OTARI MX-505MKIV-2 Manual

Operation

&

Maintenance

MX-5050MKIV-2,

Bill

Manual

MASTER

TAPE

RECORDER

I ,

, I

11'

.-.-.-.-.

lflfi!iJCJD

Part

No.

OS3-298

1!10!iJliJU

MX·5050

MKIV-2,

8111·2

MASTER

TAPE

RECORDER

OPERATION

AND

MAINTENANCE

MANUAL

THIRD

EDITION

Printed

:

May

1992

Otari,

Inc.

Ed

3

(WM)

Copyright

©

1992

Otari,

Inc

.

and

Otari

Corporation

Printed

in

Japan

This

manual

may

not

be

reproduced

by

any

means

without

written

permission.

s

CAUTION

To

prevent

fire

or

shock

hazard:

Do

not

expose

this

un

it

to

rain

or

moisture.

Do

not

remove

panels

(unless

instructed

to

do

so).

There

are

no

user-serviceable

parts

inside

.

Refer

servicing

to

qualified

service

personnel.

PLEASE

READ

THROUGH

THE

SAFETY

INSTRUCTIONS

ON

THE

NEXT

PAGE.

1.

Read

Instructions

2.

Retain

Instructions

3.

Heed

Warnings

4.

Follow

Instructions

5.

Water

and

Moisture

6.

Carts

and

Stands

7.

Ventilation

8.

Heat

9.

Power

Sources

10.

Grounding

or

Polarization

11.

Power

Cord

Protection

12.

Cleaning

13.

Non-Use

Periods

14

Object

and

liquid

Entry

15.

Damage

Requiring

Service

16.

Servicing

iv

SAFETY

INSTRUCTIONS

All

the

safety

and

operating

instructions

should

be

read

before

the

device

is

operated.

The

safety

and

operating

instructions

should

be

retained

for

future

.

All

warnings

on

the

device

and

in

the

operating

instructions

should

be

adhered

to.

All

operating

and

use

instructions

should

be

followed

.

The

device

should

not

be

used

near

water

-

for

example,

near

bathtub,

wash

bowl,

kitchen

sink,

laundry

tub,

in

a

wet

basement,

or

near

a

swimming

pool,

etc.

The

device

should

be

used

only

with

a

cart

or

stand

that

is

recommended

by

the

manufacturer.

The

device

should

be

situated

so

that

its

location

or

pOSition

does

not

interfere

with

its

proper

ventilation.

For

example,

the

device

should

not

be

situated

on

a

bed,

sofa,

rug,

or

similar

suriace

that

may

block

the

ventilation

openings;

or,

placed

in

a

built-in

installa-tion,

such

as

a

bookcase

or

cabinet

that

may

impede

the

flow

of

air

tl

l

rough

the

ventilation

openings

.

The

device

should

be

situated

away

from

heat

sources

such

as

radiator,

heat

registers

,

stoves

or

other

appliances

(including

amplifiers)

that

produce

heat.

The

device

should

be

connected

to

a

power

supply

only

of

the

type

described

in

tile

operating

instructions

or

as

marked

on

the

device

.

Precaut

i

ons

should

be

taken

so

that

the

grounding

or

polariza-tion

means

of

the

device

is

not

defeated

.

Power

supply

cords

should

be

routed

as

they

are

not

likely

to

be

walked

on

or

pi

nched

by

items

placed

upon

or

against

them,

paying

particular

attention

to

cords

at

plugs

,

convenience

recep-tacles,

and

the

point

where

they

exit

from

the

device.

The

de

v

ice

should

be

cleaned

only

as

recommended

by

the

manufacturer.

The

power

cord

of

the

device

should

be

unplugged

from

the

out-let

when

lett

unused

for

a

long

period

of

time.

Care

should

be

taken

so

that

objects

do

not

fall

and

that

liquids

are

not

sp

i

lled

into

the

enclosure

through

openings.

The

device

should

be

serviced

by

qualified

service

personnel

when:

A.

The

power-supply

cord

or

the

plug

has

be

en

damaged;

or

B.

Objects

ha

ve

falle

n,

or

liqu

id

has

been

spilled

into

the

appliance;

or

C.

The

appliance

has

been

exposed

to

rain;

or

D.

The

appliance

does

not

appear

to

operate

normally

or

ex

hibits

marked

change

in

performance;

or

E.

The

appliance

has

been

dropped

,

or

the

enclosure

damaged

.

The

user

should

not

attempt

to

service

the

device

beyond

that

described

in

the

operating

instructions

.

All

other

service

should

be

referred

to

qualified

personnel.

re

the

device

is

future

,

;

hould

be

Ir

bathtub,

wash

;wimming

pool,

ommended

by

1S

not

interfere

e

situated

on

a

'

penings;

or,

'

at

may

impede

radia

lor,

heat

produce

heat.

Ipe

described

on

means

of

walked

on

lar

aNention

they

exit

facturer,

et

when

left

e

not

e;

or

marked

r

ibed

in

~alified

COMMUNICATION

WITH

OTARI

FOR

SERVICE

INFORMATION

AND

PARTS

All

Otari

products

are

manufactured

under

strict

quality

control.

Each

unit

is

carefully

inspected

and

tested

prior

to

shipment.

If,

however,

some

adjustment

or

technical

support

becomes

necessary,

replacement

parts

are

required,

or

technical

questions

arise,

please

contact

your

Otari

dealer

or

contact

Otari

at

Ot

arl,

Inc.

Otari

Corporation

4-33-3

Kokuryo-cho

378

Vintage

Park

Drive

Chofu-shi,

Toky0182

Foster

City

Japan

California

94404

USA,

Phone

:

(0424)

81-8626

Phone

:

(415)

341-5900

Telex

:

J26604

OTRDENKI

Telex

:6503028432

MCI

UW

Fax:

(0424)

81-8633

Fax:

(415)

341-7200

Cable

:

OTAR

I

DENKI

TOKYO

Otarl

Deutschland

GmbH_

Olari

Singapore

Pte.,

Ltd

Rudolf-Diesel-S

tr

12

625

Aljunied

Road

0-4005

Meerbusch

2

(Oslerath)

#07

-

05

Aljunied

Industrial

Complex

FRGermany

Singapore

1438

Phone

:

(02159)

50861

Phone

:

(743)

7711

Telex

:

8531638

OTEL

0

Telex

,

RS

36935

OTARI

Fax

:

(02159)

1778

Fax:

(743)

6430

O

tari

(U

.

K.)

Limited

Unit

13,

Elder

Way,

Waterside

Drive,

Langley,

Slough,

Berkshire

SL3

6EP

United

Kingdom

Phone

:

(0753)580777

Telex

:

849453

OTARI

G

Fax:

(0753)

542600

Another

part

of

Otari

's

continuing

technical

support

program

for

our

products

is

the

continuous

revision

of

manuals

as

the

equipment

is

improved

or

modified

,

In

order

for

you

to

receive

the

information

and

support

which

is

applicable

to

your

eqUipment,

and

for

the

technical

support

program

to

function

properly

,

please

include

the

following

information,

most

of

which

can

be

obtained

from

the

Serial

number

label

on

the

machine,

in

all

correspondence

with

Otari:

•

Model

Number:

•

Serial

Num

ber

:

•

Date

of

Purchase:

•

Name

and

address

of

the

dealer

where

the

ma

c

hine

was

purchased

and

the

power

requirements

(voltage

and

frequency)

of

the

machine,

v

Table

01

Contents

Safety

Instructions

.

..

.......

....

.....

......

..

........

.......

......

.. v

..

...

....

....

..

........

....

vii

Communication

with

Otari

Section

1

Introduction

1.

1

MX-5050

Series

... ..

.....

.....

...

....

...

...

1-2

1.2

Using

This

Manual

....

..........

...

....

..

1-3

1.2

.1

OrgJnization

......

.

......

.

.......

.

..

...

......

1-3

1.2.2

Conventions

within

this

manual

.. .. .

...

.

..................

....

....

1-4

Section

2

Instal/aion

2.

1

Unpa

c

king

and

Inspection

. .... ........

...

........

.. .

2-2

2.2

Audio

Signal

Conne

c

tion

..

. ....

...

.. ..

....

.

.......

2-3

2.2.1

Audio

Conn

ec

tors

.

.......

.....

.....

.. .

..

.....

..

..........

...

...

.

2-3

2.2

.2

BJlJnce

/

Unbalance

Adju

s

tment

. .

..

...

....

.......

.. ... ....

....

.

2-4

2.3

Switch

Position

Adjustment

. . .. ..

......

..

...

2-5

2.4

PCB

Assembly

Location

. ..

.....

..

...

.. ..

........

...

2·9

2.

4 1

MX-5050

Bill .

....

...

2-9

24.2M

X-

5050

MKIV2

.

2·11

2.5

Po

w

er

Connection

.

2-13

2.6

Fuse

Replacement

.......... .

...

... .

....

..

.....

...... .. .. ..

....

2-

14

2.7

Speed

Conversion

(BIJI-2)

. .

.....

.

....

.....

.......

2-15

2.8

Equalizer

Change

........... . .

2-15

Section

3

Controls

and

Indicators

3.

1

Tape

Transport

.

....

.. .

3-2

3.2

Transport

Control

Panel

.. .. ..

...

.. ...

3-3

3.3

Head

Assembly

......

....

. ....

3-6

3.4

Amplifier

Panel

...

..

3-7

3.5

Audio

Connector

Panel

.

3-9

3.6

Conne

c

tor

Pin

Assignment

s

......

..

.....

3-12

Section

4

Operation

4.1

Operation

Mode

Reference

Tables

....

..

....... .

..

........

..

..

4-2

4.2

Modes

of

Operation

..

...

..

..

..

.

..

4-3

4.2.1

TrJl1spol1

Mo

de

s . .. ..

.....

. .

....

......

... ...... .. .. ..

4-3

4.2.2

Alidio

Channel

Mo

de

s

4-4

......

...

.. . ....

....

.. . ...

....

..

....

.......

Ma

y

1992

vii

Table

of

Contents

MX-SOSO

Operation

and

Maintenance

Manual

4.3

Operating

the

MX-5050

.. . ...

...

...

....

4-5

4.3.1

Placing

Reels

on

the

Machine

.....

.

.......

.. .. .. .

............

4-5

4.3.2

Threading

th

e

Tape

.. .. .

........

4·6

4.4

Operation

of

the

Transport

... ... .

........

4-7

4.4.1

Playing

Back

the

Tracks

....

4-7

4.4.2

Recording

the

Tracks

... ....

...

.. .... .

.......

4·

7

4.4.3

SEL-REP

Recording

...

.....

.. .. . ..

...

..

...

.............

4·8

4.4.4

Fast

Wind

and

CUE

Monit

or ...

...

.

....

... .

.....

.

....

.... .....

....

4-8

4.4

.5

Tape

Editing

....

.

.........

4-9

4.4

.6

Using

the

Pitch

Contr

ol

Fe

a

ture

..

..

....

..

....

....

...

..

4-10

4.5

Locator

Operation

.

......

.. ... ...

...

.....

...

..

....

.

.......

..

......

4-

11

4.5.1

Storing

Tape

Locations

4-11

4.5.2

Sear

ch

Mode

.. ..

....

.... .. . .. .....

..........

4-11

4.5.3

Search

Play

Mode

.. 4-

12

4.54

Search

Zero

Mode

..............

4-12

4.5.5

Search

Start

Mode

.. 4-

12

4.5.6

Repeat

Mode

. .. .

.........

..

..

....

........

4-13

4.6

Test

Oscillator

. .

.............

4-

13

Section

5

Maintenance

5.1

Maintenance

Scheduling

...

5·2

5.2

Demagnetizing

...

5·2

5.3

Cleaning

the

Tape

Path

. .

...

.

...........

.

..

.

.....

......

5-3

5.4

Lubrication

.... ...... ..

....

.... ...

.....

5·4

Section

6

Transport

Adjustment

and

Parts

Replacement

6.1

Transport

Access

.....

6-2

6.2

Brake

Torque

Adjustment

. ..

....

6-2

6.3

Tape

Lifter

Adjustment

....

6-4

6.4

Capstan

Motor

Adjustment

and

Pitch

Control

Adjustment

... 6·5

6.5

Pi

nch

Roller

Pressure

Adjustment

.

6·6

6.6

Tape

Speed

Adjustment

..

6-8

6.7

Reel

Table

Height

Adjustment

. 6·9

6.B

Head

Assembly

Replacement

'...

..

.

..

... ... .

..

..

.............

6-10

6.9

Head

Pos

i

tion

Adjustment

.....

6-11

J

viii

May

1992

hC

j

Maintenance

Manual

..

...

...

.......

4-5

'"

4-5

....

..

...

4-6

...

...

4-7

....

4-7

.. ..

4-7

.....

4-8

.....

..

...

4-8

.. .

4-9

..

4-10

....

4-11

. .

.....

4-11

...

. ...

4-11

...

.

4-12

. ..

..

..

4-12

.....

4-12

....

4-13

...

......

4-

13

....

5-2

5-2

....

5-3

'"

5-4

~menl

'" 6

-2

..

6-2

......

6-4

7ent

...

6-5

.

6-6

' ..

6-8

.. ..

6-9

6-10

6-11

MX-5050

Operat

i

on

and

Maintenance

Manual

Table

of

Contents

Section

7

Audio

Alignment

7.

1

Tools

and

Equipment

Required

.....

....

7-2

7.2

Block

Diagrams

.......

..

7-3

7.2

.1

Peak

Indicator

Level

Adjustment

..

7-3

7.2

.2

Test

Oscillator

Waveform

and

Level

Adjustment

.. . .. .. .

.....

.....

7-4

7.3

Reproduce

Adjustments

. .

7-5

7.3.1

Reproduce

Head

Azimuth

Adjustment

...

....

..

.... ...

........

....

7-5

7.3

.2

Reproduce

Level

Adjustment

.....

..

......

...

..........

......

7-6

7.3.3

Reproduce

Equalization

Adjustment

...

...

...

.

.......

.

7-7

7.4

Record

Electronics

Adjustments

........

... ...

....

...

..........

7-8

7.

4.1

Record

Bias

Level

Adjustment

....

.

.......

7-8

7.4

.2

Record

Head

Azimuth

Adjustment

.. .. .... ... ....... ..

7-9

7.4.3

Record

'level

Adjustment

.... .

...

.. .. .

7-10

74.4

Record

Equalization

Adjustment

.. .

.....

7-11

7.4.5

Low

Frequency

Reproduce

Equalization

Adlustment

.

7-11

7.

46

SEL-REP

Level

Ad

j

ustment

.. .

.....

.......

7-12

Section

8

Specifications

8.1

Tape

Transport

..

8-2

8.2

Electoronics

...

.. 8-3

Section

9

Exploded

Views

and

Bill

..'

.

9-2

-

9-19

MKIV-2

. ...

9-20

-

9-39

Appendix

Block

Diagram

Troubleshooting

Hints

(Electronics)

Troubleshooting

Hints

(Transport)

Index

Schematic

Diagrams

May

1992

Ix

May

1992

List

of

Figur

es

Figure

1-1

Exterior

Appearance

....

..

.

.....

...

..

......

... .

.....

1-2

Figure

2-1

Audio

Connectors

......

.....

.

.........

....

.....

.

.....

2-3

2-2

Balanced

/

Unbalanced

Connectors

..

..

.................

2-4

2-3

Switch

Setting

on

Rear

Panel

...

....

.........

..

........

2-5

2-4

Controls

on

the

CONTROL

PCB

Assembly

.

......

....

..

2-6

2-5

PCB

Assembly

Location

(Bill)

.....

...

......

.

....

....

..

2-9

2-6

AIVIP

Section

Rotation

(Bill) .

....

... ..

.....

....

.......

2-9

2-7

CONTROL

PCB

Assembly

Rotation

(Bill) ..

......

... ..

2-10

2-8

PCB

Assembly

Location

(MKIV-2)

..

...

.. .. .. .. ..

....

.

2-11

2-9

CONTROL

PCB

Assembly

Rotation

(MKIV-2)

.. ..

.....

2-12

2-10

Power

Connect

i

on

...

.......

.....

.....

.....

.....

.. ...

2-13

2-11

AC

Line

Voltage

Connector

....

.....

...

...

..........

...

2-13

2-12

Fuse

Location

.. .. ..

....

....

......

....

.....

......

.....

.

2-14

Figure

3-1

Tape

Transport

... ...

....

.. .... ........

.......

......

3-2

3-2

Transport

Control

Panel

..

..... .. ....

.......

..

...

.....

.

3-3

3-3

Head

Assembly

....

.. .

....

..

.....

......

... .. 3-6

3-4

Amplifier

Panel

(MKIV

-

2)

...

....

.... ..

.....

....

....

...

3-1

3-5

Audio

Connector

Panel

(Bill) .

..

....

... .

........

3-1

3-6

Audio

Connector

Panel

(MKIV-2)

... ..

......

.

.......

3-10

Figure

4-1

Tape

Threading

...... ... .

........

.....

....

.

...

.

.....

4-6

4-2

Edit

i

ng

a

Tape

. .. ... ..

.....

.......

4-10

Figure

5-1

Demagnetiz

i

ng

the

Head

...

.. .

......

...

.....

5-2

5-2

Cleaning

the

Head

.'

..

...

.....

...

5-3

5-3

Lubrication

... ..

...

.....

.....

.. .

5-4

Figure

6-1

Brake

Torque

Measurement

.

....

..

....

... .......

.....

6-2

6-2

Brake

Torque

Adjustment

.

.......

...

.....

...

..

......

..

6-3

6-3

Tape

Lifter

Adjustment

...

...

.....

.....

...

.. .. ..... 6-4

6-4

Waveform

on

Oscilloscope

...

.....

.....

..

....

....

....

6-5

6-5

Pinch

Roller

Pre

s

sure

Measurement

.....

........

... ..

6-6

6-6

Pinch

Roller

Solenoid

.

....

.....

.... ..

......

...

...

6-6

6-7

Pinch

Roller

Pressure

Measurement

......

.. ... ....

...

6-1

6-8

Re

el

Table

Height

Adjustment

....

..

.......

....

........

6-9

6-9

Head

Assem

bly

Repl

acem

ent

.. .. ........ .........

6-10

6-10

Height/Zenith

Adjustment

.. ....

...

..

....

...

...

6-11

6-11

Wrap

Adjustment.

... . ....

...

... ....

6-12

Figure

7-1

REC/REP

AMP

PCB

Assembly

..

..

.. ...

....

.

..

.... ..

....

1-4

7-2

Head

Adjustment

Screws

.. ... .. .........

.....

.

1-5

7-3

Wave

Shape

on

the

Oscilloscope

.

....

....

......

....

..

1-6

7-4

Head

Assemb

ly

......

....

...

.. ..... .

.....

..... ..

1-9

7-5

Waveshape

on

the

Oscilloscope

...

.....

....

....

..

......

.

1-9

May

1992

xl

List

of

Tables

Table

2-1

Standard

Accessories

...

.........

............

...

...

...

2-2

2-2

Settings

on

Rear

Panel

................................

2-5

2-3

DIP

SW

Setting

on

the

Control

PCB

..

.....

...

.....

.

......

2-6

2-4

Capstan

PLL

Refe

rence

...

.

....

...

....

....

.

..............

2-7

2-5

SEARCH

3

Key

Function

.....

...

,

...

.

........

..

...

.

......

2-7

2-6

Machine

Type

.

.......

"

.....

..

....

.

.....

,

....

...'"

.....

2-8

2-7

Fuse

Specificat

i

ons

....

...

... ......

...

.................

2-15

Tab

'

le

3-1

Parallel

110

Pin

Assign

ments

...

.

..................

..

3-12

3-2

Connector

Pin

21,

22

... .. .... .. .

........

.....

" 3-

12

3-3

Remote

Control

Connector

(MKIV-8

Option)

.. ..

......

3-13

Table

4-1

Transport

Modes

...........

...

......

.

...

.............

4-2

4-2

Audio

Channel

Modes

......

.....

........

...

........

...

4-2

4-3

Auto

Locator

Modes

.

................

.

.................

4-2

4-4

Vari

Pitch

Preset

..

.. .

...

...

...

.......

.....

.

.....

4-10

4-5

Cue

Point

Set

Mode

... ... .

......

..

.....

.........

..

...

4-11

Table

5-1

Maintena

nce

Time

Table

........

.

............

... .

.....

5-2

5-2

Too

ls

Required

for

Ma

intenance

...

...

...

.... ...

...

.

.....

5-2

Table

6-1

Necessary

Tools

..... .. ..

....

...

...

.

6-2

6-2

Brake

Tension

Values

..

.

..

.

....

.......

...

6-3

6-3

Tape

Speed

Settings

.

..

.

....................

6-8

Table

7-1

Reference

Tapes

.

...

... .

.....

........

.....

....

.. .

....

7-2

7-2

Trigger

Level

.....

....

........

7-3

7·3

Overbias

Values

....

.

.........

....

...............

..

.....

7-8

May

1992

xiii

Section

1

Introduction

This

Section

includes

a

general

description

of

the

features

of

the

MX-5050

series

tape

recorders

and

information

on

the

structure

of

this

manual.

1.1

MX-5050

Series

... 1-2

1.2

Using

This

Manual

. ...

....

.

......

1-3

1.2.1

OrgJnizJtion

1.2.2

Convent

i

ons

within

th

is

mJnuJI

...

... . .

....

1-3

....

.. .. ..... .

1-4

May

1992

1 - 1

Section

1

Introduction

MX

-5050

Operation

and

Maintenance

Manual

1.1

The

New

MX-5050

Series

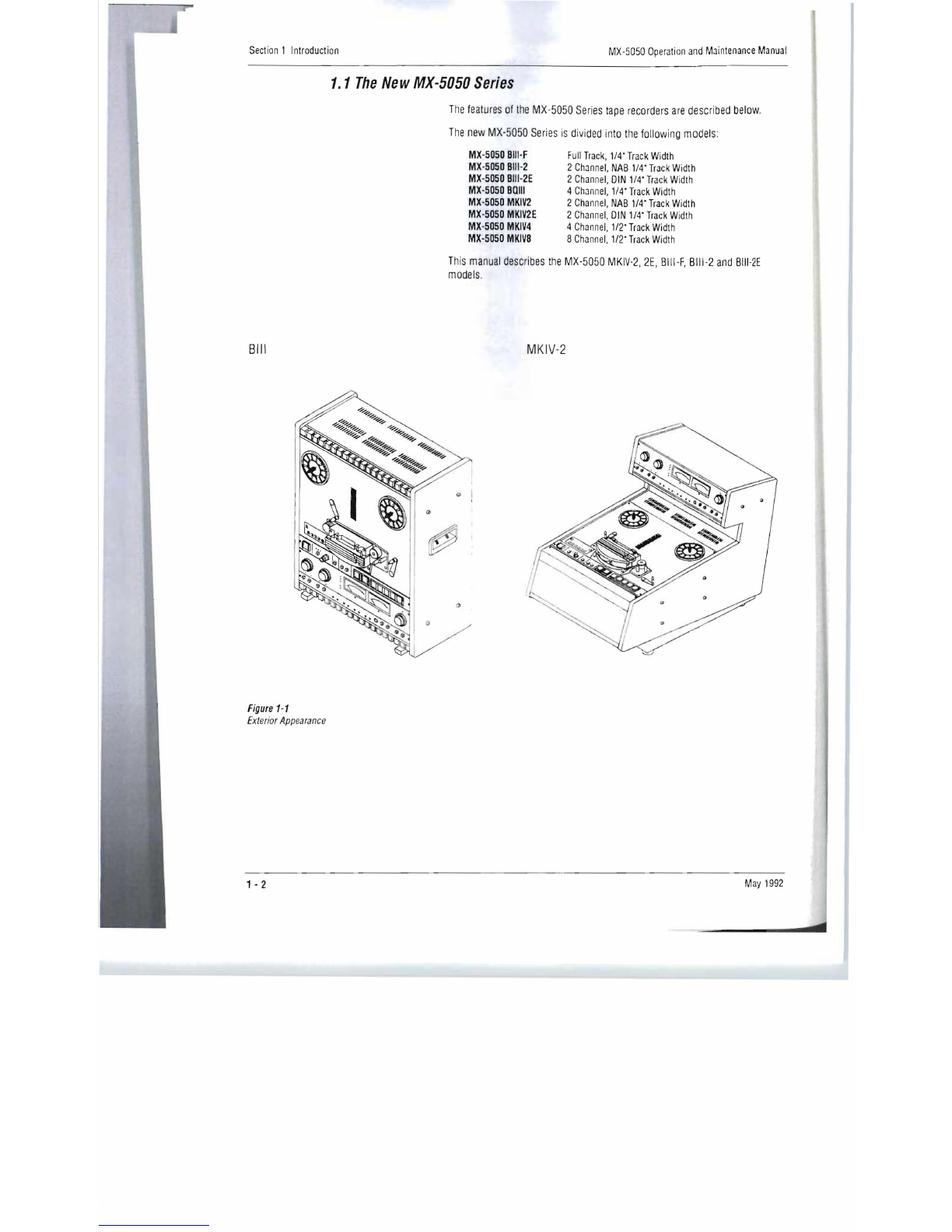

The

features

of

the

MX-5050

Series

tape

recorders

are

described

below

.

The

new

MX-5050

Series

is

divided

int

o

the

following

models

:

MX-5050

BIH

Full

Track,

1/4'

Track

Width

Mx-5050

BIII-2

2

Channel,

NAB

1/4'

Track

Width

MX-5050

BIJI-2E

2

Channel,

DIN

1/4'

Track

Width

MX

-

5050

Balli

4

Channel,

1/4'

Track

Width

MX-5050

MKIV2

2

Channel,

NAB

1/4'

Track

Width

MX

-

5050

MKIV2E

2

Channel,

DIN

1/4'

Track

Width

Mx-5050

MKIV4

4

Channel,

1/2'

Track

Widt

h

MX-SOSO

MKIV8

8

Channel,

1/2'

Track

Width

This

manual

describes

the

MX-5050

MKIV

-2,

2E,

BIII-F,

BIII

-2

and

BIII

-2E

models

.

Bill

MKIV-2

Figure

1-1

Exterior

Appearance

1 - 2

May

1992

IOd

Maintenance

Manual

MX-5050

Operation

and

Maintenance

Manual

Section

1

Introduction

lescribed

below

.

odels:

111-2

and

BIII-2E

Fealures

o/Ihe

MX-5050

Series

In

addition

to

the

usual

tape

recorder

functions,

the

MX-5050

series

has

various

additional

features

.

All

MX-5050

series

tape

recorders

have

the

OTARI

Standard

Parallel

I/O

connector

which

allows

for

post

production

editing

work

with

a

synchronizer

using

time

code

.

The

tape

timers

include

a

Mini

Locator

for

more

advanced

locator

functions.

In

addition

to

these

functions,

these

machines

also

have

the

following

features:

Sel-Rep

(Selective

Reproduce),

Edit

mode

function

which

permits

tape

spilling,

CUE

monitoring

which

enables

monitoring

the

tape

in

F.FWO

or

RWO

mode,

Standby

function

for

easy

multi-channel

recording,

and

Variable

Pitch

Control

function

(±20%)

.

1.2

Using

This

Manual

1.2.1

Organization

This

manual

is

divided

into

ten

sections

as

follows.

Section

1

Introduction

This

section

describes

the

features

of

the

MX-5050

se

ries

tape

recorders

and

the

structure

of

this

manual.

Section

2

Installation

This

section

describes

the

procedures

for

unpacking

and

hooking

up

the

machine.

This

section

also

includes

the

01

P

sw

i

tch

presettings.

Section

3

Controls

and

Indicators

Thi

s

section

describes

the

name

and

function

of

each

control.

The

connector

pin

assignments

are

also

included

.

Section

4

Operation

This

section

explains

each

mode

of

the

mach

i

ne

and

the

basic

procedures

for

reproducing

and

recording

a

tap

e.

Section

5

Maintenance

This

section

describe

s

procedures

for

daily

maintenance.

May

1992

May

1992

Section

6

Transport

Adjustment

and

Parts

Replacement

This

section

describes

the

adjustment

procedures

for

transport

mechanisms

and

re

placement

procedures

.

Section

7

Audio

Alignment

This

section

describes

the

electr

i

cal

adjustment

of

the

Reproduce

and

Record

circu

i

ts

.

Section

8

Specllicalions

This

section

of

the

manual

contains

the

operating

specifications

for

MX

·

5050

ser

i

es

tape

recorders

.

Section

9

Exploded

Views

and

Parts

lists

This

section

of

the

manual

contains

assembly

drawings

of

the

machine

"ex

ploded

"

to

show

internal

parts

and

hardware

,

and

the

order

of

assembly.

Each

exploded

vi

ew

is

keyed

to

an

accompanying

parts

list

showing

OIarl

part

numbe

rs

and

descriptions

for

all

mechanical

components

.

1 - 3

Section

1

Introduction

MX·5050

Operation

and

Maintenance

Manual

Appendix

A

Block

Diagrams

Th

is

appendix

includes

block

di

agrams

of

the

MX·5050

and

level

diagrams

of

the

circuitry

Appendix

B

Troubleshooting

This

section

describes

some

typical

problems

which

may

occur

during

operations,

their

possible

causes

and

how

to

handle

them

.

1.2.2

Conventions

within

this

manual

PCB

Assemblies:

The

term

PCB

Assembly

is

used

in

this

manual

to

refer

to

a

printed

circuit

board

which

has

components

(resistors,

connectors,

etc.)

mounted

on

it.

The

term

PCB

or

Pr

i

nted

Circuit

Board,

when

used

alone

refers

to

the

"bare

'·

printed

circuit

board

without

components

.

The

term

PCB

is

rarely

used

outside

of

the

electrical

and

mechanical

parts

lists

.

When

a

PCB

Assembly

is

referred

to

in

the

text,

the

name

or

function

of

that

PCB

Assembly

will

usually

be

given

in

ALL

CAPITAL

letters

Type

conventions

ALL

UPPER

CASE·

Generally,

this

manual

uses

all

upper

case

type

to

descr

i

be

a

switch

or

control

when

that

item

is

similarly

labeled

on

the

machine

(e

.g.,

the

PLAY

button)

.

First

Letter·

Where

a

switch

or

button

is

not

Upper

Case

labeled

,

or

the

reference

is

less

clear,

only

the

first

letter

of

the

item

is

capitalized

(e

.g

.,

the

Cue

Wheel

near

the

CUE

button)

.

Machine

status

or

operating

modes

are

described

with

an

upper

case

first

letter

(e

.g

.,

you

press

the

PLAY

button

to

place

the

machine

in

Play

mode)

.

(

),

[ ] .

Normal

parentheses

( )

are

used

for

examples

and

parenthetic

comments.

Square

brackets

[ ]

are

used

to

refer

to

certain

illustrations

.

When

used

in

te

xt,

the

square

brackets

are

either

references

to

the

same

figure

as

noted

in

that

sub'section

(e

.g,

[3],

meaning

the

part

labeled

"

3"

in

the

figu

re

noted)

or

are

preceded

by

the

fi

gure

number

(e

.g

.,

Fig.

2-1,

[3),

meaning

'3"

in

Figure

2-

1)

.

May

1992

1 - 4

Id

Maintenance

Manual

nd

level

diagrams

of

occur

during

manual

to

refer

to

a

'

nnectors,

etc.}

en

used

alone

ltS.

The

term

PCB

s

lists.

When

a

on

of

that

PCB

:ase

type

to

eled

on

the

abeled,

or

the

·italized

(e.g.,

the

ing

modes

are

3

PLAY

button

to

parenthetic

Ilustrations.

When

3

same

figure

as

j

"3

"

in

the

figure

[3J,

meaning

"3"

Section

2

Installation

This

section

of

the

manual

provides

information

on

unpacking

and

inspecting

the

tape

recorder,

and

on

power

and

signal

connections.

Refer

to

this

section

when

first

setting

up

the

machine.

This

section

includes

the

following

sub

sections.

2.

1

Unpacking

and

Inspection

... ... .

....

.... ... .

....

...

2-2

2.2

Audio

Signal

Connection

..

... ..

.....

......

.....

..

....

....

2-3

2.2.1

Audio

Connectors

.

..

. .

....

....

.....

..

.........

.

...

2-3

2.2.2

Balance/Unbalance

Adjustment

. . ... ... .. .. ..

...........

..

..

.

2-4

2.3

Switch

Position

Adjustment

... ...... ....... .....

..

........

..

.....

2-5

2.4

PCB

Assembly

Location

............

2-9

2.4

.1

MX-5050

Bill

.....

........

2-9

2.4

.2

MX·5050

MKIV2

...... .

.......

....

..

2-11

2.5

Power

Connection

.

.................

2-13

.

2.6

Fuse

Replacement

.

..........

.. ...

....

2-14

2.7

Speed

Conversion

(BIII-2)

. .

.......

.....

2-15

2.8

Equalizer

Change

..

... ....

...

.. ...

2-15

May

1992

2-1

May

1992

Section

2

Installation

MX-SOSO

Operation

and

Maintenance

Manual

2.1

Unpacking

and

Inspection

Table

2-1

Standard

Accessories

After

receiving

the

MX-5050,

examine

the

case

for

any

signs

of

damage

.

Then

unpack

and

inspect

the

equipment.

Take

care

when

unpacking

the

equipment

and

removing

packing

materials

to

prevent

damaging

the

critical

components

such

as

the

capstan,

head

assembly,

and

tension

arms.

If

there

is

any

evidence

of

damage

due

to

rough

handling

during

transportation,

a

claim

should

be

filed

with

the

transportation

company

.

We

recommend

retain

i

ng

the

packing

material

at

least

until

proper

operation

of

the

machine

has

been

established.

Verify

that

all

items,

as

listed

in

Table

2-1,

have

been

received.

Do

not

connect

or

operate

the

MX-5050

until

this

inspection

has

been

completed

.

When

send

in

g

the

machine

back

to

the

local

OTARI

dealer

or

to

OTARI,

follow

the

packing

directions

printed

on

the

carton.

MX-5050

Bill,

MKIV·2

Parts

Name

Part

No

.

Quantity

Reel

Clamp

KWOHV

2

Power

Cable

PZ9DOO3

1

Manual

OS3-

2

98

1

Lubr

ication

Oi

l

PZ9EOO3

1

Fuse

1A

FH7F010

1

(Fuse

1A

200·240V

only

FH9·032

1)

Fu

se

2A

FH9-030

1

Fu

se

2A

FH7F020

1

Fuse

3A

FH7F030

1

Fuse

4A

FH7F040

1

Fuse

SA

FH7FOSO

1

May

1992

2-2

<

and

Maintenance

Manual

;igns

of

damage.

n

unpacking

the

l

amaging

the

critical

lnsion

arms.

If

there

I

transportation,

a

Ve

recommend

tion

of

the

machine

:eived.

Do

not

;

been

com

pleted.

lr

or

to

OTARI,

follow

MX-5050

Operation

and

Maintenance

Manual

Section

2

Installation

2.2

Audio

Signal

Connection

2.2.1

Audio

Connectors

Bill

0

@

f,

'iii&

·

l

iiaai~

~

@

PARALlEL

110

@~rD

D

D

l

~

0

GAOUO" POWER

MKIV-2

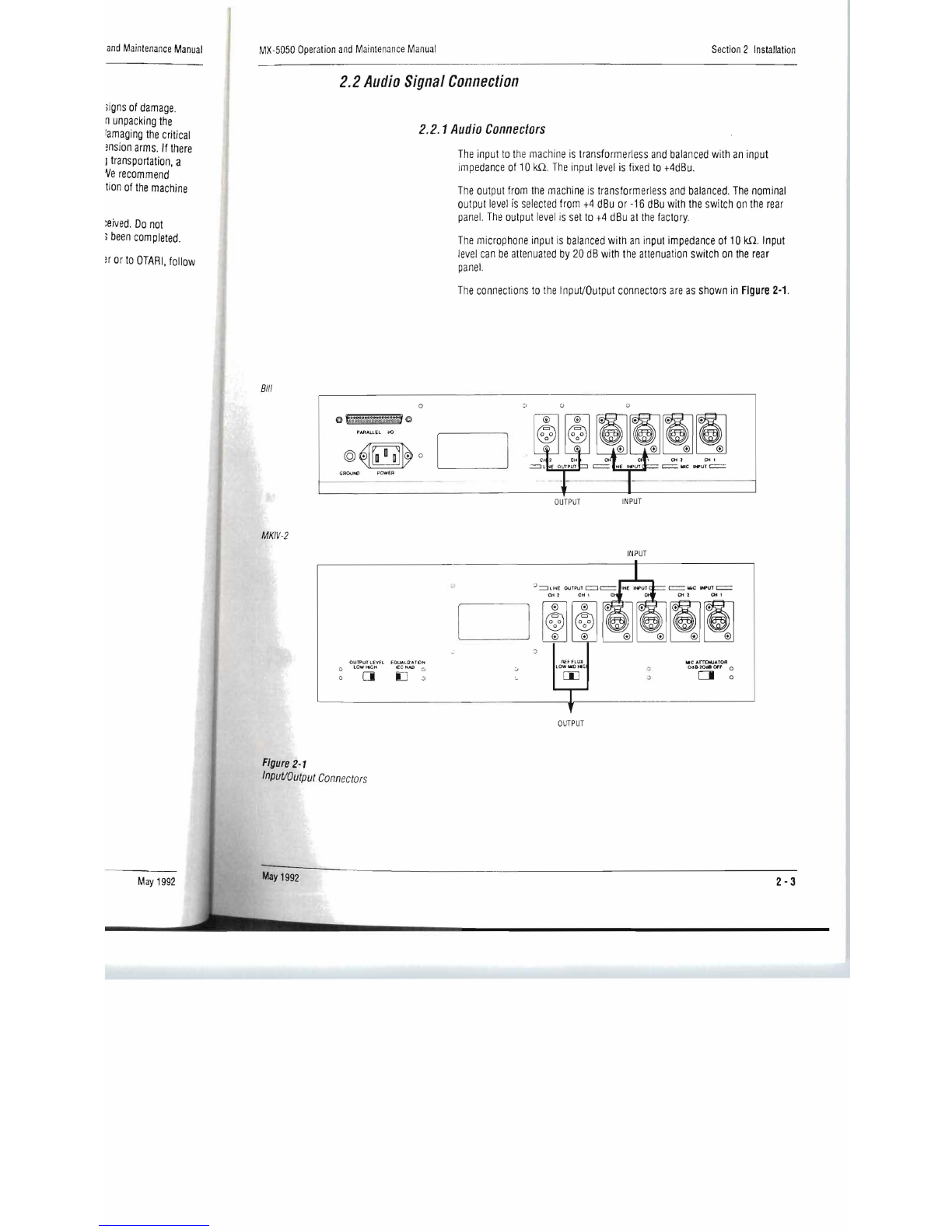

The

input

to

the

machine

is

transformerless

and

balanced

with

an

input

impedance

of

10

kil.

The

input

level

is

fixed

to

+4dBu

.

The

output

from

the

machine

is

transformerless

and

balanced.

The

nominal

output

level

IS

selected

from

+4

dBu

or

-16

dBu

with

the

switch

on

the

rear

panel.

The

output

level

is

set

to

+4

dBu

at

the

factory.

The

microphone

input

is

balanced

with

an

input

impedance

of

10

kn.

Input

level

can

be

attenuated

by

20

dB

with

the

attenuation

switch

on

the

rear

panel.

The

connections

to

the

InpuVOutput

connectors

are

as

shown

in

Figure

2-1.

:,

D " 0 .

J~II~I

"',

""

OUTP

UT

INPUT

INPUT

CH'

"',

'"

,

D 0

0

~

~

.

~~

0

~®

0

0 0 0

~

OUTPUJ

LEVEL

EQWUZA

lION

REf

flUX

"C

ATT£HUATOR

LOW

HleH

lEe

NAi;l LOWMlO~C;

0C1&20QII

Off

a

:0

0 0 ~

0

[j

~

[j]

C1

0

iJ

OUTPUT

Figure

2-1

Input/Output

Connectors

May

1992

May

1992

2- 3

Section

2

Installation

MX-SOSO

Operation

Jnd

Maintenance

Manual

2-2.2

Balanced/Unbalanced

Connection

The

InpuVOutput

connectors

are

balanced

as

shown

in

Figure

2-2.

The

pin

assignment

of

the

connectors

is

as

follows:

Pin

1

Shield

(GNO)

Pin

2

Cold

Pin

3

Hot.

When

connecting

an

unbalanced

machine

to

the

MX-5050,

change

the

pin

assignment

as

shown

in

Figure

2-2.

Balanced Input Balanced Output

Unbalanced

Input

Unbalanced Output

Figure

2-2

Optional

Input

(ZA-53T)

/O

utput

(ZA-53S)

Transformers

are

available

from

Balanced/Unbalanced

Connectors

OTARI.

For

details

contact

OTARt

or

your

nearest

OTARI

dealer.

2-4

May

1992

cd

Jnd

Maintenance

Manual

Figure

2-2,

The

pin

50,

change

the

pin

Jut

)utput

available

from

aler.

May

1992

MX-SOSO

Operation

and

Maintenance

Manual

Section

2

Installation

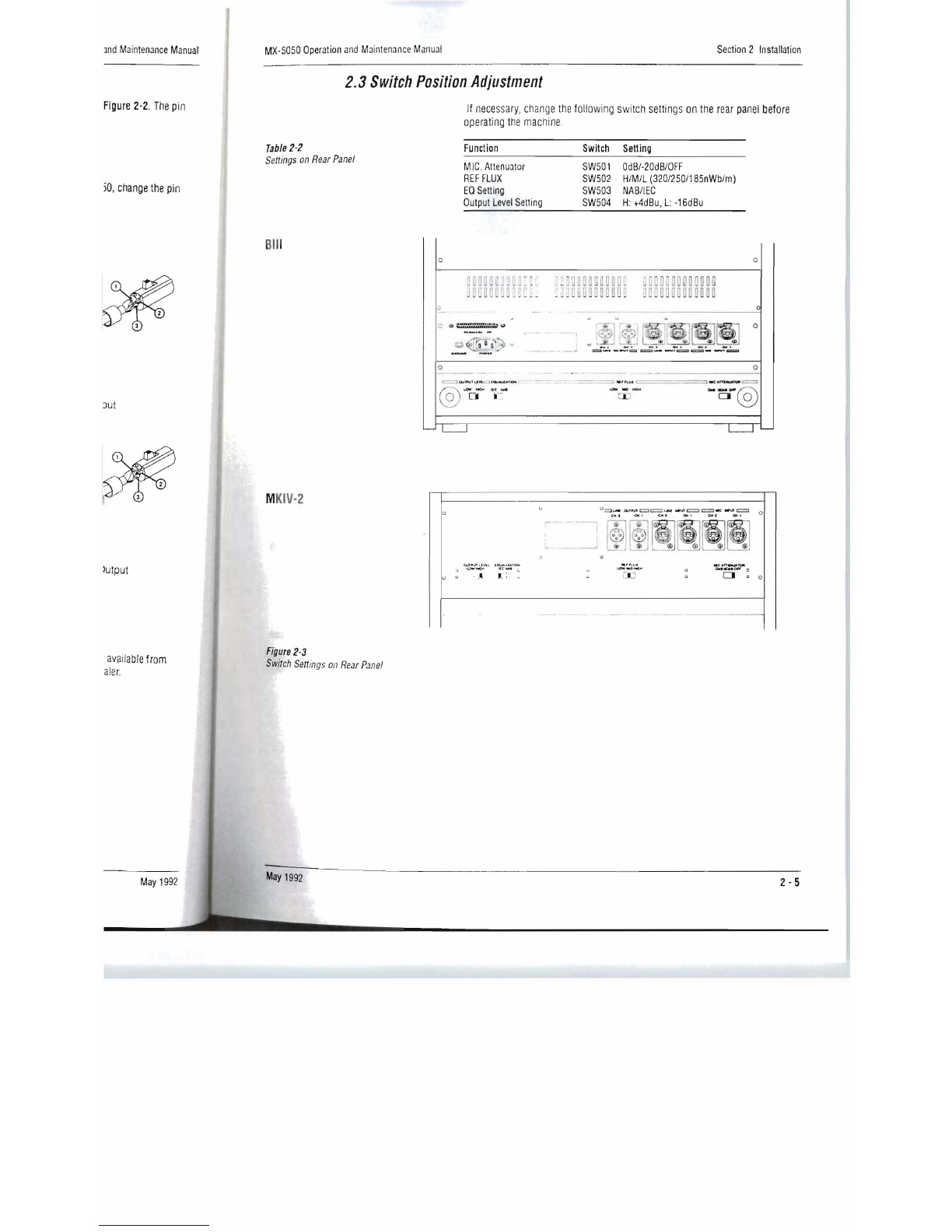

2.3

Switch

Position

Adjustment

If

necessary,

change

the

following

switch

settings

on

the

rear

panel

before

operating

the

machine

.

Table

2-2

Function

Switch

Selling

Settings

on

Rear

Panel

M

IC

.

Attenuator

SWSOI

OdB/-20dB/OFF

REF

FLUX

SWS02

H/M/L

(320/2S0/18SnWb/m)

EO

Setting

SWS03

NAB/IEC

Output

Level

Setting

SWS04

H:

+4dBu,

L:

-16dBu

Bil

l o o

_ u •

_ , :@

I'

@I

~

,

~rr

~fSl

0

o

.~

-

.

~

~

.

~

r_.t

il

L

~~

~

=--

-

......

~

==--

-.~~--~

o o

c,

\ _

....

"'-

LJ Jo '

"'o

@

M

KIV-2

~

v

c;..n.,n

"

",

.

.,

-~

u ...

~

(0

.....

·'-&10-

1

((""'"

C

,-: ,

v

,

.

--

,

U

~UOOI

o.II,Inc=Jc::=

........

ittI'lAC:=::>c=I.o

W\II't:::::j

'"'

~,

'"'

~,

'"'

"',

~~

~~~~

I @ @i

-.J

I; ; ® 0

cv

@

Q

..

~

,.v.

..c:"n_~

"

LOW.a..:;:

.. 0

......

....

0

u =IJ 0

CJ

0

0

0

--- -

--

Figure

2·3

Switch

Settings

on

Rear

Panel

May

1992

2- 5

Table of contents

Other OTARI Recording Equipment manuals

OTARI

OTARI MX-5050 BII Series User manual

OTARI

OTARI MX-50II Series User manual

OTARI

OTARI MX-505MKIII-2 User manual

OTARI

OTARI MTR-10II Series User manual

OTARI

OTARI MX-55T-M User manual

OTARI

OTARI MX-5050 User manual

OTARI

OTARI MTR-90III User manual

OTARI

OTARI MX-5050 Manual

OTARI

OTARI MX-5050BII Series User manual

OTARI

OTARI MX 5050 BQII Series User manual

Popular Recording Equipment manuals by other brands

JLCooper Electronics

JLCooper Electronics MCS6 USB user manual

ABB

ABB EP010 User's and operator's manual

Tigertronics

Tigertronics SignaLink Installation & operation

Ei Electronics

Ei Electronics Ei414 instruction manual

MORLEY PEDALS

MORLEY PEDALS POB2 manual

nuance hearing

nuance hearing Voice Selector Study user guide