OSAKA VACUUM TC163H User manual

H07401<2>

OPERATION MANUAL

SERIAL COMMUNICATION

POWER SUPPLY

FOR MOLECULAR PUMP

TC163H/TC203/TC223/TC353/TC523H/TC1104

TC443S/TC553/TC1003/TC1103/TC1503H/TC1813/TC3213

Before using the pump and the power supply, read carefully and understand

thoroughly the cautions in this manual.

Save this manual for future use and reference.

OSAKA VACUUM, LTD.

All manuals and user guides at all-guides.com

all-guides.com

H07401<2>

1

Definitions and symbols

In this manual, "Caution" and "Warning" are defined as follows:

Warning : To prevent an accident resulting in injury or death

If you don't follow it, it will cause an accident resulting in injury or death.

Caution : To prevent damage to the pump or power supply

If you don't follow it, it will cause damage to the pump (or power supply)

or injury.

Warning

Important description for preventing an accident resulting in injury or death when you

use the pump and power supply.

Caution

Important description for safe operation of pump and the power supply.

Caution

Before using the pump and power supply, be sure to read this manual for safe operation

of the pump and power supply. Operations not following the procedures in this manual

may cause a failure or accident resulting in injury etc.

All manuals and user guides at all-guides.com

H07401<2>

2

CONTENTS

Page

1.Preface------------------------------------------------------------------------- 3

2. Operation mode ------------------------------------------------------------- 3

3. Interface specifications ---------------------------------------------------- 5

3-1. Transmission specifications

3-2. Connector specifications

3-3. Cable specifications

4. Preparation ------------------------------------------------------------------ 6

4-1. Cable connection

4-2. Transmission configuration

5. Protocol specifications ----------------------------------------------------- 9

6.Commands-------------------------------------------------------------------- 9

6-1. Operation command

6-2. Monitor command

6-3. Error codes

6-4. Pump status

6-5. Alarm codes

7. Troubleshooting ------------------------------------------------------------11

All manuals and user guides at all-guides.com

H07401<2>

3

1. Preface

The power supply has a serial interface in conformity with RS232C. It operates the power

supply and monitors operational information through the upper host computer. In all operation

modes, all commands are effective except START and STOP.

1) Operations

Start/stop the pump

2) Monitor of operational information

Status (Standby / Acceleration / Normal / Brake / Reacceleration /Failure)

Details of failure

Total operational time of the power supply

Output frequency(Rotating speed)

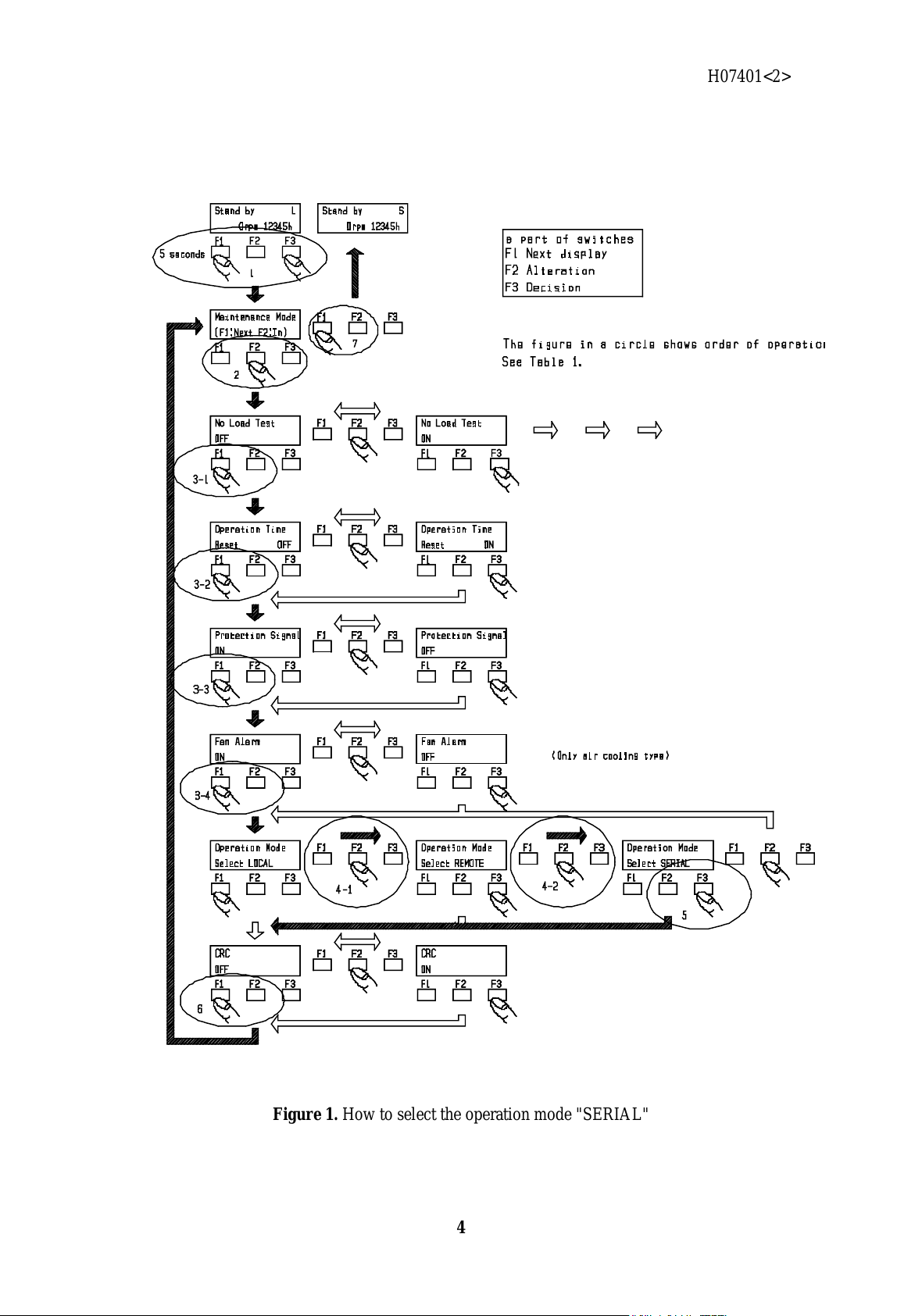

2. Operation mode

To operate on serial communication mode, it is necessary to select the operation mode

"SERIAL". How to select the operation mode "SERIAL" is shown in Table1 and Figure1.

Operation Explanation Display

1 Press the function buttons F1 and F3

(press the F3 button before F1

button.) simultaneously over 5

seconds when “Standby” is indicated

on display.

Select MAINTENANCE

MODE Maintenance Mode

(F1:Next F2:In)

2 Press the F2 button Enter into MAINTENANCE

MODE No Load Test

OFF

3 Press the F1 button four times Select Operation mode Opration Time

Reset OFF

/

Protection Signal

ON

/

Fan Alarm

OFF

/

Operation Mode

Select LOCAL

4 Press the F2 button twice Select SERIAL Operation Mode

Select REMOTE

/

Operation Mode

Select SERIAL

5 Press the F3 button Enter into SERIAL mode CRC

OFF

6 Press the F1 button Return to initial display Maintenance Mode

(F1:Next F2:In)

7 Press the F1 button Return to initial display Standby S

0 rpm 12345h

Table1. How to select the operation mode "SERIAL"

In all operation modes, all commands are effective except START(SDR1) and STOP(SDR0).

All manuals and user guides at all-guides.com

H07401<2>

4

Figure 1. How to select the operation mode "SERIAL"

All manuals and user guides at all-guides.com

H07401<2>

5

3. Interface specifications

3-1. Transmission specifications

Item Specification

Method of communication RS232C

Transmission speed 2400/4800/9600/19200(bps)

Parity bit none/odd/even

Start bit 1

Length of data bit 7/8

Length of stop bit 1/2

Protocol Refer to section 5, " Protocol specifications "

Control of flow Hard wear(RS/CS)

Note.1) "_"(under bar) is an initial value.

3-2. Connector specifications

Connector ("SERIAL" on the rear panel) D-Sub 9 pin male

(Daiichi dennshi 17JE-23090-02(D1))

Pin layout

Pin No. Signal

name(JIS) Status of signal Input/Output

1 - Not connected to inside -

2 RD Receive data Input

3 SD Send data Output

4 ER Data terminal ready Output

5 SG Signal ground -

6 - Not connected to inside -

7 RS Request to send Output

8 CS Permit to send Input

9 - Not connected to inside -

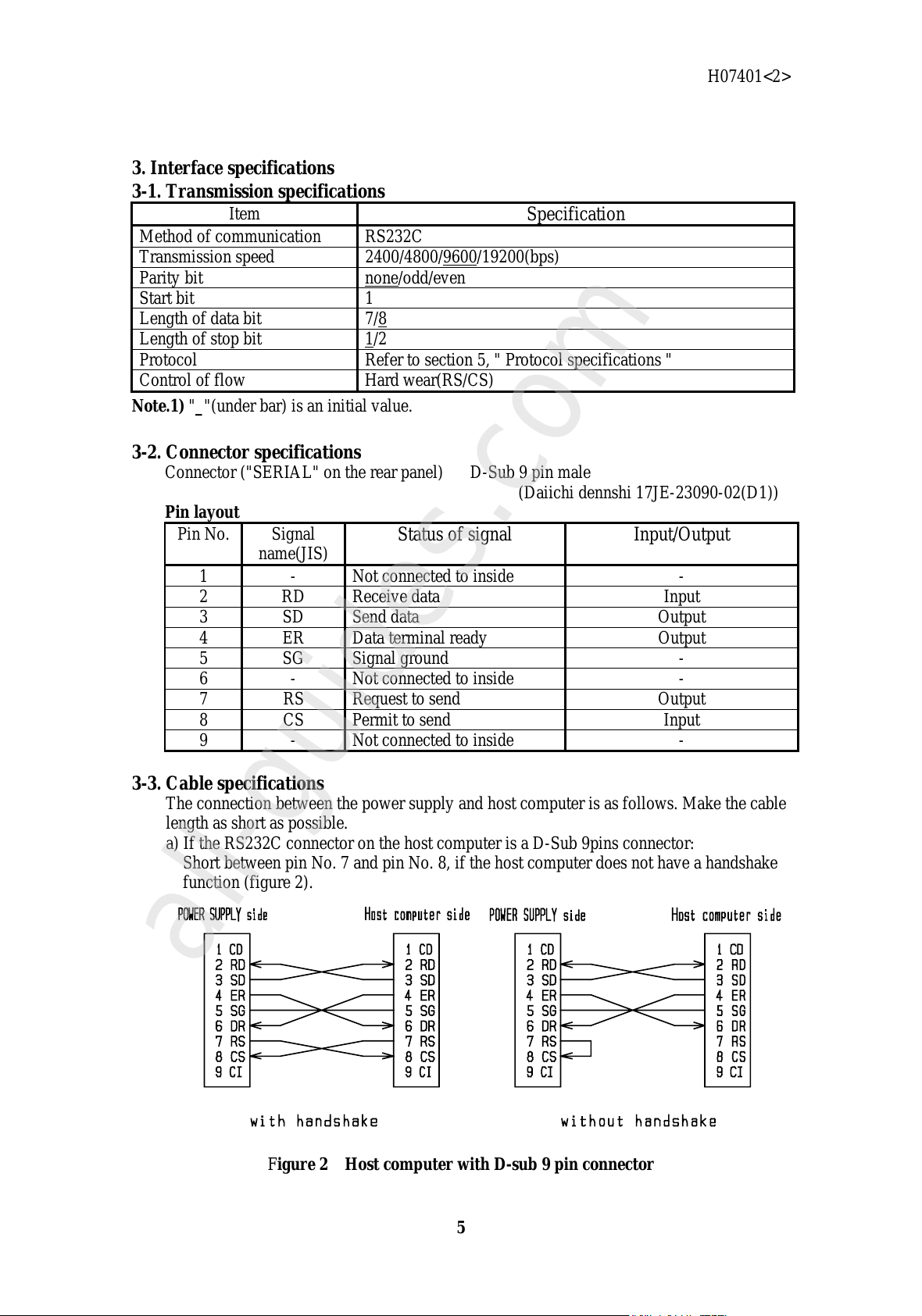

3-3. Cable specifications

The connection between the power supply and host computer is as follows. Make the cable

length as short as possible.

a) If the RS232C connector on the host computer is a D-Sub 9pins connector:

Short between pin No. 7 and pin No. 8, if the host computer does not have a handshake

function (figure 2).

Figure 2 Host computer with D-sub 9 pin connector

All manuals and user guides at all-guides.com

all-guides.com

H07401<2>

6

b) If the the RS232C connector on the host computer is a D-Sub 25 pin connector:

Short between pin No. 7 and pin. No. 8, if the host computer does not have a handshake

function (figure 3).

Figure 3 Host computer with D-sub 25 pin connector

4. Preparation

4-1. Cable connection

Cut off the input power of the power supply and the host computer. Then connect

"SERIAL" on the rear panel of the power supply to the host computer’s RS232C port with

a cable. Tighten the screws to secure the connector.

4-2. Transmission configuration

1) Push the “F1” button on front panel and change the page of the liquid crystal display.

The transmission configuration is displayed on page 3 as follows.

RS232C_Echo:OFF

9600_8 b i t_N_1sp

2) Next, push the "F2" button on front panel and change to the display for setting and

altering parameters. Parameter display changes every time the “F1” button is pushed,

like the following : " RS232C Speed " => " RS232C Length " => " RS232C Parity " =>

" RS232C Stop Bit ".

Select the parameter to alter by pushing the "F1" button (figure 4).

3) The value of the parameter changes every time the “F2” button is pushed. Select the

value to set (figure 5).

4) When the value to set is displayed, push the "F3" button to set the value.

5) Repeat the operation as described above in 2), 3), and 4) untill all parameters are set.

After all the parameters are set, push the “F1” button to return to page 1 of the display.

All manuals and user guides at all-guides.com

H07401<2>

7

Figure 4 Setting of transmission specifications

All manuals and user guides at all-guides.com

H07401<2>

8

Figure 5 Details of data setting

All manuals and user guides at all-guides.com

H07401<2>

9

5. Protocol specifications

1) String transmitted from host computer

Command (or command + parameter) + carriage return (0dh) is one unit. Use capital

letters for commands, and use capital letters or digits for parameters. No break mark is

needed between the command and the parameter.

To set two or more parameters, insert a space after each parameter.

2) String that host computer receives

Parameter (or “#” + error code) + carriage return (0dh) is one unit.

3) Sum check

The CRC method is used for checking sums (refer to the following for details). Transmit

“SCC1” from the host computer to check. Transmit “SCC0” with CRC code (*1) to end.

The power supply will send “#06” to host computer, if a CRC error has occurred.

(*1) The CRC code equivalent to "SCC0" is "b89a". In the event that CRC

communication is abnormally functioning, transmit "SCC0b89a" without the CRC

code.

<Details of the CRC method>

Make the CRC code in right-transmission with 0x8408 (in hexadecimal notation) witch is

generated from the Checking Polynomial(x16+x12+x5+1) 0x11021 (in hexadecimal notation) by

reversing right and left, according to CCITT(X.25) recommendations. To send a string, attach

the generated code (or command + parameter) as 4 byte data after the command. When

receiving, the 4byte data before the carriage return (0dh) is the CRC code.Samples of CRC code

are shown below.

Samples of CRC code

Without CRC code With CRC code

RRS RRS70ce

35 35f5a3

SCC0 SCC0b89a

6. Commands

6-1. Operation commands

Operation commands allow you to set the CRC configuration, to start/stop the pump, to

change the rated rotational speed and to confirm these operations.

Command Parameter Returned

value Function Example

(command) Example

(returned

value)

SCC [0,1] - Config CRC

[0]---Set CRC to null

[1]---Set CRC

effective

SCC1! -

SCC - [0,1] Read CRC setting SCC! 1!

SDR [0,1] - Start/stop pump

[0]---stop pump

[1]---start pump

SDR0! -

All manuals and user guides at all-guides.com

H07401<2>

10

Characters in table as above

Character Signification Character Signification

! CR [ ] Select one in [ ]

6-2. Monitor commands

Monitor commands are used to monitor the status of the pump .

Command Returned value

(normal) *1 Unit Function Example

(command) Example

(return value)

RDT d h Read the total

operational time of

pump

RDT! 100!

RSS [1,2,3,4,6,7] - Read the pump

status *2 RSS! 2!

RSA [1,#03,#12,#20

#23#30,#31,#32

#33,#34,#35,#60

#61]

- Read the failure

details

*3

RSA! #12!

RRS d Hz Read the output

frequency

(~rotating speed)

RRS! 100!

*1 Refer to section 6-3 "error code table" for returned value in case of failure.

“d” means decimal integer.

*2 Refer to 6-4 " pump status code table ".

*3 Refer to 6-5 " alarm code table ".

6-3.Error codes

When the command from the host computer is irregular, the power supply returns one of

the error codes described in the following table.

Table of error code

Code Signification

#00 There is no such command.

#01 The set parameter is irregular.

#02 The set parameter is beyond the available range.

#03 Despite failure, the operation command is inputted.

#05 The “operation mode select switch” is not set to SERIAL.

#06 The CRC code is irregular.

6-4. Pump status codes

The following table of pump status codes describes the signification of the returned value

to the command “RSS”. Table of pump status codes

Code Signification

1 Standby

2 Acceleration

3 Normal

4 Brake

6 Reacceleration

7 Failure

All manuals and user guides at all-guides.com

all-guides.com

H07401<2>

11

6-5. Alarm codes

The following table of the alarm codes describes the signification of return values to the

command "RSA". Table of alarm codes

Code Signification Code Signification

1 Normal #32 Motor temperature error

#03 Change Bearing warning #33 Excessive current

#12 Protection signal error #34 Excessive rotating speed

#20 External fan disconnected #35 Acceleration time over

#23 System error #55 P/S Fan stop error

#30 Input voltage low #60 Reacceleration time over

#31 Driver temperature error #61 No load

#03 is a code concerning only to TC223,TC353,TC1103,TC1104.

#55 is a code concerning only to TC443S,TC553,TC1003,TC1103,TC1503,TC1813,TC3213.

7. Troubleshooting

1) No string can be sent or received.

1.Check the cable connection

2.Check the transmission configuration

2) Received strings are irregular.

1.Check the transmission speed

2.Check the data bit length

3.Check the parity bit

3) Characters sometimes change and a CRC code error occurs

1.Remove noise source

2.Change the cable to shielded cable

3.Replace the cable with a shorter one

4.Reduce the transmission speed

All manuals and user guides at all-guides.com

H07401<2>

12

OSAKA VACUUM, LTD.

CA OFFICE : 911 Bern Court, Suite 140, San Jose, CA 95112

(PHONE) 408-441-7658 (FAX) 408-441-7660

HEAD OFFICE : Nissay-Yodoyabashi Bldg., 5-29, Kitahama 3-chome, Chuo-ku, Osaka

541-0041, Japan

(PHONE) +81-6-6203-3981 (FAX) +81-6-6222-3645

TOKYO OFFICE : Ginza Showa-Dori Bldg., 8-14-14, Ginza, Chuo-ku, Tokyo 104-0061,

Japan

(PHONE) +81-3-3546-3731 (FAX) +81-3-3546-1560

HACHIOUJI FACTORY : Kunugida-cho, Hachiouji-shi, Tokyo 193-0942, Japan

(PHONE) +81-426-64-5301 (FAX) +81-426-63-2016

All manuals and user guides at all-guides.com

STANDARDWARRANTYCONDITIONS

OSAKAVACUUM,LTD.

Article1Warranty

IndeliveryoftheproductindicatedintheDeliverySpecificationsand/ortheInst‑

ructionManual(Product),wewarrantthattheProductisdesignedandmanufactured

inaccordancewithourregulation,standardorruleetc.withrespecttodesign,pur‑

chase,manufactureandqualitycontrolunderISO9001StandardorISO9002Standardas

wellasthespecificationsinthesalescontract,andthatthereisnodefectindesi‑

gn,materialsormanufactureoftheProduct.

Article2Indemnification

InrelationtotheProduct,incaseanydefectindesign,materialsormanufacture

obviouslyattributabletousisfoundwithinthewarrantyperiod,oneyearfromthe

deliverydateoftheProduct(unlessotherwisestipulatedinwrittendocuments),

andanoticeofsuchdefectisimmediatelygiventous,wewill,atourelection,

correct,repairorreplacesuchdefectivepart,orreplacethewholeProductwithout

charge.ThereplacementisavailableonlyforstandardProducts,andnoreplacement

maybeallowedforanyCustom‑madeProduct.

Article3Exception

ThewarrantyandrelevantindemnificationshallbeappliedonlywhentheProductis

properlyinstalledorfixed,handled,used,storedandappropriatelymaintainedby

auserinaccordancewiththeinstructionsstipulatedintheDeliverySpecifications,

theInstructionManualoftheProduct,otherhandlinginstructionsofoursand/orthe

RelatedTechnicalDocumentswhichweprovide(RelatedTechnicalDocuments).

Unlessotherwisestipulatedinotherwrittendocument,thewarrantyandrelevant

indemnificationshallnotbeappliedtothecasesdescribedbelow;

(1)AnyfailureduetoanyusageoftheProductnotdescribedintheRelatedTechnical

DocumentsoftheProduct,oranyotherirregularusageoftheProduct;

(2)DeteriorationoftheProductduetocorrosivegases,organicsolvent,radioactive

rays,electromagneticfieldetc.;

(3)Expendablepartsandwearablepartssuchaslubricantetc.;

(4)Anyfailureduetorepairorreconstructionbyanypartyotherthanus;

All manuals and user guides at all-guides.com

(5)RepairedProducts(theStandardWarrantyConditionsforRepairedProductswill

applytotherepairedProducts);

(6)Aninsignificantdeviationfromthespecificationsinthesalescontractwhich

hasnoeffectonperformanceorfunctionoftheProduct;

(7)Anyfailureduetofire,flood,earthquake,lightningstrikeoranyotherevent

causedbyforcemajeure.

Article4ScopeofIndemnification

Thescopeofourindemnificationshallbelimitedtothecorrection,repairor

exchangeofdefectivepartsoftheProductdelivered,orreplacementofthewhole

Product(incaseofthestandardProductonly),

andshallnotincludeanycompensationfortheconsequentialdamagesandbusiness

lossesincludingthefollowing;

(1)CostsandexpensesaccruedinconnectionwiththeremovalofthefailedProduct

fromtheequipmentinwhichtheProducthasbeeninstalled;or

(2)Costsandexpensesaccruedinconnectionwithinstallmentoftherepaired

Productorreplacementtotheequipment.

Inaddition,thetotalamountoftheindemnificationshallbelimitedtothe

contractpriceoftheProduct.

AsforUsageoftheProductnotdescribedintheRelatedTechnicalDocumentsofthe

ProductstipulatedinArticle3ofthisStandardWarrantyConditions,suchusage

shallbeincludedinthescopeofindemnificationunderthisStandardWarrantyCondi‑

tionsonlywhenweagreeinwritingpriortotheuseoftheProduct.

All manuals and user guides at all-guides.com

All manuals and user guides at all-guides.com

all-guides.com

Other manuals for TC163H

1

This manual suits for next models

13

Table of contents

Other OSAKA VACUUM Power Supply manuals

Popular Power Supply manuals by other brands

Videx

Videx 520MR Installation instruction

Poppstar

Poppstar 1008821 Instructions for use

TDK-Lambda

TDK-Lambda LZS-A1000-3 Installation, operation and maintenance manual

TDK-Lambda

TDK-Lambda 500A instruction manual

Calira

Calira EVS 17/07-DS/IU operating instructions

Monacor

Monacor PS-12CCD instruction manual