Contents

Issue 1 Grid-Lok Installation Manual 1

CONTENTS

Manual scope. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

CHAPTER 1

Tools required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

CHAPTER 2

Kit description. . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

CHAPTER 3

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

CHAPTER 4

Locating the kit

Controller location . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

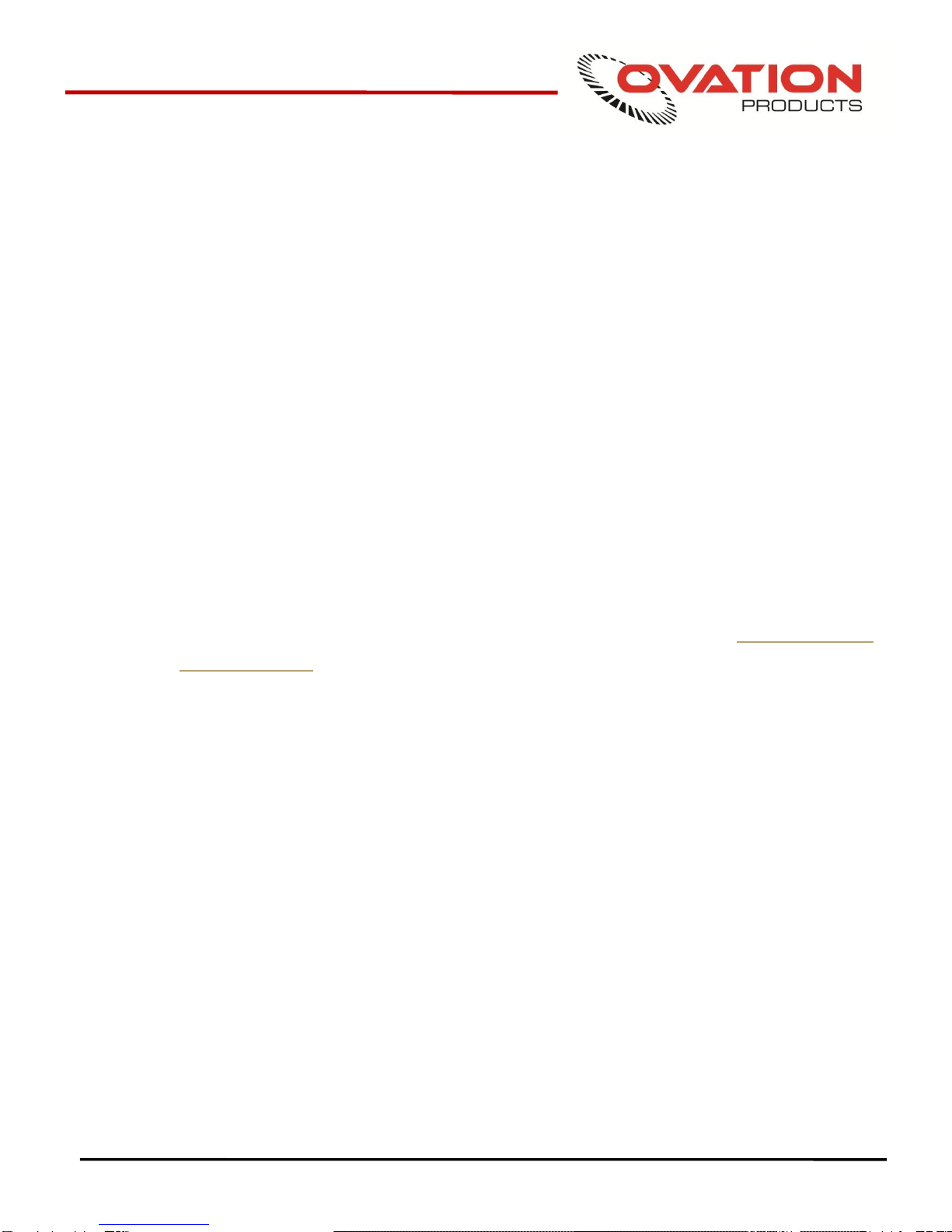

Air solenoid location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Aux power supply location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

CHAPTER 5

Connecting up

Connections overview . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Locating and fitting power and air connections . . . . . . . . . . . . . . . . . . . . . . . . .12

Table up to pressure sensor on control box . . . . . . . . . . . . . . . .. . . . . . . . . . . . . 13

Manifold to modules . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pin up and pin lock air connections to table . . .. . . . . . . . . . . . . . . . . . . . . . . . .. 16

CHAPTER 6

Specific details and instructions

Operator interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

CHAPTER 7

Adjustments and settings

Adjusting the table flow control valve . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . 18

Adjusting module timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 19

CHAPTER 8

Technical reference

Fault finding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Preventive maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

CHAPTER 9

Contacts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22