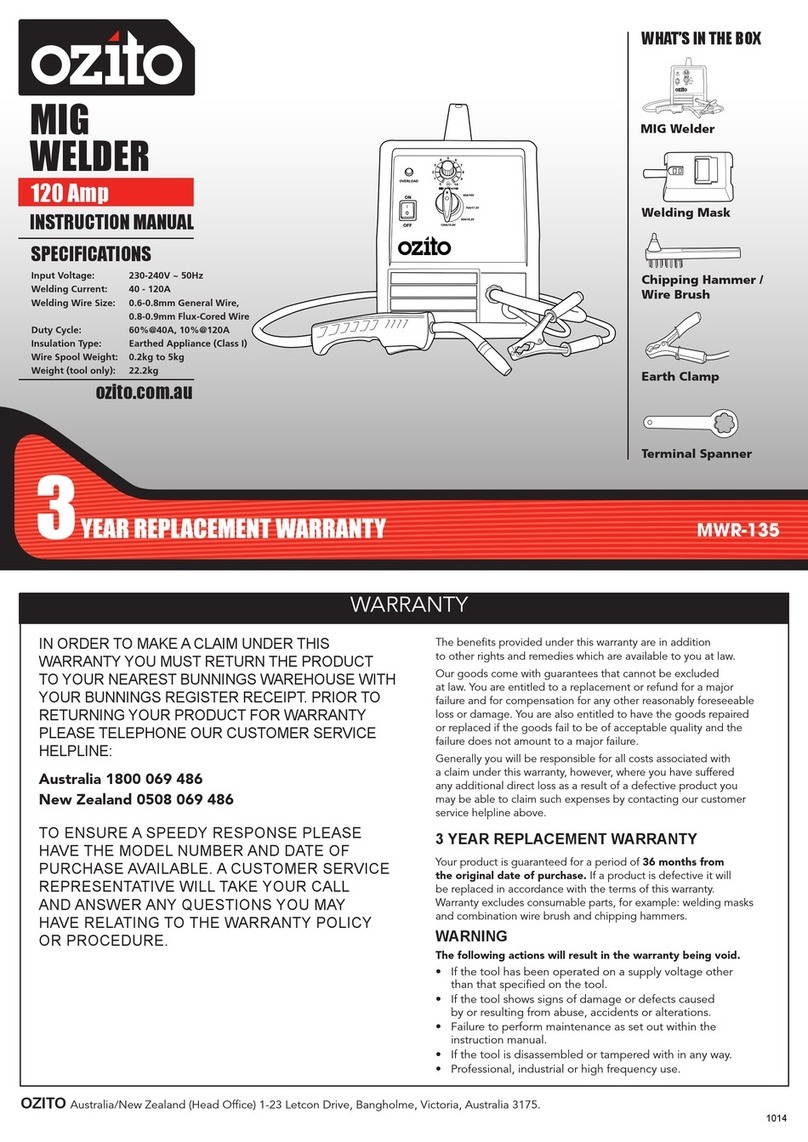

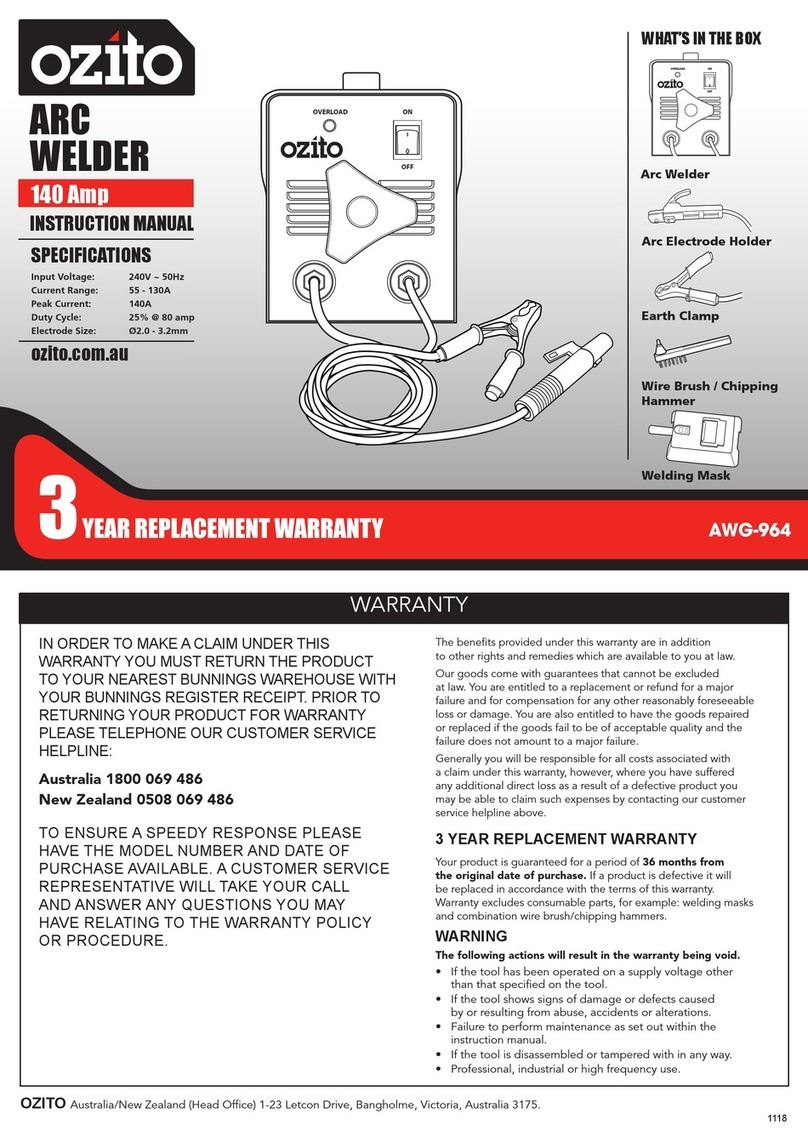

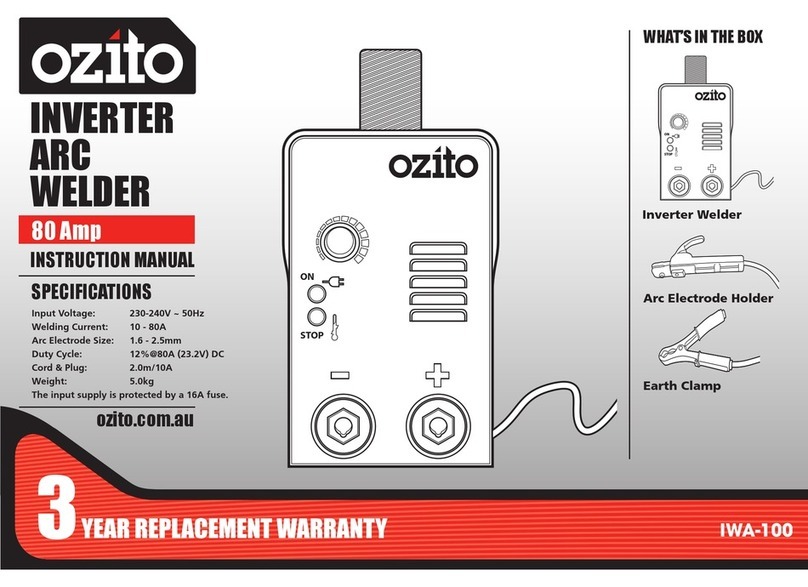

Items supplied

Please check that the article is complete as

specied in the scope of delivery. If parts are

missing, please contact our service center or the

sales outlet where you made your purchase at

the latest within 5 working days after purchasing

the product and upon presentation of a valid bill

of purchase. Also, refer to the warranty table in

the service information at the end of the operating

instructions.

• Open the packaging and take out the equip-

ment with care.

• Remove the packaging material and any

packaging and/or transportation braces (if

available).

• Check to see if all items are supplied.

• Inspect the equipment and accessories for

transport damage.

• If possible, please keep the packaging until

the end of the guarantee period.

Danger!

The equipment and packaging material are

not toys. Do not let children play with plastic

bags, foils or small parts. There is a danger of

swallowing or suocating!

Proper use

The machine is to be used only for its prescribed

purpose. Any other use is deemed to be a

case of misuse. The user / operator and not the

manufacturer will be liable for any damage or

injuries of any kind caused as a result of this.

The equipment is to be used only for its prescri-

bed purpose. Any other use is deemed to be a

case of misuse. The user / operator and not the

manufacturer will be liable for any damage or inju-

ries of any kind caused as a result of this.

Please note that our equipment has not been de-

signed for use in commercial, trade or industrial

applications. Our warranty will be voided if the

machine is used in commercial, trade or industrial

businesses or for equivalent purposes.

Symbols and technical data

Input voltage: ............................230V~ 50 / 60Hz

Welding current: ................................... 10-130A

Arc electrode size: ........................... 1.6 - 3.2mm

Tungsten electrode size: ................. 1.6 / 2.4 mm

ARC duty cycle: ............... 25% / 130A (25.2) DC

TIG duty cycle:................. 25% / 130A (15.2) DC

Insulation: ................................................ Class I

Protection type:........................................IP 21 S

EN 60974-1 European standard for

welding sets for manual arc

welding with limited on time.

Single-phase static frequency

converter transformer rectierr

~ 50 / 60 Hz Alternating current and

rated frequency value [Hz]

U0Rated idling voltage [V]

130 A/ 25.2 V Maximum welding current and

130 A/ 15.2 V the corresponding

standardized operating

voltage [A/V]

Ø Electrode diameter [mm]

I2Welding current [A]

Line input; number of phases,

the alternating current symbol

and the rated frequency value

U1Line voltage [V]

I1max Highest rated value of the line

current [A]

I1e Eective value of the highest

line current [A]

HInsulation class

XOn-load factor

Symbol for manual arc

welding with sheated rod

electrodes

Symbol for TIG (tungsten

inert gas) welding

IP 21 S Protection type

Thoroughly read and

understand the operating

instructions prior to using the

welder

Welding

Electrode (Ø mm): Welding current (A)

1.6 35 – 45

2.5 60 – 100

3.2 100 – 130

Electrode (tungsten needle)

diameter (mm)

Welding current (A)

1.6 10 – 140

2.4 10 – 250

Caution!

Residual risks

Even if you use this electric power tool in ac-

cordance with instructions, certain residual

risks cannot be rules out. The following ha-

zards may arise in connection with the equip-

ment’s construction and layout:

1. Lung damage if no suitable protective dust

mask is used.

2. Damage to hearing if no suitable ear protecti-

on is used.

3. Health damage caused by hand-arm vibra-

tions if the equipment is used over a pro-

longed period or is not properly guided and

maintained.

Safety clothing

1. While working, the welder must protect his en-

tire body from radiation and burns by wearing

suitable clothing and a face guard.

2. Slip-on gloves made of a suitable material

(leather) must be worn on both hands. They

must be in perfect condition.

3. Suitable aprons must be worn to protect clo-

thing from sparks and burns. A safety suit and,

if necessary, head protection must be worn if

required by the type of work in question, e.g.

overhead welding.

4. The protective clothing used as well as all

accessories must be in compliance with the

“Personal safety equipment” EU Directive.

Protection from radiation and burns

1. Provide information about the risk to eyes at

the working site in the form of a poster with

the wording “Caution – do not look at the a-

mes”. Workplaces are to be screened o

wherever possible so that personnel in the

vicinity are protected. Unauthorized persons

are to be kept away from the welding work.

2. The walls in the immediate vicinity of statio-

nary workplaces should not have a light color

or a sheen. Windows up to head height are

to be protected against radiation passing th-

rough them or reecting o them, for example

by coating them with a suitable paint.

For EU countries only

Never place any electric power tools in your

household refuse.

To comply with European Directive 2012/19/EC

concerning old electric and electronic equipment

and its implementation in national laws, old

electric power tools have to be separated from

other waste and disposed of in an environment-

friendly fashion, e.g. by taking to a recycling

depot.

Recycling alternative to the return request:

As an alternative to returning the equipment to

the manufacturer, the owner of the electrical

equipment must make sure that the equipment

is properly disposed of if he no longer wants to

keep the equipment.The old equipment can be

returned to a suitable collection point that will

dispose of the equipment in accordance with the

national recycling and waste disposal regulations.

This does not apply to any accessories or aids

without electrical components supplied with the

old equipment.

1~ 50 / 60 Hz

Highest welding time rated value in continuous

mode tON (max) for highest welding current rated

value at an ambient temperature of 20 °C, expres-

sed in minutes and seconds.

Highest welding time rated value in intermittent

mode ΣtON for highest welding current rated value

at an ambient temperature of 20 °C over an un-

interrupted time of 60 min, expressed in minutes

and seconds.

1~ f1f2

Beiblatt_IWT_130U.indd 2 06.03.2017 10:00:31