Table of contents

−2−

1Introduction ......................................3

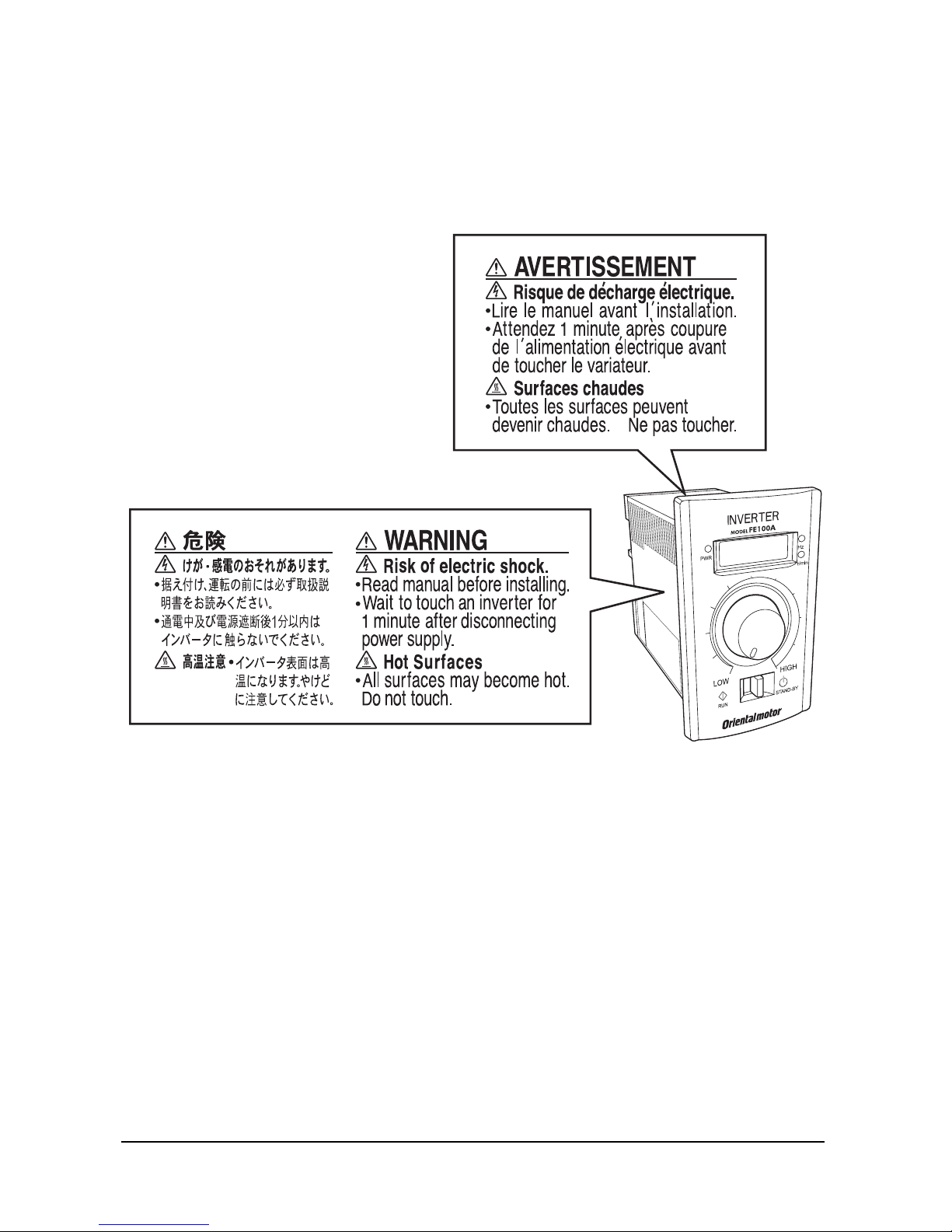

2Safety precautions ...........................5

3Precautions for use ........................10

4Preparation.....................................14

4.1 Checking the inverter ....................14

4.2 Motor/Inverter combinations .........15

4.3 Name and function of each part....17

4.4 Removing/installing the front

panel .............................................19

4.5 Installing/removing the front cover

(sold separately) ...........................21

5Installation ......................................22

5.1 Installation location .......................22

5.2 Installation condition .....................22

5.3 Installation method........................23

5.4 Installing and wiring in compliance

with EMC Directive........................24

6Connection.....................................27

6.1 List of connection terminals ..........27

6.2 Connecting the main circuit

terminals .......................................29

6.3 Connecting the I/O signal

terminals .......................................32

6.4 Example of inverter connection.....36

7Operation....................................... 37

7.1 Setup before operation .................37

7.2 Setting position of motor output

selector switch ..............................38

7.3 Operating the motor...................... 39

7.4 Operation via external input

signals...........................................41

7.5 Setting the speed..........................42

7.6 Timing chart ..................................43

8Various functions ........................... 44

8.1 Setting the acceleration time and

deceleration time ..........................44

8.2 Switching the display mode ..........45

8.3 Setting the gear ratio ....................46

8.4 Switching the carrier frequency ....50

8.5 Switching between sink input and

source input ..................................51

9Inspection ...................................... 52

10 Troubleshooting and remedial

actions ........................................... 53

10.1 Troubleshooting ............................53

10.2 Inverter alarms..............................54

11 Appendix........................................ 57

11.1 Cables (sold separately) ...............57

11.2 Front cover (sold separately) ........57

11.3 Recommended peripherals...........58

11.4 Specifications................................60