Oryx sca3600 Operating instructions

AZ 85284

2

Table of Contents

I. PRELIMINARY STEPS.........................................................................................- 4 -

II. QUICK TROUBLESHOOTING ..............................................................................- 5 -

III. REMOVING TOP COVER AND BACK PANEL..........................................................- 9 -

A. HOW TO REMOVE THE BACK PANEL....................................................................................................... - 9 -

B. HOW TO REMOVE THE TOP COVER ...................................................................................................... - 10 -

IV. PUMP ASSEMBLY REPLACEMENT .....................................................................- 11 -

A. HOW TO REMOVE THE PUMP ASSEMBLY............................................................................................... - 11 -

B. HOW TO INSTALL THE PUMP ASSEMBLY................................................................................................. - 12 -

V. SENSOR ASSEMBLY REPLACEMENT....................................................................- 13 -

A. HOW TO REMOVE THE SENSOR ASSEMBLY ............................................................................................ - 13 -

B. HOW TO INSTALL THE SENSOR ASSEMBLY .............................................................................................. - 14 -

VI. SPRAY NOZZLE REPLACEMENT .........................................................................- 15 -

A. HOW TO REPLACE THE NOZZLE ........................................................................................................... - 15 -

VII. HEATER ASSEMBLY REPLACEMENT..................................................................- 16 -

A. HOW TO REMOVE THE HEATER ASSEMBLY............................................................................................. - 16 -

B. HOW TO INSTALL THE HEATER ASSEMBLY .............................................................................................. - 17 -

VIII. DISPLAY CONTROL PANEL REPLACEMENT.......................................................- 18 -

A. HOW TO REMOVE THE DISPLAY CONTROL PANEL.................................................................................... - 18 -

B. HOW TO INSTALL THE DISPLAY CONTROL PANEL ..................................................................................... - 19 -

VIIII. PCB ASSEMBLY REPLACEMENT......................................................................- 20 -

A. HOW TO REMOVE THE PCB ASSEMBLY................................................................................................. - 20 -

B. HOW TO INSTALL THE PCB ASSEMBLY .................................................................................................. - 21 -

X. POWER SWITCH REPLACEMENT ........................................................................- 22 -

A. HOW TO REMOVE THE POWER ENTRY MODULE (PEM) SWITCH............................................................... - 22 -

B. HOW TO INSTALL THE POWER ENTRY MODULE (PEM) SWITCH................................................................. - 23 -

XI. FUSE REPLACEMENT ........................................................................................- 24 -

A. HOW TO REPLACE THE FUSES ......................................................................................................... - 24 -

AZ 85284

3

XII. TROUBLESHOOTING STEPS..............................................................................- 25 -

A. PUMP TROUBLESHOOTING................................................................................................................. - 26 -

B. HEATING ELEMENT TROUBLESHOOTING ................................................................................................ - 32 -

C. TEMPERATURE SENSOR TROUBLESHOOTING........................................................................................... - 36 -

D. WATER LEVEL SENSOR TROUBLESHOOTING ........................................................................................... - 39 -

E. NO POWER TO SCA TROUBLESHOOTING............................................................................................... - 40 -

F. NO POWER TO DISPLAY TROUBLESHOOTING OR ES ERROR........................................................................ - 47 -

XIII. DOCUMENTATION..........................................................................................- 49 -

A. ERROR CODES ................................................................................................................................. - 49 -

B. SCHEMATICS.................................................................................................................................... - 50 -

C. PCB LAYOUT ................................................................................................................................... - 52 -

D. J6 DISPLAY CONTROLLER PINOUT........................................................................................................ - 53 -

E. COMMONLY USED PARTS................................................................................................................... - 54 -

XIV. SUPPLEMENTARY INFORMATION ...................................................................- 56 -

A. SPECIFICATIONS ........................................................................................................................... - 56 -

B. CUSTOMER SUPPORT .................................................................................................................... - 57 -

C. WARRANTY INFORMATION............................................................................................................. - 58 -

AZ 85284

4

I. Preliminary Steps

Follow these steps before attempting to service the SCA

Power off and disconnect the SCA from the main power.

Allow the SCA to cool completely.

Attach a hose to the front valve and drain the tank completely.

Always disconnect the SCA from the main power and drain the tank

completely before servicing.

AZ 85284

5

II. Quick Troubleshooting

The SCA has been designed to allow the end user to resolve most operating problems. When a problem is

encountered, please read through this repair manual. If a resolution is not found in this manual, please

contact technical support.

High Risk of Electrical Shock

Always disconnect the unit from power

before removing any cover!

Problem

Probable

Causes

What to Do

No Power to SCA

Power switch is

not “On”

Press rocker switch on the back of the unit to the “On” position

(LED lit).

Power cord is

not connected to

unit or wall

If the power switch LED is not lit when the power rocker switch

is turned on, check the power cord, and make sure it is pushed

all the way into the receptacle on the system and is securely

connected to a grounded wall socket. Check the power at the

outlet. Check your building circuit breakers, and any power

circuit that the unit is plugged into for a tripped circuit breaker or

blown fuse. Reset or replace the breaker or fuse as required.

Fuse is blown

With the power disconnected, check the continuity of F1, F2

(both mounted to the chassis) and FB1 and FB2 (both on the

PCB).

Thermal Cutoff

Switch (TCO) is

tripped or

defective

A resettable Thermal Switch located on the back wall of the tank

removes power from the SCA if the temperature of the bath

exceeds 90⁰C. Wait for the bath temperature to cool to < 80⁰ C.

Reset TCO, or ohm out TCO (See Check the Continuity of the

Thermal Cutoff Switch Section XII E pg. 44).

PEM Defective

(See Check the Continuity of the PEM Section XII E pg. 45)

AZ 85284

6

Problem

Probable

Causes

What to Do

Pump will not

start, SCA is

powered up,

display panel is

lit.

Timer has not

been set and

started

The system will only run when the timer is counting down.

Check the timer display on the control panel.

If it is not counting down, press the button. If the time being

displayed is 00:00, then add time and start the system as

described in the User Manual.

Pump is

defective

(See Measure the Pump Motor Resistance Section XII A-3

pg. 27).

Run Capcitor is

defective

(See Test the Pump Motor Run Capacitor Section XII A-5 pg.

30).

PCB is defective

(See Test the Input Voltage to the Pump Motor Section XII A-

4 pg. 28).

Control Panel is

defective

(See Check the Pump Motor Enable Signal Section XII A pg.

27).

AZ 85284

7

Problem

Probable

Causes

What to Do

Warning Indicator

Flashing

High Water

or Low Water

Indicator flashing

Liquid level is

too high or too

low, audible

alarm sounding

Check if the indicator lights are flashing on the right side of the

Display Control Panel. Press the Silence Alarm Button. If either

level indicator is still flashing, add or remove water from the tank.

If the indicator stops flashing, the level sensors are satisfied and

normal operation can resume by pressing the Start Button .

ALWAYS WEAR PROTECTIVE GLOVES AND EYEWEAR

WHEN ADDING OR REMOVING LIQUID FROM THE TANK.

Basket is raised

or lowered too

quickly

If the basket is lowered into or raised out of the cleaning solution

too quickly, the solution does not fill or empty out fast enough to

maintain even water level throughout the tank. This causes a

temporary high or low water level condition. Press the Silence

Alarm Button. If either level indicator is still flashing, add or

remove water from the tank. If the indicator stops flashing, the

level sensors are satisfied and normal operation can resume by

pressing the Start Button .

Float movement

is impeded by

buildup on shaft

Remove float (See How to Remove the Sensor Assembly

Section V-A pg. 13) and inspect. If there is a buildup on the

shaft that inhibits the free up and down motion of the float, clean

off the shaft. A soft scrub pad can be used to remove any

buildup on the shaft. Ensure the float moves freely from the

bottom to the top of the shaft.

Water level

sensor is

defective

(See Water Level Sensor Troubleshooting Section XII D pg.

39).

AZ 85284

8

Problem

Probable

Causes

What to Do

Warning Indicator

Flashing

Error Code

Displayed

Audible Alarm

Internal Error

Sensor failure, power supply failure, or pump failure.

(See Error Codes Section XIII A pg. 50).

Error Codes:

*EP = Pump motor current fault

*EH = Heater current fault

ES = 12VDC out of range, power supply error

EO = Over temperature

r1 = Temperature sensor failure

r2 = High level sensor failure

r3 = Low level sensor failure

*Only displayed on the original controllers without the “No Heat”

option

Not Heating,

Over Heating,

Not reaching set

temperature.

Heater elements

have failed

(See Heating Element Troubleshooting Section XII B pg. 32).

Temperature

sensor is

defective

(See Temperature Sensor Troubleshooting Section XII C pg.

36).

Parts take longer

than normal to

dissolve support

material. White

deposits noticeable

on dark-colored

parts.

The cleaning

solution is likely

saturated with

support material.

Drain the tank and add fresh water and cleaning solution as

described in the User Manual. Generally, if using WaterWorks,

when the PH balance of the bath reaches 11.5, the effectiveness

of the dissolution drops dramatically.

Type of cleaning

agent.

If using Eco Works, try switching to Waterworks. Both are sold

by Stratasys resellers. Waterworks is a more efficient cleaning

concentrate.

The flow in the tank

appears less than

normal.

Nozzle not

latched, angle is

wrong, missing

or broke O-Ring.

Remove the nozzle and inspect. The nozzle will not latch

correctly if the O-Ring is not present or is damaged. Ensure the

nozzle is rotated to the correct angle. (See Figure 8, pg. 15).

AZ 85284

9

III. Removing Top Cover and Back Panel

A. How to Remove the Back Panel

1. Remove the Back Panel

a. With the SCA unplugged from power, remove the two screws on the top center and bottom

center of the panel.

b. Loosen the remaining six M4 screws around the outside edges.

c. Push up on the back panel and remove.

Figure 1 – Removing the Back Panel

AZ 85284

10

B. How to Remove the Top Cover

1. Remove the Top Cover

a. With the SCA unplugged from power, remove the J6 display ribbon cable from the PCB.

b. Remove the three M5 screws holding the top cover to the SCA.

c. Carefully remove the cover by pushing lightly on the back of the cover, ensure the J6 ribbon

cable does not snag on any components.

Figure 2 – Removing the Top Cover

J6 Connector PCB

AZ 85284

11

IV. Pump Assembly Replacement

A. How to Remove the Pump Assembly

1. Remove the Pump Assembly

a. Unplug the SCA from power and remove the back panel (See How to Remove the Back Panel

Section III A).

b. Remove the top cover (See How to Remove the Top Cover Section III B).

c. Disconnect the pump motor connector from the PCB Assembly.

d. Remove the screw holding the motor ground wire.

e. Gently pull the motor wires through the Bridge slot.

f. Unplug the three connectors to the sensors from the PCB.

g. Gently pull the sensor wires through the Bridge slot.

h. Remove the four M5 screws holding the pump assembly and ground wire (See Figure 4).

i. Grip the motor and carefully remove the pump assembly. The motor gasket may stick a little.

Rocking the motor back and forth slightly will help loosen the gasket.

Motor

Connector

Motor

Ground

Figure 3 – PCB Assembly

Bridge

Slot

Sensor

Connectors

AZ 85284

12

j. Grip the pump assembly by the motor and carefully guide the pump assembly through the hole

in the bridge.

B. How to install the Pump Assembly

1. Install the Pump Assembly

a. Grip the pump assembly by the motor and carefully guide the pump through the Bridge hole until

the tray is seated on the gasket on top of the Bridge.

b. Mount the pump assembly to the Bridge using the four M5 mounting screws and washers.

Ensure the gasket is aligned with the screw holes in the Bridge.

c. Thread the motor and sensor wires through the Bridge slot. Be careful not to rip off any wire

labels.

d. Attach the ground wire from the motor cable to the ground connection on the frame.

e. Plug in the connector from the motor to the PCB.

f. Plug in the 3 sensor connectors to the appropriate slots on the PCB.

g. Slide the back panel on and secure (See How to Remove the Back Panel Section III A).

h. Plug the J6 ribbon cable from the display back into the PCB.

i. Place cover back on the SCA and secure (See How to Remove the Top Cover Section III B).

NOTE:

The tray gasket may cause the

pump assembly to stick to the

bridge. If this happens, loosen the

gasket by gently rocking the

assembly back and forth.

M5 Screws

(4 places)

Figure 4 – Remove the Screws and Remove the Pump Assembly

Bridge

Bridge

Slot

AZ 85284

13

V. Sensor Assembly Replacement

A. How to Remove the Sensor Assembly

1. Remove the Sensor Assembly

a. Remove the back panel (See How to Remove the Back Panel Section III A).

b. Remove the top cover (See How to Remove the Top Cover Section III B).

c. Unplug the three sensor connectors from the PCB (See Figure 5).

d. Remove the four M5 screws holding the sensor assembly (See Figure 6).

e. Carefully pull the sensor wires through the Bridge slot.

f. Carefully remove the Sensor Assembly from SCA.

M5 Screws

(4 places)

Sensor

Connectors

Figure 5 – Top View of SCA with Top Cover Removed

Bridge

Slot

AZ 85284

14

B. How to install the Sensor Assembly

1. Install the Sensor Assembly

a. Insert the Sensor Assembly into the motor tray.

b. Mount the Sensor Assembly using the four M5 screws.

c. Carefully thread the sensor wires through the Bridge slot. Be careful not to rip off any wire labels.

d. Plug in the 3 sensor connectors into the appropriate slots on the PCB.

e. Plug in the J6 display ribbon cable back into the PCB.

f. Slide the top cover panel and secure (See How to Remove the Top Cover Section III B).

g. Slide the back panel on and secure (See How to Remove the Back Panel Section III A).

NOTE: The gasket is

attached to the Sensor

Assembly.

Figure 6 – Remove the Sensor Assembly

Bridge

Slot

AZ 85284

15

VI. Spray Nozzle Replacement

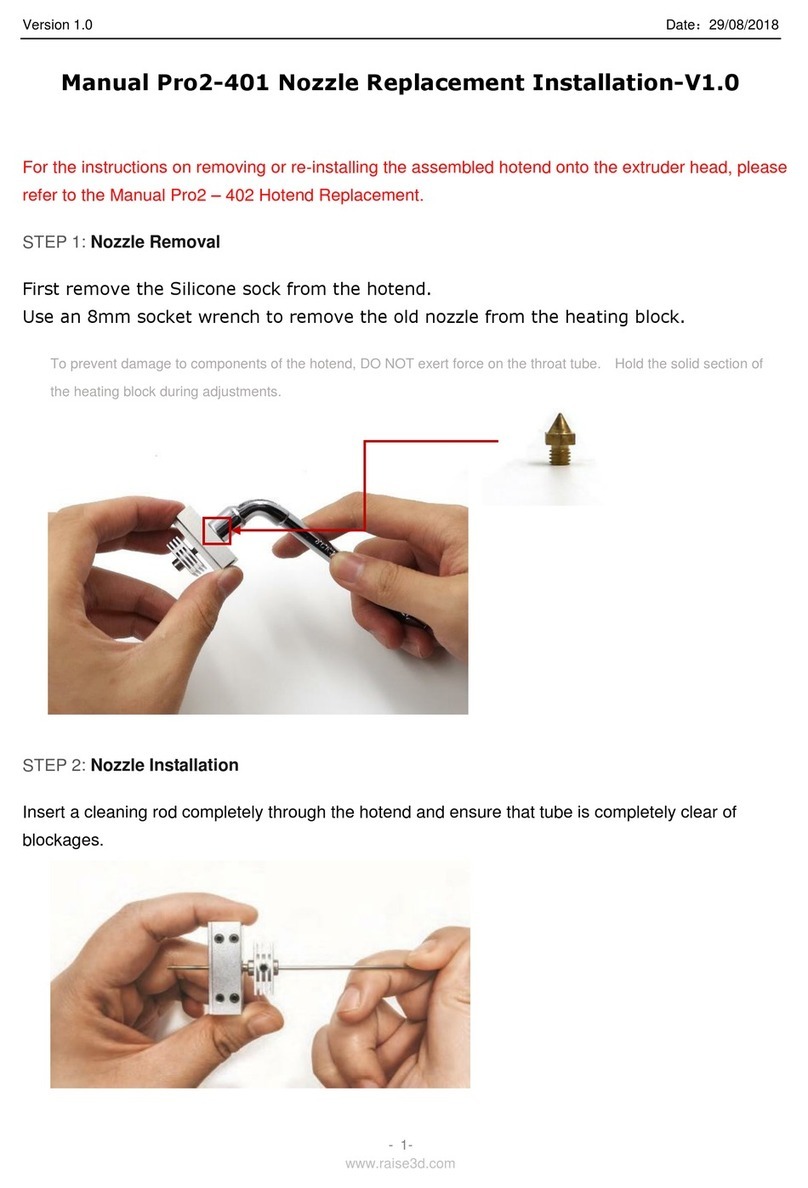

A. How to Replace the Nozzle

1. Replace the Nozzle

a. The 3600 has a Bayonet style nozzle that latches on to the pump output opening. Twist the

nozzle counterclockwise to unlatch and clockwise to latch. The nozzle O-ring must be in place to

securely latch the nozzle to the pump manifold. Ensure the nozzle is correctly orientated (See

Figure 8).

Figure 7 – Replacing the Spray Nozzle

Figure 8 – Correct Rotation of the Spray Nozzle

O-ring

AZ 85284

16

VII. Heater Assembly Replacement

A. How to Remove the Heater Assembly

1. Remove the Heater Assembly

a. Unplug the SCA from power and remove the back panel (See How to Remove the Back Panel

Section III A).

b. Remove the top cover (See How to Remove the Top Cover Section III B).

SHOCK HAZARD! PLEASE ENSURE POWER PLUG IS REMOVED FROM THE SCA.

c. Unplug the heater’s two connectors from the PCB Assembly.

Figure 9 – Heater Connectors

d. Gently pull the heater wires through the Bridge slot.

e. Remove the four M5 screws holding the Heater Assembly and ground wire (See Figure 10).

Heater

Connectors

Bridge

Slot

AZ 85284

17

ALLOW THE HEATING ELEMENT FOR COMPLETELY COOL BEFORE REMOVING.

f. Carefully remove the Heater Assembly from SCA

B. How to Install the Heater Assembly

1. Install the Heater Assembly

a. Carefully guide the Heater Assembly through the hole in the Bridge until the plate is seated on the

gasket on top of the bridge.

b. Mount the Heater Assembly to the Bridge using the four M5 mounting screws and attach the

ground wire to the tray.

c. Carefully pull the heater wires through the Bridge slot.

d. Plug the two heater wire connectors back into the PCB.

e. Plug the J6 ribbon cable from the display back into the PCB.

f. Place the top cover back on and secure (See How to Remove the Top Cover Section III B).

g. Place the back panel on to the SCA (See How to Remove the Back Panel Section III A).

M5 Screws

(4 places)

Figure 10 – Top View of the SCA with the Top Cover Removed

Figure 11 – Remove the Heater Assembly

AZ 85284

18

VIII. Display Control Panel Replacement

A. How to Remove the Display Control Panel

1. Remove the Display Control Panel

a. Unplug the SCA from power and remove the back panel (See How to Remove the Back Panel

Section III A).

b. Remove the J6 ribbon cable from the PCB.

c. Remove the top cover (See How to Remove the Top Cover Section III B).

d. Turn the cover over and remove the six M4 screws that attach the display to the bezel from the

inside.

Figure 12 – Remove Screws

e. Pull off the bezel and slide the display out of the cover.

Screws

Bezel

AZ 85284

19

B. How to Install the Display Control Panel

1. Install the Display Control Panel

a. Thread the J6 ribbon cable through the hole in the front of the top cover where the display will be

mounted.

b. Check the orientation of the display and place the bezel over the display, ensuring the bezel

screw holes align with the holes in the top cover.

c. Turn the cover over and secure the display to the bezel with the six M4 screws from the inside.

d. Thread the display ribbon cable through the Bridge slot and plug the J6 ribbon cable from display

into the PCB.

h. Place the top cover back on and secure (See How to Remove the Top Cover Section III B).

f. Place the back panel on SCA and secure (See How to Remove the Back Panel Section III A).

AZ 85284

20

VIIII. PCB Assembly Replacement

A. How to Remove the PCB Assembly

1. Remove the PCB Assembly

a. Remove back panel (See How to Remove the Back Panel Section III A).

b. Check the wires to make sure the labels are on the wires connected to the PCB.

c. Remove all the wire connectors from the PCB, be careful not to rip off a wire label.

d. Remove the screw that holds on the run capacitor to the PCB (See Figure 13). This screw is

longer than the other screws.

e. Remove the remaining eight screws that hold the PCB to the back plate standoffs (remove the

center screw last).

Figure 13 – Remove Screws and Remove PCB

f. Grip the edge of the circuit board and pull the board out. Make sure not to damage any wires as

the board is removed.

Run

Capacitor

Standoffs

Other manuals for sca3600

2

Table of contents

Other Oryx 3D Printer manuals