OTARI MX 5050 BQII Series User manual

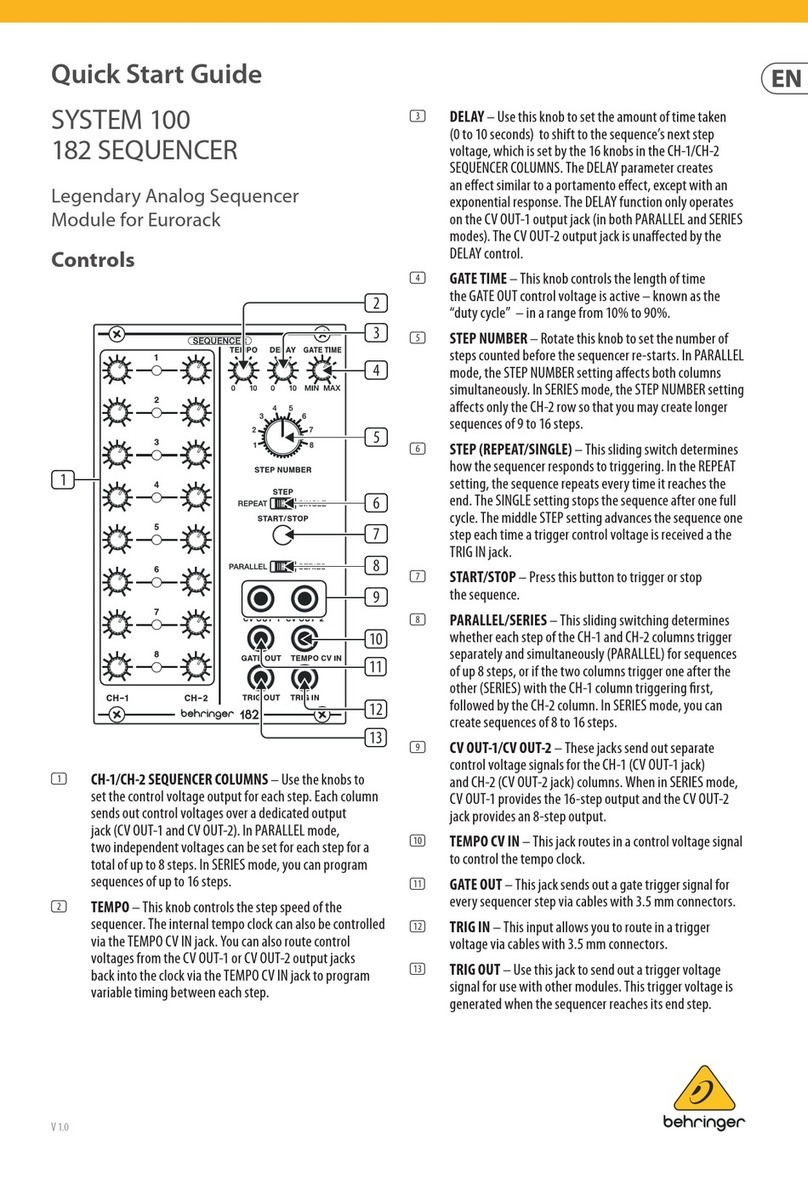

[f]11!Jmu

SYNCHRONIZER

INTERFACE

INFORMATION

FOR

MX AND

MTR

SERIES

MACHINES

EDITION

1

MAY

1985

[j]fi!iJmQ,

MX

5050

BQII

&

MK

III

SERIES

Conditions

For

Synchronizer

Use

1.

All

transport

tallies

are

low

true.

2.

Synchronizer

must

read

tach

pulses

in

fast

wind

as

machines

won't

read

time

code

at

high

speeds

without

circuit

modifications.

Also,

tape

lifters

would

need

to

be

defeated

in

all

modes

which

is

not

suggested

by

Otari.

3.

Synchronizer

must

be

able

to

control

capstan

speed.

by

varying

a

DC

voltage.

This

voltage

is

±

13v

on

machines

with

locator

connectors

and

±

3v

on

machines

without

locator

connectors.

4.

Synchronizer

must

supply

dry

contacts

for

speed

bypass

during

non-synchronizer

use

to

provide

calibrated

speed.

If

cable

is

removed

while

in

EXT

capstan

control,

the

machine

will

not

operate

at

calibrated

speed

unless

a dummy

plug

is

installed.

Note:

On

machines

with

locator

connectors,

the

choice

of

internal

or

external

capstan

control

is

located

on

the

control

PCB. When

switched

to

EXT.,

the

pitch

control

will

not

function

even

though

the

LED

will

light

when

the

pitch

knob

is

pulled

on.

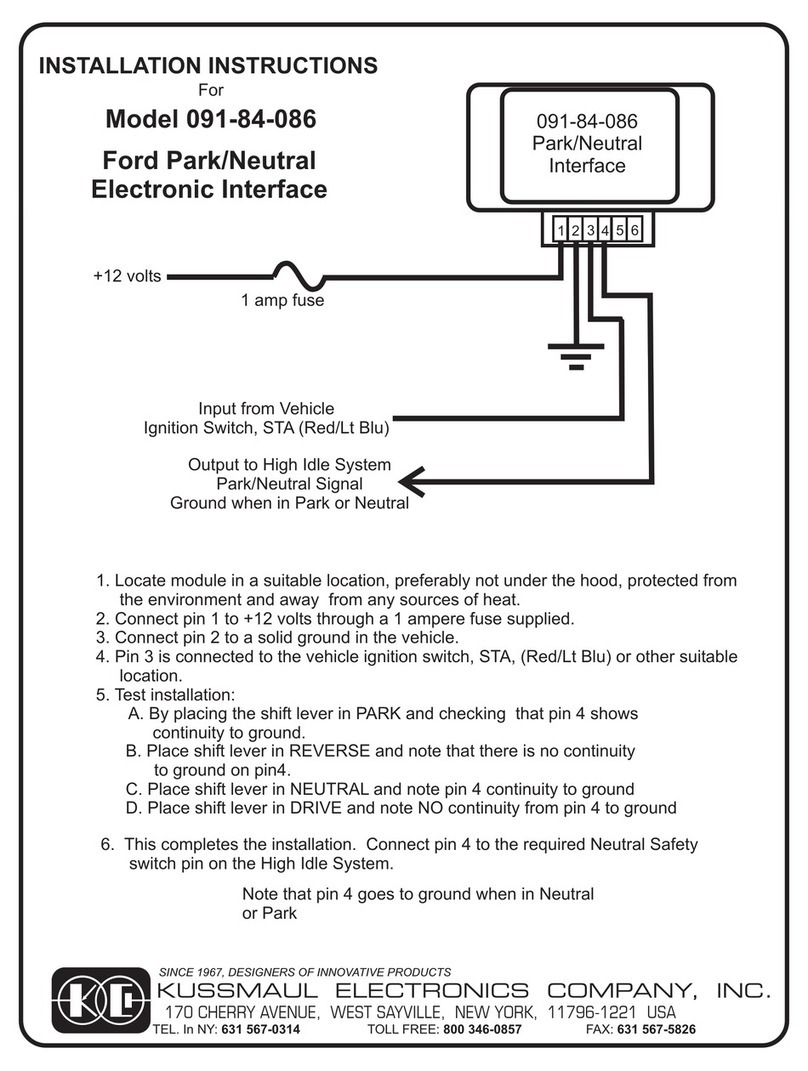

[fJOSCJUJ

MX-5050

MK

III

SERIES

TO

BTX

SHADOW

MACHINES

WITH

NO

LOCATOR

CONNECTOR

INCLUDING

BO-II

TRANSPORT

CONTROL

PCB

BTX

SHADOW

TRANSPORT

CONTROL

CONNECTOR

+5VDC

C127+

--------------+---t20

CONTROL

8UPPLY

TALLY

8UPPLY

~---+---41&

8TOP

COMMON

ITl5'JS

TAL

LY

IC28

PIN

12

----------+-----+----131

STOP

TALLY

.----It-----I

3 REC

CO

tot

M0 N

F.FW"D

TALLY

IC

1

PIN7

----------+---+--+----1

7 F

.FWD

TALLY

F.FWD

SWITCH

CONN

MW

PIN2

-----------+---+---+---417

F.FWD

COMMAND

ftW

TALLY

IC1

PINe

----------+---+--+----132

REW

TALLY

STOP

SWITCH

CONN

MW

PIN1

----------+---+--+----140

STOP

COMMAND

PLAY

TALLY

IC1

PIN2

----------+---+--+----18

PLAY

TALLY

REW

SWITCH

CONN

MW

PIN3

----------f----t--_t-__t43

REW

COMMAND

PLAY

SWITCH

CONN

MW

PIN4

----------+-

.......

----1----i14

PLAY

COMMAND

f"Wi),REV

IC30

PIN6

----------+-----+----127

DIR-

GROUND

C127----------~---_t-__t"

SY8TEM

GROUND

TACH

+

REC

SWITCH

CONN

MW

PIN6

----------------~

REC

COMMAND

TACH

COLLECTOR

012

-----

•

FROM

VARI

SPEED

SWITCH

-------

ORIGINALLY

ON

PIN

..

OF

CAPSTAN

SERVO

PCB

--------~~

TACH

-

--------1~

BYPAS8

(N.C.)

~

BYPASS

(N.O.)

L--[!]

8ERVO

VOLT

1X

•

CAPSTAN

SERVO

PCB

PIN

..

-------------------~

BYPA88

(COM)

NOTES:

1.

TO

IMPROVE

CAPSTAN

LOCK-UP

PERFORMANCE.

JUMPER

RS

..

(1K)

WITH

A

100

OHM

"

..

WATT

RE818TOR

ON

THE

MOTHER

PCB

OF

THE

8HADOW

MAINFRAME

.2.

WITH

NO

SYNCHRONIZER

CONNECTED,

JUMPER

THil8E

POINT8

FOR

NORMAL

CAPSTAN

8PEED

~

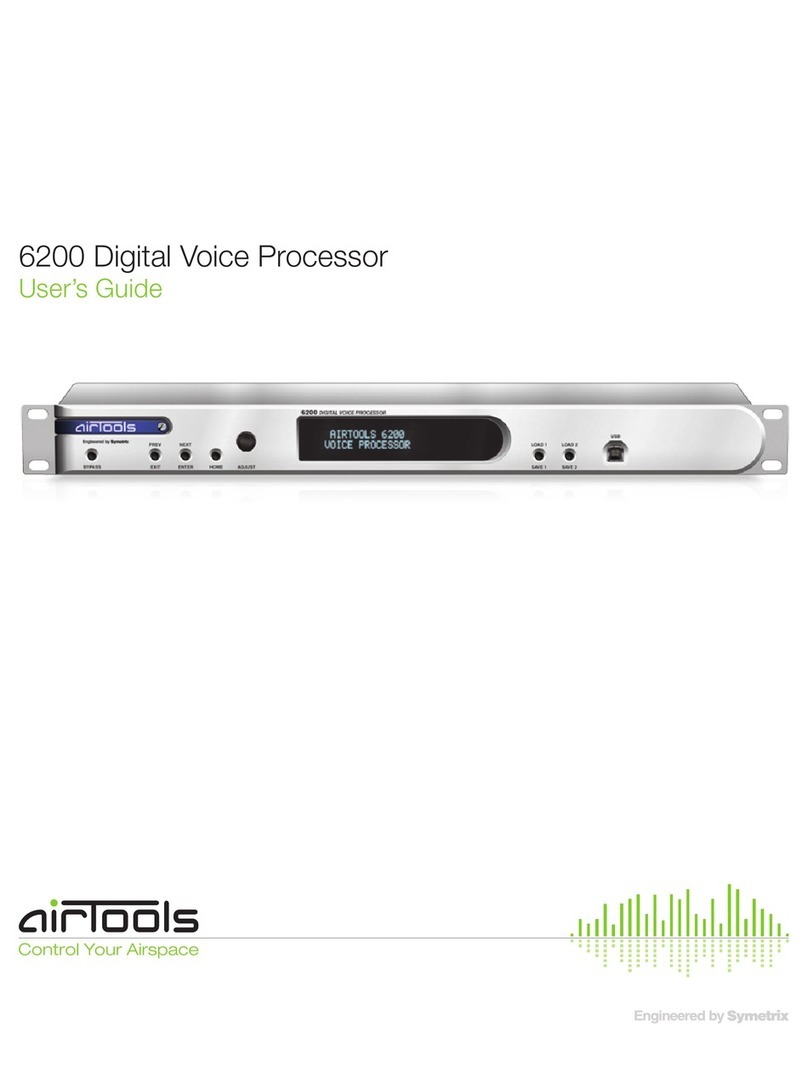

{f]fi!iJmO

..

MX-5050

MK

III

SERIES

TO

BTX

SHADOW

MACHINES

WITH

16

PIN

LOCATOR

CONNECTOR

INCLUDING

SQ-II

LOCATOR

CONNECTOR

+6VDC

~

____________

__

_STOP

TALLY

C!l-----------------

-F.FWD

TALLY

GJ~----

F

.FWD

SWITC

H

~f-----------

-REW

TALLY

~~------------

___

S

TO

P SW

ITC

H

~t----------------

-PrAY

TALLY

~~-----------------------

RE W

SWITC

H

[!!)~-------------------

PLA

Y

SWITCH

~f------------

BTX

SHADOW

TRANSPORT

CONTROL

CONNECTOR

-.--

..

-

----

-

r---::

CONTROL

SUPPL

V

~

TALLY

SUPPLY

r---+!-----§

STOP

COMMON

-+I----+i--§]

STOP

TALLY

,

-.--~---0

-7'-'-~~

r+~

!

REC

COMMON

F.FWD

TALLY

F.FWD

COMMAND

REW

TALLY

STOP

COMMAND

--+--t-----it----t

6

PLA

Y

TALL

Y

REW

COMMAND

PLAY

COMMAND

FWD/REV

~~-----------------4--------r---127

DIR-

GROUND

~~--------------------------

REC S

WITC

H

~I-----------------------

l--------

----§

SYSTEM

GROUND

~

TACH

+

--------~~

REC

COMMAND

TACH

~~-------------------------------~

TACH

-

SERVO

COM

[Q~---------

---------@:!)

BYPASS

(N.C.)

~

BYPASS

(N.O.)

~

SERVO

VOLT

1X

EXT

DC

IN

[!]I--------------------------~

BYPA

SS

(COM)

TRANSPORT

CONTROL

PCS

LOCATOR

CONNECTOR

PIN

NO.

IC

28

PIN

12

------------------[!]

IC1

PIN7----------------------~~

IC

1

PI

N6

--------------------[!]

IC1

PIN2-----------------------~

-

REMOVE

AND

INSULATE

THE

EXISTING

WIRES

TO

THESE

PINS

ADD

NEW

WIRES

TO

PINS

I.

7.

I.

8

AS

SHOWN

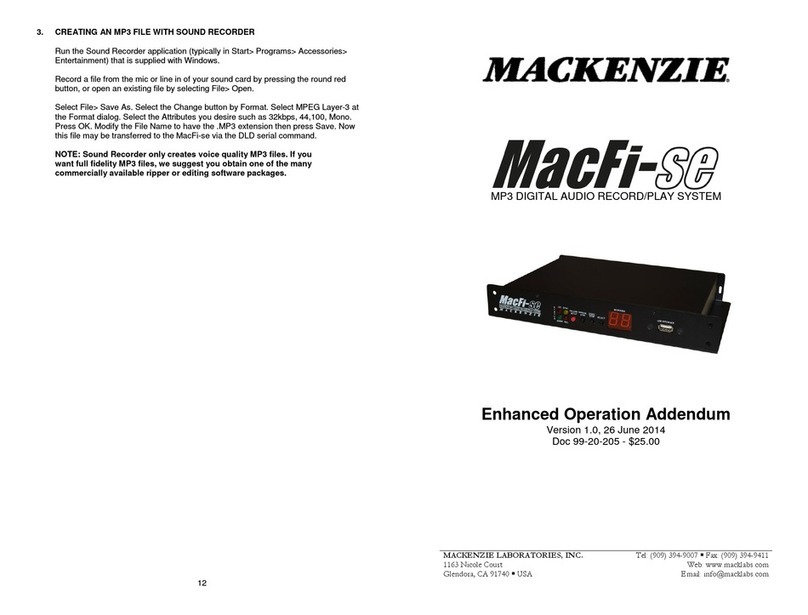

l!lfJS{f]O

MX-5050

MK

III

SERIES

TO

BTX

SHADOW

MACHINES

HAVING

34

PIN

LOCATOR

CONNECTOR

LOCATOR

CONNECTOR

BTX

SHADOW

TRANSPORT

CONTROL

CONNECTOR

• + 6 V

DC

~r____--------------

-1-··~

CONTROL

SUPPL

Y

I

~

TALLY

SUPPLY

,-

15

I

31

Sl1)!P

TALLY

~-------------------+------+--4

--0

~

TALL

Y

~---------------

t t·-

~

+--

17

j

F.

FWD

SWITCH

1I]r-----------------+--

REW

TALLY

2~------------------+-~r-----+-~

32

STOP

SWITC

H 1

t----------------+---+----+-~

40

PLAY

TALLY

31t--------------------+---+----+-~

6

I

REW S

WI

TC

H

0r----------------

!

i

.

t-

.

t-t:

: 2

PLAY

SWITCH

~r------------------------~-

~--t--B

FYVID/REV

~------------------+-------+-~

@]

GROUND

~------------------

••

-i

~

i

L-EJ

STOP

COMMON

STOP

TALLY

REC

COMMON

F.FWD

TALLY

F.FWD

COMMAND

REW

TALLY

STOP

COMMAND

PLAY

TALLY

REW

COMMAND

DIR+

PLAY

COMMAND

DIR-

SYSTEM

GROUND

TACH

+

REC

SWITCH

0----------------------------------1~

REC

COMMAND

T A C H I!:!]r____----

---[!!)

TACH

-

SE

RV

0

COM

~r-------------------------

------t~

BYPASS

(N.C.)

r~

BYPASS

(N.O.)

~

SERVO

VOLT

lX

EXT

DC

IN

~-----------------------~~

B

YPA

SS

(COM)

•

EARLY

MACHINES

WITH

34

PIN

CONNECTORS

010

NOT

HAVE

+6VDC

ON

PIN

24

AOD

A

WIRE

FROM

PIN

24

TO

CONTROL

PCB

CONNECTOR

MK

PIN

2

[f]fifiJ[j]Q

MX

70

SERIES

Conditions

For

Synchronizer

Use

1.

All

transport

tallies

are

low

true.

2.

Speed

switch

on

remote

to

EXT.

position.

3.

All

connections

for

synchronizer

are

available

on

37

pin

'D'

connector

labeled,

"PARALLEL

I/O."

See

cable

schematic.

Note:

For

code

reading

during

fast

wind,

installation

of

ZA-57l

wide

band

reproduce

assy.

is

recommended.

Contact

factory

for

details.

'6

[jJiifiJIIlO"

MX-70

TO

BTX

SHADOW

BTX

SHADOW

EXTERNAL

PARALLEL

1/0

CONNECTOR

TRANSPORT

CONTROL

+5V

33

20

CONTROL

SUPPLY

4

TALLY

SUPPLY

15

STOP

COMMON

STOP

TALLY

12

31

STOP

TALLY

3

REC

COMMON

"

TALLY

13

7

FF

TALLY

FF

SWITCH

4

17

FF

COMMAND

REW

TALLY

14

32

REW

TALLY

STOP

SWITCH

3 0

STOP

COMMAND

P'i:AY

TALLY

11

6

PLAY

TALLY

REW

SWITCH

S 3

REW

COMMAND

DIR+

PLAY

SWITCH

2 14

PLAY

COMMAND

FWD/REV

18

27

DIR-

21

SYSTEM

GND

TACH+

REC

SWITCH

28

RECORD

COMMAND

TACH

17

26

TACH-

LIFTER

[!] 37

LIFTER

SIG

GND.

16

4S

PWR GND

SERVO

COM

c=:

BYPASS

(N.O.I

33

SERVO

8800

HZ

EXT

FREQ

IN

~

~

BYPASS

(COM)

'.

@fifiJIJJO

MTR

10

1/12

1

SERIES

Conditions

For

Synchronizer

Use

1.

All

transport

tallies

are

high

true

and

can

easily

be

converted

to

low

true

if

necessary.

A. To

invert

tallies

on

a

machine

where

no

remote

or

auto

locator

is

being

used,

replace

IC

20

on

transport

control

PCB

with

an

SN7406N.

B.

To

invert

tallies

on

a

machine

where

a

remote

or

auto

locator

is

being

used,

installation

of

a

ZA-53F

tally

interface

assy.

is

necessary.

2.

Do

not

pull

lifter

defeat

(cue)

line

down

except

i~

fast

wind

modes

to

avoid

attenuated

audio.

If

synchronizer

must

do

this,

contact

factory

for

modifications

to

transport

control

PCB.

3.

RC

time

constant

shown

in

cable

schematic

must

be

used

to

prevent

accidental

enabling

of

back

play

mode.

4.

Speed

mode

switch

on

machine

to

be

set

to

EXT.

for

synchronizer

use.

For

normal

calibrated

speed,

return

switch

to

FIX

position.

5.

If

using

at

30ips

for

synchronizer

application,

jumper

across

C40

on

capstan

control

PCB.

6.

Verify

value

of

R22

on

capstan

control

PCB

is

680JL.

If

not,

install

it.

Note:

All

connections

for

synchronizer

use

are

available

on

20

pin

HONDA

connector

labeled,

"EXT. SYNC."

See

cable

schematic.

l!JOliJl11D.

MTR-1

OIl

121 TO

BTX

SHADOW

BTX

SHADOW

MTR-10/12

TRANSPORT

CONTROL

EXT

SYNC

CONNECTOR

CONNECTOR

PLAY

TALLY

[!]

\ I

l!:!I

PLAY

LAMP

•

F.FWD

TALLY

0 ,

~

F.FWD

LAMP.

REC

COM

~

I

PLAY

COMMAND

o

PLAY

SWITCH

F.FWD

COMMAND

~

0

F.FWD

SWITCH

DIR(+)

0 0

FWD/Im'V

REC

(N.O.)

1!3

[!]

REC

SWITCH

STOP

TALLY

~

f!!]

STOP

LAMP.

REW

TALLY

§]

~

REW

LAMP.

LIFTER

§J

[!]

LIFTER

DEFEAT

STOP

COMMAND

~

[!]

STOP

SWITCH

REW

COMMAND

15

REWIND

SWITCH

0.47

MFD

DIR(-)

27

CONTROL

SUPPLY

2

+I5VDC

TALLY

SUPPLY

STOP

COM

161------

.......

-...:.....,....:......---+--

........

--1

GROUND

BYPASS

(N.O.)

~

SERVO

9800

HZ

~

TACH(+)

TACH(-)

281--------~,~1-----~~~11

TACH

','

,.,

SERVO

COM

61--------~1~:-----~

BYPASS

(COM)

~I---------.!....-~--------E:!)

EXT

SYNC

FREQ

"-

'

•

TALLIES

ARE

HIGH

TRUE

FROM

FACTORY

FOR

LOW

TRUE

TALLIES.

SEE

ITEM

1

ON

CONDITIONB

SHEET

[fJf1f1Jf1]O

MTR

1011/1211

SERIES

Conditions

For

Synchronizer

Use

1.

All

transport

tallies

are

low

true.

2.

Do

not

pull

lifter

defeat

(cue)

line

down

except

in

fast

modes

to

avoid

attenuated

audio.

If

synchronizer

must

do

this,

contact

factory

for

modifications

to

the

transport

control

PCB.

3.

RC

time

constant

shown

in

cable

schematic

must

be

used

to

prevent

accidental

back

play

mode.

4.

Speed

mode

on

machine

to

be

set

to

EXT.

for

synchronizer

use.

For

normal

calibrated

speed,

return

switch

to

FIX

position.

5.

If

using

at

30ips

for

synchronizer

use,

jumper

C40

on

capstan

control

PCB.

6.

Verify

that

R22

on

capstan

control

PCB

is

680JL.

If

not,

install

it.

Note:

All

connections

for

synchronizer

use

are

available

on

37

pin

'0'

connector,

labeled

"PARALLEL

I/O."

See

cable

schematic.

[fJf1lJmo-

MTR-1

alii

1211

TO

BTX

SHADOW

BTX

SHADOW

TRANSPORT

CONTROL

CONNECTOR

MTR-l

on/l

2n

PARAllEL

110

CONNECTOR

PLAY

TALLY

&-

--------

-

------------~

P'L'AV

LAMP

I •

F.FWD

TALLY

B-~-

I ! r,:;,

----------

I

...:...------------~

I!]!'Wl5

LAMP

1

I

REC.

COM

3·

: i

~

I ,

PLAY

,4.~--~I~-------~~----~~-~--~~PLAY

SWITCH

F.FWD

§----------

-----------i0

F.FWD

SWITCH

DIR(-)

~-----------~-.-

~--

---------iE!]

~/REV

I

I

REC

(N.O.)

~

__

~

____

~

__

~~I~1

-----------~~REC

SWITCH

STOP

TALLY

§}--

@]

iTO'P

LAMP

REW

TALLY§--------

~~

LAMP

LIFTER

~--

-----.--

---,--,--

0

LIFTER

DEFEAT

I ,

STOP

~--

[2]

STOP

SWITCH

'0

KOHM8

RE~ND

~~-~-~~~~--~~-----------~~

REWIND

SWITCH

DIR(+)

2

1-----.

0.47

MFD

CONTROL

SUPPL

Y

20~---+------+-----~--'

--~....--------@)

+5

V

TALLY

SUPPLY

441-----1

STOP(COM)~-----

BYPASS

(N.O.)

~

SERVO

9600

HZ

~

TACH

(+)

1

I

, ,

-+----~'~'~--~~---~--~16

GROUND

SERVO

COM

4S~----------------~~---~----~~

, .

I

• I

BYPASS

(COM)

~------------------~~~I

--------------------~~EXT

SYNC

FREQ

.~

[fJfifjJCJO

MTR-1

0/12

WIDE BAND

Modification

of

Audio

Channel

for

Dedicated

Wide Hand

use.

1.

Turn

Off

the

Power

to

the

MTR-10/12

and

remove

the

audio

channel

PCB

from

the

channel

to

be

used

for

Time

Code,

or

modify

a

spare

PCB.

Modification

for

1/411 - 2

Track

Machines

2.

Connect

a 3

kOhm

resistor

across

Rl.

3.

Connect

a 30

Ohm

resistor

across

Rll.

Modification

for

1/211 - 4

Track

machines

2.

Connect

a

4.7

kOhm

resistor

across

Rl.

3.

Connect

a

150

Ohm

resistor

across

Rll.

Perform

the

steps

below

for

all

machines

4.

On

the

upper

(Comp)

side

of

the

PCB,

cut

the

trace

that

leads

to

Pin

16

of

the

edge

connector.

This

defeats

the

play-to-stop

and

fast

wind

muting.

5.

On

the

lower

(Dip)

side

of

the

PCB,

cut

the

trace

that

leads

to

Pin

21

of

the

edge

connector.

On

the

upper

(comp)

side

of

the

PCB,

install

a

100

kOhm

1/4

watt

resistor

from

the

junction

of

R 59

and

R 60

(close

to

VR9

in

the

center

of

the

PCB)

to

the

solder

feed-through

located

between

the

+20

and

-20

V

test

points

located

immediately

below

the

resistors.

This

defeats

the

audio

attenuation

in

Stop,

Cue

Shuttle,

and

Lifter

Defeat

modes.

NOTE:

This

modification

provides

good

quality,

non-phase-

compensated

code

output.

If

your

synchronizer

requires

better

quality

code

than

this

modification

provides,

installation

of

a

WBR-I

Wide

Band

Kit

on

one

of

your

Audio

PCBs

may

be

required.

Please

contact

OTARI

for

further

details.

lflfiDf1JO

MTR

901

SERIES

Conditions

For

Synchronizer

Use

1.

All

transport

tallies

are

low

true

2.

Speed

mode

on

transport

in

EXT.

position.

3.

If

synchronizer

pulls

cue

line

down

in

stop,

center

the

cue

slider

potentiometer

to

avoid

tape

crawl.

4.

9

pin

EXT.

CLOCK

'0'

connector

is

used

for

incoming

and

outgoing

9600Hz

(see

cable

schematic).

5.

50

pin

AUTO

LOCATOR

'D'

connector

contains

tach,

direction

and

transport

command

lines

(see

cable

schematic).

6.

Tallies

are

available

from

lamp

power

resistors

located

on

transport

control

mother

board

#2

which

is

located

inside

left

of

lower

rear

panel.

Use

clipleads

or

EZ

hooks

(see

tally

drawing).

Note:

Since

tally

lines

are

derived

from

low

side

of

button

lamps,

it

is

suggested

to

individually

add

lOOK

pull

up

resistors

from

the

+20V

line

(pin

33)

to

tally

lines

to

prevent

loss

of

tally

information

in

the

event

of

a

lamp

burning

out.

!

! .

I

·,

@i1!iJfJJ

U

MTR-90

I

TO

BTX

SHADOW

BT X SH

ADOW

TRAN

SPO

RT

C

ONTR

OL

CONNE

C

TOR

PL

AY TALLY

~

--

AUTO

LOCATOR

CONNECTOR

--

------

~

~

PLAY/STOP

F. F

we

T A

LL

Y

0

-------~

-'--+

-------

--..j

0

nwo

TAll

Y

PLA

Y

(N.C

.)

PLAY

SWITCH

REC

(COM)

F.F

WO

(N

.

O.)

[!!]

1-

-------

--:'----:------

---

--1

~

F.

FWD

SWITCH

0IR(

- )

~1-

------

-~~~------

-

--1

~

FWD/REV

RE C

(N

.0 .)

~

--------

-'----'-----

---

-

-I

~

A

EC

SWITCH

S

TOP

TALL

Y

@j

--

- -

--

-

--+-+

-

----

--

_I0§1'01.iTAlLY

REW

TALLY

~

------

-

--+-+-----

--

--..j

~

~

TALLY

LIFTERS

(N.OJ

~

-

--

-

-----

-

-+---:----

---

-

--..j~

CUE

SWITCH

STOP

(N.C .)

~

---------c---'--------

-

--..j

E21

STOP

SWITCH

REW

(N.D.)

@

------

--

c-

+----

---

_I~

REW

SWITCH

S

TOP

(CO

M)

~

---------'----'------

--

--I

[!J

-

20VDC

OIR

<+)

2

I-

------

~

TAL

LY 5UP

PLY

"41-

------

--<

I-

--

----"---'----------

--

----

----jHI

...

5 V0 C

C

ONTA

0 L S

UPPL

Y

20

1-

---

+

---

-'-<

~

---

----

___1

2

GRO

UNO

TACH

(+1

I-

--------I-

-

-

-----'-

-+---------

--------

--j~

+ 6 V0 C

TACH

(-)

~

--------

-

f

--------'---7-------

-------

--1~

T A C H

(A

1/1

0)

BY

PASS

(N.D.>

S

ERVO

FRED

OUT

ED----t

~

2 20

OHM

1/4W

B

YPA

5 S (N.Col

36

1-

----

--

---'--'--

---

-

---

-___1

9600

HZ

, ,

BY

PAS

S

(C

0

M)

315

f--

- -

------f--

--;.---\-

---

-

--1

3

EXT

CLOCK

SERV0 F

REa

0 A

au

N0 4

5

f--

----

---------

--'

---+

~

------------

--j

5

GROUND

•

TALLIES

ARE

NOT

PRESENT

ON

THE

CONNECTOR

USE

CLIP

LEAD

S

TO

LAMP

RESISTORS

ON

TRANSPORT

CONTROL

MOTHER

PCB

i~

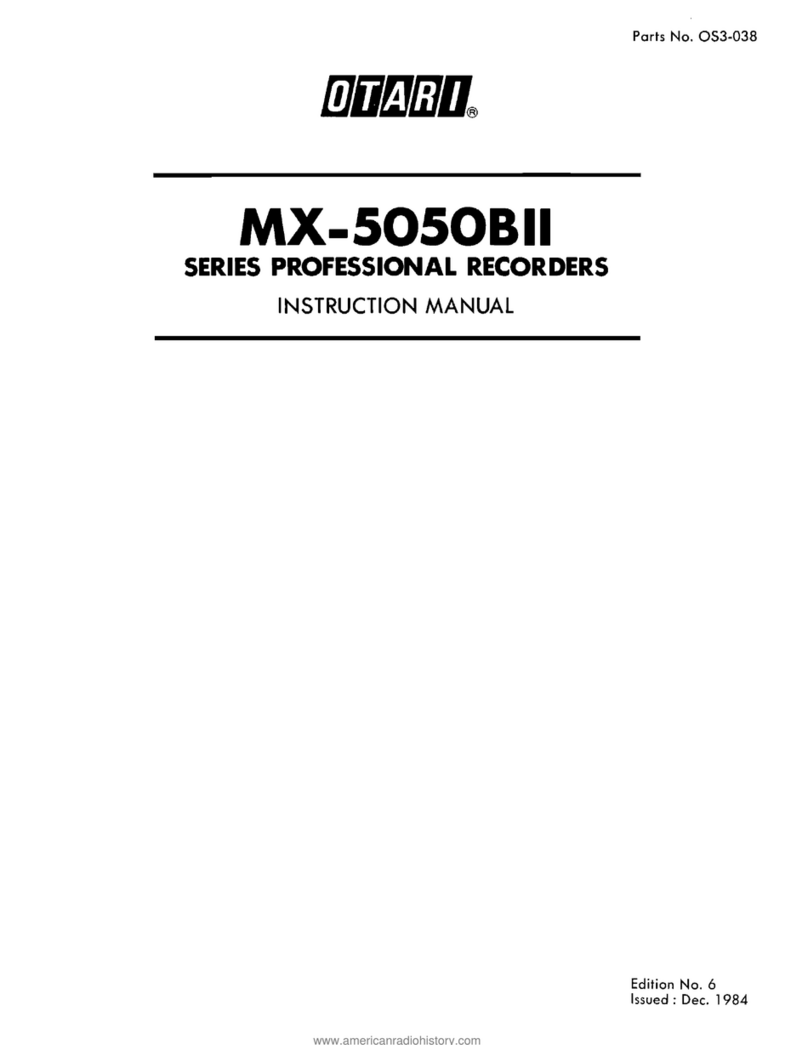

lilfi!iJli1H

~

MTR-90

I TALLIES

-~-I

@)

(@ (@

(@

CN1

CN2

CN3

CN10

n n

r--l

I !

I

USE

EZ

HOOKS

OR

CLIPLEADS

-~-

-+-

F.FWD

TALLY

TALLIES

ARE

LOW

TRUE

WITH

+15V

PULL

UP

REW

TALLY

--.

I--PLAY

TALLY.

STOP

TALLY

REC

TALLY

•

•

NOT

USED

WITH

BTX

SHADOW

--

GREEN

POWER

RESISTORS

I I

I

I L

I

I

U

@)

@)

@) @)

TRANSPORT

CONTROL

MOTHER

PCB"

LOCATED

INSIDE

LEFT

SIDE

OF

LOWER

REAR

PANEL

@fjBlllO

MTR-90

I WIDE BAND

Modification

of

Audio

Channel

for

Dedicated

Wide

Band

use.

1.

rrurn

Off

the

Power

to

the

MTR-90

I

and

remove

the

audio

channel

PCB

from

the

channel

to

be

used

for

Time

Code,

or

modify

a

spare

PCB.

2.

Install

a

10K

ohm

resistor

across

R

101.

3.

Install

a 10K ohm

resistor

across

R

176.

4.

Cut

the

trace

leading

to

pins

28

A & B

of

the

edge

connector

(This

defeats

the

Stop-to-Play

Mute

for

this

channel)

•

5.

Cut

the

trace

between

the

edge

connector

finger

for

pin

14

A & B

and

the

adjacent

feedthrough.

Connect

a

10

kOhm

resistor

from

this

feed

through

to

pin

32

A & B.

(This

connection

defeats

the

Fast-Wind

mute

for

this

channel).

NOTE:

This

modification

provides

good

quality,

non-phase-

compensated

code

output.

If

your

synchronizer

requires

better

quality

code

than

this

modification

provides,

installation

of

a

WBR-l

Wide

Band

Kit

on

one

of

your

Audio

PCBs

may

be

required.

Please

contact

OTARI

for

further

details.

[f]fi!iJ[JJD

MTR

90

II

SERIES

Conditions

For

Synchronizer

Use

1.

All

transport

tallies

are

low

true.

2.

Speed

mode

switch

on

remote

in

EXT.

position.

3.

All

connections

for

synchronizer

use

are

available

on

25

pin

Honda

connector

labeled,

"EXT CLOCK.

II

See

cable

schematic.

{j]OMma

MTR-90

II

TO

BTX

SHADOW

STX

SHADOW

TRANSPORT

CONTROL

CONNECTOR

-

PLAY

TALLY

&

F.FWD

TALLY

7

REC

COM

3

PLAY

14

F.FWD

17

DIR

(-)

27

REC

N.O.

28

STOP

TALLY

31

REW

TALLY

32

LIFTER

37

STOP

40

REWIND

43

DIR

(+)

2

CONTROL

SUPPLY

20

TALLY

SUPPLY

44

STOP

COM

15

BYPASS

N.O.

1 1

SERVO

9600

HZ

33

TACH

(+)

1

TACH

(-)

26

SERVO

COM

45

BYPASS

COM

35

BYPASS

N.C.

36

1..0-

~-----.--.

MTR-9011

EXT.

CLOCK

CONNECTOR

iitAY

TALLY

" -

. 2

.-

F.FWD

TALLY

1 1

PLAY

CMD

13

F.FWD

CMD

21

fWl)/REV

10

REC

CMD

3

~

TALLY

; 5

REW

TALLY

I

I 6

,

LIFTER

DEFEAT

I

I

12

STOP

CMD

14

REW

CMD

20

+5

VDC

17

GROUND

\,

~

~"\

I I

, I

,

, I

15

TACH

OUT

Y

~

, I

, I

. I

18

~

16

\J

EXT

CLOCK

9600

HZ

OUT

'--

[j]fj{j[j]O

MTR-90

II WIDE BAND

Modification

of

an

Audio

Channel

for

Dedicated

Wide Band Use

1.

Turn

Off

the

Power

to

the

MTR-90

II

and

remove

the

audio

channel

PCB

from

the

channel

to

be

used

for

Time

Code,

or

modify

a

spare

PCB.

2.

Install

a 10K ohm

resistor

across

R

101.

3.

Install

a 10K ohm

resistor

across

R

125.

4.

Connect

a

wire

from

Pin

6

of

IC

510

to

Pin

14

of

IC

51~.

(This

connection

defeats

the

Stop-to-Play

Mute

for

this

channel).

5.

Connect

a

wire

from

the

cathode

(banded

end)

of

0

535

to

IC

103

Pin

8.

(This

connection

defeats

the

Fast-Wind

mute

for

this

channel).

NOTE:

This

modification

provides

good

quality,

non-phase-

compensated

code

output.

If

your

synchronizer

requires

better

quality

code

than

this

modification

provides,

installation

of

a

WBR-l

Wide

Band

Kit

on

one

of

your

Audio

PCBs

may

be

required.

Please

contact

OTARI

for

further

details.

[j]ii!i.Jf1JO

MTR

20

SERIES

Conditions

For

Synchronizer

Use

1.

All

transport

tallies

are

low

true.

2 .

Speed

switch

on

machine

to

EXT. 1

or

EXT. 2

(depending

on

options)

.

3.

All

connections

for

synchronizer

use

are

available

on

37

pin

'D'

connector

labeled,

"PARALLEL

I/O."

See

cable

schematic.

This manual suits for next models

14

Other OTARI Recording Equipment manuals

OTARI

OTARI RADAR User manual

OTARI

OTARI MTR-10II Series User manual

OTARI

OTARI MX-55T-M User manual

OTARI

OTARI MX-5050 User manual

OTARI

OTARI MX-5050BII Series User manual

OTARI

OTARI MX-5050 Manual

OTARI

OTARI RADAR II User manual

OTARI

OTARI MTR-90III User manual

OTARI

OTARI MX-505MKIII-2 User manual

OTARI

OTARI MX-50II Series User manual