OSAKA-CI 49 Operating instructions. PAGE 2

The outgoing from the set points programming it’s automatically

obtainable not working on any key for 5 sec. approx. or

pressing only one time the key F, thus the counting value willl

again be displayed.

The programming of the sets is always possible, both with

counting on or off.

2.2 -PARAMETERS PROGRAMMING

To have access at the functioning parameters, it’s necessary to

push Key Set and keep it pushed for 5 sec. approx.

After 4 sec. will appear the label of the first parameter ("F1").

Now it possible to release Key Set and it will appear the value

programmed for parameter "F1".

To modify this value work on keys UP or DOWN.

Once the desired value has been programmed, pushing again

Key Set the display will show the label of the successive

parameter.

Releasing then key Set, it will appear the value programmed for

that parameter which can be modified working on keys UP and

DOWN.

Pushing and releasing Key Set it’s possible to visualize all the

parameters labels (when key is pushed) and the relative

programming (when key is released) one after the other.

The outgoing from the parameters programming it’s obtainable

not working on any key for 20 sec. approx. or pressing only one

time the key F, thus the counting value willl again be displayed.

P.A.: During the counting is not possible to enter in the

parameters programming mode.

2.3 -PARAMETERS LOCK

It’s possible to lock the access at the programming parameters

with the following procedure :

Switch off the instrument, push Key Set and keep it pushed

while the instrument is switched on again.

After approx. 5 sec. on the display will appear "uL" (unlock)

which indicates that the parameters are accessible.

Keeping pushed Key Set and pushing key DOWN it will appear

"Lo"

(lock) which indicates that the parameters are not accessible.

Release Key Set to exit from this modality.

The display will go back to the normal functioning, the

parameters will not be accessible anymore and it will only be

possible to modify the Set Point.

To have again access at the parameters, repeat the same

procedure pushing Key Set and selecting "uL" ; finally go out

from the parameters lock modality.

3 -INSTALLATION AND USE ADVICES

3.1 -PERMITTED USE

The instrument has been projected as measure and

control device, built according to EN61010-1 for the

altitudes operation until 2000 ms.

The use of the instrument for applications not expressly

allowed by the above mentioned rule has to foreseen proper

protection devices.

The instrument CAN’T be used in environments with dangerous

atmosphere (flammable or explosive) without a proper

protection.

It has to be reminded that the user has to take care that the

electromagnetic rules are being respected also after the

instrument installing, eventually using proper filters.

Whenever a failure or a bad functioning of the instrument may

cause dangerous situations or damage to people, things or

animals it has to be reminded that the plant has to be equipped

with additional electromechanical devices in order to grant the

safety.

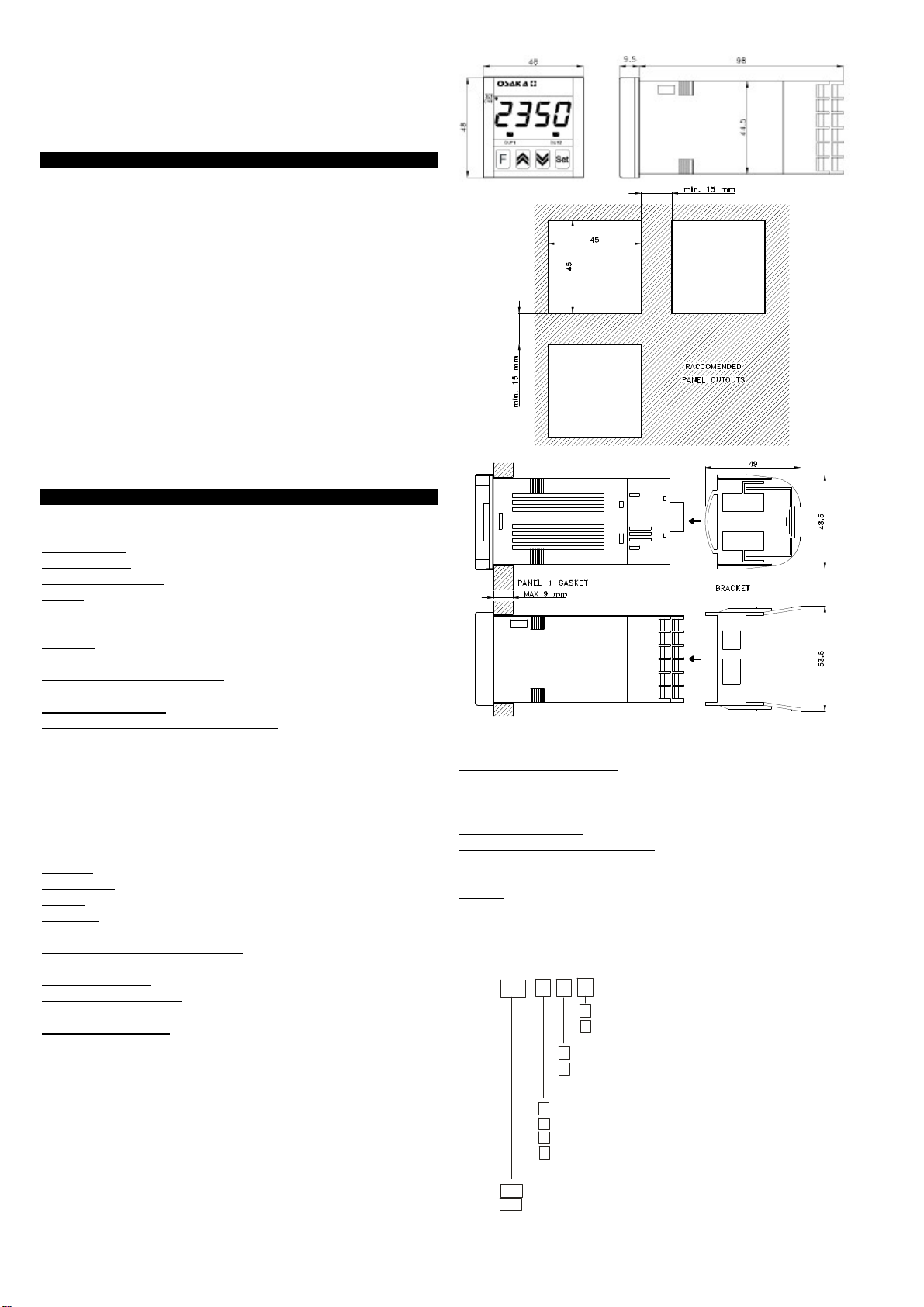

3.2 -MECHANICAL MOUNTING

The instrument, in DIN case 48 x 48 mm, is designed for flush-

in panel mounting. Make a hole 45 x 45 mm and insert the

instrument, fixing it with the provided special bracket. We

recommend to mount the gasket to obtain the front protection

degree as declared. Do avoid to place the instrument in

ambient with very high humidity ordirt that may create

condensation or introduction into the instrument of conductive

substances. Ensure the adequate ventilation to the instrument

and avoid the installation within boxes where are placed

devices which may overheat or have as a consequence the

instrument’s functioning at higher temperature than allowed

and declared. Connect the instrument as far as possible from

source of electromagnetic disturbances so as motors, power

relays, relays, electrovalves,etc. The instrument is removable

from its housing by the front side : is recommended to

disconnect the power supply from the instrument when it’s

necessary to effectuate this operation.

3.3 -ELECTRICAL CONNECTIONS

Carry out the electrical wiring connecting only one wire for each

terminal , according to the following diagram, checking that the

power supply is the same as indicated on the instrument and

the loads current is not higher than the maximum current

admitted. The instrument, being a built in equipment with

permanent connection into a cabinet, is not equipped neither

with switches nor with internal devices protecting from

overcurrent : the installation shall employ atwo-phase circuit-

breaker, placed as near as possible to the instrument, located

in a position easily reachable by the user and marked as

instrument disconnecting device. It's recommended,

furthermore, to properly protect all the electric circuits

connected to the instrument, with devices (ex. fuses)

proportionate to the circulating currents. It's strongly

recommended to use cables with proper insulation, according

to the working voltages and temperatures. Furthermore, the

input cable of the probe has to be kept separate from line

voltage wiring. If the input cable of the probe is screened, it has

to be connected on the ground with only one side. Finally, it is

advisable to check that the parameters are those desired

before connecting the outputs to the actuators in order to avoid

plant anomalies which may cause injuries to people, things or

animals.

OSAKA and its legal representatives are not responsible

for any eventual damages to people, things or animals

deriving from the instrument violation, not proper or wrong

use or in any case not in accordance with the instrument

features.

3.4 -ELECTRICAL CONNECTION DRAWING