OSO HOTWATER Nano - N 5 User manual

146007-09 - 10-2021

Manufactured by OSO Hotwater AS

Industriveien 1 - 3300 Hokksund - Norway

Tel: + 47 32 25 00 00 / Fax: + 47 32 25 00 90

Nano - N

5 l.

EN

SAFETY INFORMATION

O&M INFORMATION

INSTALLATION MANUAL

TDS - TECHNICAL DATA SHEET

2

CONTENTS

1. Safety instructions................................................ 3

1.1 General information..................................... 3

1.2 Safety instructions for users..................... 4

1.3 Safety instructions for installers............. 4

2. Product description ............................................. 5

2.1. Product identification.................................. 5

2.2. Intended use ................................................... 5

2.3 CE marking....................................................... 5

2.4 Technical data.................................................. 5

2.5. ErP data (TDS).................................................. 5

3. Installation instructions..................................... 6

3.1. Products covered by these

instructions........................................................ 6

3.2. Included in delivery....................................... 6

3.3. Product dimensions ..................................... 6

3.4. Requirements for installation

location .............................................................. 7

3.5. Pipe installation............................................... 8

3.6. Electrical installation................................... 10

4. Initial commissioning ......................................... 12

4.1. Filling with water.......................................... 12

4.2. Turning on the power ............................... 12

4.3. Control points................................................ 12

4.4. Emptying of water....................................... 12

4.5. Handover to end-user............................... 12

5. User Guide................................................................ 13

5.1. Settings.............................................................. 13

5.2. Maintenance................................................... 13

6. Troubleshooting................................................... 14

6.1. Faults and fixes.............................................. 14

7. Warranty conditions.......................................... 15

7.1. Warranty and registration....................... 15

7.2. Customer service.......................................... 15

8. Removing the product..................................... 15

8.1. Removal............................................................ 15

8.2. Returns scheme............................................ 15

3

1. SAFETY INSTRUCTIONS

1.1 General information

•Read the following safety instructions

carefully before installing, maintaining or

adjusting the water heater.

•Personal injury or material damage may

result if the product is not installed or

used in the intended manner.

•Keep this manual and other relevant doc-

uments where they are accessible for fu-

ture reference.

•The manufacturer assumes compliance

(by the end-user) with the safety, oper-

ating and maintenance instructions sup-

plied and (by the installer) with the fitting

manual and relevant standards and regu-

lations in effect at the date of installation.

Symbols used in this manual:

!

WARNING Could cause serious injury or death

!

CAUTION Could cause minor or moderate injury or damage to property

DO NOT

!

DO

!

This document should be kept in a suitable place where it is accessible for future reference.

!

4

1.3 Safety instructions for installers

!

WARNING

The overflow from the safety valve must NOT be sealed or plugged.

Fitting an external control unit managing the power supply to the product is NOT allowed

without approval from the manufacturer.

!

Any overflow pipe from the safety valve MUST be >1/2 mm inside, clear, undamaged and

frost-free with a fall to the drain.

!

Fixed electric fittings shall be used for installation in new homes or when changing an

existing electrical setup in accordance with regulations.

!

The mains cable shall withstand 90°C. A strain reliever must be fitted.

!

The product shall be filled with water before the power is switched on.

!

The relevant regulations and standards, and this installation manual, must be followed.

1.2 Safety instructions for users

!

WARNING

The overflow from the safety valve must NOT be sealed or plugged.

The product must NOT be covered over the cover on the front.

The product must NOT be modified or changed from its original state.

Fitting an external control unit managing the power supply to the product is NOT allowed

without approval from the manufacturer.

Children must NOT play with the product or go near it without supervision.

!

The product shall be filled with water before the power is switched on.

!

Maintenance/settings shall only be carried out by persons over 18 years of age, with sufficient

understanding

!

CAUTION

The product must not be exposed to frost, over-pressure, over-voltage or chlorine treatment.

See warranty provisions.

Maintenance/settings shall not be carried out by persons of diminished physical or mental

capacity, unless they have been instructed in the correct use by someone responsible for their

safety.

!

CAUTION

!

The product shall be fitted in accordance with Part G3 of building regulations.

Liability for consequential damage will only apply if this is followed.

!

The product shall be properly aligned vertically and horizontally, on a floor or wall suitable for

the total weight of the product when in operation. See type plate.

!

The product shall be mounted to allow access to the junction box when needed.

5

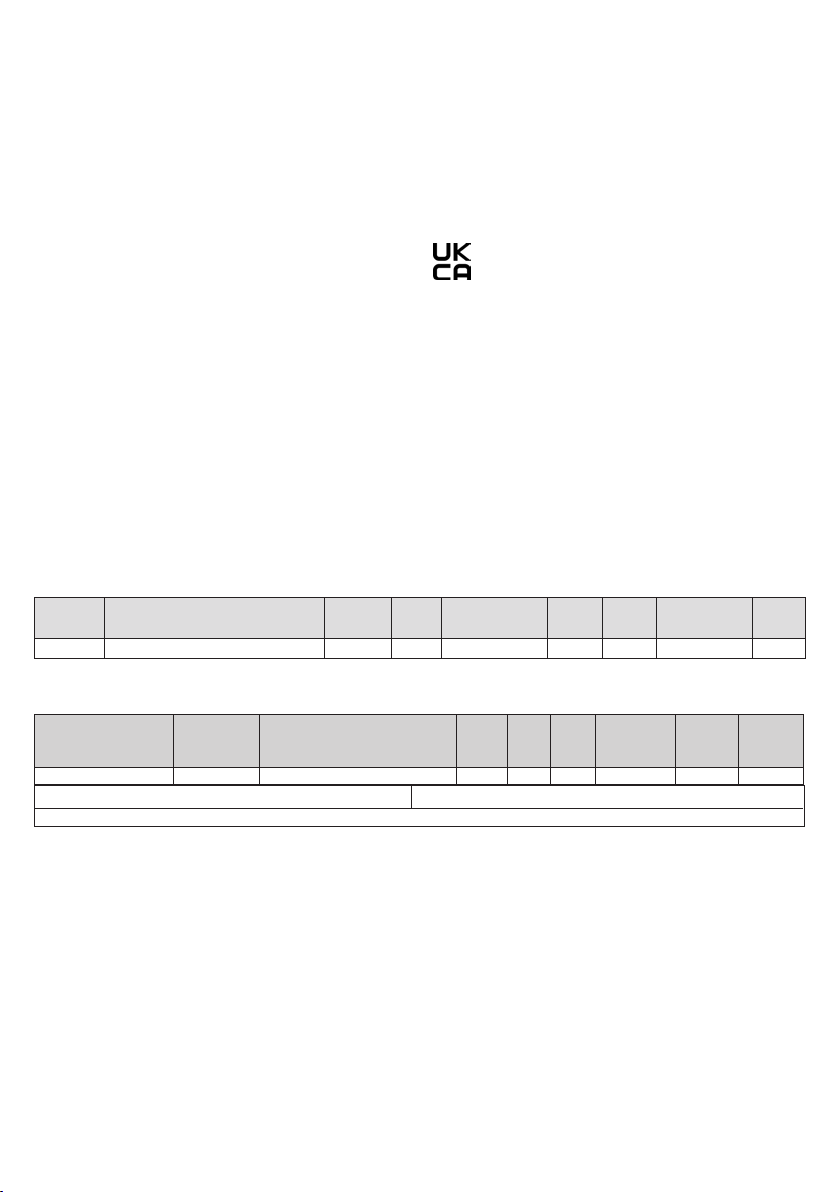

2.4 Technical data

NRF no. Product code: Capacity

persons Weight

kg. WxDxH

mm. Freight

vol. m³ IP

class Heating time

hours Dt 65°C Heat

loss W

1080 6051 N 5 - 2.8 kW 1x230V 0.5 12 200x234x500 0.03 IP44 0.1 13

2.5 ErP data - Technical Data Sheet

Brand Model-no. Model name Tap

profile

ErP

Rating

Energy

eff. % AEC - kWh/a

Thermo-

stat set-

ting °C

Volume

40°C

water

OSO Hotwater AS

1080 6051 Nano - N 5 - 2.8 kW 1x230V

XXS A 35 525 60 7

Directive: 2010/30/EU Regulation: EU 812/2013 Directive: 2009/125/EC Regulation: EU 814/2013

Efficiency-tested according to standard: EN 50440: 2015

2. PRODUCT DESCRIPTION

2.1 Product identification

Identification details for your product can be found

on the type plate fixed to the product. The type

plate contains details of the product in accordance

with EN 12897:2016 and EN 60335-2-21, as well as

other useful data. See Declaration of Conformity at

www.osohotwater.co.uk for more information.

OSO products are designed and manufactured in

accordance with:

• Pressure vessel standard EN 12897:2016

• Safety standard EN 60335-2-21

• Welding standard EN ISO 3834-2

OSO Hotwater AS is certified for

• Quality ISO 9001

• Environment ISO 14001

• Work environment ISO 45001

2.2 Intended use

The Nano is designed to supply homes with hot

water, and to reheat water where there are long

lengths of pipe etc.

The product is designed to be mounted on a wall

2.3 UKCA marking

The UKCA mark shows that the product complies

with the relevant Directives. See Declaration of

Conformity at www.osohotwater.co.uk for more

information.

The product complies with Directives for:

• Low voltage LVD 2014/35/EU

• Electromagnetic compatibility EMC 2014/30/EU

•

Pressurised Equipment Directive

PED 2014/68/EU

Any safety valve(s) used should be CE-marked

and comply with the PED 2014/68/EU.

This manual suits for next models

1

Table of contents

Other OSO HOTWATER Industrial Equipment manuals