en

7

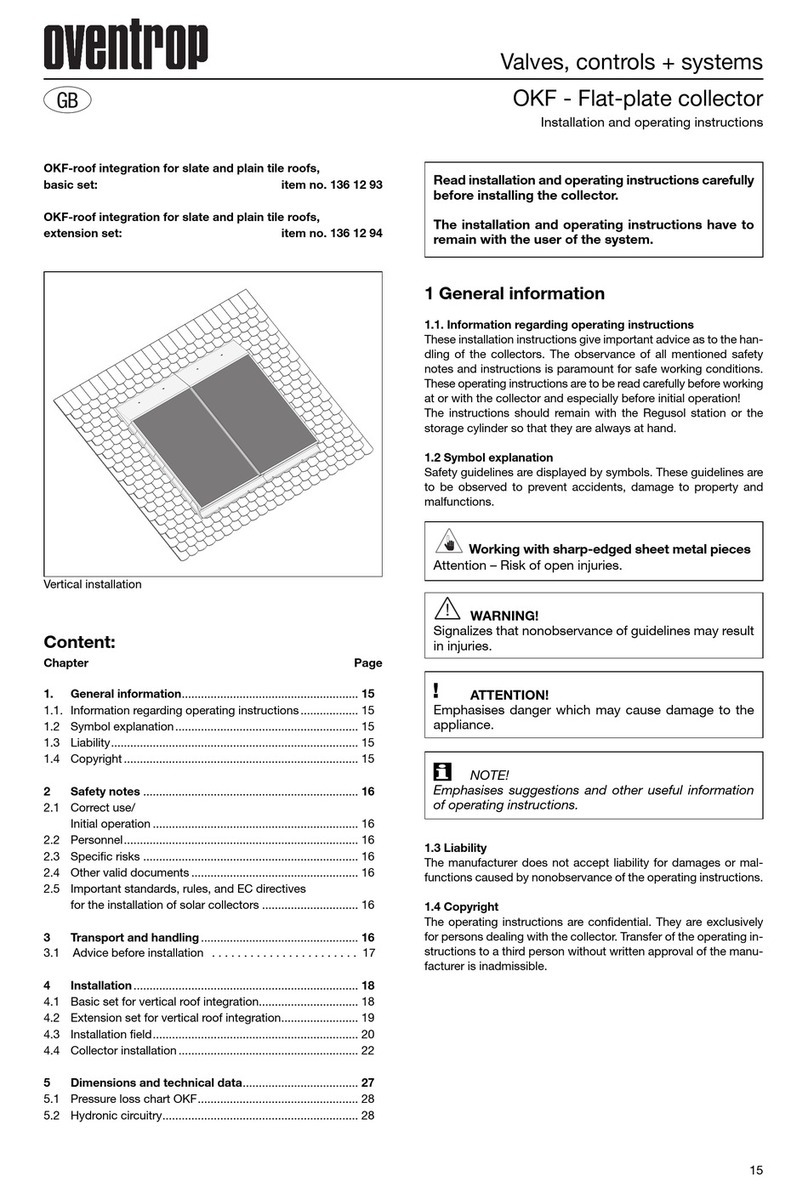

Installation

CommissioningAdjustmentsTroubleshooting Data communication

2 Commissioning

When the hydraulic system is lled and ready for op-

eration, connect the controller to the mains.

The controller runs an initialisation phase in which

the directional pad ashes red.

When the controller is commissioned for the rst

time or when it is reset (see page 32), it will run

a commissioning menu after the initialisation phase.

The commissioning menu leads the user through the

most important adjustment channels needed for op-

erating the system. For navigating in the commission-

ing menu, see page 8.

2.1 Step-by-step parameterisation

a. Running the commissioning menu

The commissioning menu is run after the rst con-

nection and after every reset (see page 32). It will

request the following basic adjustments:

• Menu language

• Time

• Date

• Circulation

• Afterheating

• Disinfection

When the last item Save at the end of the commis-

sioning menu is selected, a security enquiry appears.

If the safety enquiry is conrmed, the adjustments

are saved. For further information about the com-

missioning menu see page 13.

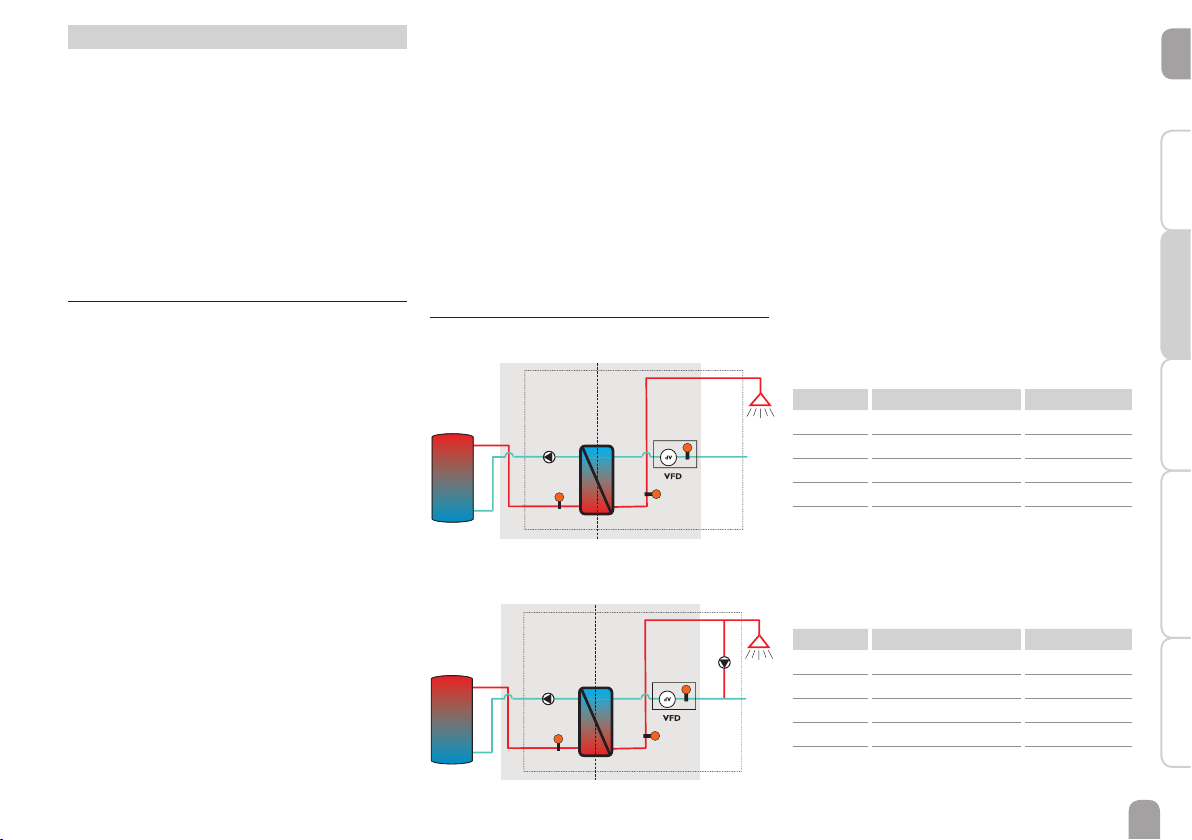

Relay / sensor allocation

Relay / sensor allocation

Terminal Description Display screens

R4 + PWM Primary pump R4

R2 Circulation pump R2

S1 Store ow sensor T-store ow

S2 Hot water ow sensor T-HW

VFD Cold water sensor T-CW

VFD Circulation ret. sensor T-circ return

Terminal Description Display screens

R4 + PWM Primary pump R4

S1 Store ow sensor T-store ow

S2 Hot water ow sensor T-HW

VFD Cold water sensor T-CW

VFD Flow rate sensor Flow rate

b. Activating the main functions

Adjustments for the main functions Circulation,

Afterheating and Disinfection can be made. Main

functions that have not been activated in the com-

missioning menu can now be activated here.

Free relays can be allocated to main functions which

require a relay.The controller always suggests the nu-

merically smallest free relay.

Sensors can be allocated to more than one function.

For further information about the main functions see

page 17.

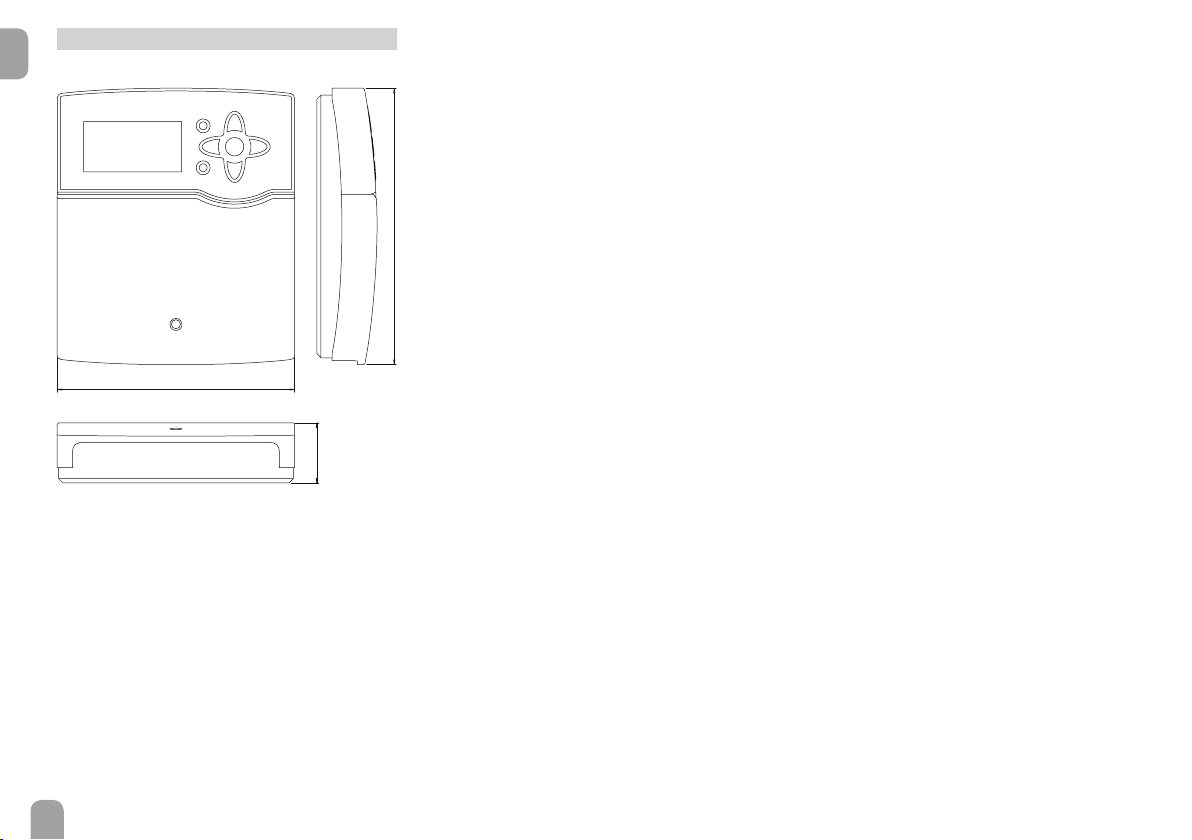

2.1.1 Overview of relay and sensor allocation

DHW heat exchange module without circula-

tion

Primärseite Sekundärseite

R4/PWM

S1 S2

primary side secondary side

DHW heat exchange module with circulation

Primärseite Sekundärseite

R4/PWM

S1 S2

R2

primary side secondary side

c. Activating additional functions

Only after the required main functions have been ac-

tivated and adjusted, should the additional functions

be activated.

Any free relay can be allocated to any of the main

functions.The controller always suggests the numeri-

cally smallest free relay.

Sensors can be allocated to more than one function.

For further information about the additional func-

tions see page 28.