36

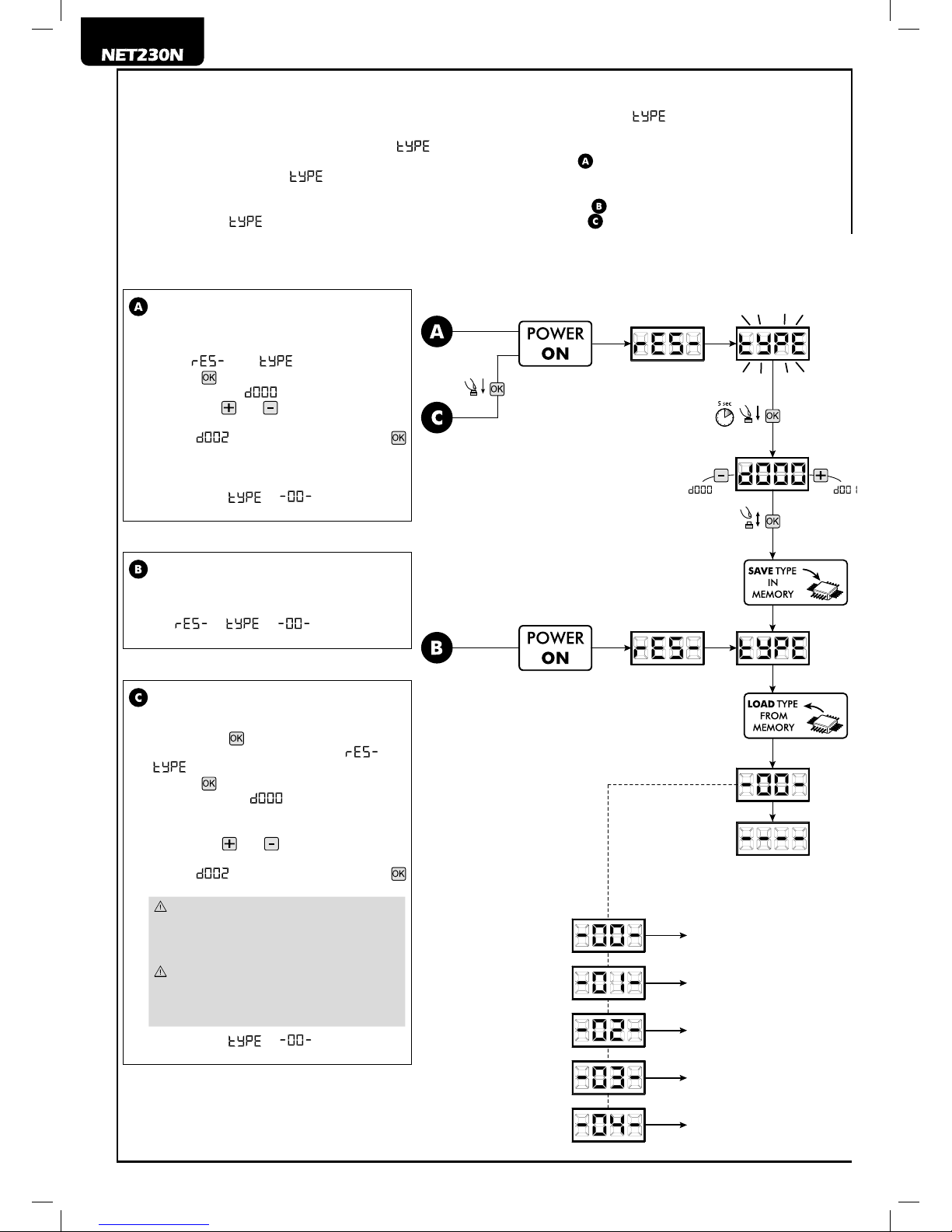

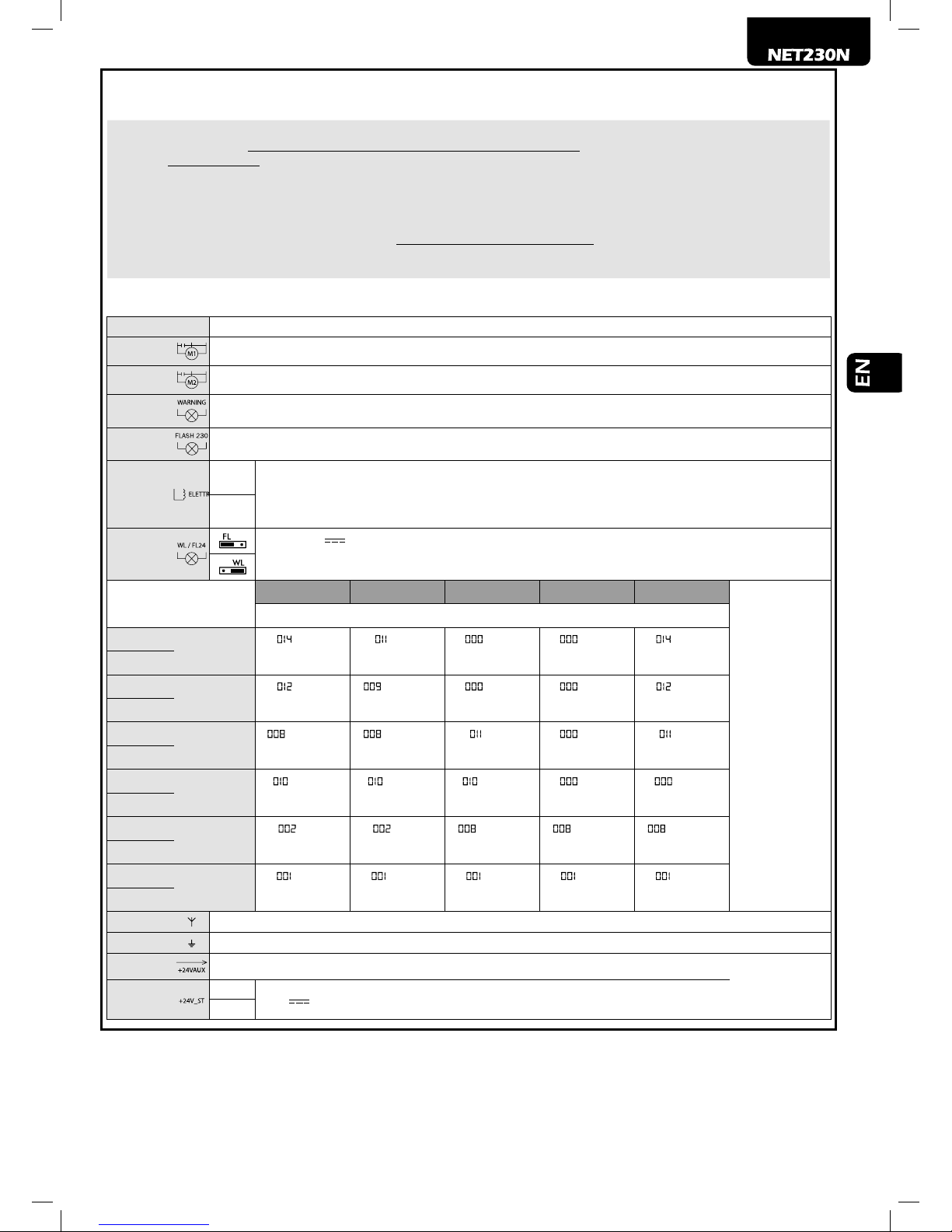

4 CONFIGURATION OF THE CONTROL PANEL

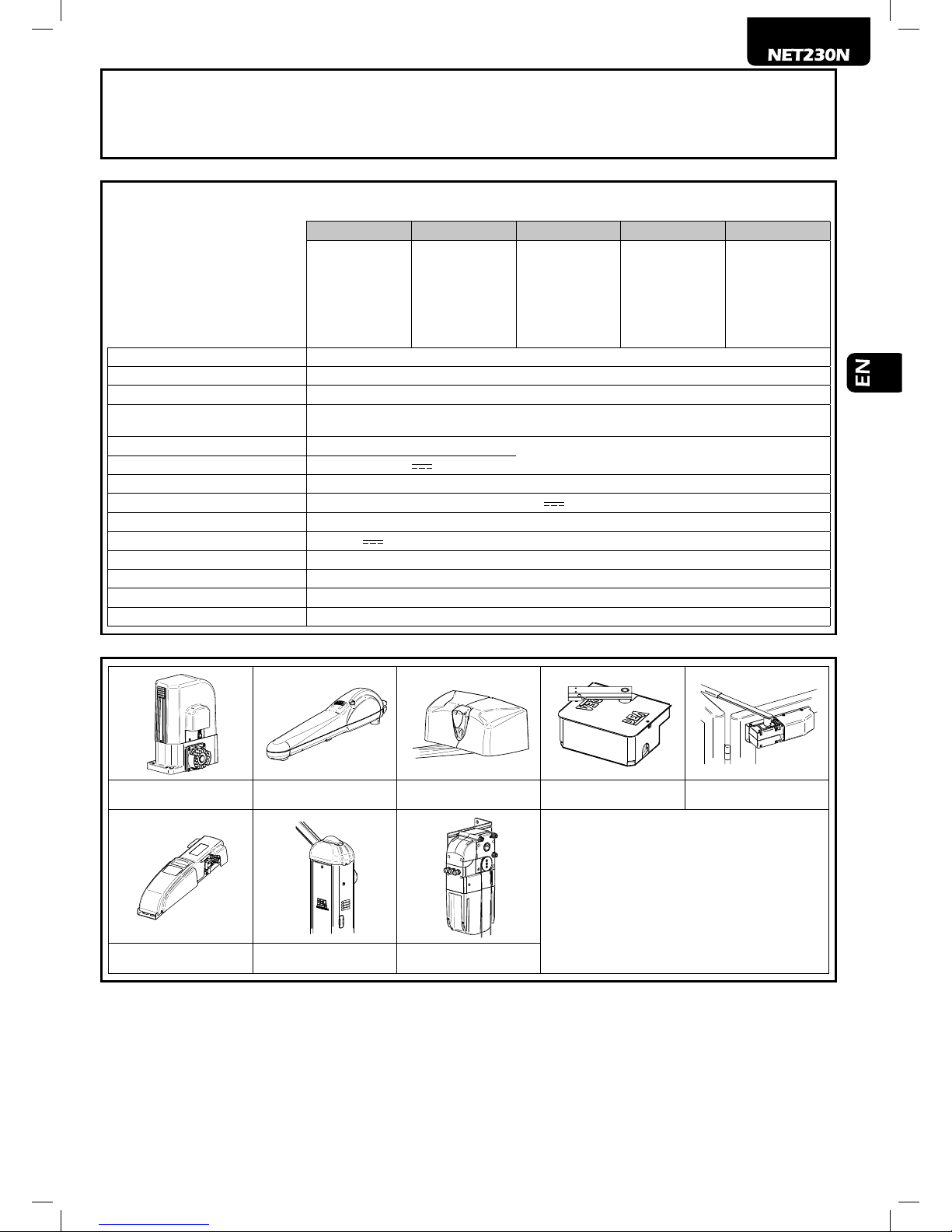

The universal control unit NET230N can be used for the management of the following types ( ) of closures motorized by DEA Sy-

stem: swing and sliding gates, overhead doors and barriers.

In order to ensure maximum adaptability to each of closure, the control board provides an initial procedure, performed only at the

rst turn, for the optimal conguration of inputs, outputs and parameters (see diagram ). Once congured, the control panel will operate

in the mode “dedicated” to the of selected closing. After performing the initial conguration it is sufcient to execute the standard

programming for the installation on which it is operating.

All settings remain in memory even in the case of subsequent are-ups (see diagram ).

If necessary the of congured closing can be later adjusted following diagram .

FIRST CONTROL BOARD IGNITION

Conguration after the rst ignition

For the rst control panel ignition, proceed as fol-

lows:

1. Apply power, the display shows in sequence the

writing “ ” and “ ” ashing;

2. Press the button and hold for 5 seconds until

the display shows on the display;

3. Acting on the and keys, select the desired

conguration depending on the type of installa-

tion (es. ) and conrm by pressing the

button;

At this point, the selection will be stored and relo-

aded each time in the future.

4. Follow signs, “ ”, “ ” followed by the

symbol of closed gate “- - - - ”.

Following ignitions

If you have already saved a conguration, pro-

ceed as follows:

Apply power, the display shows in sequence the

writing “ ”, “ ”, “ ” followed by the

symbol of closed gate “- - - - ”.

Modify the existing conguration

If you have already saved a conguration and you

want to change it, proceed as follows:

1. Hold down the button and give power, the di-

splay shows in sequence the writing “” and

“” ashing;

2. Press the button and hold for 5 seconds until

the display shows (the value changes to

match the previous conguration used) on the

display;

3. Acting on the and ,select the new desired

conguration depending on the type of installa-

tion (es. ) and conrm by pressing the

button;

Stop the reconguration procedure prior

to conrmation, involves loading the previous

conguration by the control panel without any

modication.

However, if the reconguration procedure is

brought to an end, the new conguration will

take the place of the previous one and will be

reloaded each time in the future.

4. Follow signs, “ ”, “ ” followed by the

symbol of closed gate “- - - - ”.

Sliding gates

Swing gates

Overhead doors

Barriers

Sectional doors