OTARI MX-5050BII Series User manual

Other manuals for MX-5050BII Series

1

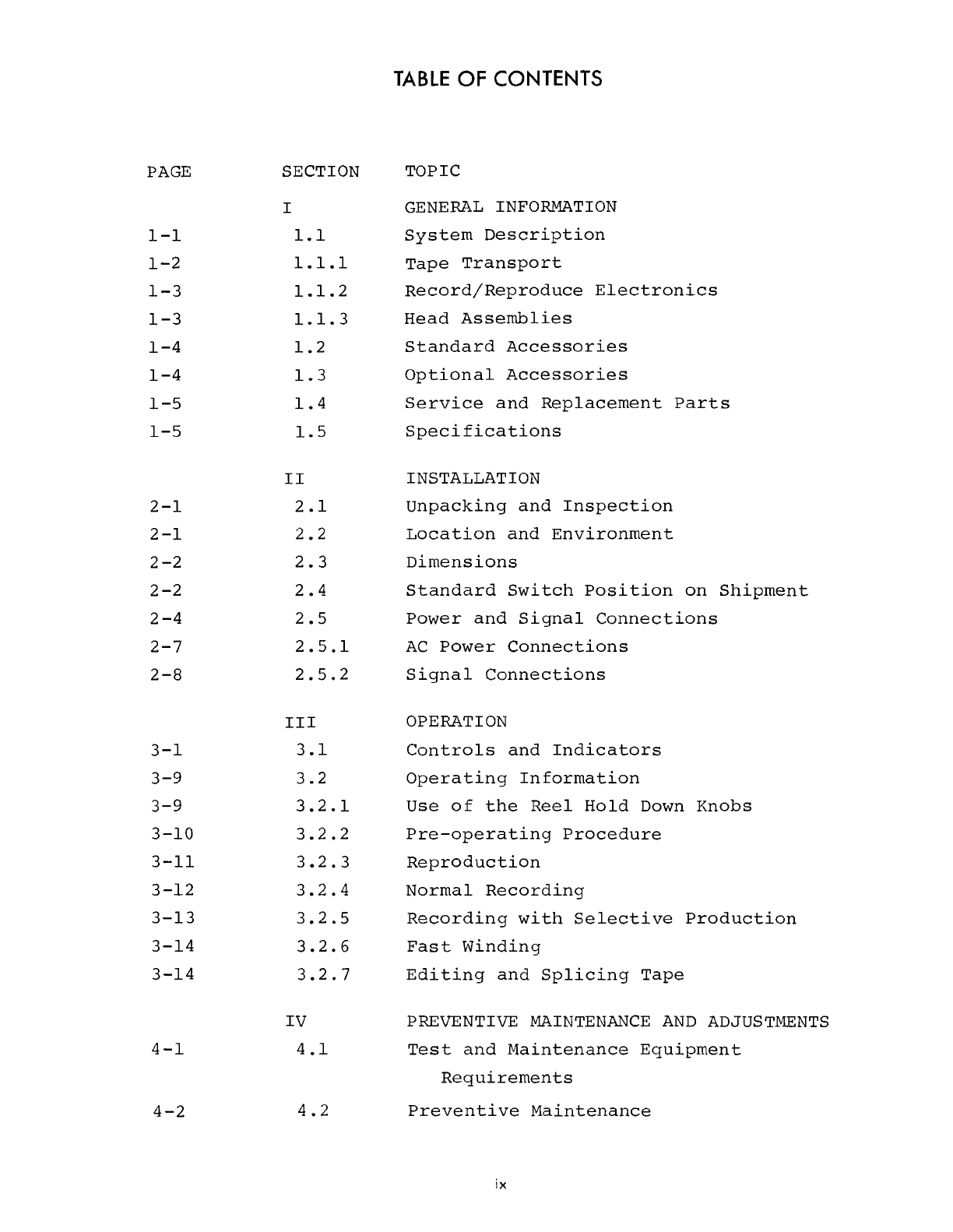

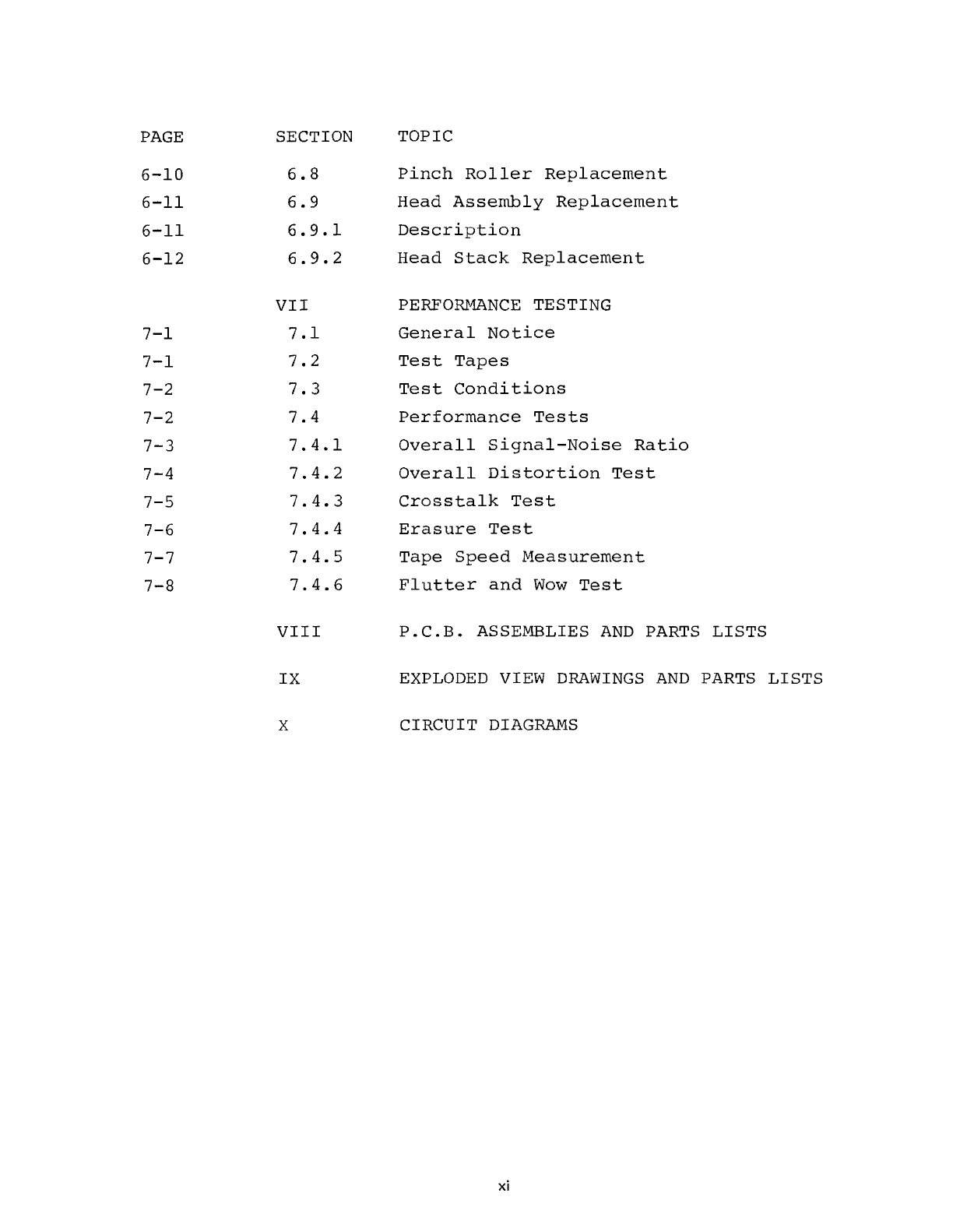

Table of contents

Other OTARI Recording Equipment manuals

OTARI

OTARI MX-505MKIII-2 User manual

OTARI

OTARI MX-50II Series User manual

OTARI

OTARI MX 5050 BQII Series User manual

OTARI

OTARI MTR-90III User manual

OTARI

OTARI MX-55T-M User manual

OTARI

OTARI MX-5050 User manual

OTARI

OTARI MTR-10II Series User manual

OTARI

OTARI RADAR User manual

OTARI

OTARI MX-5050BII Series User manual

OTARI

OTARI MX-505MKIV-2 Manual

Popular Recording Equipment manuals by other brands

Sound Devices

Sound Devices 788T User guide and technical information

Interlogix

Interlogix Kalatel KA2 ProBridge Series Product Overview & Installation Manual

VoiceCollect

VoiceCollect IR44CF-II Battery changing instructions

Megatron

Megatron ETA25PS Programming manual

Nav TV

Nav TV W213-N RVC quick reference

Citronic

Citronic DSM48 user manual

ADJ

ADJ American Audio XEQ-152B instruction manual

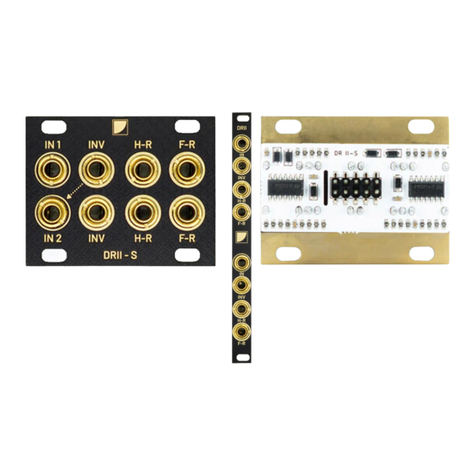

BLACK NOISE

BLACK NOISE Dual Rectifier II - S user manual

Peavey

Peavey Digital Effects Processor user guide

Wheatstone

Wheatstone E-Series Technical documentation

Zoom

Zoom G7.1ut Operation manual

Velleman

Velleman USB INTERFACE KIT FOR ROBOTIC ARM Assembly and instruction manual