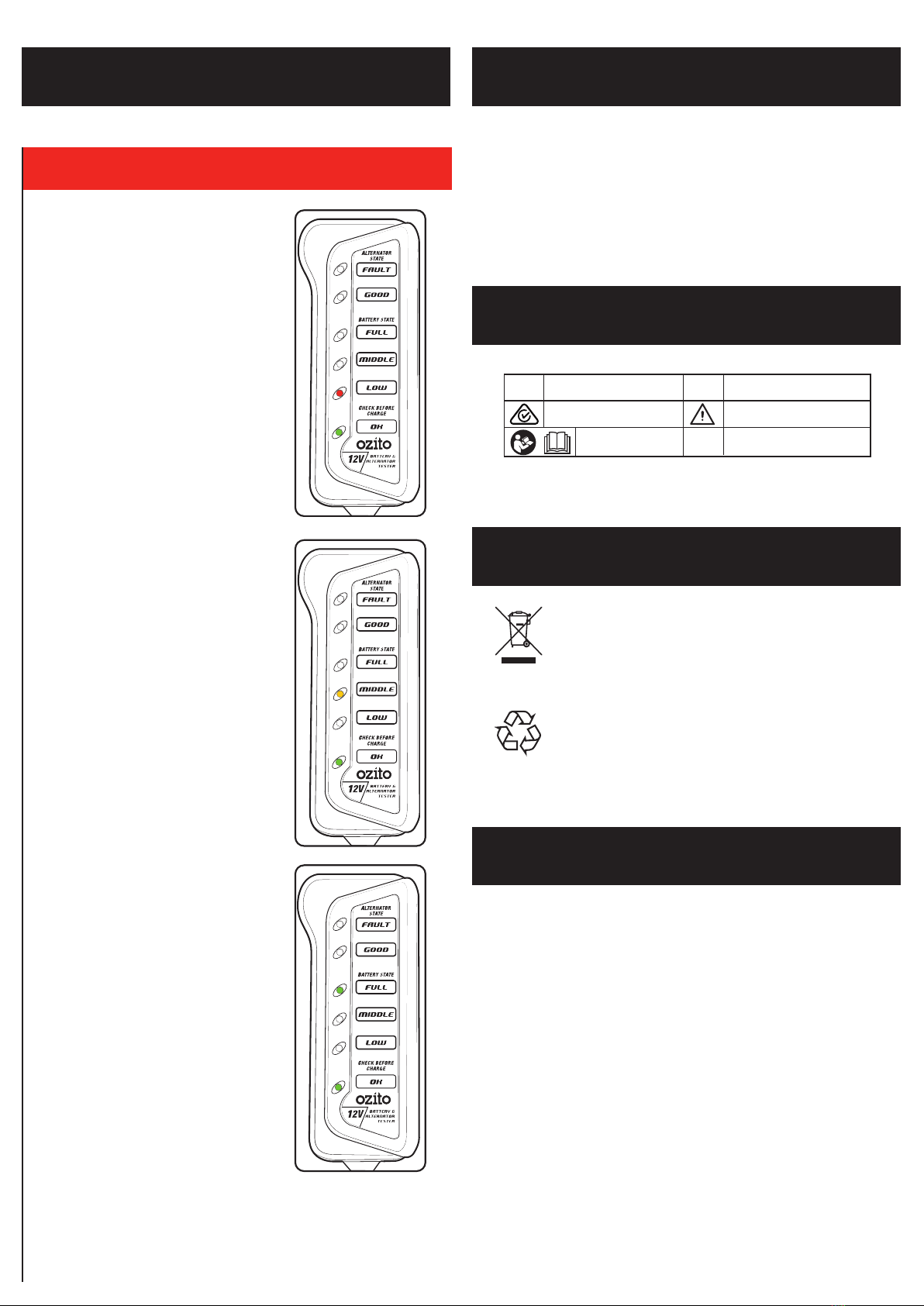

BATTERY &

ALTERNATOR

TESTER

INSTRUCTION MANUAL

SPECIFICATIONS

Input Max.: 12V DC

Weight: 0.1 kg

OCBT-1200

STANDARD EQUIPMENT

WARRANTY

OZITO Australia/New Zealand (Head Office) 1-23 Letcon Drive, Bangholme, Victoria, Australia 3175.

ozito.com.au

12V Battery & Alternator Tester

1120

IN ORDER TO MAKE A CLAIM UNDER THIS

WARRANTY YOU MUST RETURN THE PRODUCT

TO YOUR NEAREST BUNNINGS WAREHOUSE

WITH YOUR BUNNINGS REGISTER RECEIPT.

PRIOR TO RETURNING YOUR PRODUCT

FOR WARRANTY PLEASE TELEPHONE OUR

CUSTOMER SERVICE HELPLINE:

Australia: 1800 069 486

New Zealand: 0508 069 486

The benefits provided under this warranty are in addition to other rights and remedies

which are available to you at law.

Our goods come with guarantees that cannot be excluded at law. You are entitled to a

replacement or refund for a major failure and for compensation for any other reasonably

foreseeable loss or damage. You are also entitled to have the goods repaired or replaced

if the goods fail to be of acceptable quality and the failure does not amount to a major

failure.

Generally you will be responsible for all costs associated with a claim under this warranty,

however, where you have suffered any additional direct loss as a result of a defective

product you may be able to claim such expenses by contacting our customer service

helpline above.

TO ENSURE A SPEEDY RESPONSE PLEASE

HAVE THE MODEL NUMBER AND DATE OF

PURCHASE AVAILABLE. A CUSTOMER SERVICE

REPRESENTATIVE WILL TAKE YOUR CALL AND

ANSWER ANY QUESTIONS YOU MAY HAVE

RELATING TO THE WARRANTY POLICY OR

PROCEDURE.

BATTERY TESTER WARNINGS

WARNING! Read all safety warnings and all instructions. Failure to follow the warnings

and instructions may result in electric shock, fire and/or serious injury.

1. Work area safety

a. Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b. Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or

fumes.

c. Keep children and bystanders away while operating a power tool. Distractions can cause

you to lose control.

2. Electrical safety

a. Power tool plugs must match the outlet. Never modify the plug in any way. Do not use

any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching

outlets will reduce risk of electric shock.

b. Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges

and refrigerators. There is an increased risk of electric shock if your body is earthed or

grounded.

c. Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

d. Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

3. Personal safety

a. Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol

or medication. A moment of inattention while operating power tools may result in serious

personal injury.

b.Use personal protective equipment. Always wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

c. Prevent unintentional starting. Ensure the switch is in the off-position before connecting

to power source and/or battery pack, picking up or carrying the tool. Carrying power

tools with your finger on the switch or energising power tools that have the switch on invites

accidents.

d. Remove any adjusting key or wrench before turning the power tool on. A wrench or a key

left attached to a rotating part of the power tool may result in personal injury.

e. Do not overreach. Keep proper footing and balance at all times. This enables better control

of the power tool in unexpected situations.

f. Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in

moving parts.

h. Do not let familiarity gained from frequent use of tools allow you to become complacent

and ignore tool safety principles. A careless action can cause severe injury within a fraction

of a second.

4. Power tool use and care

a. Do not force the power tool. Use the correct power tool for your application. The correct

power tool will do the job better and safer at the rate for which it was designed.

c. Disconnect the plug from the power source and/or the battery pack from the power tool

before making any adjustments, changing accessories, or storing power tools. Such

preventive safety measures reduce the risk of starting the power tool accidentally.

d. Store idle power tools out of the reach of children and do not allow persons unfamiliar

with the power tool or these instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

e. Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts

and any other condition that may affect the power tool’s operation. If damaged, have the power

tool repaired before use. Many accidents are caused by poorly maintained power tools.

g. Use the power tool, accessories and tool bits etc. in accordance with these instructions,

taking into account the working conditions and the work to be performed. Use of the

power tool for operations different from those intended could result in a hazardous situation.

h. Keep handles and grasping surfaces dry, clean and free from oil and grease. Slippery

handles and grasping surfaces do not allow for safe handling and control of the tool in

unexpected situations.

5. Service

a. Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

12V

3 YEAR REPLACEMENT WARRANTY*

Your product is guaranteed for a period of 36 months from the original date of

purchase.If a product is defective it will be replaced in accordance with the terms of

this warranty. Warranty excludes consumable parts, for example: valve adapters and

accessories.

*This product is intended for DIY use only and replacement warranty covers domestic use.

WARNING

The following actions will result in the warranty being void.

If the tool has been operated on a supply voltage other than that specified on the tool.

If the tool shows signs of damage or defects caused by or resulting from abuse, accidents

or alterations.

Failure to perform maintenance as set out within the instruction manual.

If the tool is disassembled or tampered with in any way.

Professional, industrial or high frequency use.

GENERAL POWER TOOL SAFETY WARNINGS

WARNING! Save all warnings and instructions for future reference

WARNING! Read all safety warnings and all instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or serious injury.

- This appliance is only intended for lead acid batteries

- This appliance is not intended for use by young or infirm persons unless supervised by a

responsible person to ensure that they can use the appliance safely.

- The warnings, cautions and instructions discussed in this instruction manual cannot cover all

possible conditions and situations that may occur.

- Common sense and caution are factors that cannot be built into this product but must be

supplied by the operator.

- It is recommended to work with someone who can come to your aid when working near a lead

acid battery.

- Do not come in contact with leaking battery.

- Have plenty of fresh water and soap nearby in case battery acid contacts skin, clothing or eyes.

- If battery acid contacts skin or clothing, wash immediately with soap and water. If acid enters

eye, immediately flood eye with running cold water for at least ten minutes and get medical

attention immediately.

- Be extra cautious to reduce risk of dropping a metal tool onto the battery. It could spark or short-

circuit the battery or other electrical parts and could cause an explosion.

- Remove personal metal items such as rings, bracelets, necklaces and watches when working

with a lead acid battery. It can produce a short circuit current high enough to weld a ring or the

like to metal causing a severe burn.

- Clean battery terminals. Be careful to keep corrosion from coming in contact with eyes.

- Before testing inspect the battery for cracks or broken case or cover. Of the battery is damaged,

do not use tester

Work Area

- Operate in a safe work environment. Keep your work area clean and well lit.

- Keep anyone not wearing the appropriate safety equipment away from the work area.

Note: Minimize distractions in the work environment.

- Distractions can cause you to lose control of the tool.

- When connecting the battery tester cables to the battery, avoid creating sparks; especially when

the battery is being charged. Explosive gases are created during charging. Sparking could also

damage the vehicle electrical system.

- Always lock up tools and keep them out of the reach of children

- Do not expose battery tester to rain, snow or wet conditions.

- Stay clear of hot engine and car parts.

Personal Safety

- Wear ANSI-approved safety goggles and protective gloves during set up and use of the Battery

Tester.

- Test in a well ventilated area. Explosive gases may be produced during testing. Do not smoke,

cause sparks, or strike matches near the battery when testing.

- Protective, electrically non-conductive clothes and non-skid footwear are recommended when

working. Wear steel-toed boots to prevent injury from falling objects.

- Refer to the user manual of the battery being tested for testing instructions and precautions prior

to using the battery tester.

- Do not connect in reverse polarity.

- Use this product in accordance with these instructions, taking into account the working

conditions and the work to be performed. Use of this product for operations different from those

intended could result in a hazardous situation.

- This product is not a toy. Keep it out of reach of children.

- Maintain labels and nameplates on the unit. These carry important safety information.

- People with pacemakers should consult their physician(s) before use. Electromagnetic fields in

close proximity to heart pacemaker could cause pacemaker interference or pacemaker failure.

Caution is necessary when near coil, spark plug cables, or distributor of running engine. Engine

should be off during distributor adjustment.

- Undercharged lead-acid batteries will freeze during cold weather. Do not test or charge a frozen

battery.

- Do not smoke or have open flames near the battery.

- Never remove battery load tester clamps while testing.

- Ensure automatic vehicles are in park with the handbrake engaged before starting the engine.

- Ensure manual vehicles are in neutral with the handbrake engaged before starting the engine.

- Put blocks on drive wheels and never leave car unattended while running tests.

- Road Safety Road Rules 2009 penalty code 2135, it is illegal to leave “motor vehicle unattended

with keys in ignition, motor running, brakes not secured or doors unlocked.

Risk of Electric Shock

- Never touch the clamps and the terminals with wet hands.

- Do not pull the clamps from the terminals by pulling on the clamp cables.

- Check the clamp leads for damage before every use.

- Be certain of the test battery polarity before connecting the battery tester clamps. The RED (+)

positive battery clamp goes to the positive terminal of the battery. The BLACK (-) negative battery

clamp goes to the negative terminal of the battery. Reversing the battery tester battery clamps on

the battery may damage the battery tester.

- Do not drop the battery tester as it may affect proper operation.

- Do not smoke or have open flames near the battery.

- The warnings and precautions discussed in this manual cannot cover all possible conditions and

situations that may occur. It must be understood by the operator that common sense and caution

are factors which cannot be built into this product, but must be supplied by the operator.

- Use extreme caution when working around the ignition coil, distributor cap, ignition wires and

spark plugs. These components create hazardous voltages when the engine is running.

Tester Use and Care Instructions

- This battery tester was designed for specific functions. Do not modify, disassemble or alter the

battery tester, all parts and accessories are designed with built-in safety features that may be

compromised if altered.

- Do not use the battery tester in a way for which it was not designed.