4. Installation procedure (example)

The installation procedure varies based on the accuracy of component parts of equipment.

•If centering is possible without adjustment of assembled parts due to high accuracy of each part, install in order of the Step 1, Step 2, Step 3-A, and Step 4.

•If centering is not easy because of low-accuracy parts, install in order of the Step 1, Step 2, Step 3-B, and Step 4.

Step 1 Installing a guide rail

1. In order to set the position of the guide rail and mounting plate for actuator,

install positioning pins on the base plate.

Intersect at a right angle

Positioning pin

2. Secure a guide rail using screws while pressing the reference surface of

the guide rail to the positioning pin.

Positioning pin

Reference surface

of the guide rail Positioning pin

*Check the manufacturer of a guide rail

for the position of the reference surface

of the guide rail.

Step 2 Installing a mounting plate

Secure a mounting plate for actuator using screws after positioning it with the

positioning pins on the base plate.

Provide a mounting plate for actuator with reference to "5. To design movable

plate and mounting plate for actuator."

Positioning pin

Step 3-A Installing a movable plate (If centering is possible without adjustment of assembled parts due to high accuracy of each part)

1. In order to set the position of the movable plate and guide block,

install positioning pins on the movable plate.

Positioning pin

Screw shaft

mounting hole

Note Design a screw shaft mounting hole in consideration

of a margin so that stacked tolerances of parts can be

absorbed. Provide a mounting plate for actuator with

reference to "5. To design movable plate and mounting

plate for actuator."

2. Secure the movable plate with screws while pressing the

positioning pins on the movable plate to the reference surface of

the guide block.

Reference surface

of guide block

Positioning pin

*Check the manufacturer of a guide rail for the

position of the reference surface of the guide block.

Step 3-B Installing a movable plate (If centering is not easy because of low-accuracy parts)

3. Install the movable plate by either of the following methods.

•Place the movable plate and mounting plate for actuator

together, and secure with screws so that there is no gap

between them.

•Put a block gauge or similar parts between the movable plate

and mounting plate for actuator, and secure with screws so that

there is no gap.

If there is a gap, reinstall the movable plate.

∗㻌If there is a distance between the movable plate and mounting plate

for actuator, use a block gauge or similar parts.

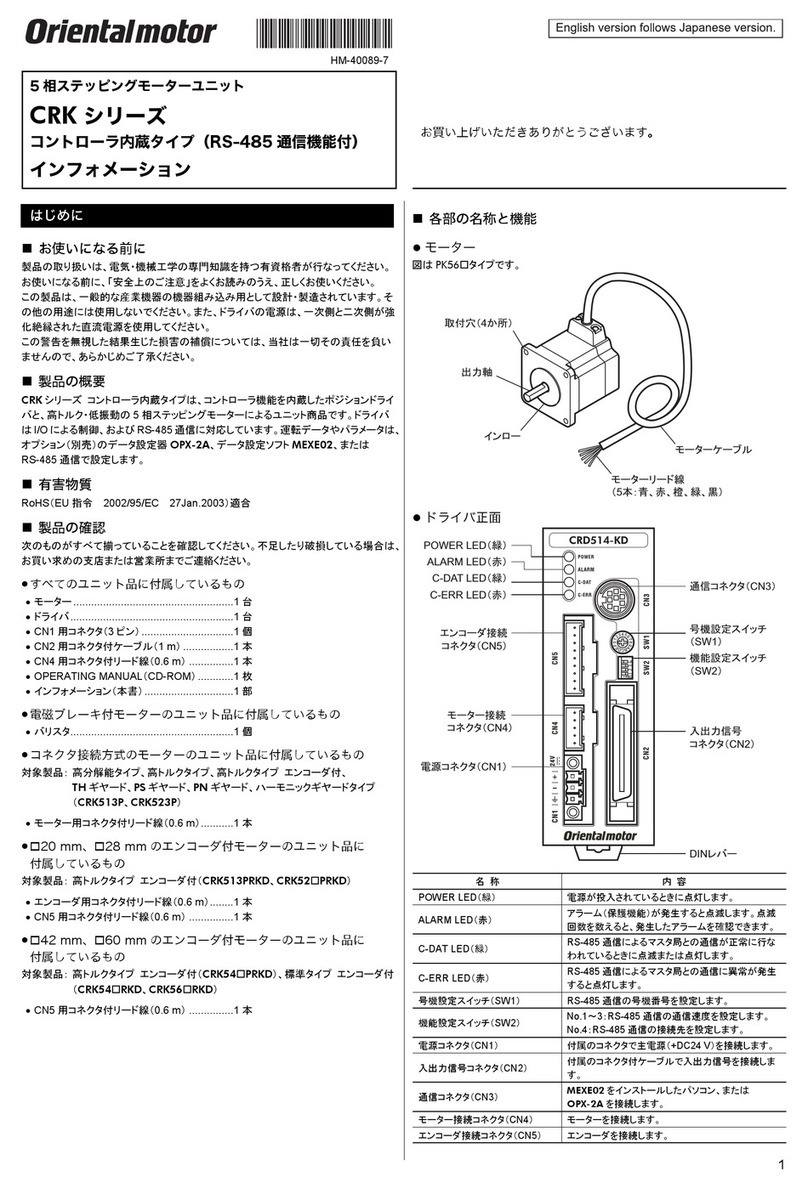

4. Fit the centering shaft with the pilot of the mounting plate for

actuator, and align the centering shaft with the central axis of the

screw shaft mounting hole on the centering adjustment plate.

5. Slide the movable plate back and forth, and secure the movable

plate and centering adjustment plate with screws after checking

that the movable plate can move smoothly so that the centering

shaft does not contact.

If the movable plate does not move smoothly, adjust axis

misalignment between the centering shaft and the centering

adjustment plate while moving the centering adjustment plate

from right to left or up and down.

㻼㼕㼘㼛㼠㻌㼛㼒㻌㼙㼛㼡㼚㼠㼕㼚㼓

㼜㼘㼍㼠㼑㻌㼒㼛㼞㻌㼍㼏㼠㼡㼍㼠㼛㼞

Screw shaft mounting hole

of centering adjustment plate

Centering adjustment plate

Adjust axis misalignment between the centering shaft and the

centering adjustment plate in the upper, lower, right,

and left directions, using the centering adjustment plate

Note

•Provide a centering shaft with reference to "6. To

design centering shaft and centering adjustment

plate."

•Design the centering adjustment plate and pilot of

the mounting plate for actuator according to the

centering shaft.

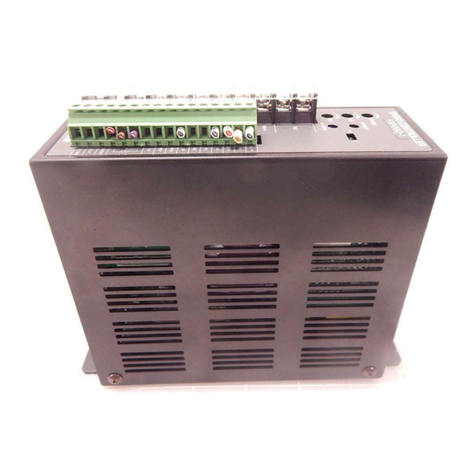

Step 4 Installing the screw shaft and

movable plate

1. Secure a compact linear actuator to the mount plate for actuator with

screws.

Model Screw size Tightening torque

[N·m(oz-in)]

DR20 M2 0.4 (57)

DR28 M2.5 0.6 (85)

DR42 M4 1.8 (256)

DR60 M5 5 (710)

2. Push the screw shaft into the actuator body once until the set collar stops,

and then pull it out a little. Adjust the screw shaft length to be pulled out so

that the set collar does not contact the actuator body when the screw shaft

is tightened with tools.

3. Secure the screw shaft with a nut after pass it through the screw shaft hole

on the movable plate. (Secure the DR42 and DR60 with a screw.)

Model Screw size Tightening

torque

[N·m(oz-in)]

DR20

DR28 M3 nut 0.6 (85)

DR42 M4 screw 1.8 (256)

DR60 M8 screw 5 (710)

4. Perform test operation to check if there is no place to generate abnormal

noises.