Permeation Chamber User’s Manual

Page 2

2.0 How it Works

The information contained in the following subsections is provided to “demystify” OTR

analysis. Your understanding of the method and the instrumentation will greatly increase

the ease of producing a valid OTR result.

2.1 Instrumentation

Using an OxySense® instrument, one is able to obtain non-invasive (i.e. in-situ) oxygen

concentration measurements by way of fluorescence quenching analysis, where, an

optical, oxygen-selective sensor (e.g. an OxyDot®) resides within a sealed container,

affixed to a transparent surface. The instrument is capable of capturing the optical signal

from the sensor and transducing the signal in to an oxygen concentration.

The OxyPerm® Permeation Chamber is equipped with an OxyDot® that resides within the

chamber, opposite a transparent reading window. An OxySense® 5000 series instrument is

used to capture an oxygen concentration reading from the sensor without disturbing the

integrity of the chamber. The space where the OxyDot® resides is isolated from the

oxygen-containing atmosphere by the material being analyzed.

2.2 Dynamic Accumulation

OxySense employs the principle of dynamic accumulation (DA) for OTR determination,

where oxygen gas that permeates through the material gradually accumulates within a

container. OxySense® instrumentation, which is ideal for the in-situ measurement of

oxygen accumulation, is used to record the increasing oxygen concentration within that

container over time. The OTR is then calculated from the oxygen accumulation data.

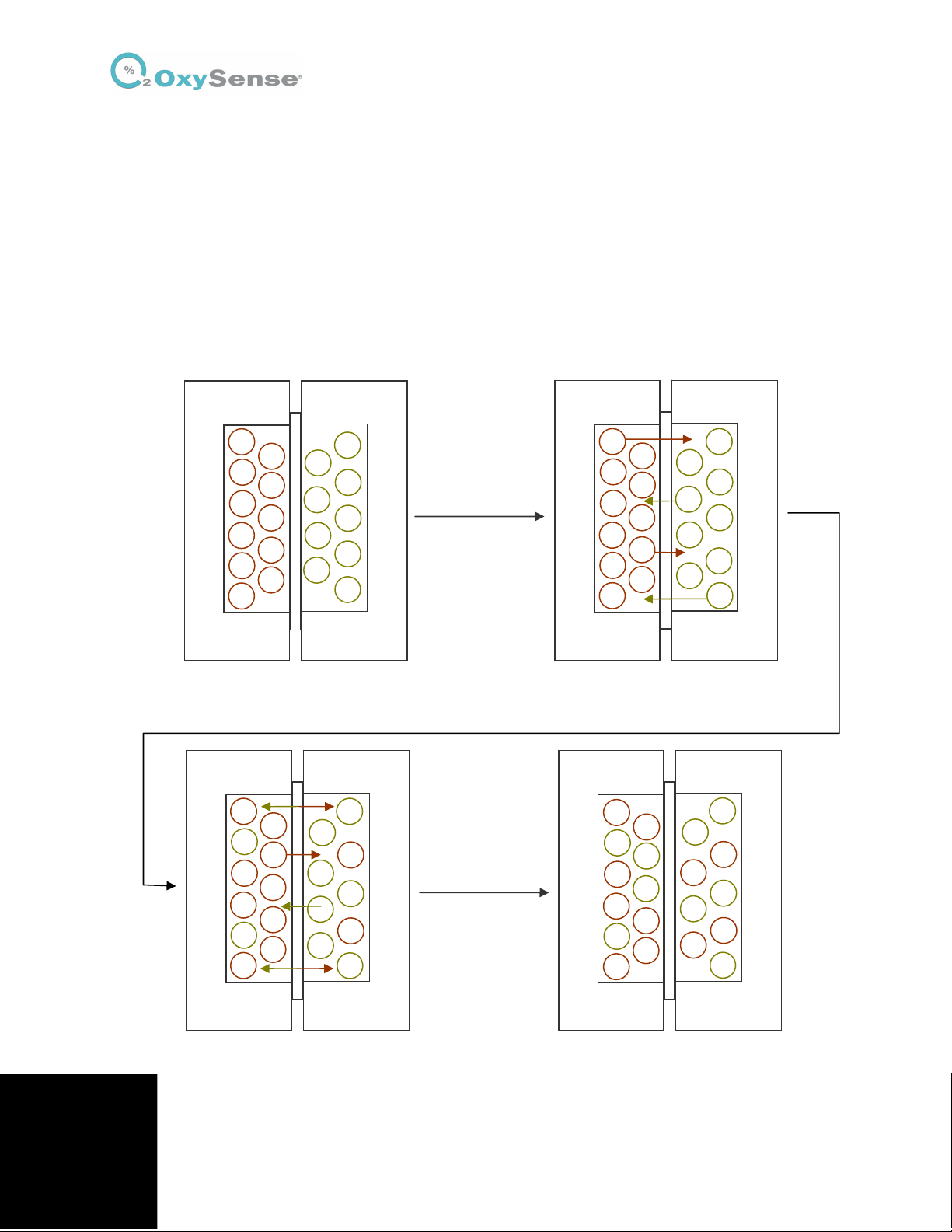

2.3 Film Permeation Tests

When determining OTR by DA using the OxyPerm® permeation chamber, the portion of the

chamber where the OxyDot® resides, called the sensing well, is first purged with an inert

gas (i.e. nitrogen) rendering the volume surrounding the sensor free of oxygen. The portion

of the well opposite the sensing well is called the driving well, the volume of which is filled

by an oxygen-containing gas (e.g. pure oxygen or air).

As gas crosses from the driving well through the film and in to sensing well, the oxygen

concentration rises. Data is captured periodically over time. The recorded oxygen

concentration and time data is then used to calculate the OTR as the oxygen and time

data are both directly correlated to the permeability of the film.

Copyright © Industrial Physics Product Integrity 2020