OTARI MX-55T-M User manual

Parts

No.

OS3-207

[fJOSCJH

MX-55T-M,

T,

N-M

PROFESSIONAL

RECORDERS

OPERATION

AND

MAINTENANCE

MANUAL

SIXTH

EDITION

Printed

:

May

1990

Ed

.6

(GK)

Otari,

Inc.

Copyright

©

1989,

1990

Otari,

Inc.

Printed

in

Japan

This

manual

may

not

be

reproduced

by

any

means

without

written

permission

.

CAUTION

To

prevent

fire

or

shock

hazard:

Do

not

expose

this

unit

to

rain

or

moisture.

Do

not

remove

panels

(unless

instructed

to

do

so).

There

are

no

user-serviceable

parts

inside.

Refer

servicing

to

qualified

service

personnel.

PLEASE

READ

THROUGH

THE

SAFETY

INSTRUCTIONS

ON

THE

NEXT

PAGE.

1.

Read

Instructions

2.

Retain

Instructions

3.

Heed

Warnings

4.

Follow

Instructions

5.

Water

and

Moisture

6.

Carts

and

Stands

7.

Ventilation

8.

Heat

9.

Power

Sources

1

D.

Grounding

or

Polarization

11

.

Power

Cord

Protection

SAFETY

INSTRUCTIONS

All

the

safety

and

operating

instructions

should

be

read

before

the

device

is

operated.

The

safety

and

operating

instructions

should

be

retained

for

future

.

All

warnings

on

the

device

and

in

the

operating

instructions

should

be

adhered

to.

All

operating

and

use

instructions

should

be

followed.

The

device

should

not

be

used

near

water

-

for

example,

near

bathtub,

wash

bowl,

kitchen

sink

,

laundry

tub,

in

a

wet

basement,

or

near

a

swimming

pool,

etc

.

The

device

should

be

used

only

with

a

cart

or

stand

that

is

recommended

by

the

manufacturer.

The

device

should

be

situated

so

that

its

location

or

position

does

not

interfere

with

its

proper

ventilation

.

For

example,

the

device

should

not

be

situated

on

a

bed,

sofa,

rug,

or

similar

surface

that

may

block

the

ventilation

openings;

or,

placed

in

a

built-in

installation,

such

as

a

bookcase

or

cabinet

that

may

impede

the

flow

of

air

through

the

ventilation

openings.

The

device

should

be

situated

away

from

heat

sources

such

as

radiator

,

heat

registers,

stoves

or

other

appliances

(including

amplifiers)

that

produce

heat.

The

device

should

be

connected

to

a

power

supply

only

of

the

type

described

in

the

operating

instructions

or

as

marked

on

the

device.

Precautions

should

be

taken

so

that

the

grounding

or

polarization

means

of

the

device

is

not

defeated.

Power

supply

cords

should

be

routed

as

they

are

not

likely

to

be

walked

on

or

pinched

by

items

placed

upon

or

against

them,

paying

particular

attention

to

cords

at

plugs,

convenience

receptacles,

and

the

point

where

they

exit

from

the

device.

iii

12.

Cleaning

The

device

should

be

cleaned

oll

'

ly

as

recommended

by

the

13.

Non-Use

Periods

14

Object

and

Liquid

Entry

15.

Damage

Requiring

Service

16.

Servicing

man

ufactu

rer.

The

power

cord

of

the

device

should

be

unplugged

from

the

outlet

when

left

unused

for

a

long

period

of

time.

Care

should

be

taken

so

that

objects

do

not

fall

and

i

that

liquids

are

not

spilled

,

into

the

enclosure

through

openings.

The

device

should

be

serviced

by

qualified

service

personnel

when:

A.

The

power-supply

cor

,d

or

the

plug

has

been

damaged;

or

B.

Objects

have

fallen,

or

liquid

has

been

spillled

'

into

the

appliance;

or

C.

The

appliance

has

been

exposed

to

r

ain;

or

D.

The

appliance

does

not

appear

to

operate

nor

m

ally

or

exhibits

marked

change

in

performance;

or

E.

The

appliance

has

been

dropped,

or

the

enclosure

damaged.

The

user

should

not

attempt

to

service

the

device

beyond

that

described

in

the

operating

instructions.

All

ot

l

her

serv

,

ice

should

be

referred

to

qualified

personnel.

iv

WARNING

This

equipment

generates,

uses

and

can

radiate

radio

frequency

energy

and

if

not

installed

and

used

in

accordance

with

the

instructions

manual,

may

cause

interference

to

radio

communications.

It

has

been

tested

and

found

to

comply

with

the

limits

for

a

Class

A

computing

device

pursuant

to

Subpart

J

of

Part

15

of

FCC

Rules,

which

are

designed

to

provide

reasonable

protection

against

such

interference

when

operated

in

a

commercial

environment.

Operation

of

this

equipment

in

a

residential

area

is

likely

to

cause

interference

in

which

case

the

user

at

this

own

expense

will

be

required

to

take

whatever

measures

may

be

required

to

correct

the

interference.

v

COMMUNICATION

WITH

OTARI

FOR

SERVICE

INFORMATION

AND

PARTS

The

Otari

products

are

manufactured

under

strict

quality

control

and

each

unit

is

carefully

inspected

and

tested

prior

to

shipment.

If,

however,

some

adjustment

or

technical

support

becomes

necessary,

replacement

parts

are

required,

or

technical

questions

arise,

please

contact

your

nearest

Otaril

dealer

or

contact

Otari

at:

Otarl,

Inc.

4-33-3

Kokuryo-cho

Chofu-shi,

Toky0182

Japan

Phone

:

(0424)

81-8626

Telex

:

J26604

OTRDENKI

Fax

:

(0424)

81-8633

Cable

:

OTARIDENKI

TOKYO

Otarl

Deutschland

GmbH.

Rudolf-Diesel-Str.12

D-4005

Meerbusch

2

(Osterath)

F.

R.

Germany

Phone

:

(02159)

50861

Telex

:

8531638

OTEl

D

Fax

:(02159)1778

Otari

(U.

K.)

Lt

d.

22

Church

Street

Slough

Berkshire

Sl1

1

PT

United

Kingdom

Phone:

(0753)822381

Telex

:

849453

OTAR

IG

Fax:

(0753)823707

Otarl

Corporation

378

Vintage

Park

Drive

Foster

City

California

94404

USA

Phone

:

(415)

341-5900

Telex

:

650

302

8432

MCI

UW

Fax

:

(415)

341-7200

Otari

Singapore

Pte.,

Ltd.

625

Aljunied

Road

#07-05

Aljunied

Industrial

Complex

Singapore

1438

Phone

:

(743)

7711

Telex

:

RS

36935

OTARI

Fax:

(743)

6430

Another

part

of

Otari's

continuing

technical

support

program

for

our

products

is

the

continuous

revision

of

manuals

as

the

equipment

is

improved

or

modified.

In

order

for

you

to

receive

the

information

and

support

which

is

applicable

to

your

equipment,

and

for

the

technical

support

program

to

function

properly,

please

include

the

following

information,

most

of

which

can

be

obtained

from

the

Serial

number

label

on

the

machine,

in

all

correspondence

with

Otari:

•

Model

Number:

•

Serial

Number:

•

Date

of

Purchase:

•

Name

and

address

of

the

dealer

where

the

machine

was

purchased

and

the

power

requirements

(voltage

and

frequency)

of

the

machine.

vii

MX-55

Operation

and

Maintenance

Manual

Table

of

Contents

Ta

ble

Df

CDntents

Safety

Instruc

t/on

s

...

..

.

....

..

..

......

.

..

.

...

.............

.

.......

........

..

..

.

..

.

...................................

iii

Communi

cat

ion

with

Otarl

..

......

......

...

..

....

..

............

...

.......

...

..

.

.....

...........

.....

...

..

.

......

vII

Sec

tion

1

Introduction

1.1

MX

-5

5

Seri

es

Tape

Rec

orders

.......................

..

...........

.

.................................

1

·1

1.2

U

sin

gT

his

Manua

l

........

...

..............................

..

.......

..

.........

.......

....

....

......

......

..

1

·3

1.2.1

Orga

ni

zation

..

......

......

..

.

.....

..

.....

...

......

........

......

..

........

.....

..

.........

....

.......

1

·3

1

.2.2

Con

vention

sw

ithin

t

his

manual

.....

.........

......

....

...............

....

......

..

....

. 1

·4

Sec

tion2

Controls

and

Indicato

rs

2.1

Tap

eT

ra

n

sport

....

......

........

....................

..

....................

.

................

...

................

2·1

2.2

T

ransport

Con

t

ro

l

Panel

.......

..

....

...

..

...............

......

..

..........

..

....

..

.

........

..

...........

2·4

2.3

He

ad

Assembly

......

.....

....

.

.....

..

.

....

..

.....

....

....

......

....

.........

...

.................

....

.......

2

·12

2.4

Amp

li

f

ier

Pane

l

..

....

.......

....

..........

.

....

...

....

.....

...

......

..

......

..

................

..

.......

......

2

·13

2.5

Au

d

io

Co

nne

cto

r

Pan

el

....

.

..

..

........

...

..

.

.............

...

............

.

...........

..

...............

2

·18

2.6 T

ransport

Connec

tor

Pane

l .

.......

...

......

.......

.......

...

.....

....

......

....

...................

.

2·20

2.7

Controls

on

Audio

Am

plifier

PC

B

Assembly

.........

..

.......

..

............

.

..

.

.....

....

2·22

2.8

Contro

ls

on

MicA

mp

li

fier

PCB

As

sembly

..

..............

......

..........

..

...............

2·24

2.9

Con

tro

ls

on

Mother

Boa

rd

P

CB

Ass

embly

....

.

..

.....

..

.

..

....

..............

.

......

..

....

2·25

Section

3

Operation

3.1

M

odes

of

Operation

..

...

..

....

......

.......

...

....

.....................

....

.....

....

......

....

............

.

3·1

3.2 M

ou

nti

ng

the

R

ee

ls

an

dThrea

ding

the

MX-55

.

......

..

.

......

........

.....

.............

3·4

3.

2.1

Pl

acing

the

Ree

lson

the

Machine

.....................................................

3·4

3.2

.

1.

1

Us

i

ng

5"

or

7"

EIA

R

eels

........

......

.....

.

..........

..

..........................

3·4

3

.2.1

.2

Usi

ng

10.5

"

NAB

Reels

............

...

.

......

..

....

..

....

...

..

......

...

....

..

.

...

..

3·4

3.2.

1.

3

Using

AEG

(or

DIN

)

Hub

s

..

......

..

...........

.......

..

....

........

...

..........

3·4

3.2

.2

Threading

the

tape

.......

..

..

....

.....

......

..

.........

....

.................

..

...........

....

...

3·5

3.3

Tra

n

sport

Modes

..

....

......

.....

....

.....

......

....

..

..

.

..

.

..

.

..

......................

.....

.......

...

....

..

3·6

3.3.1

Pl

ay

mode

...

..................

.

.....

.

..

...

.

..

.....

....

.....................

.

.................

....

....

3·

6

3.3

.2

Fast

Forwa

rd

mode

..

....

......

..........

...................................

........

....

........

3·

6

3

.3

.3 R

ewind

mode

........

......

........

...

..

..

...

..

...

......

....

......

..

.....

.

..

....

......

.....

..

.

....

..

3·6

3.

3.4

R

ecord

mode

..

.....

......

....

.....

.

...

..

..........

.....

.....

.

..........

.

..........................

3·6

3.3.5

Ed

it

R

eady

mode

....

..

...............................

..

..

..

.

................

.....

..

....

..

.......

3

·7

3.3.6

Edit

Pl

ay

mo

de

...............

......

..

........................................

.....

......

..

.....

.

...

3·

7

3.3

.7

Cue

mode

..

...........

.

..........

..

..........

..

.

.........................................

.

..........

3·

7

3.

3.8

Vari

Speed

mo

de

...........

..

...

...

....

.......

.. ..

.

..

............

...

................

........

....

. 3 · 7

3.

3.9

Presett

ing

th

e

Vari

S

peed

amount

........

.

..

.....

..

...

.......

.

...

........

...........

3·8

3.4

Aud

io

Channel

Modes

...........

....

......

.

.................................................

...

..

....

...

3·9

3

.4.

1 R

ecord

Ready

mode

..

.

..

..

..

.....

..

....

....

..

....

.....

....

.....

.......

...

.............

..

......

3 · 9

3

.4

.2

Record

Safe

m

ode

...............................................................................

3-9

3.4.3

Inpu

t

Monitor

mo

de

...

......

....

..

.

...

..

...

..

..

...

....

......

..

................................

3·9

3.4.4

Sel

·

Rep

Monitor

mode

..

.............

....

..

.

................

.

....

....

.

...

.......

..

.

....

.... 3-9

3.4

.5

Repro

Mo

nit

or

mod

e

..

........

.

....

.

.............................

.

..

.............

.......

. 3-10

3

.4.

6

Vo

i

ce

Edit

mode

..

...........

.

.............

..

.....

....

......

...

..

............

......

...

......

. 3-

10

3.5

Time

Code

Modes

.......

....

..

..

........

.

..

.

..

.

......

....

.....

...

..

...........

..

....

......

.....

...

3-11

3.5

.1

Record

R

eady

mo

de

.......

......

...

.

.........

..

......

..

.

.....

....

.....

...

....

3-

11

3.5

.2

Record

Safe

mod

e .

.........

..

.........

....

..

..

.

......

.......

.......

..

......

.....

....

.........

3-11

3.

5.3

Input

Mon

ito

r

mode

..

..

...........

....

......

...

..........

..

..

..

..

..

.....

....

.......

..

.. 3-11

3

.5.4

Sel

·

Rep

Mon

ito

r

mode

..

......

..

.

..

.

......................................................

3-11

3.5.5 R

epro

Mo

ni

tor

m

ode

....

...

.

.......

........

..

...

............................

...

......... 3·11

November

1989

Ix

x

Table

of

Contents

MX-55

Operation

and

Maintenance

Manual

3.6

Auto

Locator

Modes

..

.

....

..

........

..

...

..

.

...

...

.

.....

..

...........

.

...

.

...

..

..

........

..

..

...........

3

·12

3.

6.1

Set

mode

............................................................................................

3

·12

3.

6.2

Repeat

mode

......................

....

........

.......

....

..

......

......

......

..

....

......

....

.....

3

·13

3.

6.3

Search

mode

..............

....

......

..

..........

.

..........

....

..

......

.......

............

....

....

3

·13

3.6.4

Search

Play

mode

....................

..

..........

....

......

....

..................

......

......

. 3

·13

3.6.5

Search

Zero

mode

........

....

.................................................................

3

·13

3.6

.6

Search

Start

mode

............

........

........

..

....

..........

..........

........

....

..........

3

·13

3.7

Test

Oscillator

..

....

..........

....

......

....

............

......

............

..

................................

. 3

·14

3.8

Tape

Editing

...................................................................................................

3

·15

Section

4

Maintenance

and

Adjustment

4.1

Routine

Maintenance

..

....

..........

..

..

........

......

............

....

....

........

......

......

........

...

4·1

4.1

.1

Demagnetizing

the

Heads

and

Tape

Path

..........

............

.......

............

4·1

4.1.2

Cleaning

the

Tape

Path

......

............................

..

..........

........

............

..

...

4·2

4.1.3

Lubrication

......

........

....

............

..

..............

............

..

..

..

...........................

4·4

4.2

Transport

Alignment

Procedures

...........................................................

......

4·5

4.2.1

Head

Position

Adjustment

....

....

.....................

....

..

..........

.....

......

......

..

.

4·

&

4.

2.2

Reel

Table

Height

Adjustment

....

..

....

....

.

........

....

...........

.

..

......

...

.........

4·8

4.2.3

Reel

Brake

Adjustment

............

..

..............

.

....

..

......

.

....

..

............

......

...

4

·10

4.2.4

Pinch

Roiler

Pressure

Adjustment

....

....

........

....

..................

..

..........

4

·12

4.2.5

Tape

Lifter

Adjustment

............

......

..........

..

................

....

..........

....

.....

4

·14

4.2.6

Capstan

Motor

Servo

Adjustment

..........

........

..........

......

......

.......

....

4

·15

4.3

Audio

Alignment

....

................

..

..............................................

..

.....................

4·

17

4.3.1

Tools

and

Equipment

required

..

..

.......................

..

.......

........

........

....

4·17

4.3.2

Preliminary

Adjustments

............

..

..

..

..........

....

........

.......

............

..

.....

4

·18

4.3.

2.1

Peak

Indicator

Level

Adjustment

........

............

........

......

......

. 4

·18

4.3.2.2

Test

Oscillator

Waveform

and

Level

Adjustment

........

....

...

4·20

4.3.3

Reproduce

Electronics

Adjustment

..........

..

........

..

..........

....

..

..........

4·21

4.3.3.1

Precautions

Before

Making

Adjustments

......

..............

......

..

..

4·21

4.3

.

3.2

Head

Azimuth

Adjustment

........

..

..............

..

....

..........

....

........

4·22

4.3.3.3

Reproduce

Level

Adjustment

..........

..

........

......

....

....

............

.

4·24

4.3

.

3.4

Reproduce

Equalization

Adjustment

...

..........

.........

..........

...

4·25

4.3.4

Record

,

Electronics

Adjustment

....................................

..

................

.

4·26

4.3

.

4.1

Level

Matching

..

......

........

....

....

......

..

..

...........

..

........

..

..............

4·26

4.3.4.2

Erase

and

Bias

Current

Adjustment

..

..

..............

....

.............

..

4·27

4.3.

4.3

Record

Bias

Level

Adjustment

....

.........................................

4·28

4.3.4.4

Recor

·d

Head

Azimuth

Adjustment

.....

....

..

.......

..

....

...

......

.....

4·29

4.3.4.5

Record

Level

Adjustment

........

.

..

....

............

.....

...........

.........

..

4·31

4.3.4.6

Record

Equalization

Adjustment

...........

..

............

..

...............

4·

32

4.3.4.7

Low

Frequency

Reproduce

Equalization

Adjustment

........

4·33

4.3.4.8

Sel·Rep

Level

Adjustment

......

......

.......

....

....

....

........

..

............

4·34

4.4

Time

Code

Channel

Adjustment

.........

..

............

......

........

......

....

.......

.....

..

.

...

4·35

4.4.1

Input/Output

Level

Adjustment

........................................

...

.........

.

..

4·35

4.4.2

Time

Code

Reproduce

and

Sel

·

Rep

Level

Adjustments

....

......

....

. 4·3&

4.4.3

Erase

and

Bias

Current

Adjustment

.................

....

.......

..

..................

4·36

4.4.4

Bias

Adjustment

...........................................

..

............

....

..

....

......

.......

4·37

4.4.5

Record

Level

Adjustment

.......................

.

..............................

.

..........

4·37

Section

5

Installation

5.1

Uncrating

and

Inspection

........

..

............

..

....

.

........

....

.............

..

......................

5·1

5.1.1

Uncratingthemachine

........

....

..........................

......

..........

.....

............

5·1

5.1

.2

Inspection

....

..............

..

....

......

,

.......

..

..........................

.............

.....

......

...

5·2

5.1.

2.1

Audio

Amp

PCB

..........

..

.

....

.......

....

....

..

.........

....

..

.

.......

.....

..........

5·2

5.1

.

2.2

Transport

Control

PCB

....

......

.................

...

.........

..

...................

5·4

November

1989

MX-55

Operation

and

Maintenance

Manual

Table

of

Contents

5.1.2.3

Power

Supply

Voltage

Selector

inspection

..........

....

....

...

..

.......

5·6

5.2

Connections

....

...................

...

...............

.

.......

..............................

.

........

..

..........

5·7

5.2.1

Power

Connection

............

....

..

..............

............

......

..

...........................

5·7

5.2.2

Changing

the

Supply

Voltage

Requirement

.....

.......

.

..

.

.... ..

...............

5·7

5.2.3

Connecting

the

Audio

Signal

....................................

..

......................

.

5·8

5.2.4

Connecting

the

Remote

Control

Unit

...............

...................

..

.

..........

.

5·9

5.2.5

Connecting

Time

Code

......

..............

....

........

.

......

..

.

..

.............

..

.

..

.......

5

·10

5.3

Prior

to

Operation

........................................................

..

.

..

...

........

..........

.......

5 ·11

5.3

.1

User-selectable

Functions

...............

..

.................

.....

..........

..

............

. 5 ·11

5.3.1.1

SEARCH

3

button

functions

....

.

..

.....................

......

...

..

..........

5

·11

5.3.1.2

Punch

In

Method

Selection

......

..

...............

................

.. ..

.......

5 ·11

5.3.1.3

Punch

Out

Method

Selection

.

......

........

...

......

....

....

................

5

·11

5.3.1.4

Foot

Switch

Function

Selection

.....

..

....

...........

......................

5

·12

5.3.1

.5

Fader

Start

Selection

....................

......

..

.....

.........

.

..................

5·12

5.3.1.6

Tape

Speed

and

Reel

Size

Change

..........

..

.. ..

.......................

5

·12

5.3

.

1.7

Selection

of

Reference

Flux

Level

..

....

......

.

..

....................

.....

5·13

5.3

.1.8

Changing

the

speed

version

............

...............

............

..

........

5

·13

5.4

Optional

Accessories

....................................

....

..

....

..............

......

....

........

......

5

·14

5.4

.1

Installing

the

Accessories

......

............

.......

..................

......

....

........

5

·14

5.4.1.1

Changing

the

Machine

Feet

for

Horizontal

Operation

.......

5

·14

5.4.1.2

Installing

the

Optional

19"

Rack

Mount

kit

............

.............

5

·14

5.4

.2

Optional

Stands

for

the

MX-55

..........

...............

..

.

....................

5

·15

5.4

.2.1

Assembling

the

ZA-81

B-T

without

Spacer

.........

....

..

..

........

5-15

5.4.2.2

Assem

bling

the

ZA-81

B-

T

with

Spacer

....................

..

....

.....

5

·16

5.4

.

2.3

Assem

bling

the

ZA-81

C-S

..........

.....

....

..

...................

..........

..

5·17

5.4.3

OptionallnpuVOutput

Transformers

....

...

...............

..

................

.

....

5

·18

5.4.4

VEM

Unit

Installation

..

.......

................

....

....

................

....

..

........

.

..

......

5·20

5.4.4.1

VEM

Installation

on

the

MX-55T-M

(MX-55N-M)

.......

......

5·20

5.4.4

.2

VEM

Installation

on

the

MX-55T

................

....

.. ..

..

.......

.........

5·20

5.4.5

Operation

Instructions

for

Voice

Edit

Mode

..................................

5·21

5.4.6

Mounting

the

Foot

Switch

Jack

or

Fader

Control

Connector

......

5·22

5.4.7

Mounting

the

Proximity

Sensor

........

..........................

................

....

5·22

Section

6

Specifications

6.1

Tape

Transport

.

..

..............

............

.....................

....

..

.................................

..

.....

6·1

6.2

Electronics

........

...............

.............

.........

.

.............

..

.................

..

..........

..

....

......

.

6·

2

6.3

Physical

..........

............

.......................

........

..

..................

..

...........................

...

.

6·

4

6.4

Accessories

..........

....

.....

....

........

....

.......

......

......

........

.............

..

........................

6·

4

Section

7

Exploded

Views

and

Parts

Lists

7.1

General

..

..

..........

..............

......................................

.

........................

..

................

7·1

7.2

Parts

Lists

...............................................

..

..

....

....

......

........................

..

.. ..

..

...

...

7·1

Section

8

Printed

Circuit

Board

Layouts

and

Parts

Lists

8.1

General

......

...

............................

.....

.......................

........

......

..

.................

.........

8·1

8.2

Parts

Lists

............

......

..

........

...

......

....

..

.....................

....

........

.....

...

...........

8-1

Recommended

To

ols

Schematics

November

1989

xi

xii

Table

of

Contents

MX-55

Operation

and

Maintenance

Manual

List

of

Figures

Figure

2-1

Tape

Transport

.

....

...

..

..

...............

.

......

.

......

.

.....

.

....

.

....

...

..

..

.....

....

.....

2

·1

2-2

Transport

Control

Panel

..

....

...

.........

.....

.

..

..

................

..

...

..............

2·4

2-3

Head

Assembly

.......

..

.......

...............

....

.......

..

..

..........

..

....

.

...........

.2

·12

2-4

Amplifier

Panel

......

..

...........................

.............

.

..

.....

.....

..

....

..

.....

.2

-13

2-5

Amplifier

Connector

Panel

..

..

......

.....

.......

.................

..

....

........

....

2

·19

2-6

Transport

Connector

Panel

....

..........

...........................

.......

..

..

....

2·21

2-7

Controls

on

the

Audio

Amplifier

PCB

Assembly

........

..

..

..........

.2-

23

2-8

Controls

on

the

Mic

Amplifier

PCB

Assembly

...................

......

2·24

2-9

Controls

on

the

Mother

Board

PCB

Assembly

..

.

.... ....

....

..

..

..

..

.

2·25

Figure

3-1

Reel

Spindle

...

..

................

...

.....

..

....

..

.

........

...

...........

....

..

...........

.....

3·1

3-2

Mounting

the

Reel

Table

....

..

.

..

.................

..

...

..

......

....

....

...............

3·1

3-3

Mounting

the

AEG

(DIN)

Hub

Adapter

..........

....

....

........

...

..

........

3-1

3-4

Tape

Threading

........

.

..

....

..

......

.

....

.........

.....

....

......

..........

..

.. ..

.

........

3·2

3-5

Editing

the

TApe

..

.......

..

..........

............

.....

....

..........

..

...

.

..

.....

.........

3

·15

Figure

4·1

Demagnetizing

the

Heads

....

...

........

................

...

..

.

......

......

.

..

........

4·2

4-2

Cleaning

the

Heads

..

..

....

..

.

............

....

.. ..

..........................

.......

....

...

4·3

4-3

Capstan

M

oto

r

Bearing

Lub

rication

....

...........................

....

......

..

4·4

4-5

H

ead

He

ight

and

Zenith

Adjustment

.... ....

...

....

......

..

..

...

..

...

......

..

..

4 - 7

4-6

Wear

Patterns

......

...........

......

.....

..

....................

....

..........

..

....

..

......

4·7

4-7

Measuring

Reel

Table

Height

.....

..

....

..

....

..

........

..

............

......

.......

4·8

4-8

Reel

Table

Adjustment

.....

...

.

......

..

.........

.

........

.........

.....

.. .. ..

..........

4·9

4-9

Reel

Brake

Tension

Measurements

...........

..........

..

..

.............

.

..

.4

-10

4-10

Reel

Brake

Adjustment

......

..

..............

.....

..

...

..................

.......

..

.

...

4 -11

4-11

Pinch

Roller

Pressure

Measurement

....

...

..

..

..

....

..

.......

..

..

......

....

4

-12

4-12

Pinch

Roller

Pr

es

sure

Adjustment

.......

..

..

.

......

..

..

....

..

..

......

....

...

4·13

4-13

Tape

Lifter

Clearance

Measurement

........

........................

.......

..

4

·14

4-14

Tape

Lifter

Adjustment

....

....

...........

...........

.

..

..

......

.....

....

......

.....

..4

·14

4-15

Controls

on

the

Transpo

rt

Control

PCB

Assembly

..

....

............

4

·15

4-16

Capstan

Waveform

Display

...

..

.......

.......

........................

...........

.4

-15

4-17

Capstan

Servo

Block

Diagram

.......

.....

...

..

..

............

..

..

......

....

..

...

4

-16

4-18

Audio

Amplifier

Block

Diagram

......

..

.

...

........

..

.....................

......

4

·18

4-19

Location

of

Trimmers

on

Audio

Amplifier

PCB

Assembly

....

.4

-19

4-20

Test

Oscillator

Waveform

....

.

..........

.....

........

....

..

..........

.............

..

4 -

20

4-21

Azim

uth

Test

Set-Up

......

..

............

.

..

..

......

...............

....

....

..

..

......

..

4 -

23

4-22

Azimuth

Adjustment

Screws

......

..

..

..............

..

....

....

..

..

...............

4 -

23

4-23

Azimuth

Adjustment

Displays

..

....

..

..........................

...

..........

....

4 -

23

4-24

Location

of

Trimmers

on

Audio

Amplifier

PCB

Assembly

...

4·24

4-25

Adjustment

Points

and

Amplitude

Adjustment

............

..

.... ....

.

..

4·27

4-26

Re

cord

Azimuth

Adjustment

Set-Up

...

..

.........

...

.......

..

.....

..

.

..

....

4 -

29

4-27

Re

c

ord

Head

Azimuth

Oscilloscope

Display

.....

..

...

..

....

......

......

4 -

30

Figure

5-1

Opening

the

Amp

Top

Panel

..

...

.

........

........

..

...........

......

.......

........

5 - 3

5-2

Opening

the

Transport

Rear

Panel

..

............

..

..

..

..

..

...

.

............

......

5·4

5-3

Pin

Assignment

of

Power

Connector

.........

....

..

........

..

............

....

5·7

5-4

Voltage

Select

Wiring

........

.............

....

....

.

.........

....

....

....

....

..

......

....

5 - 7

5-5

Audio

Connector

Wiring

..

..

.....

....

..

..

........

..

...

......

...

......................

.5 - 8

5·6

Connection

of

the

Machines

....

..

........

..

...................

....

.

..

..

..

........

5

-10

5-7

Installing

Rear

Legs

............

......

.

........

.

..

.

..

..........

.........

..

.............

5

-14

5-8

Mounting

the

ZA-SCG

Rack

Adapter

..............

..

....

.

....

....

..

....

.....

5

-14

5-9

Mounting

Hole

Spacing

.. ..

........

......

........

....

....

...

....

.........

....

....

...

5

-14

5-10

Assembling

the

ZA-81

B-

T

Pedestal

.......

..

.

..

...

.

........

.

..

..

....

......

...

5

·15

5-11

Assembling

the

ZA-81

B-

T

Pedestal

with

Spacer

..

...

..........

.....

5

·16

4-4

Head

Posi

tion

Ad

jus

tment

Screws

......

....

..

...............

.........

.. ..

.....

4-7

November

1989

MX-55

Operation

and

Maintenance

Manual

Table

of

Contents

Figure

5-12

Assembling

the

ZA-81C-S

Pedestal

....

..

.

..

....

..........

.

..

..

.

..

..

.....

....

5-17

5-13

Opening

the

Amp

Panel

........

..

......

..............

....

......

......

......

..

....

...

5

-18

5-14

Mounting

the

Input/Output

Transformer

PCB

......

......

..

....

......

.5

-19

5-15

Wiring

of

the

Transformers

........

....

........

..

......

....

....

....

..

......

..

.....

5

-19

5-16

Mounting

the

VEM

PCB

....

....

.. ....

......

......

........

..

....

......

....

......

..

..

.5 -

21

5-17

Mounting

Foot

Switch

Jack/Fader

Control

Connector

..

....

......

5 -

22

5-18

Mounting

the

Proximity

Sensor

..

........

....

........

..

........

..

....

......

....

5 -

22

List

of

Tables

Table

1-1

MX-55

Series

Machine

Configurations

...........

....

......

..

....

.........

. 1 -1

Table

4-1

Recommended

Overbias

..

....

..

.

....

....

..

....

....

......

...........

....

......

..

..

4 -

28

Table

5-1

Standard

Accessories

....

..

......

..

....

....

................

....

......

........

........

.

5-1

5-2

DIP

Switch

Positions

................

.

..

......

.........

....

............

....

....

....

..

..

5 - 5

5-3

PARALLEL

I/O

Connector

Pin

ASSignment

..

........

..

....

.

........

.....

5 - 9

November

1989

xiii

MX-55

Operation

and

Maintenance

Manual

Introduction

Section

1

Introduction

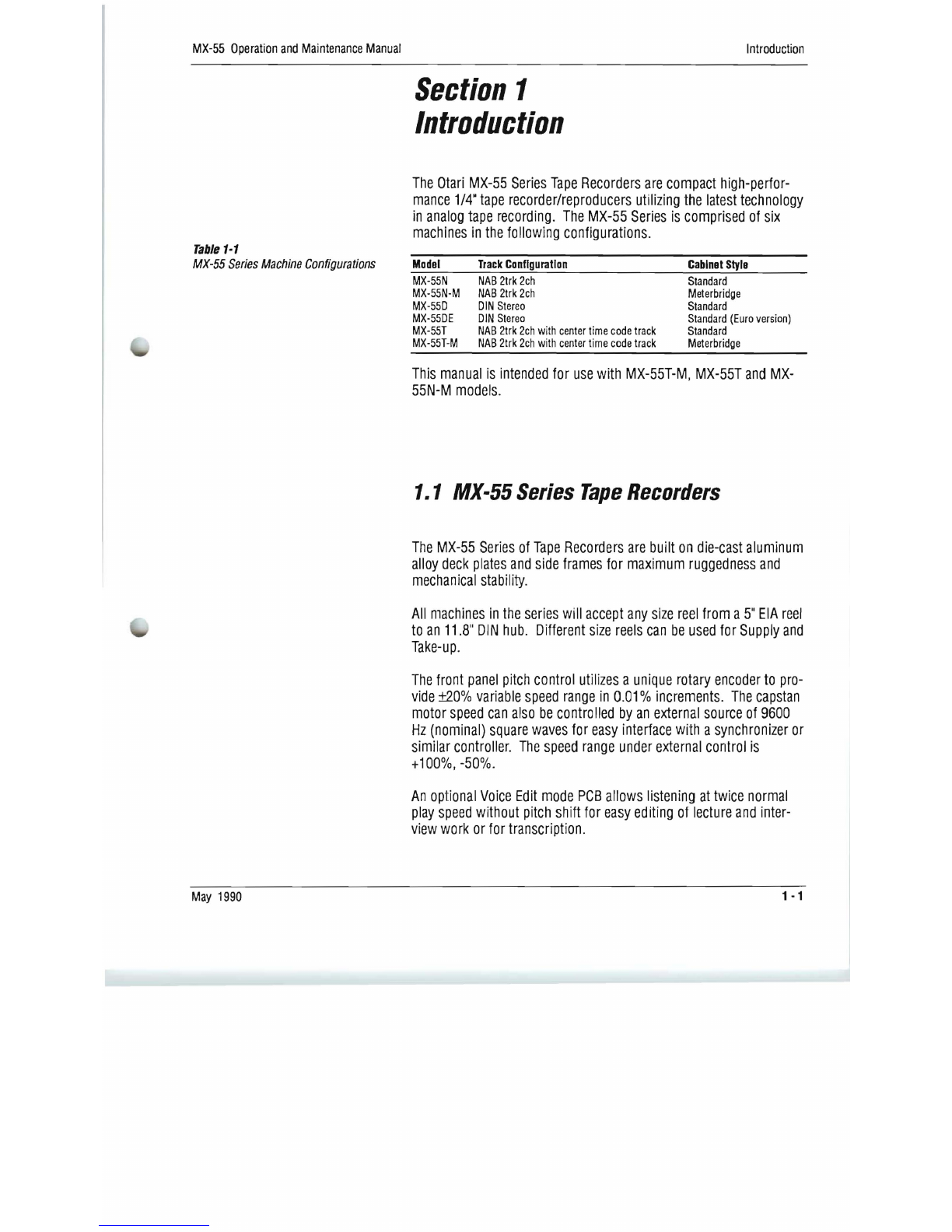

The

Otari

MX-55

Series

Tape

Recorders

are

compact

high-perfor-

mance

1/4"

tape

recorder/reproducers

utilizing

the

latest

technology

in

analog

tape

recording

.

The

MX-55

Series

is

comprised

of

six

machines

in

the

following

configurations.

Table

1-1

MX-55

Series

Machine

Configurations

Model

Track

Configuration

Cabinet

Style

MX-55N

NAB

2trk

2ch

Standard

MX-55N-M

NAB

2trk

2ch

Meterbridge

MX-55D

DIN

Stereo

Standard

MX-55DE

DIN

Stereo

Standard

(Euro

version)

MX-55T

NAB

2trk

2ch

with

center

time

code

track

Standard

MX-55T-M

NAB

2trk

2ch

with

center

time

code

track

Meterbridge

This

manual

is

intended

for

use

with

MX-55T-M,

MX-55T

and

MX-

55N-M

models.

1.1

MX-55

Series

Tape

Recorders

The

MX-55

Series

of

Tape

Recorders

are

built

on

die-cast

aluminum

alloy

deck

plates

and

side

frames

for

maximum

ruggedness

and

mechanical

stability.

All

machines

in

the

series

will

accept

any

size

reel

from

a

5"

EIA

reel

to

an

11.8"

DIN

hub.

Different

size

reels

can

be

used

for

Supply

and

Take-up.

The

front

panel

pitch

control

utilizes

a

unique

rotary

encoder

to

pro-

vide

±20%

variable

speed

range

in

0.01

%

increments.

The

capstan

motor

speed

can

also

be

controlled

by

an

external

source

of

9600

Hz

(nominal)

square

waves

for

easy

interface

with

a

synchronizer

or

similar

controller.

The

speed

range

under

external

control

is

+

100%,

-50%.

An

optional

Voice

Edit

mode

PCB

allows

listening

at

twice

normal

play

speed

without

pitch

shift

for

easy

editing

of

lecture

and

inter-

view

work

or

for

transcription.

May

1990

1-1

Introduction

MX-55

Operation

and

Maintenance

Manual

The

built-in

tape

timer

displays

the

current

tape

position

as

Hours

,

Minutes

and

Seconds,

or

the

tape

speed

in

inches

per

second,

or

the

tape

speed

as

a

percentage

of

change

from

the

selected

play

speed.

The

tape

timer

incorporates

a

four

point

search-to-cue

locator

with

three

cue

point

memor

ies

and

a

zero

location

memory.

The

includ-

ed

repeat

function

allows

continuous

repeat

play

between

any

two

selected

cue

pOints.

One

cue

point

memory

can

be

set

to

store

the

location

where

Play

or

Record

was

last

entered,

for

easy

return

to

the

beginning

of

a

sequence

or

take.

All

machines

in

the

Series

feature

front

panel

selection

of

two

oper-

ating

speeds,

with

internal

switch

selection

of

either

High

(15

ips

and

7.5

ips)

or

Low

(7.5

ips

and

3.75

ips)

speed

pair

operat

,

ion.

The

MX-55

Series

ma

chines

provide

switc

h

selection

of

NAB

or

lEG

equalization;

+4

dBm

or

-16

dBm

Input

and

Output

levels;

185,

250

or

370

n

Wb

/m

Reference

Fl

ux

level

with

front

panel

indication

of

Reference

Flux

lev

el

and

eq

ualization.

XL

type

connectors

are

pro-

vided

for

Inputs

and

Outpu

ts

with

transformerless

active

balanced

Circuit

ry.

The

MX-55

Ser

ies

mach

ine

s

also

provide

the

HX

Pro·

Headroom

Extension

System.

HX

Pro

improves

the

high

frequency

perfor-

mance

of

any

tape

recorded

on

the

MX-55

by

analyzing

the

high

fre-

quency

components

of

th

e

au

dio

signal

and

continuously

adjusting

recording

bias

to

mai

nta

in

bias

linearity

for

optimum

distorUon,

noise,

and

frequency

response

characteristics.

HX

Pro

is

not

an

"encoding"

process,

and

does

not

require

any

decoding

during

playback.

*

Dolby

HX

Pro

:

HX

Pro

Headroom

Extension

originated

by

Bang

&

Olufsen

and

manufactured

under

license

from

Dolby

Licensing

Corporation.

UDolby"

and

the

Double-D

symbols

are

trademarks

of

Dolby

Li

censi

ng

Corporation.

1 - 2

November

1989

MX-55

Operation

and

Maintenance

Manual

Introduction

1.2

Using

This

Manual

This

manual

is

intended

for

use

with

MX-55T-M,

MX-55T

and

MX-

55N-M

model.

For

convenience,

the

descriptions

and

references

apply

to

MX-55T-M,

where

any

differences

exist

between

this

model

and

others

in

the

series,

those

differences

will

be

fully

explained

in

context.

1.2.1

Organization

This

manual

is

divided

into

nine

sections

beginning

with

this

INIRO-

DUCTION

which

contains

general

information

about

the

MX-55

Series

and

about

the

manual.

Section

2,

CONTROLS

AND

INDICATORS,

contains

a

keyed

reference

guide

to

the

operating

controls,

indicators

and

connectors

on

the

machine.

This

section

contains

detailed

information

about

each

control

and

its

function.

Refer

to

this

section

when

you

have

a

question

about

the

function

of

a

particular

control,

indicator,

or

con-

nector.

Section

3,

OPERATION

describes

the

operation

of

the

MX-55

machines,

and

is

divided

into

two

parts;

a.

A

table

of

machine

operating

modes,

which

lists

each

mode

and

the

controls

necessary

to

enter

that

mode;

and

b.

Detailed

operating

instructions,

which

describe

each

operation

and

the

controls

and

indicators

associated

with

that

operation.

Section

4,

MAINIENANCE

AND

ADJUSTMENT,

provides

the

infor-

mation

necessary

to

perform

routine

maintenance

operations,

including

head

cleaning

and

demagnetizing

and

capstan

motor

lubrication.

It

also

covers

the

audio

and

transport

adjustments

associated

with

normal

operation

of

the

machine.

Section

5,

INSTALLATION,

contains

the

information

necessary

when

first

unpacking

and

installing

the

machine.

The

information

and

procedures

contained

in

this

section

should

be

followed

very

care-

fully

when

the

machine

is

first

unpacked

and

installed.

Performing

the

inspection

and

checkout

steps

will

familiarize

you

with

the

machine

and

its

component

parts

if

this

is

your

first

contact

with

the

MX-55

series

of

tape

recorders.

November

1989

1 - 3

Introduction

MX-55

Operation

and

Maintenance

Manual

Section

6

lists

the

SPECIFICATIONS

of

the

MX-55T-M,

MX-55T

and

MX-55N

-M

tape

recorders.

Section

7,

EXPLODED

VIEWS

AND

PARTS

USTS,

contains

assembly

drawings

of

the

machine

"exploded"

to

show

internal

parts

and

hardware,

and

the

order

of

assembly.

Each

drawing

is

keyed

to

an

accompanying

Parts

List

containing

the

Otari

part

number

for

each

mechanica

'l

component.

Section

8,

PRINTED

CIRCUIT

BOARD

LAYOUTS

AND

PARTS

USTS,

contains

two-color

"X-ray"

views

of

the

printed

circuit

boards

(PCBs)

showirilg

component

locations

and

foil

traces.

This

section

also

contains

Parts

Lists

of

the

e'

lectronic

components

associated

with

each

PC'S.

The

final

section

contains

the

SCHEMATIC

DIAGRAMS

for

all

elec-

tronics

assemblies

and

pr

i

rlted

circuit

boards.

1.2.2

Conventions

within

this

manual

Generally

this

manual

uses

all

capital

letters

to

describe

a

control,

indicator,

or

connector

when

that

item

is

similarly

labeled

on

the

mach.ine

(e.g.,

INPUT

level

control

or

PARALLEL

lID

connector).

Where

a

control

or

indicator

is

not

labeled

on

the

machine,

the

name

of

that

item

,

is

spelled

with

initial

cap

'

italletters

only

(e.g.,

Mic

Input

connector

or

Cue

Spea

'

ker).

The

six

major

transport

control

buttons

are

not

labeled

on

the

machine,

but

are

labeled

on

the

but-

ton

caps

with

graphic

symbols.

Th

l

is

manual

uses

the

name

of

the

button

rather

than

the

graphic

symbol

whenever

the

buttons

are

ref-

erenced.

BuHonSynoi

Name

PLAY

RECORD

STOP

FAST

FORWARD

(F.

FWD)

REWIND

CUE

1

·4

November

1989

This manual suits for next models

2

Table of contents

Other OTARI Recording Equipment manuals

OTARI

OTARI MX-5050 User manual

OTARI

OTARI MX-5050 BII Series User manual

OTARI

OTARI MX 5050 BQII Series User manual

OTARI

OTARI MX-505MKIV-2 Manual

OTARI

OTARI MTR-90III User manual

OTARI

OTARI RADAR User manual

OTARI

OTARI MX-50II Series User manual

OTARI

OTARI MX-505MKIII-2 User manual

OTARI

OTARI MX-5050 Manual

OTARI

OTARI MX-5050BII Series User manual