E-822-9-E

1. GENERAL .............................................................................................................................. 3

〈FEATURES〉........................................................................................................................ 3

2. PART NAMES......................................................................................................................... 3

3. OUTLINE DIMENSIONS ........................................................................................................ 3

4. INSTALLATION ...................................................................................................................... 4

4.1 Installation Location.........................................................................................................4

4.2 Mounting Panel................................................................................................................ 4

4.3 Installation Procedure......................................................................................................4

5. WIRING .................................................................................................................................. 5

5.1 Cables for Field Wiring ....................................................................................................5

5.2 Wiring Connections..........................................................................................................5

5.3 Terminal Block for External Connections ......................................................................... 5

6. OVERALL BLOCK DIAGRAM ................................................................................................ 6

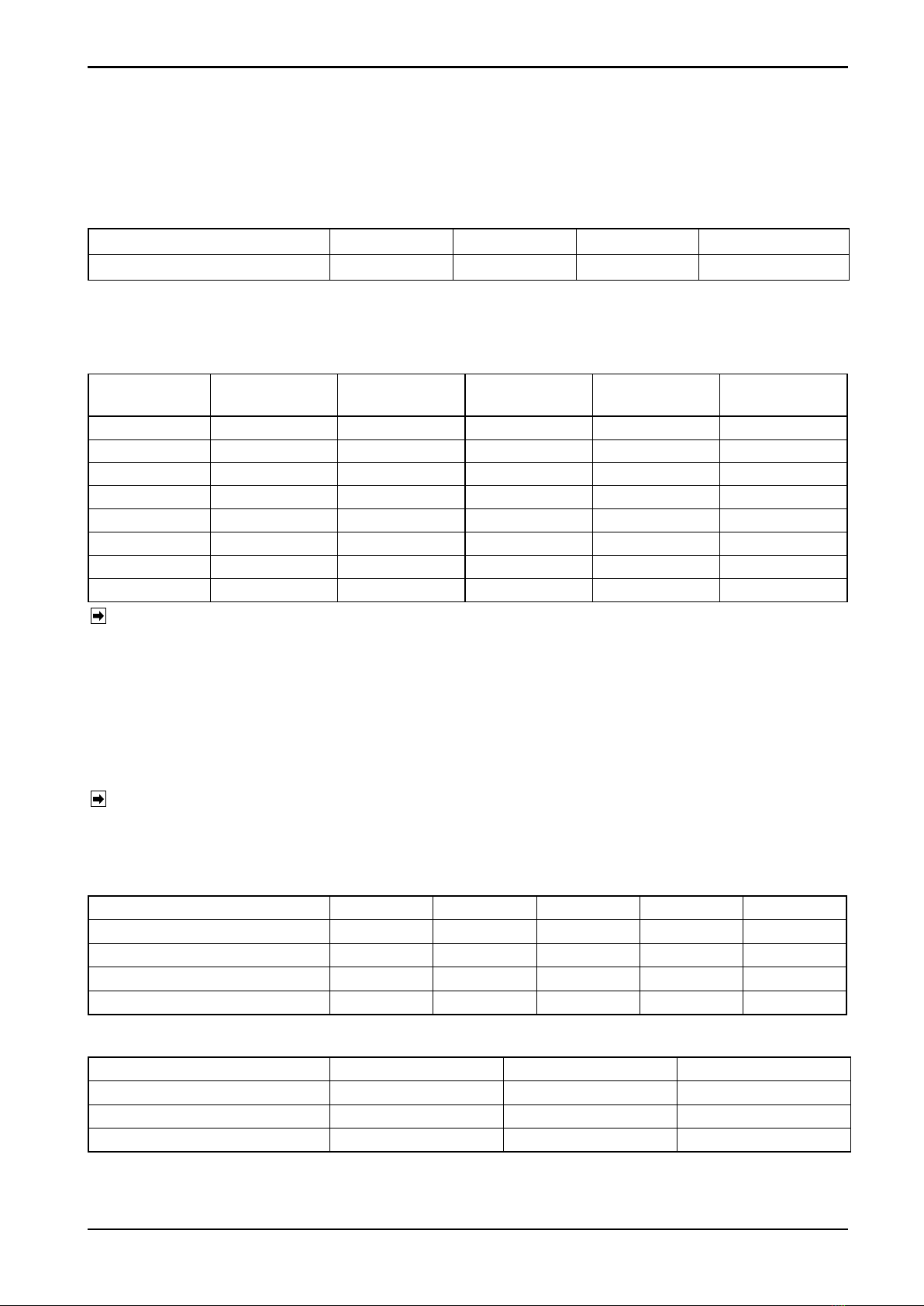

7. CONVERSION FORMULA..................................................................................................... 6

8. CHANGING THE PULSE GENERATOR TYPE, METER SIZE (nominal bore),

METER ERROR, AND SCALER SETTINGS ......................................................................... 7

9. PULSE/ANALOG CONVERTER BOARD (OPTION) ............................................................. 8

10. OPERATION......................................................................................................................... 8

10.1 Preparation Before Operation........................................................................................ 8

10.2 Operation ....................................................................................................................... 8

11. TROUBLESHOOTING.......................................................................................................... 8

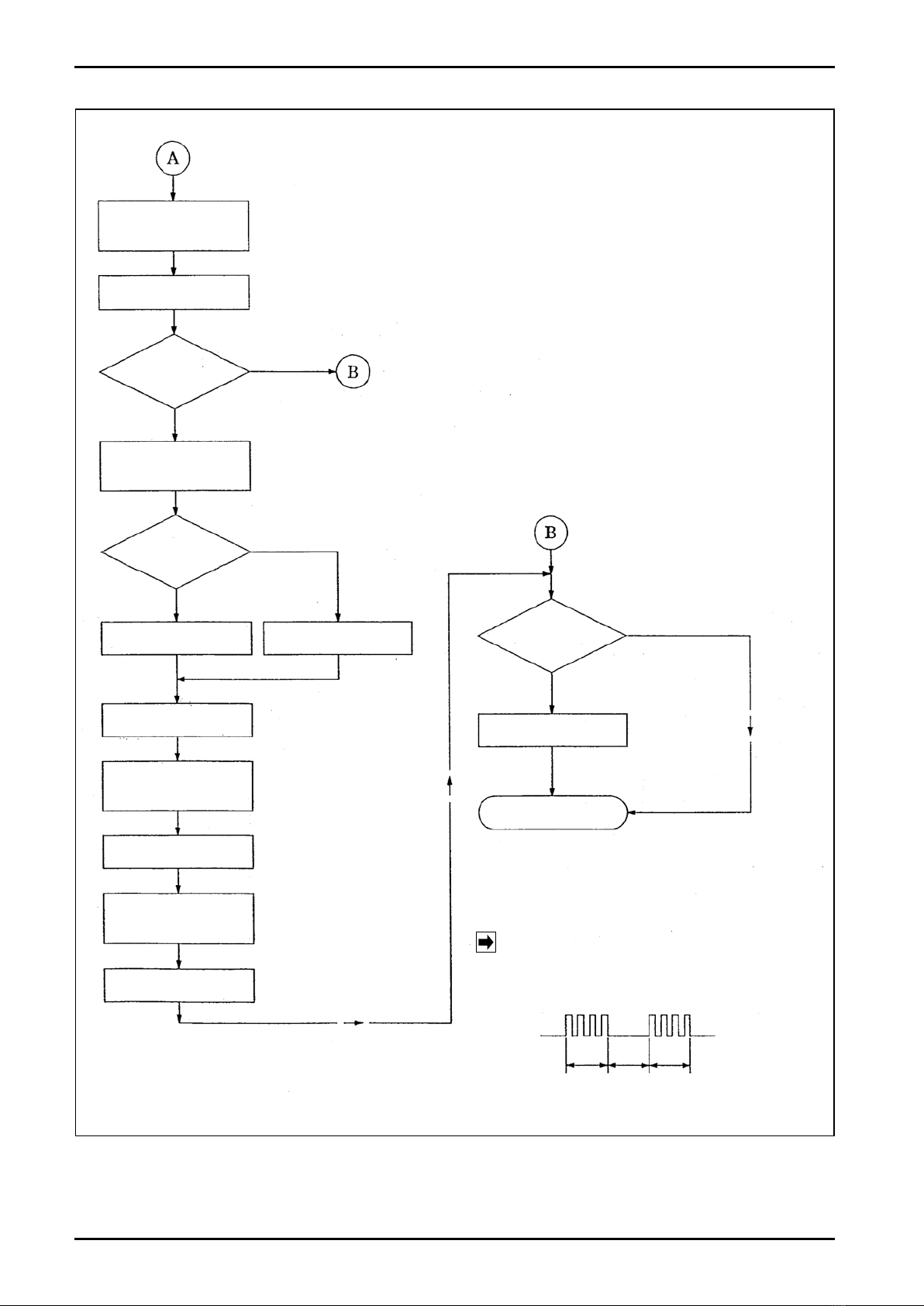

12. OPERATION FLOW CHART................................................................................................ 9

13. PRODUCT CODE EXPLANATION .................................................................................... 11

14. TOTAL COUNTER AND OUTPUT UNITS.......................................................................... 11

15. GENERAL SPECIFICATIONS............................................................................................ 12

CONTENTS

This manual uses the precaution words

"NOTE", "CAUTION", and "WARNING" as explained below:

NOTE:

Notes are separated from the general text to bring the user's

attention to important information.

CAUTION:

Caution statements inform the user of hazards or unsafe practices

which could result in minor personal injury or product/property

damage.

WARNING:

Warning statements inform the user of hazards or unsafe practices

which could result in severe personal injury or death.