OSMOSEA EVO 300 Service manual

INSTALLATION, USE AND MAINTENANCE MANUAL

Version 03 16/11/17

English Version

OSMOSEA EVO 300

Reverse Osmosis Watermaker.

Code Number

190506D285

Year

05/2019

Installation, Use and Maintenance Manual

2

Index

GENERAL PREMISE.........................................................................................................................3

WARRANTEE....................................................................................................................................4

GENERAL PRINCIPLES OF SAFETY...............................................................................................5

TECHNICAL DATA ............................................................................................................................6

INSTALLATION .................................................................................................................................8

ABOUT REVERSE OSMOSIS.........................................................................................................12

INSTRUCTION FOR THE OPERATION OF THE PLANT................................................................14

MAINTENANCE...............................................................................................................................17

TROUBLESHOOTING GUIDE.........................................................................................................21

DEMOLITION AND DISPOSAL OF THE PLANT .............................................................................21

DECLARATION OF CONFORMITY.................................................................................................22

Installation, Use and Maintenance Manual

3

GENERAL PREMISE

This documentation is an integral part of the plant and provides information necessary for the:

Machine identification;

Presence of risk factors on the plant

Overall dimensions and characteristics of the plant

Installation’s rules

Use and maintenance instruction

Warnings

This CPS is an integral part of the technical documentation of the machine used for water treatment.

The instructions are designed both to protect the physical integrity of the person using the machine, and to

provide guidance regarding the most appropriate behavior for the proper use of the machine, as suggested

by OSMOSEA SRL.

Given the importance of this manual in terms of safety, please read it carefully before using the plant and re-

read it when difficulties or concerns arise.

The manual must be stored carefully, and made widely available to all persons concerned; we recommend

not alter or remove any information that are needed to identify the plant.

Manufacturer’s Info

For any need OSMOSEA SRL is at your entire disposal to provide you with technical assistance to resolve

any problems and organize at best any sort of interventions.

OSMOSEA SRL

Via Dante Alighieri, 7 –91025 Marsala (TP)

Tel. +39 0923 719867

Fax +39 0923 569793

www.osmosea.it

Installation, Use and Maintenance Manual

4

Plant’s ID

The plant is identified through an adhesive plate in which is reported the details to be quoted to OSMOSEA

Srl in case of need, this plaque is the only one recognized by the manufacturer as means of identification of

the product.

WARRANTEE

Osmosea srl ensures this plant in the following terms and conditions:

1.The Seller guarantees the product to be free from defects in material and workmanship under normal use

in accordance with the directions given in the technical literature for a period of 24 months after delivery to

customer and agrees to repair or replace, at its option, the product at no charge should it become defective

and which its examination shall disclose to be defective and under warranty. All defective products shall be

returned to Seller. carriage paid. The guarantee shall expire 24 months after delivery to customer even in the

event that the product has not been used for whatever reason.

2.All descriptive specifications and particulars of weights and dimensions laid down in catalogues. quotations

or order confirmations are approximate only. The Seller reserves the right to make any modifications and

improvements to its products which it may deem desirable or opportune without prior notice.

3.The guarantee does not extend to any of the Seller's products which have been subjected to neglect,

misuse, incorrect maintenance, tampering with on the part of the Purchaser or of third parties, improper

installation, or to use in violation of instructions supplied by the Seller, or any other reasons whatsoever

beyond Seller's control.

The Seller shall not be held responsive for damage to goods during loading, transport and unloading, All

claims for any such damage must be put forth to the carrier at the time of delivery. Goods shall be properly

packed and protected.

4.In the event that Purchaser sells the goods to third parties, Purchaser shall undertake to provide any such

third parties with all technical information and instructions furnished to it by the Seller, otherwise the

guarantee shall became null and void.

The guarantee shall not cover any damage or failures resulting from exceptional circumstances.

5.Any claim for damage or latent defects must be made in writing within eight days from the date of

discovery, otherwise they shall not be considered.

6.Whenever products are returned, this shall not mean automatically that they were found to be defective

unless a specific claim to this effect has been put forth.

7.Should a defect be suspected, Purchaser shall submit to Seller a request for repair or replacement of the

defective product and Seller shall repair or replace at no charge any such product which its examination shall

disclose to be defective In material and workmanship, Any such defective products shall be repaired at the

Seller's works. Any defects in a particular product shall not form the subject of a claim for a full consignment

of products that includes several types of products. Purchaser shall not therefore be entitled to withhold

payment of any products other than those which are the subject of the claim.

8.In respect of the guarantee, Seller shall not be responsible to Purchaser for any charges other than those

specified herein.

9.!n no case shall Purchaser have the right to request inspection or repair on a site other than the Seller's

premises.

10.Delivery dates shall not be binding and may be subject to change for any unforeseeable events.

11.Should the Purchaser fail to make payment (s) on due date (s), then and in such event delayed payment

will be subject to overdue interest at the rate of three points above the "ABI prime rate". In such event. the

guarantee shall be withheld until full payment has been made but its expiration date shall not be postponed

accordingly.

Installation, Use and Maintenance Manual

5

12.If any question, dispute or difference in connection with the contract arises between Seller and Purchaser,

the same shall be referred to the Court of Marsala. However, Seller may. at its option, submit any such

question. dispute or difference to the Court of jurisdiction of the Purchaser.

These general conditions of sale supersede all previously issued terms and conditions. and no variations

hereto can be accepted unless approved in writing by the Seller.

Process Warranties

The performance of the plant is guaranteed only when:

The temperature of the incoming fluid is greater than 3 ° C and less than 40 ° C. The incoming fluid does not

contain pending or colloidal substances; chemical compounds such as surfactants, solvents, oil-soluble,

etc..; Ozone, permanganate or other strong oxidizing agents.

GENERAL PRINCIPLES OF SAFETY

General Security

Before beginning the installation, read and understand this CPS carefully, applying all the requirements and

recommendations contained therein.

It’s absolutely forbidden to neutralize, remove, alter or render ineffective any security or protection device;

wherever it might be located, must be kept in conditions of perfect and constant efficiency.

In case of danger, the user must stop the plant from the switch placed on the framework of the central

command: this move will allow the immediate shutdown of the plant.

Risks

There is danger of getting hurt for the operator who will remove the protective casing of the engine due to the

high speed of the cooling fan.

There is danger of getting hurt for the operator who will carry out maintenance operations with the plant in

motion due to the high working pressure of the plant.

Noise of the plant

Design and implementation were made in order to reduce to a minimum the issue of aircraft noise at source,

according to the requirements of European Directive 89/392.

There is no need for the operator to be present while the plant is in function, only in case of routine

maintenance and regulation.

The source that provides greater noise is the high pressure piston pump.

Installation, Use and Maintenance Manual

6

TECHNICAL DATA

Drawings

Pattern of flow

Installation, Use and Maintenance Manual

7

Electrical Features

Voltage

230 V

380 V

Frequency

50 Hz

Max Installed Power

3.4 kW

Electrical Absorption

17 A

230 V

7 A

380 V

Electrical cabinet Class

IP 65

Operational Parameters

Type of operation

Single passage

Pressure

58/60 bar

Working Temperature

15°C / 20°C

Minimun temperature allowed

3°C

Maximun temperature allowed

40°C

Membrane Features

Configuration

Wrapped spiral

Materials

Film Composit

Dimensions

2.5” x 40”

Maximun temperature allowed

40°C

Quantity

4

Installation, Use and Maintenance Manual

8

INSTALLATION

Suggestions

It is recommended to provide for the installation of the plant an area properly illuminated.

It’s the costumer responsibility to provide all the preparatory work (ex. electricity, water etc.).

The power line must be provided with the adequate power.

It is the costumer responsibility to provide all the security conditions necessary for the "earthing" of the plant.

The plant must conform to the existing regulations in the country of installation and regularly checked by

qualified personnel.

Installation, Use and Maintenance Manual

9

Positioning of the plant

The plant must be placed on a solid foundation and well level, not affected by vibrations from other machines.

Place the plant in a way to allow maintenance operations.

Place the plant in a covered or otherwise protected area from rain, sun and wind.

Installation Basics

-Read the directions!

-Avoid tight hose bends and excessive runs.

-Use heavy gauge wire.

-Install feed pump module as low as possible.

-Use a dedicated thru-hull with scoop type

strainer.

-Do not mount components over electrical

devices.

-Avoid getting dirt or debris into the piping or

hoses during assembly. A small bit of debris can

stop the system!

Sea flow

Thru-hull Location: The system must be connected to a dedicated scoop strainer thru hull and seacock,

forward facing scoop-type intake thru-hull and seacock.

Install the thru-hull intake as far below the waterline and as close to center line as possible to avoid

contamination and air entering the system. Do not install the intake close to, or down-stream of, a head

discharge, behind the keel, stabilizer fins, or other underwater fixtures.

Thru-hulls in the bow area are susceptible to air intake in rough conditions. Sharing a thru-hull can introduce

unforeseen problems such as intermittent flow restrictions, air bubbles, contami-nants, and will void the

warranty. For racing boats and high speed boats traveling above 15 knots, a retractable snorkel-type thru-hull

fitting is preferred because it picks up water away from the hull.

The brine discharge thru-hull should be mounted above the waterline, along or just above the boot stripe, to

minimize water lift and back pressure.

Double clamp all hose connections below the waterline.

Avoid restrictions or long runs on the entire inlet side of the plumbing from the thru-hull to the feed pump

module.

Pipe Fitting Instructions: to fix the pipes at the connection push fit fitting, insert the pipe inside the

connection hole and push to the end.

Secure the piping away from moving objects such as engine belts and hatches. Prevent chafe on the tubing as

required. Test and inspect all piping and hose clamps after several hours of operation..

Wiring

- Pay attention to wire size or system performance will be impaired

- Perform wiring to UL, ABYC, CE or applicable standards

Installation, Use and Maintenance Manual

10

Connections

Hydraulic connections

Listed below all the hydraulic connections:

Connections

Hose

Fitting

From

To

Sea water inlet

Armovin

20 mm

Thru-hull

Seawater pump

Freshwater exit

PVC

10 mm

Watermaker

Post Carbon Filter

Freshwater exit

PVC

10 mm

Post Carbon Filter

Tank

Drain exit

PVC

10 mm

Watermaker

Drain Discharge

Unsafe water

PVC

10 mm

Watermaker

Drain Discharge

Flushing water Inlet

PVC

10 mm

Freshwater Pump

Watermaker

Installation, Use and Maintenance Manual

11

Connection to the electric grid and Command Unit connections

The customer is committed under his own responsibility to install a differential system for protection against

short circuits according to the data reported.

Before performing any operation, VERIFY the line-power source is in accordance with applicable regulations

and technical specifications required by the plant (voltage, frequency and power consumption).

To avoid disturbance of communication, it's necessary that the plant is connected to the "ground" of

the boat.

Dopo aver verificato, collegare il cavo di alimentazione in dotazione contrassegnato all’interruttore magneto

termico.

Remote Control Connection

-Connect the supplied cable as showed here below:

Installation, Use and Maintenance Manual

12

Checkings before turning the device on

1. Remove anything that can block the movement of the equipment.

2. Connect the electrical panel to the power.

3. Check that there are no obstructions in the line of input of the plant.

ABOUT REVERSE OSMOSIS

General considerations about the process of reverse osmosis

Reverse Osmosis is the process in which you force the passage of solvent molecules from the solution more

concentrated to the less concentrated by applying to the solution more concentrated a pressure greater than

the osmotic pressure. In practice, reverse osmosis is obtained with a membrane that holds the solute on one

side, preventing its passage and allows you to get the pure solvent from the other side. This phenomenon is

not spontaneous and requires the full fillment of a mechanical work equal to the one necessary to cancel the

effect of the osmotic pressure.

Process

Separable particle

Bar Pressure

Examples

Reverse Osmosis

< 10 Angstrom

15-80

Ion, Salt

Nano filtration

< 0,002 micron

10-15

Surfactans, organic compounds

Ultrafiltration

0,002 –0,1 micron

0,5-5

Virus, colors, Surfactans, organic compounds

Microfiltration

0,1 –10 micron

0,1-5

Colloids, bacteria, suspended solids

Operational Variables

The operational variables can affect the membranes and their operational life. The main operational variables

that must be taken into consideration by the operator are:

1. Temperature

Temperature plays an important role during the process of permeation, because a temperature variation

involves a change in the viscosity that, if applied at equal pressure, causes an increase of the total

permeated of about 3% per degree centigrade. At this point, it would be appropriate to operate at a high

temperature, but has to be compatible with the resistance of membranes.

2. Pressure inside the vessel

The working pressure inside the vessel is an indirect reading of the speed of flow through the membranes. If

the pressure increases, the volume of purified water produced increases as well, but this advantage has a

limit beyond which the membranes could be damaged. It is not allowed to exceed the amounts of the

membranes used prescribed by the manufacturer.

The ideal working pressure is 58/60 bar

4. Make sure the oil level in the high

pressure piston pump, is correct

Installation, Use and Maintenance Manual

13

Temperature Effect Comparison Chart

Temperature Effect Chart on this page illustrates the loss or gain of productivity across the RO membrane.

To determinate what normal (in spec.) flow of the RO membrane would be at 77° F / 25° C follow these

directions:

1. Determine feed source temperature;

2. Locate the corresponding temperature on the cahrt;

3. Follow the corresponding temperature in a vertical line up to the plotted production line;

4. From this temperature point at the production line, move left horizontally to the plotted productivity percent;

5. Calculate the system’s present productivity per day by multiplying the liter per hour product water flow meter

reading by 24;

6. Divide the figure reached in step 5 above, present liter per day productivity, by the plotted productivity

percentage from step 4 above. The answer will be equivalent to the membranes present productivity at

specification test parameters 56 bar (820 psi) e 25° C (77° F).

Installation, Use and Maintenance Manual

14

Membrane

The membranes are able to offer high performance and efficiency over time, only when they meet the

standards set out below.

1. The conservation of the membranes should always take place inside a wet environment, using the

appropriate solutions and avoiding freezing.

2. It 'absolutely prohibited the use of cationic surfactants and / or organic solvents.

The exposure to halogen free, usually can produce irreversible damages to the membranes.

INSTRUCTION FOR THE OPERATION OF THE PLANT

Avoid running the watermaker if the vessel is in contaminated water. The system should be fully tested

before leaving port. If the location or weather prevents proper testing, start the watermaker using artificial

seawater. You can dissolve 30 g / l of salt in clean water without chlorine, using a large bucket minimum 50

liters and by sucking the feed pump from this bucket.

Warning! Damage may occur if the purge sequence is by passed and the membrane is pressurized

with storage chemical in it.

First Check:

-Thru-hull inlet and the brine discharge valves are open;

-All of your hose connections are tight;

The command unit allows you to command the stages of the process. It does not require ignition or shutdown.

Connecting the plant to the power it will appear on the display INFO SCREEN. After this stage, we will have

the System Standby screen, where the total hours of work and the total water produced will be displayed.

Installation, Use and Maintenance Manual

15

First Start

1. Unscrew the 30 and 5 micron pre-filters and fill them clean water free of chlorine;

2. Screw the filters in the appropriate filter seat making sure not to invert them;

3. Power up the system by turning on the circuit breaker;

4. Start the watermaker pushing Washing key. The feed pump will start. Wait until the pump is well primed

and make a smooth sound.

If the Watermaker is above the waterline, it’s necessary to fill the inlet hose manually from the cap

placed at the top of the SEA WATER PUMP;

5. When the SEAWATER PUMP is primed, press STOP;

6. Start the system by pressing the START key. The screen will change in SYSTEM RUNNING, on the

bottom of the display it will appear WAITING. When the High Pressure Pump will start, WAITING will

change in SYSTEM RUNNING.

7. Adjust the High Pressure at 58/60 bar by the High Pressure Valve. If the system is equipped with

APS, this operation will be automatic. Use the High Pressure Valve in the event of failure of the

electronic control unit or of the APS system only

The Display will shows the following information:

-Inlet Pressure (IN)

-High Pressure on the membrane (HI)

-Freshwater Quality (UNSAFE or GOOD) and Salinity (µS)

-Freshwater Flowmeter (lt/h)

-Electrical Absorption ( A )

-Timer (W/h)

8. Check that the system is operating within its normal parameters. Compare with parameters that you find

here below.

HIGH PRESSURE: min. 55 bar - max 60 bar;

INLET PRESSURE: min. 1 bar - max 3.5 bar;

In the event of an emergency due to faults in the control unit and therefore in manual operation from inside

the control unit, the working pressure can always be displayed on the analogue pressure gauge marked

"HIGH PRESSURE"

The system will start producing water. The first water produced will be automatically discarded until the

display will show UNSAFE. When the conductivity drops below 1.200 μS, the valve will automatically allow

water to flow to the Freshwater outlet. In subsequent starts it will be sufficient to repeat points 3, 6, 7.

Start without Timer

1. Turn On the Electrical Power;

2. Press START.

Installation, Use and Maintenance Manual

16

Start with Timer

It is possible to select the water maker's operating time from a minimum of 1 hour to a maximum of 4 hours.

1. Turn On the Electrical Power;

2. Press START => the watermaker will Starts;

3. Press START again to select the operating time (min. 1 hour –max 4 hour). Each press of START key

corresponds to 1 hour of work. The remaining time will be displayed on the lower part of the Display.

Watermaker Shutdown

1. Press STOP key;

2. Open the High Pressure Valve. If the system is equipped with APS, this operation will be

automatic;

3. Close the Seacock;

For Periodic Flushing Programming:

1. From Stand-by press FLUSHING;

2. Press FLUSHING again to select the interval days between cycles Flushing (min. 2 days –max

4 days). Each press of FLUSHING key corresponds to 1 day of work. The remaining time for

the nest Flushing will be displayed on the lower part of the Display.

Standard configuration, the Flushing will start automatically,after 10 minutes from the

STOP.

If the system will not be used for more than 2 days, it’s necessary to Start the Periodic

Flushing. Make sure that the tank is full and the Freshwater Pump is ON.

If you plan a period of stop for the plant longer than 20 days it’s necessary to carry out

the procedure for the preservation of the osmotic membrane.

If the system is equipped with AWS the operation will be automatic by pressing the

FLUSHING key.

Installation, Use and Maintenance Manual

17

MAINTENANCE

Precautions

Maintenance operations guarantee a longer life for the plant as well as greater reliability. It’s highly

recommended to pay special attention to the membrane’s maintenance. Read this section carefully before

carrying out any type of maintenance procedure: this will ensure greater safety conditions for the personnel

responsible and improved reliability of the actions taken.

Ordinary Maintenance

Osmotic-Membrane

The membranes are the most delicate part of the plant and therefore it is useful to follow certain instructions

in order to avoid any breakage or loss of production:

1. If the plant will remain shut down for more than 24 hours we recommend to make a FLUSHING at the end of

the production.

2. If you plan a period of stop for the plant longer than 30 days it’s necessary to carry out the procedure for the

preservation of the membranes in order to prevent the proliferation of microorganisms such as bacteria,

yeasts and mold.

3. Don’t expose the membranes at temperatures over 40°C or below 3°C. When the membranes are inside the

vessel, the water inside functions as thermal insulation. If the outside temperature falls below 3 ° C, add 20%

of glycerin to the washing water in order to prevent the formation of ice.

4. In plants with manual adjustable pressure of work, must be avoided to operate the plant at a pressure

exceeding 60 bar. A failure to abide by this rule may cause the rupture of membranes.

5. The membranes must always be kept wet. In case you must take out a membrane from the vessel you must

place it in a container that can keep it wet. (ex. A tube closed at one end).

Remember that all operations of inspection or membranes replacement should be run by the staff or

OSMOSEA service point.

Hoses and High pressure circuits

Periodically, It’s a good idea to check the status of high-pressure pipes and joints.

The high-pressure pipes (blacks tubes with steel junctions at the end) must not show signs of deterioration

and, with the plant to its full capacity, the joints must not have any losses of water.

For better maintenance it’s preferable to let the assistance centers of OSMOSEA SRL

carry out this types of control.

Installation, Use and Maintenance Manual

18

High Pressure Pump

The high pressure pump requires a periodic inspection of the internal oil. To check the oil level make sure

that on the window, placed on the left side of the pump, the level reaches the middle of the window.

For the first time change the oil after 50 hour of works.

The subsequent oil changes must be performed every 500 hours of work.

High Pressure Pump Oil Replacement

1. Turn off the power;

2. Unscrew the cap with the word OIL in order to allow the air to enter;

3. Place a container under the oil drain valve, placed on the back of the pump;

4. Open the oil drain valve and collect the used oil on the container;

5. At this point, completely unscrew the cap bearing the words OIL and fill with new oil until the level reaches

the midle on the window;

6. Screw the cap bearing the words OIL;

7. Press STOP key, 4 times, to reset the Alarm;

8. Do not release into the environment the oil used.

Pre Filters

The work of the pre-filters is to ensure that the input water is free of suspended solids and therefore they

represent a security feature for the good operation of the plant. Please be careful If while the plant is

functioning any of the following cases occur:

1. The low pressure falls more than 30% compared to when the cartridges of the prefilters were new (0.8 bar / 1

bar);

2. The plant start functioning but after a few seconds it shutdowns with an alarm indicating LOW PRESSURE

ALERT;

3. The exercising pressure it’s not steady;

4. There is an strange noise coming from the high pressure pump

All of the above are to indicate a clogging or deterioration of the filtering cartridges and therefore you must

proceed with the maintenance:

1. Stop the plant;

2. Close the valve that connects the plant with the inlet sea water;

3. Using the key supplied with the plant, unscrew the pre-filters glasses putting a hand underneath in order to

avoid discharges;

4. Empty the plant and pull out the cartdrige;

5. Clean the inside of the glass with a neutral detergent;

6. Place the new cartdrige

7. Make sure that the O-rings (the rounded seal) is well positioned on its slot at the top of the glass;

Screw the glass by hand making sure that the cartridge corresponds to the code written on the label on the

pre-filter; DO NOT USE THE KEY TO CLOSE THE GLASS;

Installation, Use and Maintenance Manual

19

Extra Maintenance

Procedure to preserve membranes in case of a long stop.

The procedure for the preservation of membranes must be done every time the plant remains shutdown for

more than 30 days. In some cases where the outside temperature exceeds 30 ° C, we recommend making

the procedure after three days of stop.

To perform the procedure of membranes preservation, you must follow the steps described below:

1. Make a Flushing;

2. Fill a vat with 15 liters of clean water without chlorine and dissolving 150 gr. (half bottle) of CLEANER A;

3. Connect a pipe at the inlet in the free two-way valve on the sea water pump;;

4. Dip the pipe into the vat containing the solution;

5. Acting on the two-way valve, closing the sea water line and opening the water intake line connected to the pipe

immersed in the solution;

6. Disconnect the Drain pipe and dip into the vat containing the solution by creating a closed loop;

7. On watermaker mod. Classic, make sure to have opened the High Pressure Valve;

8. Press WASHING or START (su mod. Classic) and wait for 30 min. at least;

9. Press STOP;

10. Reconnect the DRAIN pipe to its original position;

11. Make n. 3 FLUSHING cycle;

12. Fill a vat with 15 liters of clean water without chlorine and dissolving 150 gr. (half bottle) of CLEANER B;

13. Disconnect the Drain pipe and dip into the vat containing the solution by creating a closed loop;

14. Press WASHING or START (on mod. Classic) and wait for 30 min. at least;

15. Press STOP;

16. Reconnect the DRAIN pipe to its original position;

17. Make n. 3 FLUSHING cycle;

18. Fill a vat with 10 liters of clean water without chlorine and dissolving 1 lt di STORAGE SOLUTION;

19. Disconnect the Drain pipe and dip into the vat containing the solution by creating a closed loop;

20. Press WASHING or START ( on mod. Classic) and wait for 5 min;

21. Press STOP;

22. Reconnect the DRAIN pipe to its original position;

23. Acting on the two-way valve, closing the water intake line connected to the tube immersed in the solution and opening

the sea water line;

24. Leave the watermaker full with this solution;

25. Replace the Filter Cartridges before using the watermaker.

At the next start, press the WASHING button and wait for min. 5 minutes. On Classic models, press START and

wait for min. 5 minutes before adjusting the High Pressure to 60 bar.

This procedure must be performed before the long winter break, during which it is good to

repeat the practice every 6 months

It is recommended the use of chemicals provided by OSMOSEA SRL to avoid a

deterioration of membranes caused by not suitable products.

Installation, Use and Maintenance Manual

20

Osmotic-Membrane replacement

1. Remove the power cable from the plant;

2. Unscrew and remove the high and low pressure pipes from the vessel containing the membranes;

3. Remove the screws retaining the vessel caps and remove the half-moons

5. Tighten the screws to the middle and with two wrench extract the white caps leveraging.

6. Remove the membranes following the direction of the arrow indicated on the vessel;

7. Lubricate the O-ring of the new membrane, placed on one end of the membranes and those on the white

caps of the vessel with silicone grease;

8. Insert the new membrane following the direction of the arrow indicated on the vessel and taking care that the

end of the membrane with the O-ring is on the feeding side;

9. Insert the caps;

10. Insert the half-moons and tighten the screws;

11. Connect the tubes previously detached;

12. Turn on the plant and make sure there are no losses;

For better maintenance it’s preferable to let the assistance centers of OSMOSEA SRL

carry out this types of control

Each procedure of disassemble and reassemble must be done with:

1. Absolute certainty that the plant is shut down. In case the machine is on, remove the power to the central

command by pressing the emergency button on the control unit.

2. Making sure the working environment is an area adequately equipped with all necessary equipment and

free of dangerous combinations;

3. Thoroughly clean each piece reassembled, scouring or lubricating depending on the particular destination;

Table of contents

Other OSMOSEA Water System manuals

Popular Water System manuals by other brands

Reliable

Reliable DDX-LP PrePak Instructions for installation, operation care and maintenance

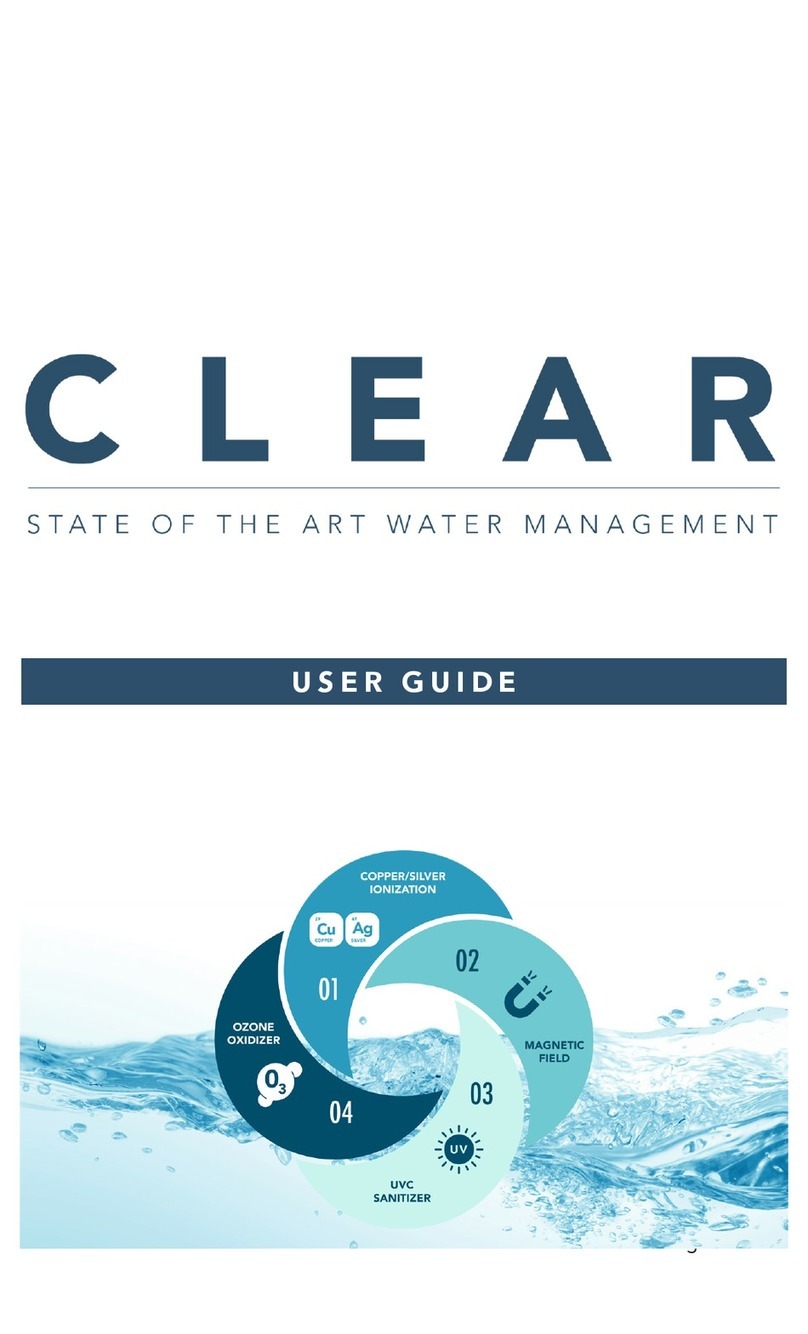

Clearwater Spas

Clearwater Spas CLEAR user guide

Taylex

Taylex ABS5000 installation manual

Hilti

Hilti DD-WMS 100 Original operating instructions

Zip

Zip HydroTap G4 Series installation instructions

Santevia

Santevia Gravity Water System user manual