Tieppo 4-75 Manual

1

OPERATING AND

MAINTENANCE

HANDBOOK

POWER TROWEL

4-75

2

ATTENTION!!

THE PRESENT MANUAL MUST ALWAYS BE

AVAILABLE TO THE OPERATOR

Assistance: Tel +39 0423746008

Fax +39 0423746050

info@tieppoluisello.it

www.tieppoluisello.it

Tieppo roup srl, Via Minato 26/C

31039 TREVISO, Vallà di Riese Pio X

ITALIA

The present manual includes:

- Instructions for the utilization

- Maintenance regulation

- Spare parts

Inside you will find all the necessary information for a correct utilization of

the machine.

We invite the user to follow carefully the warning included inside and to read

it in each of its parts to be able to know better our machinery and to avoid

any problem caused by a wrong utilization of it.

On the base of the safety rules (law 626) , the operators must be equipped

with all the individual protective devices D.P.I. (safety shoes, gloves, helmet,

glasses, caps, proper clothes).

The content of the present manual can be modified without any notice, only

by the producer, at the purpose to improve the machinery performance

already dispatched.

It is forbidden to reproduce and translate the present manual without the

written authorization of Tieppo Group srl.

3

SECURITY

This manual is proposed to issue the necessary instructions to the operator for the

correct use of the equipment safety.

Before using the equipment be sure to read every parts of this manual and perform

all the indications given.

During operation of the machine at all times observe the safety instructions in this

manual.

Failure to read and follow the instructions for use may endanger the safety of the user

and the people near the machine.

The manufacturer assumes no responsibility for any accidents caused by changes to the

machine.

Any unauthorized modification of the machine will void all warranties.

Any changes should be made only by the manufacturer, which shall check that the

machine complies with current safety standards.

During operation the engine produces carbon monoxide, a toxic gas that can cause

death if inhaled.

NEVER USE this machine in environments with limited space or closed structures that

don’t allow a good air.

This machine CAN’T BE USED by minors.

During operation the engine produces carbon monoxide, a toxic gas that can cause

death if inhaled.

4

NEVER USE this machine in environments with limited space or closed structures that

don’t allow a good air.

This machine CAN BE USED ONLY by personnel instructed in advance on its use.

DO NOT USE this machine for different purposes from those descrive in this manual.

DO NOT USE this machine in case of illness given to tiredness or in case of taking

medications.

NEVER USE this machine under the influence of alcohol and/or drugs.

MAKE SURE that there are no persons other than the operator in action when the

machine is working.

MAKE SURE that the work area is clear of debris, tools or anything else constitutes a

danger during work.

KEEPYOUR MACHINE IN GOOD AND SAFE CONDITION

CHECK that the machine doesn’t form accumulations of concrete or debris.

REPAIR immediately any damage to the machine and always replace the broken parts

DO NOT PUT oil or waste fuel directly on the ground, in the water discharge or in a

water source.

Dispose the hazardous waste( engine oil, filters,…) in accordance tih regulations.

NEVER STORE the machine with fuel in the tank for extended periods

SAVE the machine out of the reach of children, in a closed environment to prevent

unauthorized persons from coming into contact with the same.

ALWAYS CHECK the correct fitting of all parts only the machine before starting the

same.

USE the machine in a well lit work

CARRYING machine in an horizontal position on a vehicle or means of transport

according to applicable regulations.

USE the machine on a flat surface with a maximum inclination of 3°

DO NOT wear loose clothing or jewelry that could get caught in the controls or in the

moving parts because this could cause serious injury or uncontrolled movements of the

machine.

5

To clean the machine carefully follow the regulations for the disposal of clearing fluids.

The fuel for this machine is extremely flammable and its vapors can cause an explosion

if ignited, any leakage of fuel could easily cath fire if they came into contact with hot

engine parts or sparks of the ignition system.

DO NOT START the engine in case of leakage of fuel or liquid fuel.

DO NOT FILL the fuel tank while the engine is hot or running.

DO NOT SMOKE or naked flames near the machine

MAKE refueling in a sufficiently ventilated area with the engine is off , in the absence

of open flames and/or sparks.

DO NOT USE fuel as a cleaning agent

Engine components can generate high temperatures and cause burns

DO NOT TOUCH these parts while the engine is running or immediately after turning

off the machine.

DO NOT REMOVE covers thermal and gear/belt/pulley/clutch of movement on the

machine protection

6

The transmission of the movement and its rotor tamping are moving parts that can

cause injury.

DO NOT REMOVE the protections and safety cover when the machine is turned on.

Always MAKE SURE that the protections and safety guards are present intact and

efficient.

ABSOLUTELY prohibited lubricate, clean, adjust and repair while the machine is in

motion or at work.

ABSOLUTELY forbidden to carry or at least pick up the personnel on the machine

when it is in motion or at work with the exclusion of the operator where it is expected.

Is require to work with the machine described in this manual the use of all personal

protective equipment, gloves, ear muffs, booth or shoes with steel tip, safety glasses and

7

respiratory protection mask.

ATTENTION during the lifting of the machine doesn’t stand under it and don’t’ permit

anyone else does it.

USE

INTRODUCTION

The machine described in this manual of use and maintenance is a power trowel with one

rotor, suitable for smoothing of industrial floors, sidewalks, chute, .etc.

This work is made possible by the rotation of the blades that go to smoothen the surface

being machined.

The movement of the same is made by a internal combustion engine (petrol or diesel) and

transmitted by means of pulleys, belts and gearbox to cruise where the blades are

attached.

The operator to manage the machine is positioned on the side of the handle and grips the

handle strongly.

WARNING in working environment MUST be guaranteed a value of average lighting

of 50 lux according to European standard in force.

All components used are approved and comply with current legislation.

NOTE: It is recommended not to use the machine for purposes other than those for which

it was designed.

In the case of demolition is necessary to follow the provisions on waste disposal in the

country where the demolition takes place.

8

TECHNICAL CHARACTERISTICS:

DESCRIPTION

UNIT OF

MEASUREMENT

ENGINE HONDA GX160 5.5 HP

Maximum dimensions mm

1548X944X765

Shipping weight Kg 60

Alimentation Tipo Petrol

Power HP 5.5

Maximum engine speed Rpm 3600

Maximum cruise speed Rpm 125

Starting Tipo Recail starter

Reduction relation of gearbox - 1:20

9

We have performed tests of noise and vibration for the this model and we found the

following values for their affect on the operator.

Values of the residual noise for the machine during the work

Medium sound pressure

dB

82.6

Medium acoustic power

dB

109.7

Acoustic pressure on the

side work

dB

96.4

Value recorded for the vibrations of the machine at work

Value recorded for the vibrations on the

handle

m/s2 3.33

3. GENERAL WARNING

3.1 ALIMENTATION

The power of the machine is supplied by a combustion engine, air-cooled and powered to

the liquid fuel (gasoline or diesel).

The engine start is done manually through a recoil starter

The fuel from the tank comes to the carburetor after it was filtered.

The rotary motion of the blades is transmitted from the engine through pulleys and belts,

protected by appropriate protection.

3.2 WORKING RULES FOR THE OPERATOR

In the case of people present in the workplace of the machine, it is recommended to keep a

safety distance to avoid inadvertent and / or random contact with the motion machine or

with tailings in place. (splinters of cement, residues of the cutting disk due to break of the

same)

Before the use of the machine inspect the same in every part and pay attention to any

malfunctions, (bolts loose, damaged or improperly attached) verify the correct operation

of levers, circuits, and anything else needed for the good operation of the same

10

IMPORTANT :

MAKE THE SUPPLY OF FUEL IN A SUFFICIENT VENTILATED PLACE WITH

ENGINE OFF, IN THE ABSENCE OF AN OPEN FLAME, AND/OR SPARKS.

You wear always personal protective equipment (gloves, safety shoes, headphones,

helmet, goggles, clothing) according to the legal provisions in force concerning safety in

the workplace.

IMPORTANT :

For requirements of stability of the machine we recommend the use of the same in flat

surfaces or on slopes, not superior of 3%.

Eventual or ordinary repair and extraordinary maintenance must be made with the engine

off.

The wear of the blades can make the fragile structure of the same, so always wear

protective gloves and Always be special attention during the exercise of the above

operations.

Always wear appropriate clothing to work in progress, don’t EVER wear clothes

unfastened and / or torn and everything not suitable for processing.

The workplace must be adequately illuminated with a value of average illumination of 50

lux so that the operator always has an excellent visibility according to European

regulations.

The workplace must be sufficiently ventilated to disperse the exhaust gases of the machine.

MAKE SURE THE FUEL IS THAT INDICATED IN THE OWNER'S MANUAL ENGINE

INSTALLED.

When working on construction sites with wells formed on the smooth floor, they must be

properly marked with appropriate barriers and / or guardrails with a minimum height of 1

m above the floor in question, in order to avoid dangerous situations

To prevent loss of control of the machine in the starting phase, the operator must be

always stay in the driving seat before starting the machine itself or on the side of the

handle.

USING THE MACHINE MUST BE PERFORMED BY A PROPERLY INFORMED

ADULT PERSON ON THE USE OF THE SAME.

Store the machine in a place sheltered from the rain and closed to avoid unauthorized

persons from coming into contact with it.

11

In the phase of transport of the machine and in the process of loading and unloading keep

the safety distance from the ray of rotation of the crane, or by the lifting device suitable

used.

STARTING AND MOVEMENT

4.1 INSTALLATION

The machine is delivered appropriately packed and suitable for the transport

Download the same with a lift truck suitable to lifted the weight, all of this machine should

be placed on a stable and horizontal surface.

Unpack the upper and lower side and lifting the same with a mechanical arm attached to

the appropriate lifting hook (not disperse the packaging in the habitat, comply with the

regulations in force in the country of use), use cables and / or straps approved for the type

of load to be lifted.

The power trowel is delivered completely assembled

On receipt of the machine, check that it is ok in all its parts

If you find any abnormalities immediately contact the retailer or manufacturer. (See act of

purchasing)

4.2 PRELIMINARY CHECKS

Before operating the machine must make the following checks:

1)check the engine oil level and provide for topping up if necessary (for the type of oil

see manual of use and maintenance of the engine)

2) check the fuel level in the tank, if necessary, provide for refueling

3) make sure that the thickness of the floor is appropriate for support the weight of the

machine

NOTE: MAKE SURE THAT THERE IS NO WATER IN THE FUEL.

THE OPERATION OF SUPPLY MUST BE DONE IN SUFFICIENT

VENTILATED PLACE

AND AWAY FROM HEAT SOURCES AND/OR FLAMES FREE.

4.3 STARTER

For the operation of the machine, proceed as follows:

1) Move to the front of the machine

12

2) Close the air lever

3) Release the accelerator into the minimum position

4) Keep closer the stop lever

5) Pull the starter rope and start the engine

6) When the machine is started open the air lever

7) The engine starting is at low speeds

4.4 END OF WORK

To stop power trowel bring the throttle setting at idle, release the stop lever so as to reach

the engine from stalling. Close the fuel valve.

Move the machine to deposit or appropriate place for parking.

5GENERAL RULES FOR USE OF THE MACHINE

Preparation of the action area.

Wear personal protective equipment

Cleaning the surface of materials which can interfere with the processing of smoothing of

the floor

Illuminate your work surface with special headlights if there are problems with visibility '

Prepare ventilated the workplace for the disposal of exhaust gases.

5.1 CLEANING OF THE MACHINE

Clean the machine at the end of each working day when you can remove the dust

After cleaning with brush or compressed air, moisten the exposed parts with oil disarming

(never with fuel oil), avoid oiling the rubber parts

During this operation verify the functionality of the parts subject to wear and tear, using

the appropriate personal protective equipment (gloves, glasses, ect.)

5.2 TRASPORT

To transport the machine inside the yard use a lifter.

Don’t use the lifter for transport on street.

For the correct transport the operator must:

13

1) Make sure that the machine is turned off

2) Handle the same through the appropriate lifting hook

3) Load the machine on an appropriate vehicle

4) Download the machine on the place that you need

At the time of the loading and unloading of the same use special lifting hooks

For lifting the machine, use a crane or lifter appropriate of lifting the weight of the

machine (see technical data)

For the transport by truck to have the power trowel in an horizontal position with all of

the finish blades on the ground and secure with appropriate cables or straps approved

To change the oil engine follow any regulations of the attached manual of instruction and

use of the motor.

14

MAINTENANCE

6MAINTENANCE

For any maintenance work you have to operate with the machine stopped

Before you start any maintenance clean the machine thoroughly

Usury of the blades can make them extremely sharp, so use protective gloves

The supply or engine oil replacement are described in the manual of use and maintenance

of the engine.

6.1 PERIODIC MAINTENANCE

The power trowel not requires special maintenance, however it is good practice to follow

the following guidelines:

1) Make careful clearing of the machine from the working waste

2) Make occasional repairs (in case of doubt contact manufacturer)

3) Clean air filter (see engine manual)

4) Check engine oil level (see engine manual)

5) Check the state of wear of the blades

6) Check the tightness of screws and hex nuts (those subject to vibration)

7) Check for any emergency stop

6.1 WEEKLY CHECKS

1) Check tension and wear of the transmission belts

2) Clean the sparking plug of the engine (see engine manual)

6. REPLACEMENT OF BELTS

For replacement of belts the operator must:

1) Remove the protective cover unscrewing the appropriate fixing screws

2) Pull the loose or damage belts by turning pulley

3) Set the new belts

4) Relocate the protective cover

7.0 PROBLEMS AND REMEDY

Before carrying out any maintenance work, the operator must::

1) Make sure that the machine is turned off

2) Find the problem and solve it

15

PROBLEMS

CAUSES

SOLUTIONS

Oil spilling from the

machine

1) Too much oil in the

reducer

2) Screw of reducer caps

are loosen

3) Defective gaskets

4) Reducer oil seals are

worn-out

1) Unscrew oil cap

2) Tighten screws

3+4)Contact our

technical support

Machine does not start

1) Lack of fuel

2) Air lever is open

3) Fuel cock is closed

4) Dirty fuel

5) Defective power supplì

6) Dirty fuel filter

1) Fill up

2) Close air lever

3) Open fuel cock

4) Clean and fill with

clean fuel

5) Check filters and

sparking plugs

6) Replace filter

No increase in engine

revolutions

1) Accelerator cable is

broken

2) Dirty air filter

3) Problems with the

engine

4) Dirty carburator

1) Replace accelerator

cable

2) Clean filter

3+4) Contact our

technical support

The blades don’t get up

1) The lift blade cable is

broken

2) Absent locking hexagon

nut for rope of lift blade

3) Broken lift blade fork

4) Arms locked

1) Replace the lift blade

cable

2) Assemble the absent

hexagon nut

3) Replace lift blade fork

4) Contact our technical

support

The power trowel moves

up and down on the floor

1) Hardened concrete

under crossing of blades

2) Blades not adjuste or

worn-out

3) Central shaft is bent

1) Cleaning the blades

and the crossing of

blades

2) Adjust the angle of the

blades

3) Contact our technical

support

16

With the increase of

engine revolutions, rotors

don’t rotate

1) Worn-out/broken belts

2) Worn-out clutch linings

1) Replace belts

2) Replace clutch linings

17

8.0 SPARE PARTS

18

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

DADO M6 AUTOBLOCCANTE ZINCATO 4CODADO62

VITE TESTA CROCE 4 X 10 ZINCATA 4COVTCR410

CAVO ACCELERATORE 2360mm TESTA CIL T Ø 5*7 4COCAVO2360

VOLANTINO A 5 LOBI M10*50 ELESA 69977 4COVOL5L5

VITE TE 10X125 ZINCATA PARZIALE FILETTO 4COVTE10125

MANOPOLA PVC Ø 27 1MA08015 8PR0000001037

ACCELERATORE A LEVA IN METALLO CON PERNO M6 L44 4COACCPALL

LEVA STOP Ø 27 MOD AVVOLGENTE CON CAVO ELETTRICO L 2400mm

8PR0000001039

MOTORE HONDA HP 5,5 - GX160-QX-4-OH 4MOHGX1606

MANICO 4-60/4-75 LATO OPERATORE CROMATO 4COMANICO81

MANICO 4-60/4-75 LATO MACCHINA CROMATO 4COMANICO82

RONDELLA A SPESSORE 28*8 SVASATA ZINCATA 4CORONDSPE2

DISCO FRATTAZZO Ø 75 ZINCATO 3CODISCOF751

COVER-OIL FILTER VANGUARD 807689 4MOTAPPO8

TAPER BUSCH 1610 Ø19 4OTTB161019

CINGHIA A 23,5 ROFLEX 4OTCINGA235

DEFLETTORE SCARICO HONDA 5000000 4MODEFLET1

FRIZIONE PAF Ø75 1 GOLA TIPO A 4-60 - 4-75 ALB Ø19,5 4OTF1G4601

CARTER PROTEZ CINGHIA 4-60 - 4-75 4COCARTER6

PULEGGIA 1 GOLA TIPO A Ø 112 CON FORO PER TAPER BUSCH 1610

4OTPU1G112

CHIAVETTA 8 X 7 X 50 4OTCHIA8750

BOCCOLA FISSAGGIO ALBERO LENTO RIDUTTORE 4OTBOCCOLA1

SUPPORTO CARTER 4-60 IN METALLO 4CASUPCAR460

RONDELLA CROCERA 4-60/4-75 4CRROND2

CHIAVETTA 6 X 6 X 25 4OTCHIA6625

ALBERO LENTO 4-60 / 4-75 / TLK75 4OTALBERO26

GANCIO SOLLEVAMENTO 4-60/4-75 4COGANCSOL2

PALETTE 4-75 ESTERO (PACCHI DA 4 PZ) RB-47510M6-TL 3COPALE475E

CERCHIO STABILIZZATORE BRACCETTI 4-75 4COCERCSB475

VITE TESTA TONDA QUADRO SOTTOTESTA M8X30 4COVTT830

GRANO A PUNTA 8 X 20 4COGRANO8201

DADO M8 RIBASSATO ZINCATO 4CODADO84

BRACCETTO 4-60 Ø20 L269 Ø25 4CRBRAC6020

GOMITO 4-60 / 4-75 TL NEW 4CRGOMITO20

GRANO DA 8*20 ESTREMITA' CILINDRICA DA 5 4COGRANO853

Pos DESCRIZIONE ARTICOLO

CROCERA 4-60 / 4-75 RICAVATA DAL PIENO GS400 4CRCRO4601

PARAOLIO Ø20INT 28EST SP 5X7 DSI TTO 4COPARO202857

19

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

PIASTRA SUPPORTO MOTORE 4-60/4-75 4MOPIASTRA1

CHIAVETTA 6 X 6 X 30 4OTCHIA6630

VITE TE 8 X 30 8 8 ZINCATA 4COVTE830

DADO M8 AUTOBLOCCANTE ZINCATO 4CODADO82

VITE TCEI 8 X 20 8 8 ZINCATA 4COVTCEI820

VITE TCEI 8 X 25 8 8 ZINCATA 4COVTCEI825

VITE TCEI 10 X 40 8 8 ZINCATA 4COVTCEI1040

RONDELLA Ø 10 ZINCATA 4COROND10

DADO M10 AUTOBLOCCANTE ZINCATO 4CODADO102

VITE TE 6 X 35 8 8 ZINCATA 4COVTE635

RONDELLA GROVER Diam 6 MAGGIORATA ZINCATA 4CORONDGR6

FORCELLA ALZAPALE TL 4-60 / 4-75 4COFORC2

PERNO FORCELLA Ø8 - LUNG 145 mm 4COPERNO11

SEGER EST Ø 8 UNI 7435 - 8 4COSEGERES8

PRIGIONIERO 10 X 45 8 8 ZINCATO 4COPRI1045

DADO M10X1,5 RIBASSATO CHIAVE 13 4OTDADO1013

VITE TSPEI 8 X 20 8 8 ZINCATA 4LEPERNOAP1

CERCHIO PROTEZIONE 4-75 PEHD ROSSO Ø765mm SPESSORE 15mm (Cod 32100004)

4CACERC4751

FLANGIA CONTENIMENTO DISCO NYLON 4-60 / 4-75 4COFLANGIA6

RIDUTTORE SPAGGIARI NRV-P063 r 20 4OTRIDNRVP063

CAMPANA ALZAPALE 4-60 / 4-75 TL NEW 8PR0000000487

COPRICUSCINETTO 4-60 / 4-75 TL NEW 8PR0000000488

CUSCINETTO 6908 NSK DDU (61908 SKF) (Øe62 Øi40 Sp 12) 4COCU6908

CUSCINETTO REGGISPINTA ALZAPALE AXK 1528 4COCURAP1

SPINA ELASTICA 6 X 40 4COSPINEL640

SEGER INTERNO Ø66mm SPESSORE 2mm (UNI 7437 62)

8PR0000000585

SPINA CILINDRICA 8 X 40 4COSPINA840

TAPPO PARAOLIO 52X7 TTO FORATO 5COTAPPO527

CUSCINETTO RONDELLE SPALLAMENTO ALZAPALE AS 1528 4COCURAP

SUPPORTO CORDA ALZAPALE 4LESUP8

SUPPORTO BARRA FILETTATA ALZAPALE 4LESUP6

PERNO FILETTATO ALZAPALE 4LEPERNOAP1

SUPPORTO PERNO FORCELLA SX 4-60/4-75 4LESUPSX2

VOLANTINO A 6 LOBI Ø99*44 art 74511 LAVORATO 5COVOL6L3

PIATTO ALZAPALE 4-60/4-75 TL 4LEPIATTOAP1

MOLLA Ø19,05 LUNGHEZZA 914,40mm FILO 1,6 mm art LEC063G36M

8PR0000001081

VITE TESTA CROCE 4 X 10 ZINCATA 4COVTCR410

SUPPORTO PERNO FORCELLA DX 4-60/4-75 4LESUPDX2

DADO M6 AUTOBLOCCANTE ZINCATO

4CODADO62

20

77

78

VITE TE 6 X 16 8 8 ZINCATA

4COVTE616

VITE TSPEI 8 X 30 8 8 ZINCATA 4COVTSPEI830

Table of contents

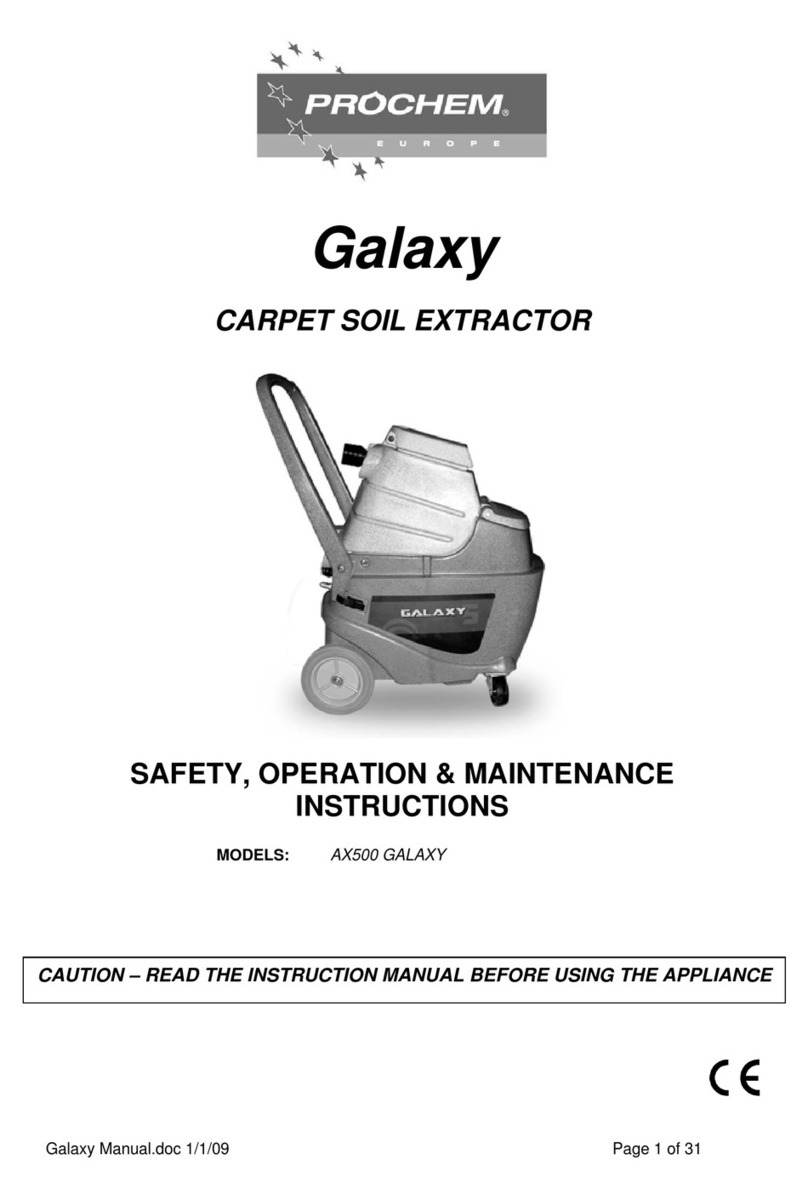

Popular Floor Machine manuals by other brands

Prochem

Prochem AX500 Galaxy Operating & maintenance instructions

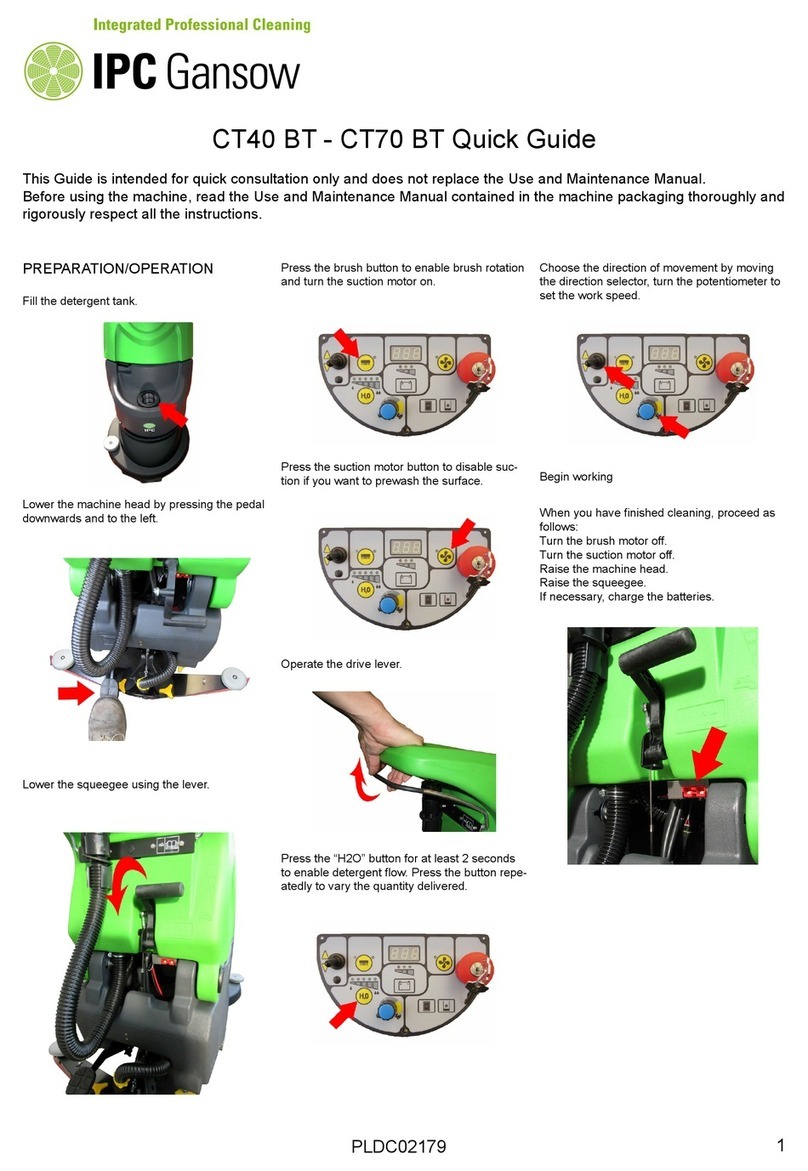

IPC Gansow

IPC Gansow CT40 BT quick guide

Powr-Kraft

Powr-Kraft Betstco ATKSP120 Operations & parts manual

CleanMaster

CleanMaster RX-Express owner's manual

Kärcher

Kärcher BR 530 BAT operating instructions

COMAC

COMAC CS90 D Use and maintenance manual

Windsor

Windsor CB20 Operator instructions

Superabrasive

Superabrasive LAVINA 25-S-E user manual

Bissell

Bissell FMU-2000 Safety, operation and maintenance manual with parts list

Nobles

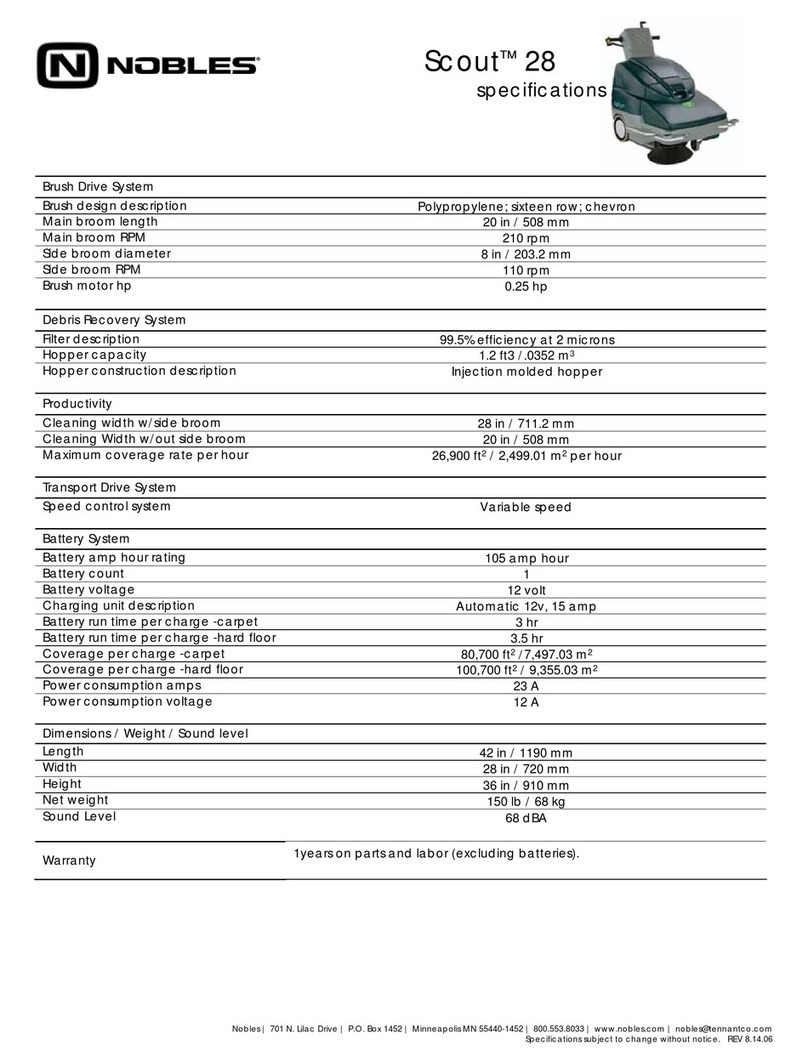

Nobles Scout 28 Specifications

Nilfisk-Advance

Nilfisk-Advance SW5500 Instructions for use

Viper

Viper DR1500H-EU user manual