Regulatory Compliance Mark

(RCM) Warning

VVolts AAmperes

Read Instruction Manual

A

CCA Cold Cranking Amps

DC Direct current

DESCRIPTION OF SYMBOLS

BATTERY TESTER SAFETY WARNINGS

WARNING! Save all warnings and instructions for future reference

WARNING! Read all safety warnings and all instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or serious injury.

- This appliance is only intended for lead acid batteries

- This appliance is not intended for use by young or infirm persons unless supervised by a

responsible person to ensure that they can use the appliance safely.

- The warnings, cautions and instructions discussed in this instruction manual cannot cover all

possible conditions and situations that may occur.

- Common sense and caution are factors that cannot be built into this product but must be supplied

by the operator.

- It is recommended to work with someone who can come to your aid when working near a lead

acid battery.

- Do not come in contact with leaking battery.

- Have plenty of fresh water and soap nearby in case battery acid contacts skin, clothing or eyes.

- If battery acid contacts skin or clothing, wash immediately with soap and water. If acid enters eye,

immediately flood eye with running cold water for at least ten minutes and get medical attention

immediately.

- Be extra cautious to reduce risk of dropping a metal tool onto the battery. It could spark or short-

circuit the battery or other electrical parts and could cause an explosion.

- Remove personal metal items such as rings, bracelets, necklaces and watches when working with

a lead acid battery. It can produce a short circuit current high enough to weld a ring or the like to

metal causing a severe burn.

- Clean battery terminals. Be careful to keep corrosion from coming in contact with eyes.

- Before testing inspect the battery for cracks or broken case or cover. Of the battery is damaged,

do not use tester

Work Area

- Operate in a safe work environment. Keep your work area clean and well lit.

- Keep anyone not wearing the appropriate safety equipment away from the work area.

Note: Minimize distractions in the work environment.

- Distractions can cause you to lose control of the tool.

- When connecting the battery tester cables to the battery, avoid creating sparks; especially when

the battery is being charged. Explosive gases are created during charging. Sparking could also

damage the vehicle electrical system.

- Always lock up tools and keep them out of the reach of children

- Do not expose battery tester to rain, snow or wet conditions.

- Stay clear of hot engine and car parts.

Personal Safety

- Wear ANSI-approved safety goggles and protective gloves during set up and use of the Battery

Tester.

- Test in a well ventilated area. Explosive gases may be produced during testing. Do not smoke,

cause sparks, or strike matches near the battery when testing.

- Protective, electrically non-conductive clothes and non-skid footwear are recommended when

working. Wear steel-toed boots to prevent injury from falling objects.

- Refer to the user manual of the battery being tested for testing instructions and precautions prior

to using the battery tester.

- Do not connect in reverse polarity.

- Use this product in accordance with these instructions, taking into account the working conditions

and the work to be performed. Use of this product for operations different from those intended could

result in a hazardous situation.

- This product is not a toy. Keep it out of reach of children.

- Maintain labels and nameplates on the unit. These carry important safety information.

- People with pacemakers should consult their physician(s) before use. Electromagnetic fields in

close proximity to heart pacemaker could cause pacemaker interference or pacemaker failure.

Caution is necessary when near coil, spark plug cables, or distributor of running engine. Engine

should be off during distributor adjustment.

- Undercharged lead-acid batteries will freeze during cold weather. Do not test or charge a frozen

battery.

- Do not smoke or have open flames near the battery.

- Never remove battery load tester clamps while testing.

- Ensure automatic vehicles are in park with the handbrake engaged before starting the engine.

- Ensure manual vehicles are in neutral with the handbrake engaged before starting the engine.

- Put blocks on drive wheels and never leave car unattended while running tests.

- Road Safety Road Rules 2009 penalty code 2135, it is illegal to leave “motor vehicle unattended

with keys in ignition, motor running, brakes not secured or doors unlocked.

Risk of Electric Shock

- Never touch the clamps and the terminals with wet hands.

- Do not pull the clamps from the terminals by pulling on the clamp cables.

- Check the clamp leads for damage before every use.

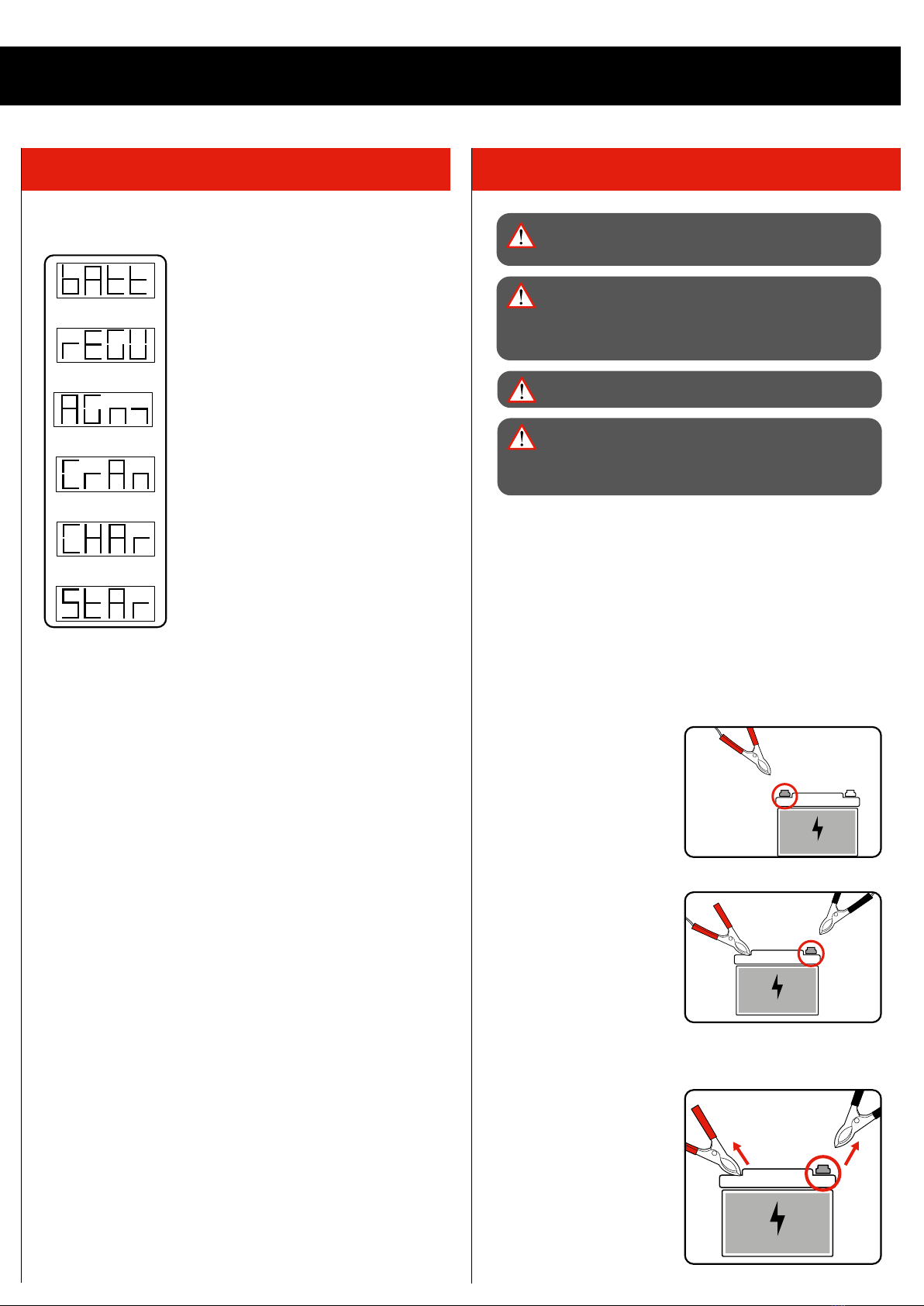

- Be certain of the test battery polarity before connecting the battery tester clamps. The RED (+)

positive battery clamp goes to the positive terminal of the battery. The BLACK (-) negative battery

clamp goes to the negative terminal of the battery. Reversing the battery tester battery clamps on

the battery may damage the battery tester.

- Do not drop the battery tester as it may affect proper operation.

- Do not smoke or have open flames near the battery.

- The warnings and precautions discussed in this manual cannot cover all possible conditions and

situations that may occur. It must be understood by the operator that common sense and caution

are factors which cannot be built into this product, but must be supplied by the operator.

- Use extreme caution when working around the ignition coil, distributor cap, ignition wires and

spark plugs. These components create hazardous voltages when the engine is running.

Tester Use and Care Instructions

- This battery tester was designed for specific functions. Do not modify, disassemble or alter the

battery tester, all parts and accessories are designed with built-in safety features that may be

compromised if altered.

- Do not use the battery tester in a way for which it was not designed.