1

TABLE OF CONTENTS

INTRODUCTION................................................................................................................. 2

TECHNICAL SPECIFICATIONS ......................................................................................... 3

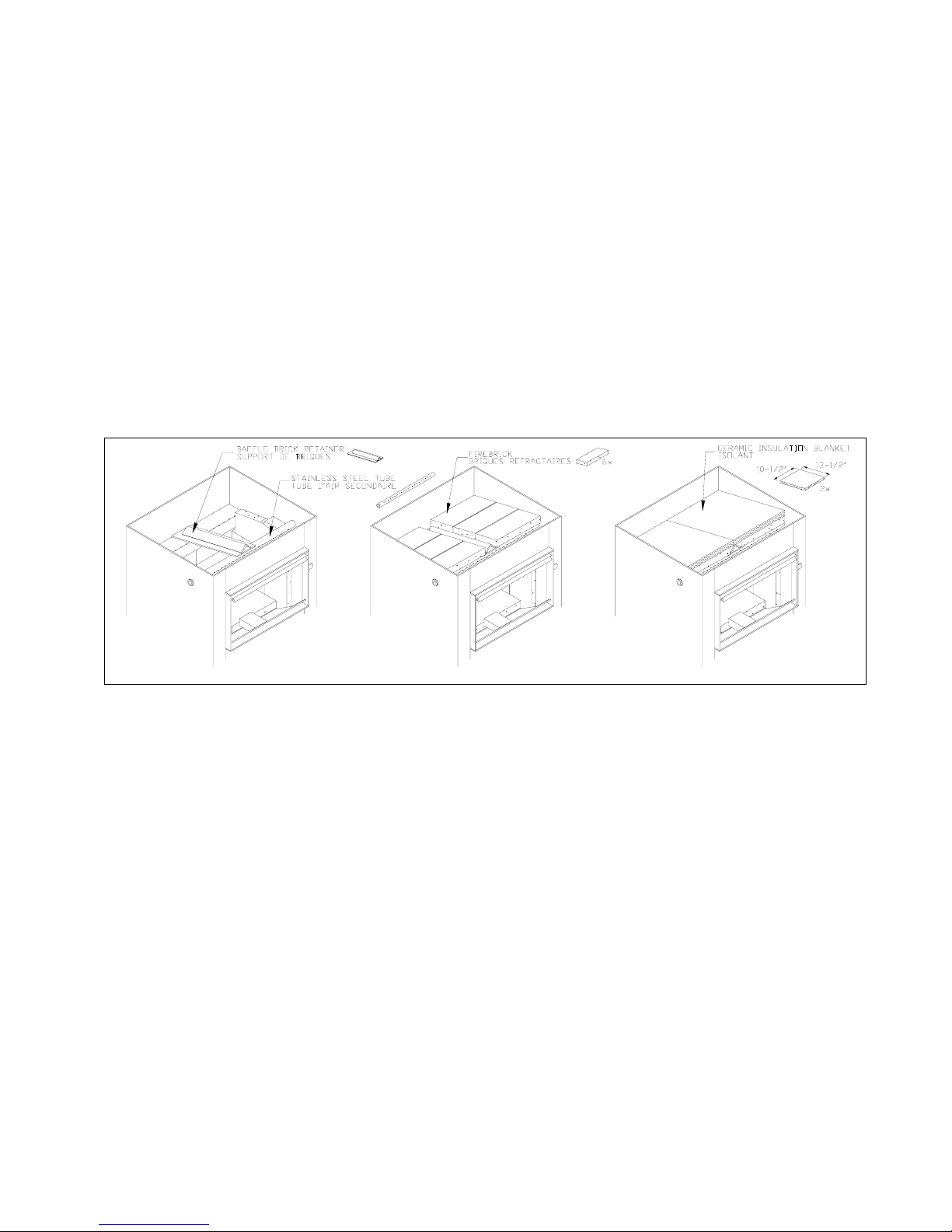

ASSEMBLY ......................................................................................................................... 4

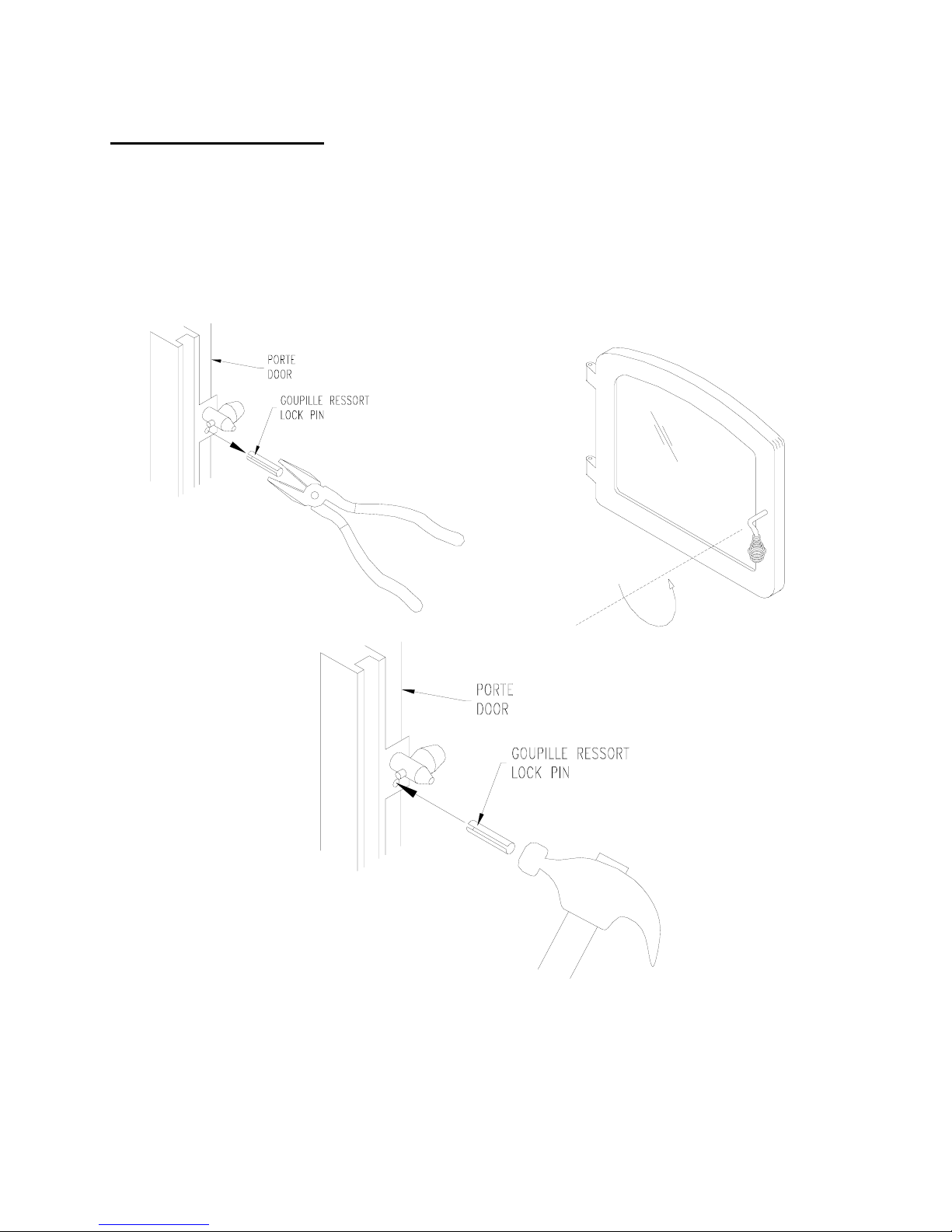

DOOR ADJUSTMENT ..................................................................................................... 6

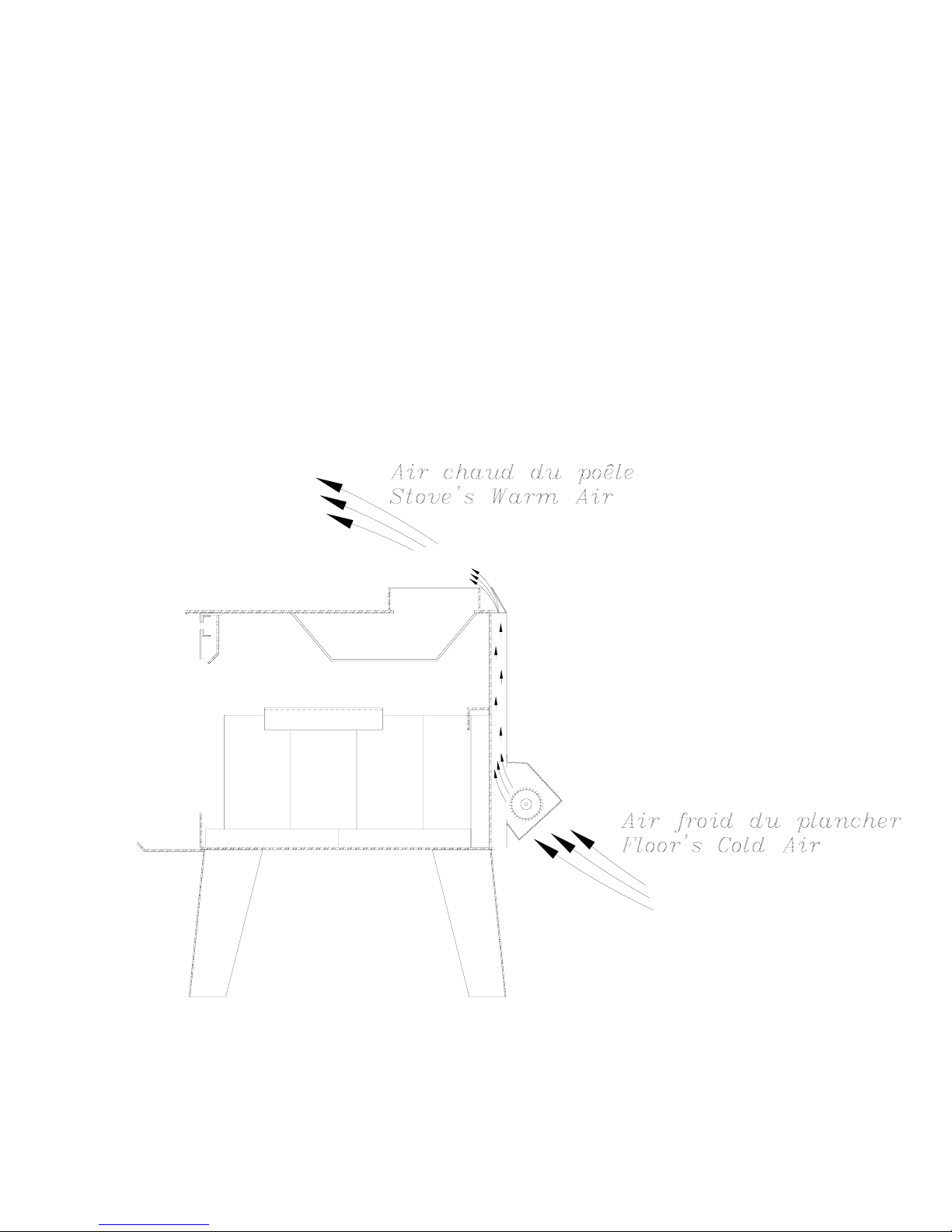

THE BENEFITS OF INSTALLING A BLOWER ................................................................... 7

INSTALLATION................................................................................................................... 8

POSITIONING THE STOVE ............................................................................................ 8

FLOOR PROTECTOR..................................................................................................... 9

CLEARANCES FROM COMBUSTIBLES ...................................................................... 10

REDUCED CLEARANCES (CANADA ONLY)............................................................... 12

CHIMNEY ...................................................................................................................... 13

CHIMNEY CONNECTOR (STOVE PIPE)...................................................................... 14

TYPICAL INSTALLATIONS ........................................................................................... 15

OUTSIDE COMBUSTION AIR....................................................................................... 19

WOODSTOVE UTILISATION............................................................................................ 20

AVERAGE ENERGY YIELD OF ONE AIR DRIED CORD OF CUT WOOD .................. 20

TESTING YOUR WOOD ............................................................................................... 21

THE FIRST FIRES......................................................................................................... 21

IGNITION....................................................................................................................... 21

HEATING....................................................................................................................... 22

RELOADING.................................................................................................................. 23

CREOSOTE FORMATION AND NEED FOR REMOVAL.............................................. 23

ASH DISPOSAL ............................................................................................................ 24

MAINTENANCE ................................................................................................................ 25

GLASS...........................................................................................................................25

GASKETING.................................................................................................................. 25

PAINT ............................................................................................................................ 25

LIMITED LIFETIME WARRANTY...................................................................................... 26