Blocks ONE MKII User manual

ONE MKII

USER GUIDE

MANUAL DE UTILIZADOR

English 03-32

Português 35-65

USER GUIDE MANUAL DE UTILIZAÇÃO ONE MKII

03

Limitation of liability

Please read the user manual and all the documentation that accompanies your Blocks

product. If you don’t do it, you’re assuming the risk of ireversibly damage the equipment

that can lead to accidents and injuries. The user must also make sure that anyone who

operates the equipment is able to do so, and understands all the contents described in the

user manual.

The user manual of this product refers to the “Blocks one MKII” 3D printer. For the correct

use of the equipment, the user must follow this user manual strictly. This electro-mechani-

cal equipment is intended for the creation of digitally shaped parts or models through the

deposition of molten thermoplastics. Despite the quality we believe we have achieved with

this machine, the qualication of the work performed on this machine for a specic pur-

pose is the user responsibility.

The indications in both this user manual are derived from our experience and from sources

we consider reliable, but if you have any questions please contact Blocks or one of our deal-

ers.

This equipment has been tested and found to comply with the standards regarding the

CE marking, the collection of electrical and electronic equipment waste and the collec-

tion of recyclable packaging.

01 06

07

11

11

11

Unpacking

Add a machine

Print prole conguration

Build platform calibration and leveling

Calibrate probes

Level plate

Nozzle Adjustment

Doing a print

Setting up the printer directly on the screen

20

20

23

24

26

Security

Installation

29

31

29

29

29

29

Rod Lubrication

Belt tensioning

Cleaning and maintenance of the extruder

Nozzle clearing

30

32

29

11

13

14

16

18

02

03

04

05

Troubleshooting

06

Introduction

Operation

Maintenance

ONE MKII USER GUIDE MANUAL DE UTILIZAÇÃO

06

Security

1. Blocks one MKII should always be used with the accessories supplied with the printer.

2. Never use damaged power cords.

3. This machine have moving components that can cause injury if handled while the printer

is operating.

4. The nozzle in Blocks one MKII operates at high temperatures, so it should never be

touched in the heating and cooling processes or while the machine is printing.

5. Never access the electronics area while the machine is on or with the power cord

connected to the mains power

6. Do not use the printer in explosive environments or near chemicals that may react to

high temperatures or electrical surges.

7. Do not leave liquids near the printer.

8. The printing process should always be supervised.

9. The printer should be installed in a well-ventilated area, as vapors that are harmful to

health may be released during the printing process. The recommendations of the

material manufacturer must always be followed.

10. Do not install the printer in direct contact with solar radiation or in an environment that

may exceed the recommended operation temperature, It may occur deformation of

some printed parts that can cause damage to the equipment.

11. Note the following symbols:

Security01

This symbol indicates the presence of moving parts inside

the machine.

This symbol indicates the presence of parts

with high temperatures.

This symbol indicates the possibility of electric shock.

USER GUIDE MANUAL DE UTILIZAÇÃO ONE MKII

07

Blocks one MKII illustration

Introduction02

1

2

3

4

5

6

7

8

3

5

6

7

8

1

4

2

Set of cables for printhead electronics components.

Filament passage tube between the extruder and the hotend.

Set of components that allow melting, deposition and solidication of the

lament.

Assembly of components that applies the force required for the lament

to move in the system.

Set of components that includes the plate that serves as the platform for

the prints.

To insert the SD card with the gcode le to be printed.

Where you can see information about machine status and printing process.

For navigation and selection in the menus visible on the LCD screen.

Cable guide

PTFE tube

Printing head (Hot End)

Extruder

Build platform

SD card slot

LCD Screen

Selection button

ONE MKII USER GUIDE MANUAL DE UTILIZAÇÃO

08

Extruder illustration

Fitting

Pinion

Bearing

Hinge

Filament runout sensor

Component for xation of the PTFE tube to the extruder.

Component that transmits the motor rotation and imposes linear motion

on the lament.

Accompanies the movement of the lament imposed by the pinion.

Component that allows to relieve tension in the lament facilitating its

insertion.

Filament sensor that detects if the lament nished or broke and puts

the printer in pause.

Introduction02

1

2

3

4

5

1

2

3

5

4

USER GUIDE MANUAL DE UTILIZAÇÃO ONE MKII

09

Hot End illustration

PTFE tube

Electronic cables

Fitting

Heatsink

Hot End fan

Belt tension screw

Part cooling blower fan

Heatbreaker

Heat block

Z-probes

Nozzle

Is where the lament moves between the extruder and the hot end.

Set of cable for printhead electronics components.

Fixation component between the PTFE tube and the hot end.

This component serves to thermally insulate the heating block and nozzle

from the remaining components of the printhead. Note: the operator

must make sure that the fan connected to the heatsink is running when-

ever the machine is switched on.

Fan that promotes the cooling of the hot end heatsink.

Screws that allows to adjust the tension of the timing belts.

Fan that promotes the cooling of the molten lament at the nozzle exit.

Connecting element between the heatsink and the heating block. The

interior has a PTFE part. Note: this component must always be mounted

with the PTFE part facing the nozzle.

Where the heating element and the hot end temperature sensor are locat-

ed and allows the temperature control of the lament extrusion.

Electro-mechanical sensors responsible for the vertical axis positioning,

print platform calibration and auto bed leveling

Replaceable component with a reduced diameter that allows accurate

deposition of the melted plastic. Note: the tightening tension should

always be between the nozzle and the heatbreaker and not between the

nozzle and the heating block.

Introduction02

1

2

3

4

5

6

7

8

9

10

11

1

2

3

4

5

6

11

10

9

8

7

10

ONE MKII USER GUIDE MANUAL DE UTILIZAÇÃO

Technology

Build Volume (x, y, z)

Material diameter

Layer resolution

Traveling speed

Build plate

Material types

Nozzle diameter

Hot end temperature

Hotend heating time

Building plate heating time

Material storage

Connectivity

Build plate leveling

Power requirements

External dimensions of the printer

(including Bowden tube and coil holder)

Weight

Operational conditions

Printer storage conditions

Firmware

Recommended slicer

Supported Operating System

File types for slicer

Fused lament fabrication

200 x 210 x 210 mm

1,75 mm

Nozzle 0,4 mm: 40-300 mícrons

180 mm/s

Glass plate 3 mm

PLA, Wood and Metal Filaments,

Flex, PETG, ABS, Nylon

0,4 mm

180–285°C

< 2 min

45º 1,5 min | 90º 4,5 min

Filament spool holder

SD card, USB

Auto and Manual - rmware assisted

In: AC 100-240V, 4A, 50/60Hz

Fuse: 2 un. 5x20mm/10A

Aprox. 40x50x50cm (x,y,z)

14 Kg

15 - 30 °C, 10 - 90%

5 - 35 °C

Marlin based rmware

Cura

Windows, Mac OSX, Linux

gcode

Environmental Conditions

Software

Introduction02

Properties

Dimensions

11

USER GUIDE MANUAL DE UTILIZAÇÃO ONE MKII

When receiving the Blocks one MKII printer you must make sure that you open the carton

box by the correct side. Doing so in this way ensures that the unboxing will be done without

damaging the equipment.

03.1 Unpacking

1. Open the carton box by the correct side.

2. Carefully remove the protective foam from the top. Carefully remove the machine from

the carton. Take special care to remove the accessories that are on the printing platform.

3. During the unboxing and instalation process, if any components are missing or damaged,

contact the dealer where you purchased the equipment or Blocks immediately.

4. Follow all the installation and conguration steps of the machine in the correct order as

described in the equipment documentation.

5. Inside the package you will nd the following accessories: tweezers, SD card, spatula,

declogging needles, spool holder, USB cable and power cable.

03.2 Conguration and calibration

, but it may be undergoing updates so

we advise you to visit the equipment page on our website and check if the installed version

(can be seen on the screen when the printer is switched on) is the latest version available.

After you have unboxed the Blocks one MKII you will need to go to our website to the prod-

uct page and download the software for preparing the 3D printing les and also download

the pre-congured printing proles for the different materials and resolutions.

Software conguration

To congure the recommended preparation software (Cura) follow these steps:

1. Add a machine

1.1. First of all, make sure you have the right version of Cura installed (v3.3.1).

1.2. Open the software and click Settings » Printer » Add Printer

1.3. Select Custom » Custom FDM printer

1.4. Write the name for it (ex: Blocks one MKII) and press Next

1.5. Fill in the data for Printer and Extruder settings as shown in the next page images.

You can nd the texts to Start and End G-Code in page 13.

Installation03

12

ONE MKII USER GUIDE MANUAL DE UTILIZAÇÃO

Printer settings tab

Extruder settings tab

Installation03

13

USER GUIDE MANUAL DE UTILIZAÇÃO ONE MKII

Attention: Copy and Paste the following text in the respective boxes for Start G-code and

End G-code (but only for the Printer tab, not for the Extruder tab):

Start G-code:

G21 ;metric values

G90 ;absolute positioning

M82 ;set extruder to absolute mode

M107 ;start with the fan off

G28 X0 Y0 ;move X/Y to min endstops

G28 Z0 ;move Z to min endstops

G29

G1 X-14 Y0 F6000

G1 Z0.1

G92 E0 ;zero the extruded length

G1 F2000 E10 ;extrude 10mm of feed stock

G92 E0 ;zero the extruded length again

G1 Z0.2 F6000

G1 F6000

M117 Printing...

End G-code:

;End GCode

M104 S0 ;extruder heater off

M140 S0 ;heated bed heater off (if you have it)

G91 ;relative positioning

G1 E-1 F300 ;retract the lament a bit before lifting the nozzle, to release some of the pressure

G1 Z+0.5 E-5 X-20 Y-20 F6000 ;move Z up a bit and retract lament even more

G28 X0 Y0 ;move X/Y to min endstops, so the head is out of the way

M84 ;steppers off

G90 ;absolute positioning

2.1. Download to your computer the Blocks one MKII print proles provided by Blocks

2.2. In the top tabs in Cura software select: Settings » Prole » Manage Proles

2.3. Click the tab Import and select the desired proles to import to the software

2.4 After that you can choose the correct prole for the desired material and quality by click-

ing Activate in the same menu or by clicking Settings » Prole and choosing the desired

prole immediately.

Installation03

14

ONE MKII USER GUIDE MANUAL DE UTILIZAÇÃO

Installation03

Build platform calibration and leveling

Plate calibration and leveling is one of the most important processes in 3D printing. By

making sure the plate is leveled, you are ensuring that the entire surface of the platform is

at the ideal nozzle distance.

We advise the operator to regularly level the plate. This is crucial for the rst layer of the

printed object to have an optimal adhesion to the printing plate and to ensure the printing

is successful.

Attention: It is mandatory to follow this process in the same order as shown here.

1. Calibrate probe

1.1. In the menu select Plate » Calibrate Probes.

1.2.Follow the instructions on the screen, as shown below.

1.3. Place the calibration piece in the right place as illustrated in the next page.

Attention: Make sure that the glass is in the heated plate and properly align with it and

also the bulldog clips are in the position as shown in the next page.

2

Main Screen

4

3

5

1

15

USER GUIDE MANUAL DE UTILIZAÇÃO ONE MKII

Installation03

Calibration piece positioning

Heated plate and glass alignment

Correct

Incorrect

16

ONE MKII USER GUIDE MANUAL DE UTILIZAÇÃO

Installation03

2. Level plate

2.1. In the menu select Plate » Level Plate

2.2. Follow the indications on the screen to adjust the height of the plate by turning the

Plate knob adjacent to the nozzle position in the correct direction (you will have to

adjust three knobs)

Attention: Execute this step (level plate) at least two times.

Plate knobs that should be adjusted

17

USER GUIDE MANUAL DE UTILIZAÇÃO ONE MKII

Installation03

2

4

3

5

1

Main Screen

6 7

18

ONE MKII USER GUIDE MANUAL DE UTILIZAÇÃO

3.1. In the menu select Plate » Nozzle Ajustment.

3.2. If the nozzle appears to have a lot of residues that can affect it's distance to the plate

please select the option "No" to properly clean the nozzle from all residues. (See page 29

for the nozzle cleaning procedure.)

3.3. Put a thin paper sheet between the nozzle and build plate.

3.4. By rotating the LCD knob, adjust the distance of the plate to the nozzle until you feel a

light pressure on the paper.

Installation03

Paper sheet between the nozzle and build plate

19

USER GUIDE MANUAL DE UTILIZAÇÃO ONE MKII

Installation03

2

4

3

5

1

6 7

8

Main Screen

20

ONE MKII USER GUIDE MANUAL DE UTILIZAÇÃO

Begin by connecting the power supply supplied with the equipment into the power plug and

into the wall outlet. Then turn the printer on by clicking the switch on the back of the machine.

04.1 Loading the lament

1. Press the selection button once, rotate until you select Filament and press it again.

2. Then select the Load or Unload option and press the button again.

3. Choose the type of material to be Loaded or Unloaded

4. Wait while the hotend reaches the set temperature

5. For the Loading procedure, insert the lament into the extruder pulling the hinge at the

same time, and just

above the extruder.

6. Wait while the lament is routed along the PTFE tube in the Bowden.

7. After the lament begins to exit through the nozzle, the operator may choose to terminate

the process or wait for the machine to do it after thirty beeps.

Illustrated steps in the next page

Note: If there is a change in the lament color or material, we recommend that you allow this last step

to be taken until the machine has nished.

Operation04

Other manuals for ONE MKII

2

Table of contents

Languages:

Other Blocks 3D Printer manuals

Blocks

Blocks Pro S30 User manual

Blocks

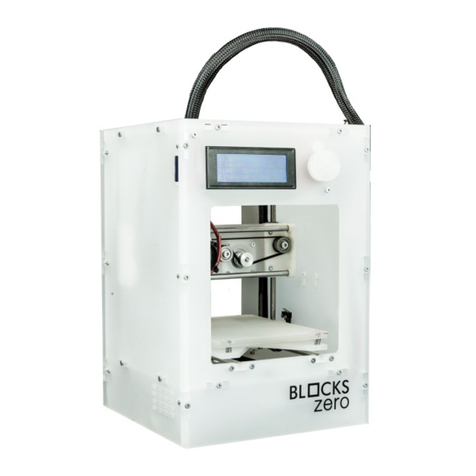

Blocks ZERO User manual

Blocks

Blocks ONE MKII User manual

Blocks

Blocks PRO 30 User manual

Blocks

Blocks R21 User manual

Blocks

Blocks Pro S30 User manual

Blocks

Blocks ONE MKII User manual

Blocks

Blocks RD50 User manual

Blocks

Blocks One User manual

Blocks

Blocks ZERO User manual