1.2 Using this Manual

This manual is intended for use with both MX-50II models. For convenience,

the descriptions and references apply to the MX-50II-N, where any

differences exist between this model and others in the series, those

differences will be fully explained in context.

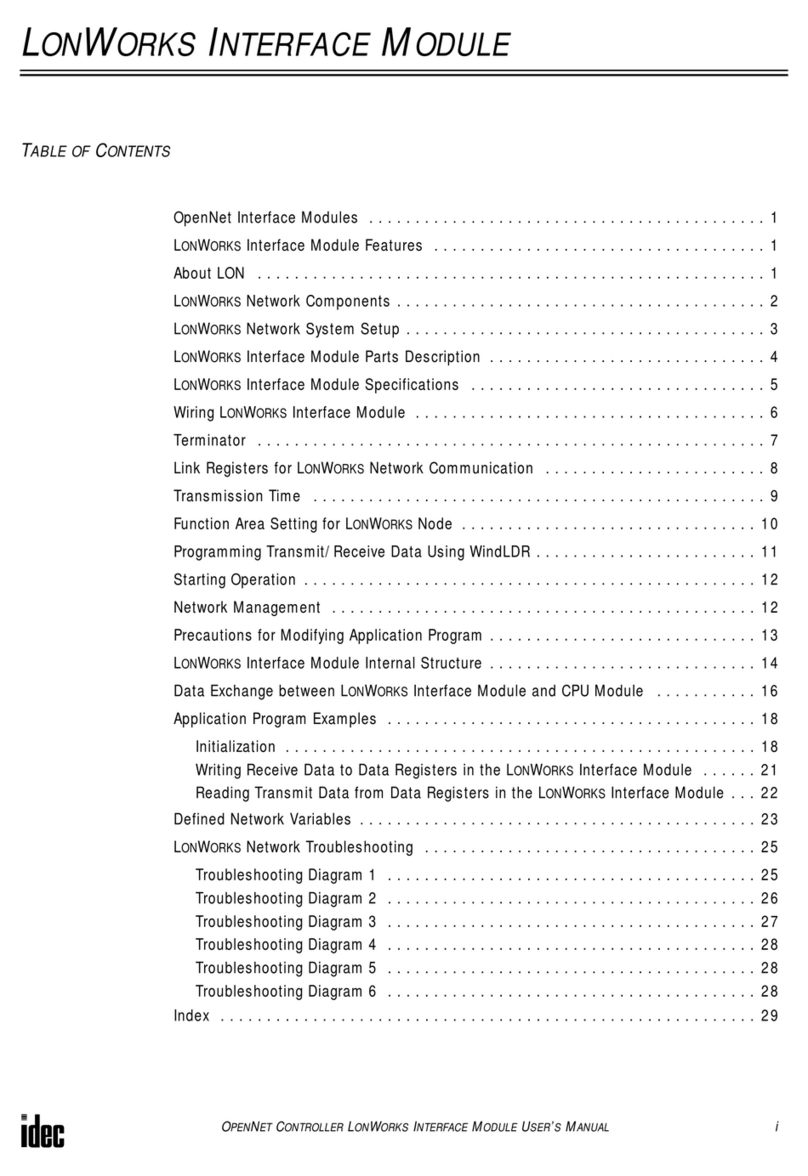

◆ Organization: This manual is divided into nine sections beginning with

this Introduction which contains general information about the MX-50II

Series and about the manual.

Section 2, Installation, contains the information necessary when first

unpacking and installing the machine. The information and procedures

contained in this section should be followed very carefully when the machine

is first unpacked and installed.

Section 3, Controls and Indicators, contains a keyed reference guide to the

operating controls, indicators, and connectors on the machine. This section

contains detailed information about each control and its function. Refer to

this section when you have a question about the function of a particular

control, indicator, or connector.

Section 4, Operation, describes the operation of the MX-50 machines, and is

divided into two parts; a. A table of machine operating modes listing each

mode and the controls necessary to enter that mode; and b. Detailed

operating instructions, which describe each operation and the controls and

indicators associated with that operation.

Section 5, Maintenance and Alignment, provides the information necessary

to perform routine maintenance operations, including head cleaning and

demagnetizing and capstan motor lubrication. It also covers the audio and

transport adjustments associated with normal operation of the machine.

Section 6 Printed Circuit Board Layouts and Parts Lists, contains two-color

“x-ray” views of the printed circuit boards (PCBs) showing component

locations and foil traces. This section also contains Parts Lists of the

electronic components associated with each PCB.

Section 7 Exploded Views and Parts Lists, contains assembly drawings of

the machine “exploded” to show internal parts and hardware, and the order

of assembly. Each drawing is keyed to an accompanying Parts List

containing the Otari part number for each mechanical component.

Appendix contains the installation instruction for optional accessories.

The final section contains the Schematic Diagrams for electronics

assemblies and major printed circuit boards.

◆ Conventions within this Manual

This manual uses the following notation:

Buttons, Switches PLAY BUTTON or TAPE TIMER

Indicators, LED lamps READYINDICATOR

Modes PLAY or PLAY MODE

The six major transport control buttons are not labeled on the machine, but

are labeled on the button caps with graphic symbols. This manual uses the

name of the button rather than the graphic symbol whenever the buttons are

referred.