall not be liable whatsoever for any problems relating to industrial

property rights arising from use of any information, circuit, equipment or device

provided or referenced in this manual.

•Characteristics, specications and dimensions are subject to change without notice.

•While we make every eort to oer accurate information in the manual, we welcome

your input. Should you nd unclear descriptions, errors or omissions, please contact the

nearest oce.

•is a registered trademark or trademark of Oriental Motor Co., Ltd., in

Japan and other countries.

© Copyright ORIENTAL MOTOR CO., LTD. 2017

Published in January 2022

echnical Support Tel:800-468-3982

8:30am EST to 5:00pm PST (M-F)

www

.orientalmotor.com

• Please contact your nearest Oriental Motor oce for further information.

Schiessstraße 44, 40549 Düsseldor

f, Germany

echnical Support Tel:00 800/22 55 66 22

.orientalmotor.de

araday Oce Park, Rankine Road,

, Hampshire RG24 8QBUK

el:+44-1256347090

.oriental-motor.co.uk

el:+33-1 47 86 97 50

.orientalmotor.fr

el:+39-02-93906347

.orientalmotor.it

,Taito-ku,Tokyo 110-8536

el:+81-3-6744-0361

.orientalmotor.co.jp

Tel:400-820-6516

www.orientalmotor.com.cn

Tel:0800-060708

www.orientalmotor.com.tw

Singapore

Tel:1800-842-0280

www.orientalmotor.com.sg

Tel:1800-806-161

www.orientalmotor.com.my

Tel:1800-888-881

www.orientalmotor.co.th

Korea

Tel:080-777-2042

Tel:1800-120-1995 (For English)

1800-121-4149 (For Hindi)

www.orientalmotor.co.in

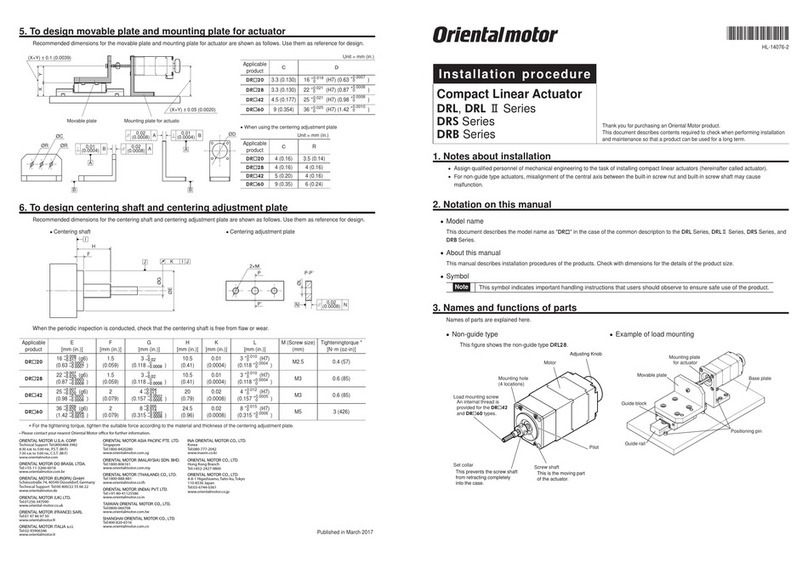

Alarm

If an abnormality occurred in the speed controller or fan, the ALARM LED on the speed

controller blinks in red. Also, the alarm message can be checked by the indication level of

the indicator. If the fan was stopped, ensure safety before removing the cause of the alarm.

Alarm lists

Indicator

status Item Cause Remedial action Status of

fan

Stall

The fan was stopped.

Check the lifetime of

the fan or adherence

of a foreign particle.

Stop *1

There is no pulse

sensor output from the

fan.

Check if there is a

disconnection in the

lead wires of the fan.

Rotating

Overvoltage

The power supply

voltage exceeded

approximately 30 VDC. Check the power

supply voltage.

Stop *2

Undervoltage

The power supply

voltage fell below

approximately 18 VDC.

Overheat

The internal

temperature of the

speed controller

exceeded the specied

value.

Check the number of

units connected and

the operating ambient

temperature.

*1 The fan starts rotating when the cause that the fan has stopped is removed.

*2 The fan automatically starts rotating when the cause of the alarm is removed and the

power supply is turned on again.

z"Stall" alarm

The MD Series Vtype fans have a function of the pulse sensor output. The speed controller

can capture the pulse sensor output of the fan and output as the stall alarm if the fan

stops.

Inspection and maintenance

Inspection

It is recommended that periodic inspections for the items listed below are conducted after

each operation. If an abnormal condition is noted, discontinue any use and contact your

nearest Oriental Motor sales oce.

zInspection item

•Check if any of mounting screws of the speed controller or fan come loose.

•Check if the speed controller or fan generates unusual noises.

•Check if the speed controller has unusual smells or appearance defects.

Warranty

Check on the Oriental Motor Website for the product warranty.

Disposal

Dispose the product correctly in accordance with laws and regulations, or instructions of

local governments.

General specications

Operating

environment

Ambient

temperature -10 to +60 °C [+14 to +140°F] (non-freezing)

Ambient

humidity 85% or less (non-condensing)

Altitude Up to 1000 m (3300 ft.) above sea level

Surrounding

atmosphere

No corrosive gas, dust, water, or oil

Cannot be used in radioactive materials, magnetic eld,

vacuum or other special environment

Storage

environment

Shipping

environment

Ambient

temperature -20 to +70 °C [-4 to +158°F] (non-freezing)

Ambient

humidity 85% or less (non-condensing)

Altitude Up to 3000 m (10000 ft.) above sea level

Surrounding

atmosphere

No corrosive gas, dust, water, or oil

Cannot be used in radioactive materials, magnetic eld,

vacuum or other special environment

Regulations and standards

CE Marking

This product is axed the CE Marking under the EMC Directive.

zEMC Directive

This product has received EMC compliance under the conditions specied in "Example of

installation and wiring."

•Applicable Standards

EMI: EN 55011 group1 class A, EN 61000-6-4 EMS: EN 61000-6-2

Caution: This equipment is not intended for use in residential environments nor for use on a

low-voltage public network supplied in residential premises, and it may not provide

adequate protection to radio reception interference in such environments.

RoHS Directive

This product does not contain the substances exceeding the restriction values.

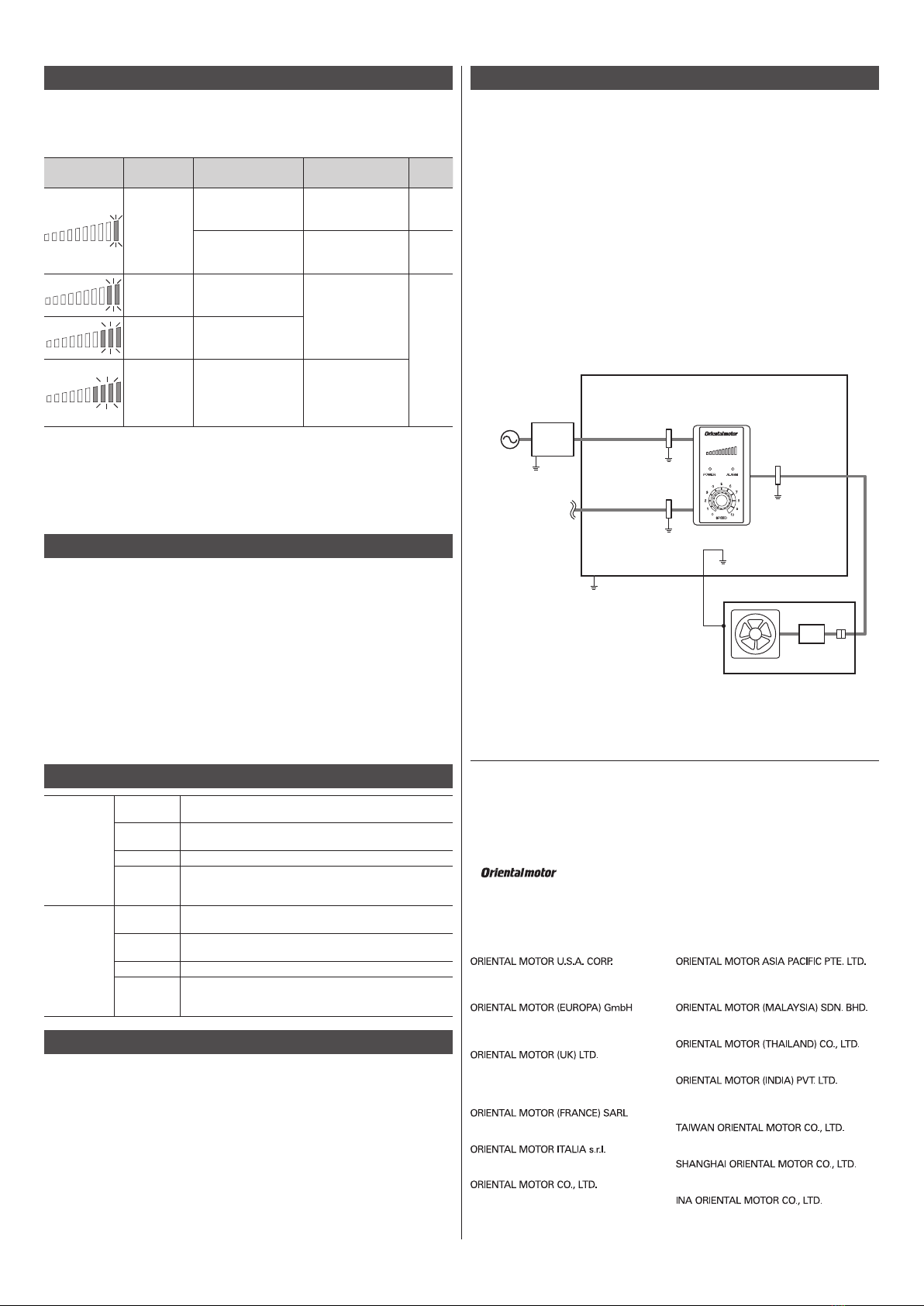

Installing and wiring in compliance with EMC Directive

FSC-24 has been designed and manufactured to be incorporated in equipment.

The EMC Directive requires that your mechanical equipment in which the product

is installed satises the applicable requirements. Installation and wiring methods of

FSC-24 explained here represent the basic methods that are eective in helping your

mechanical equipment conform to the EMC Directive. The nal level of conformance of

your mechanical equipment to the EMC Directive will vary depending on control system

equipment including FSC-24 and fans, conguration of electrical parts, wiring, layout,

and the like. It therefore must be veried through conducting EMC measures on your

mechanical equipment.

Without eective measures to suppress the electromagnetic interference (EMI) caused by

FSC-24 in the surrounding control system equipment and the electromagnetic spectrum

(EMS) generated by FSC-24, the function of your mechanical equipment may be seriously

aected. Implementing the following installation and wiring methods allows FSC-24 to

conform to the EMC Directive.

Ferrite core

When extending the cable, wind the cable around a ferrite core twice before use.

The ferrite core reduces the negative eects of external noise.

Use a ferrite core of the model ZCAT3035-1330 (TDK Corporation) or its equivalent. Install

the ferrite core as close as possible to the fan.

Example of installation and wiring

Cable

cramp

Power supply

cable

Signal cable

DC power

supply

Fan extension

cable

Ferrite

core

Shielded enclosure

Fan

(Ground panel)

Speed controller

Shielded cable

Grounding

Grounding

Grounding

Cable

cramp

Cable

cramp

Grounding

[2 m(6.6 ft.)]

Grounding

[2 m(6.6 ft.)]